-

Posts

4,403 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Lownslow

-

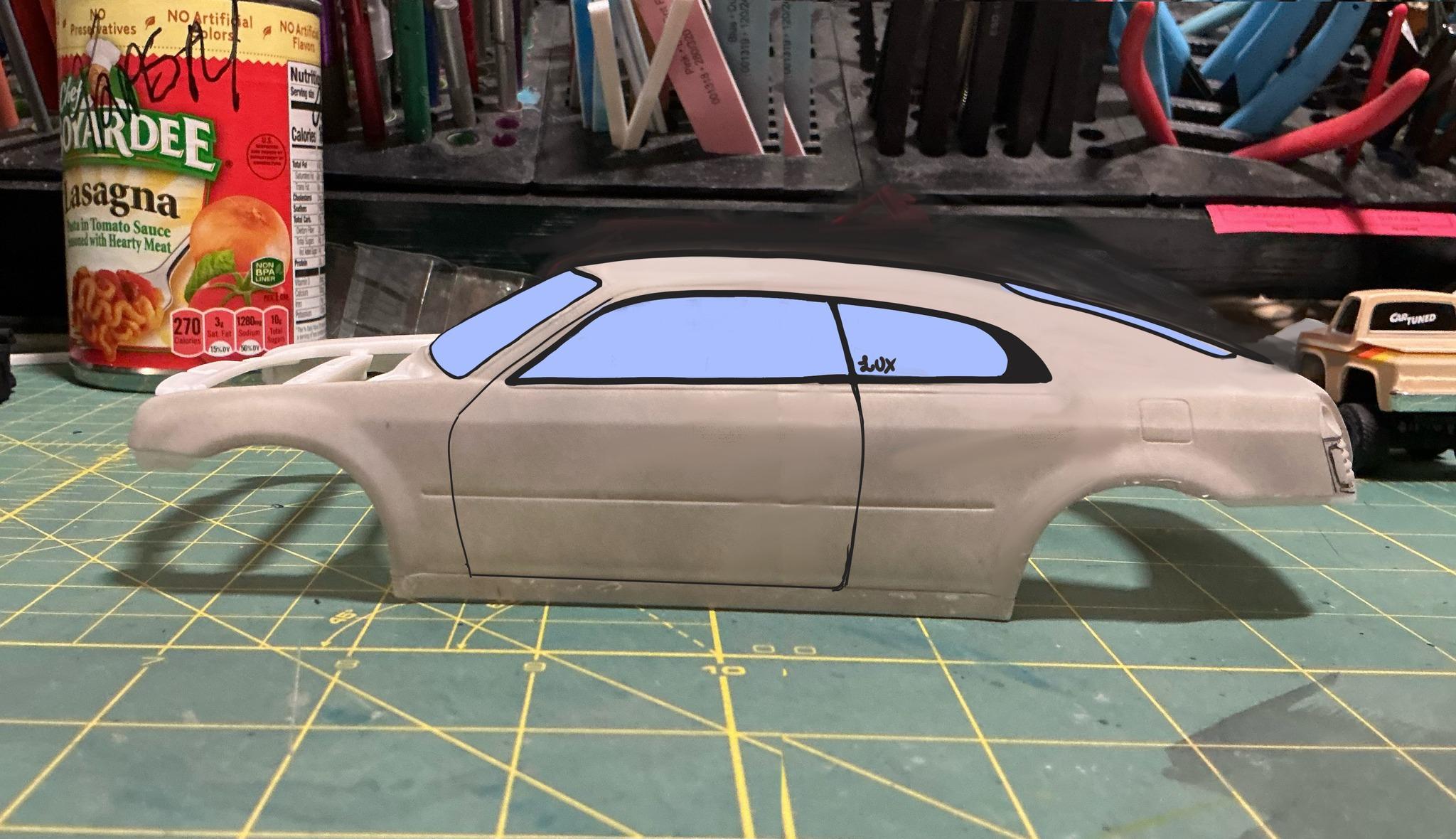

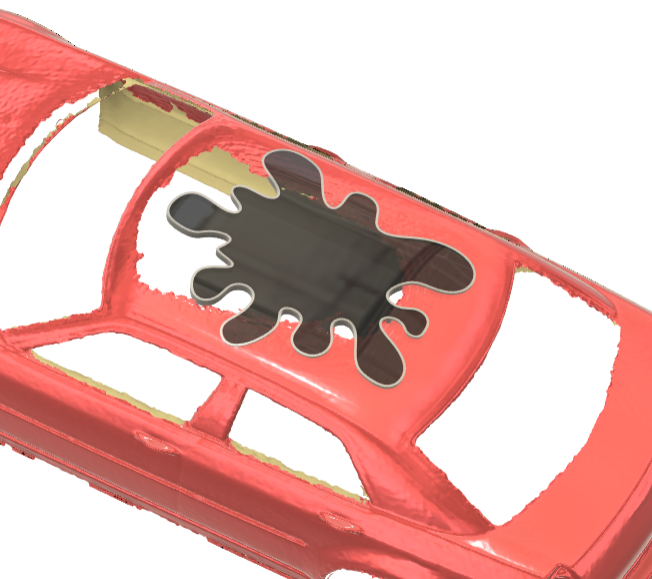

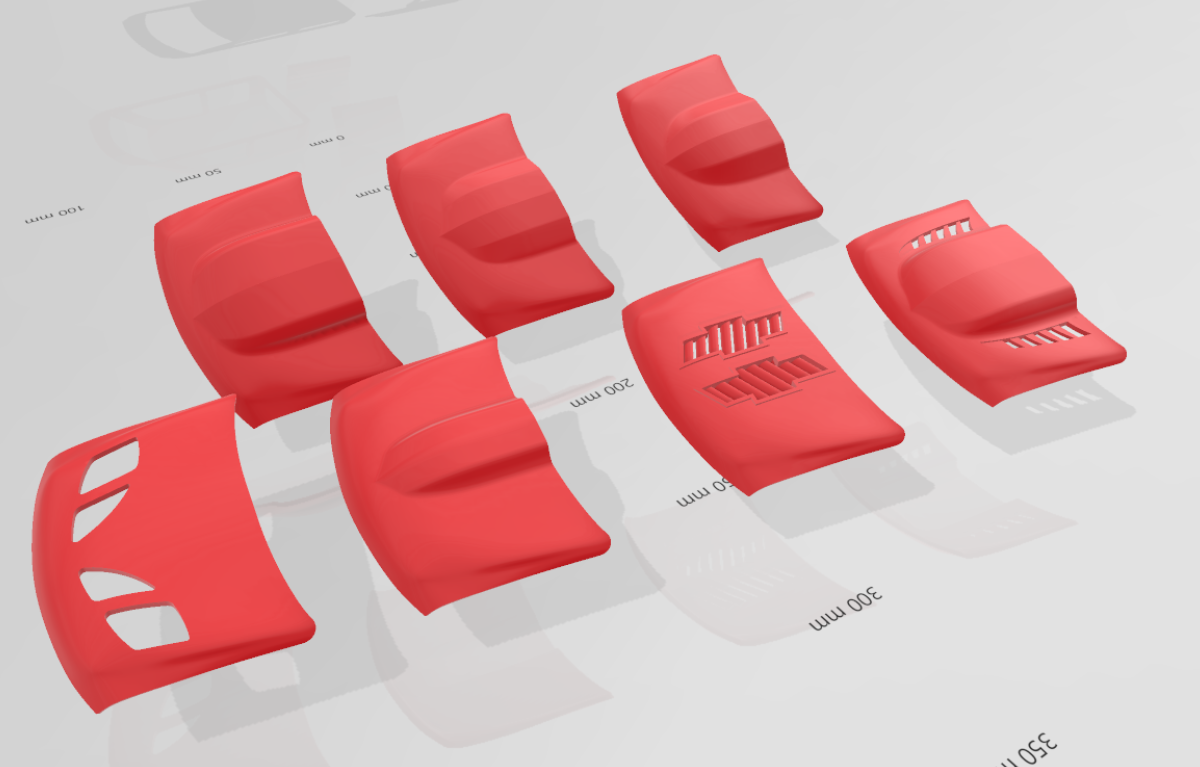

drawn on sketchbook as rough ideas for a upcoming build, im choosing the practical option since its the easiest of the 3 and its gonna fit the build theme. the first was the Z chop because i wanted to see what it would look like, chances are high this will end up on a second build just to flex the custom back window. Second option is the hardest of the 3 because it requires stretching the body to get the bentley roofline to work with RR inspired side windows. 3rd option is what im building which is a simple benz profile

-

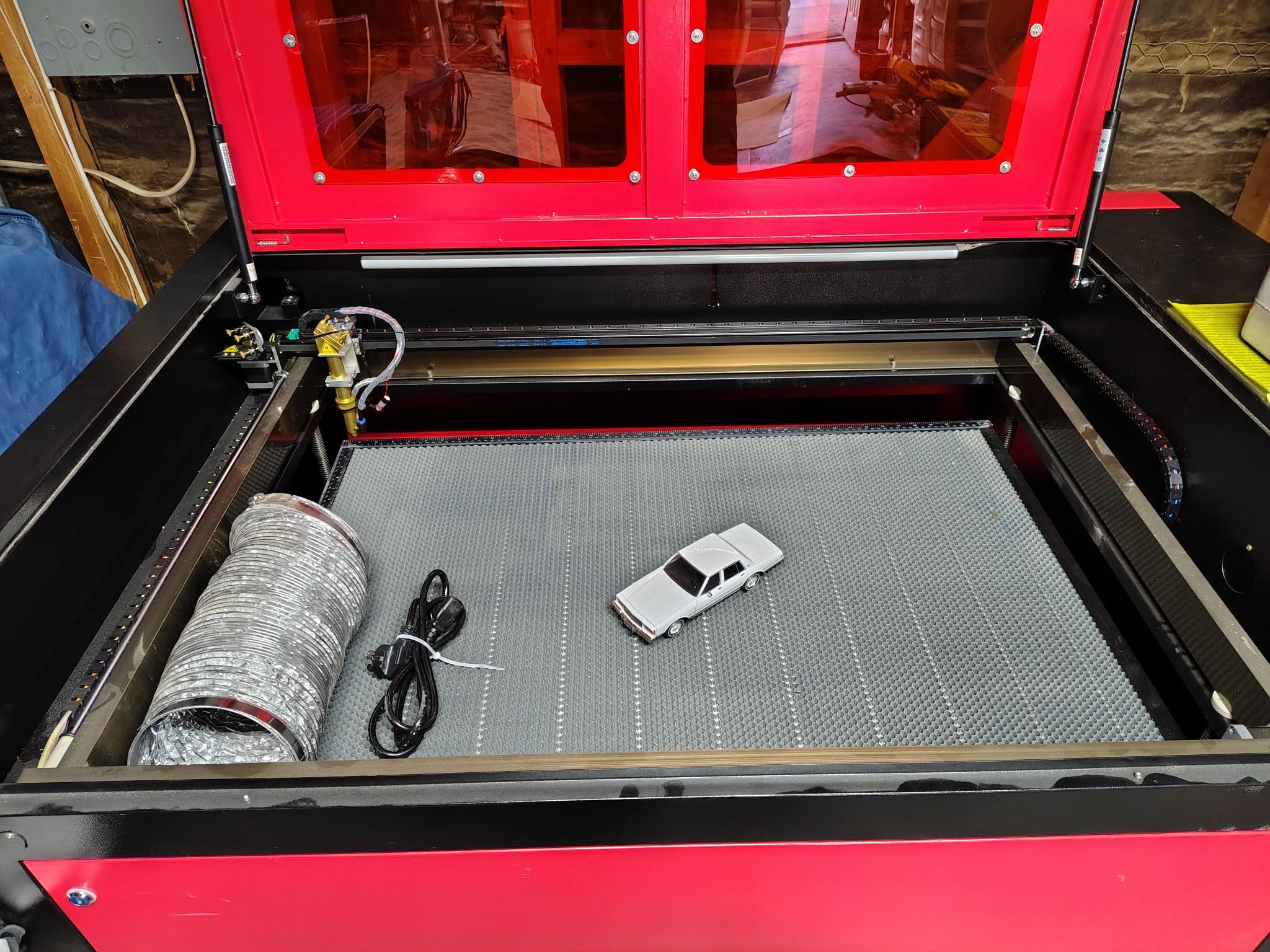

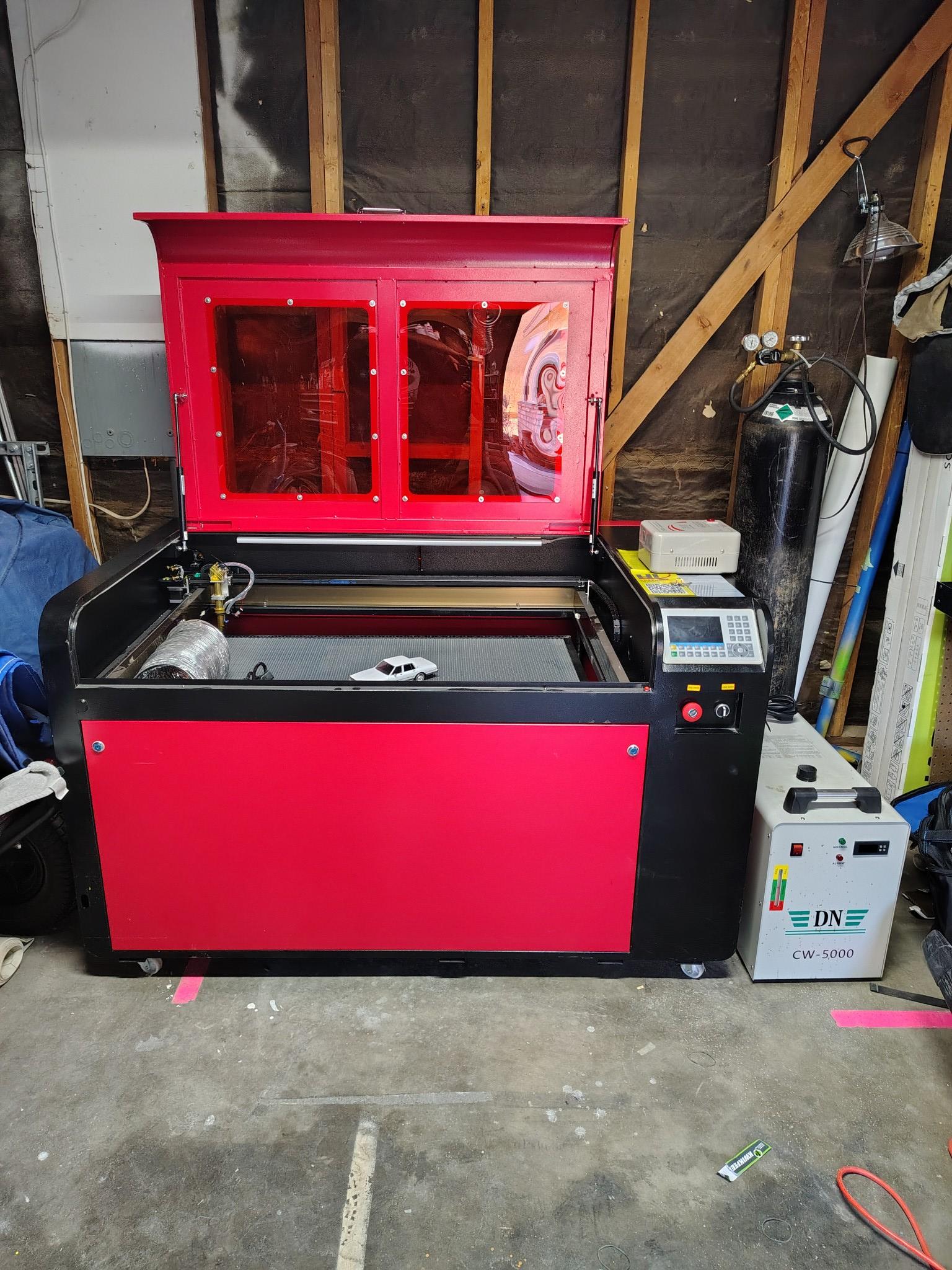

its gonna have its uses one of them primarily will be making bench organizers and other random hobby bench tools.

- 39,190 replies

-

- 4

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

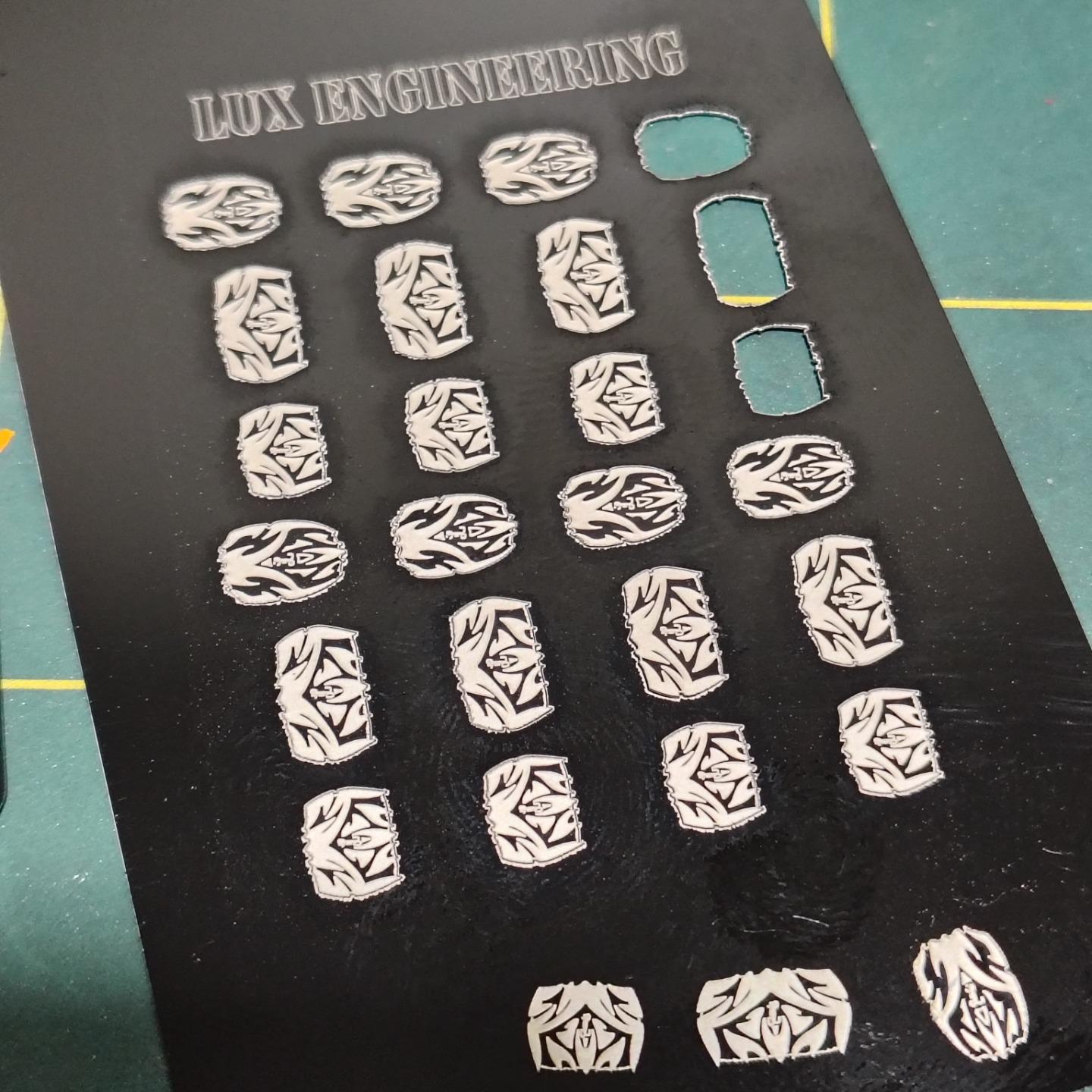

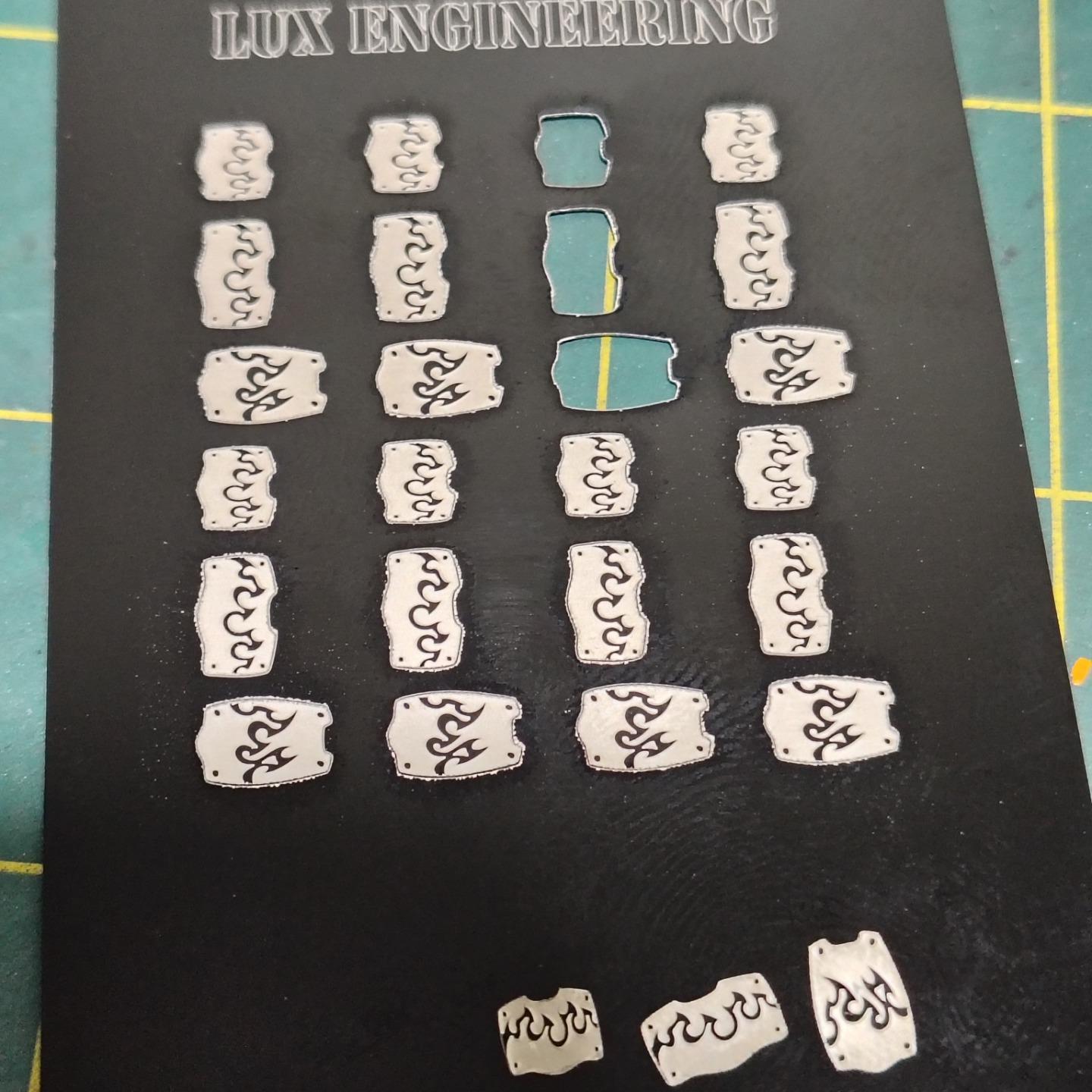

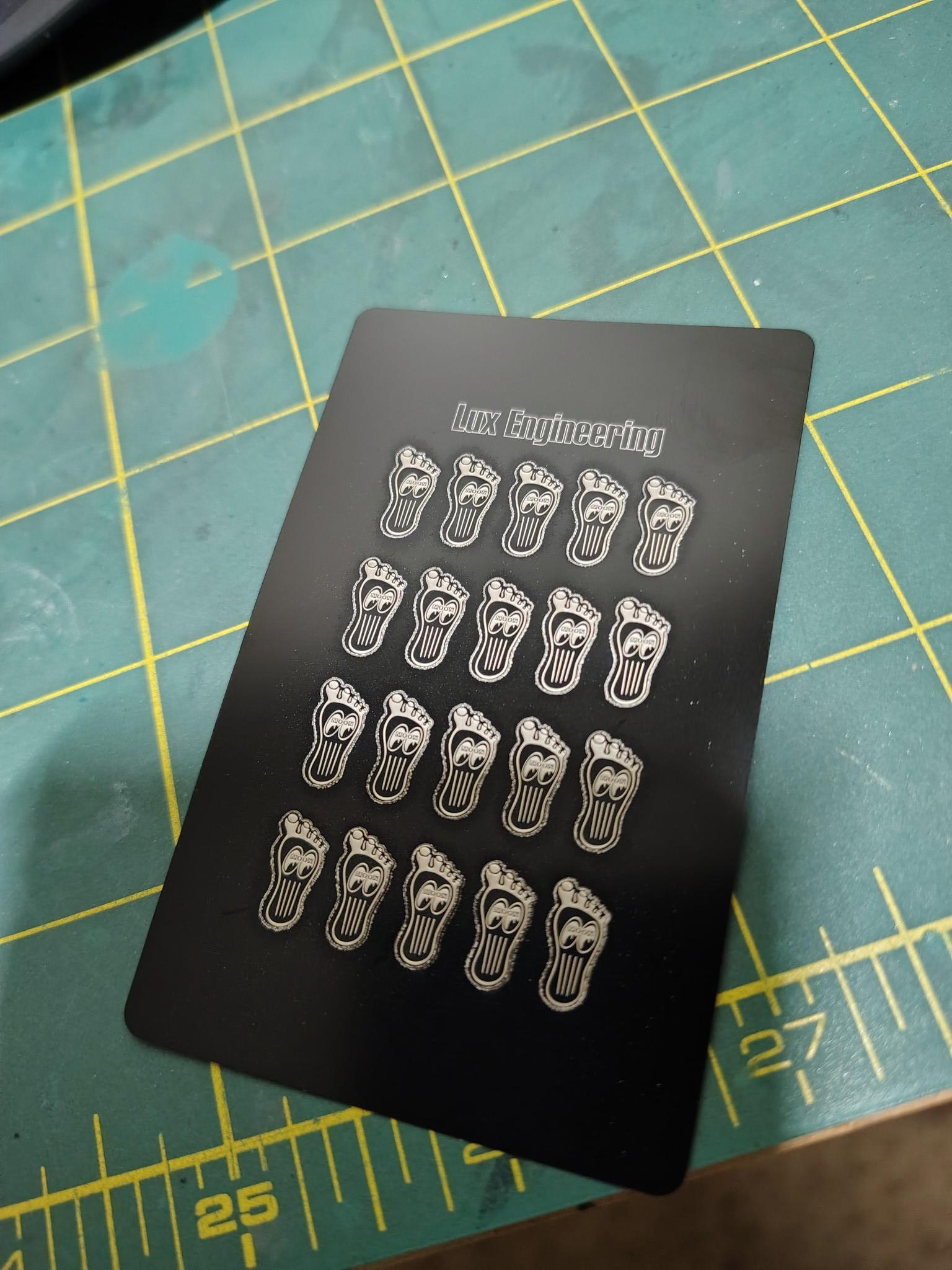

Custom pedals one tribal the other is flames

-

-

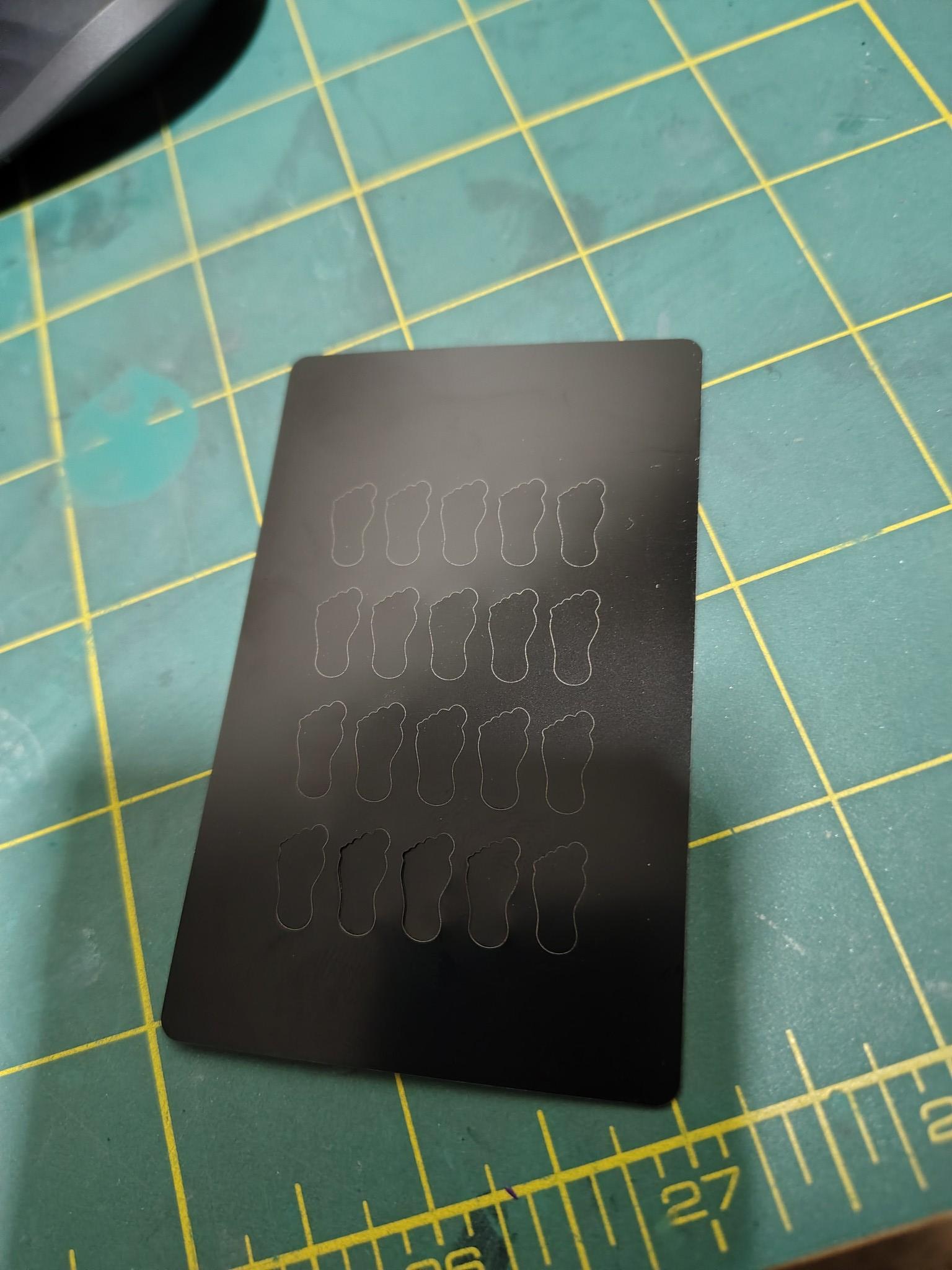

its modified from the good year artwork then adjusted for scale, itll do small lettering if i slow it down but that also causes the material to burn or melt so i had to make due with middle of the road for now, All the artwork was done through the software i use which is Lightburn a third party laser program, most lasers come with their own software but i wanted something universal so i spent the 200+ to get it. 50k is fast but you have to keep in mind that with this style engraving, speed and power=heat so you have to really know your materials otherwise it will catch on fire, too fast you loose details, too slow it will catch fire or melt the material

-

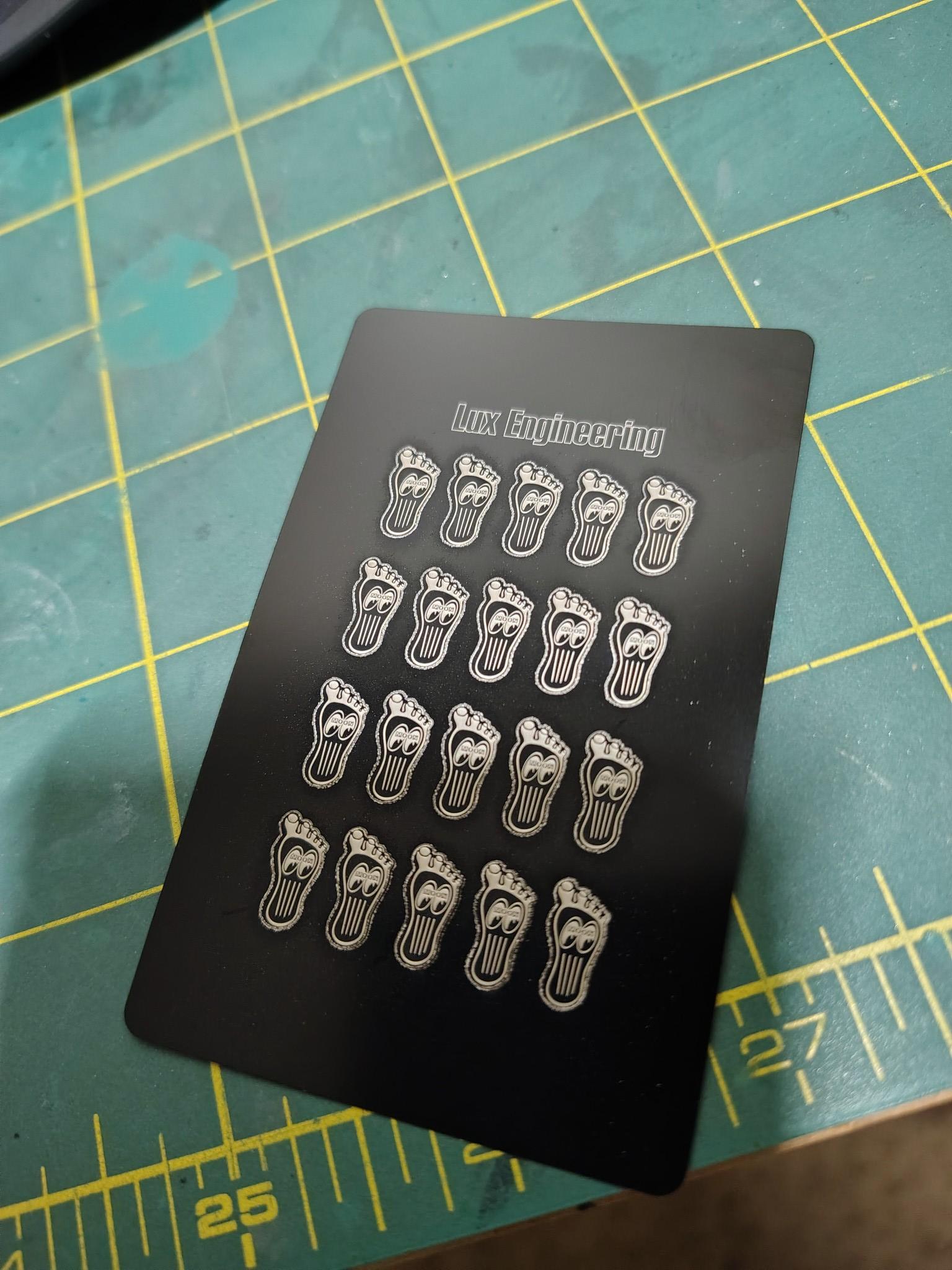

Yeah thats what i went for i wanted the letters to stay smooth like on my 1:1 tires and most of the sidewall is textured thats a lot harder to do on scale vinyl and rubber but i think i nailed the attempt on these. i wanna say i shaved roughly .0005 of the tires surface at the laser speed i set it at which for my machine was around 50000mms

-

Theres a few products on the market now the most user friendly is Gweike, the process was simple low power/fast speed i cant say exactly because no two tires engrave the same like soft foose tires dont engrave well at all even at the lowest settings. this is the lowest cost machine i found that should do the job https://www.gweikecloud.com/products/g2-fiber-laser-marking-machine?gad_source=1&gad_campaignid=20510607347&gbraid=0AAAAABdYeuo0gD57OuLpMAvIO3IY3zyvv&gclid=Cj0KCQjwuKnGBhD5ARIsAD19RsZwCSzwxr87tzBNPor0HBxjgi1dZVGZhNbco75QhXfgqpdOVVSnpygaAl8OEALw_wcB

-

It was something thats been nagging me for weeks since i started working on the Porsche but now i dont have to worry about it since i now can detail the sidewalls with my laser engraver. the process was insanely quick about 2 for the pass shown, the downsides are Fiber Lasers are stupid expensive, its incredibly difficult to center, it wont be black, and not all kit tires will react the same way to being shot at with lasers.

- 27 replies

-

- 17

-

-

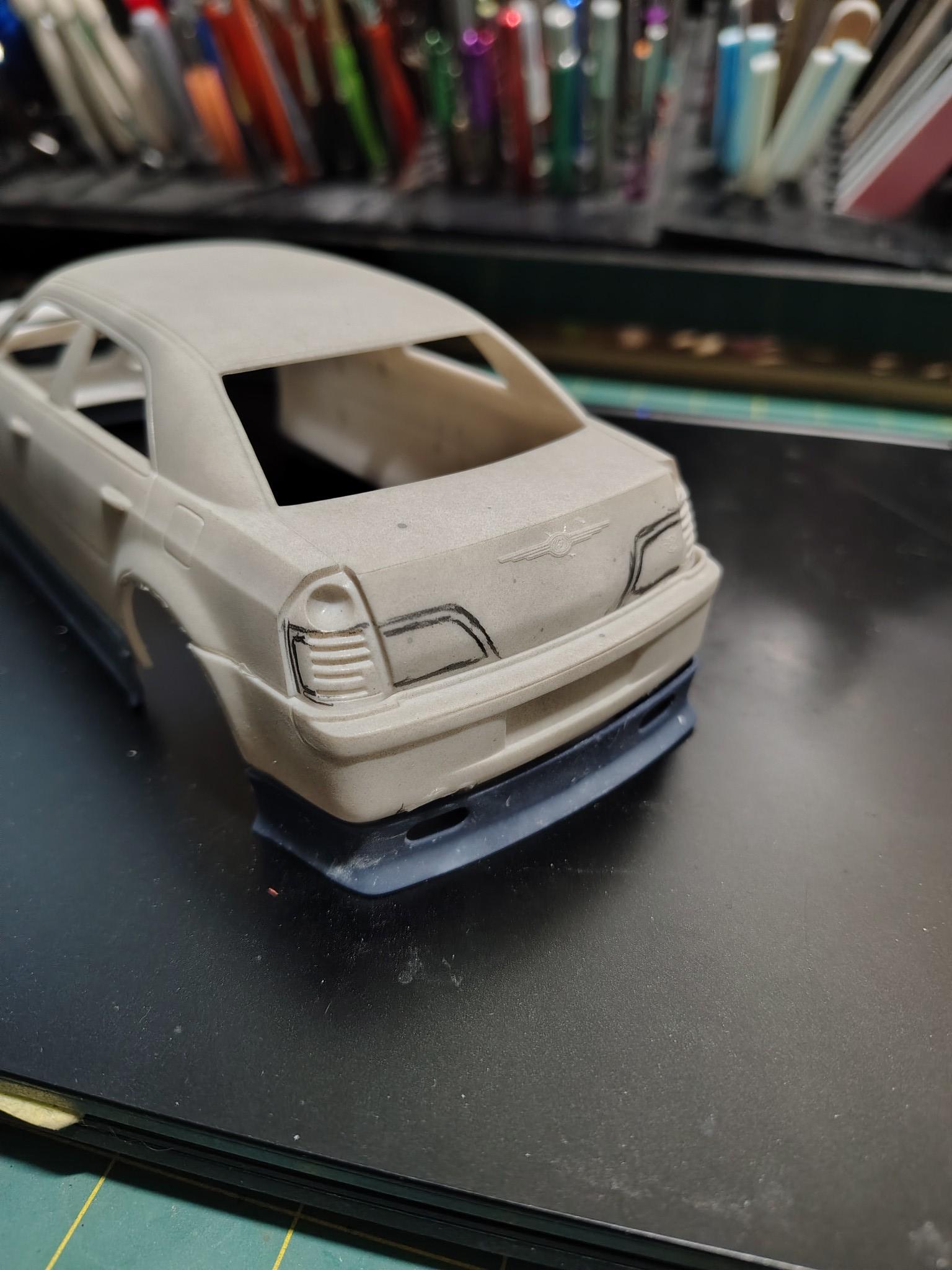

Its pretty easy to use but the difficulty to make parts for it is in the 7 and up difficulty scale, scanners cant see chrome or glass i fixed this by using baby powder but that also creates a grainy surface when scanned. the problem is as you can tell the dozens of dents created by light refraction that would take days to fix and maybe even weeks or months to make a usable body for printing.

.jpeg.61d282d82341388770ec86e89369f071.jpeg)