-

Posts

1,459 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by mr68gts

-

Thank you! Looks like I habe some repair work to do on the chassis lol.

-

-

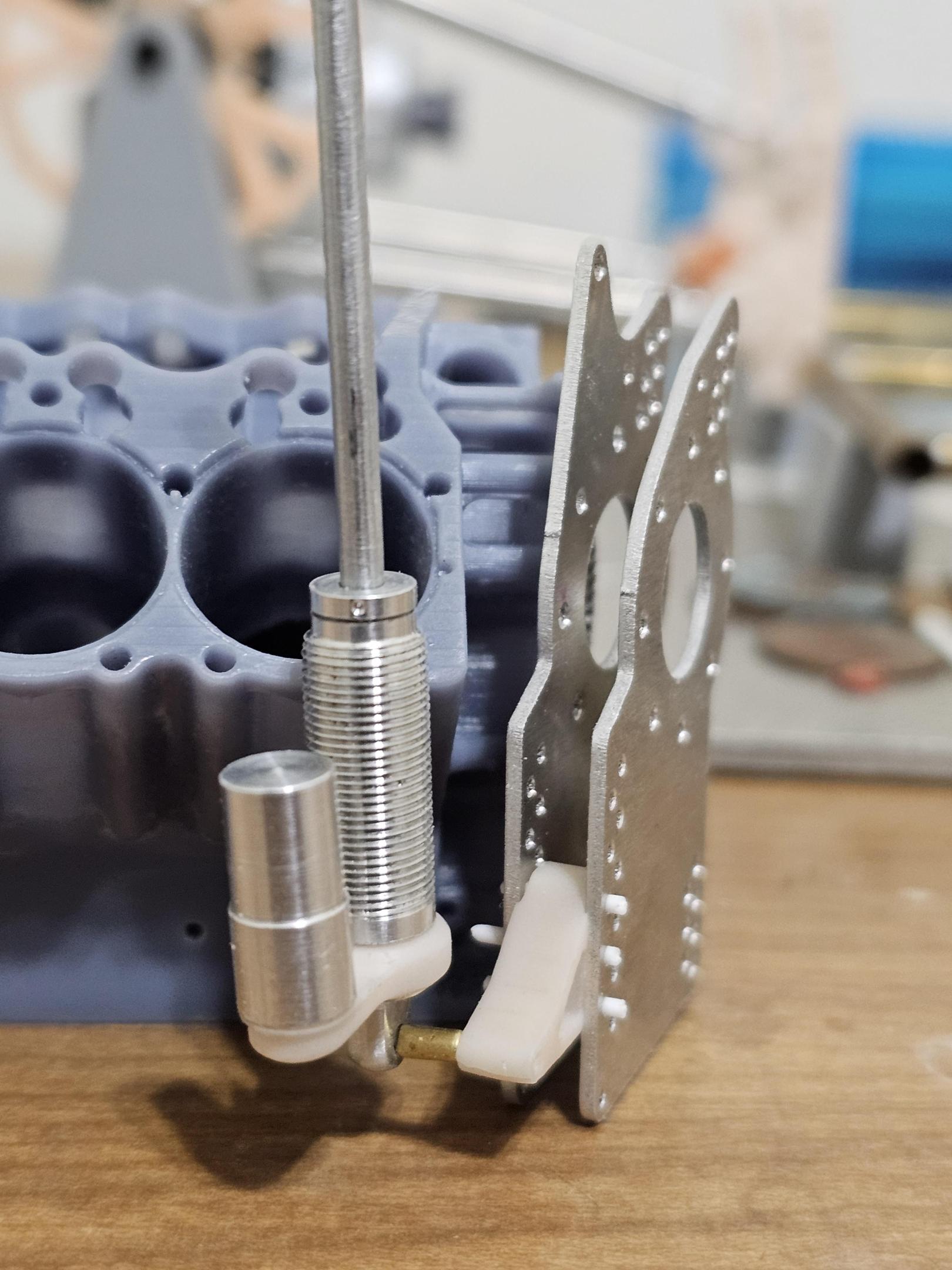

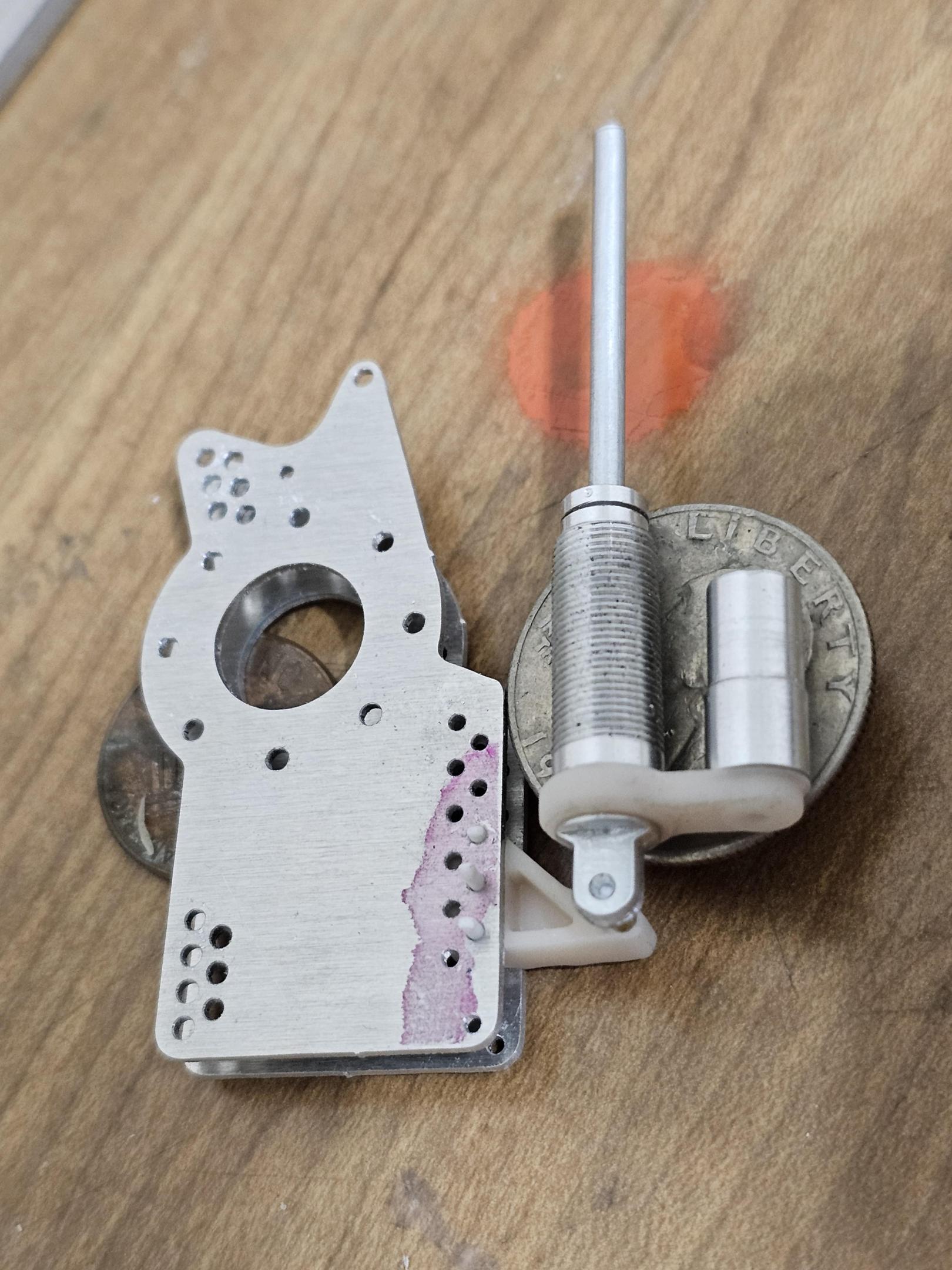

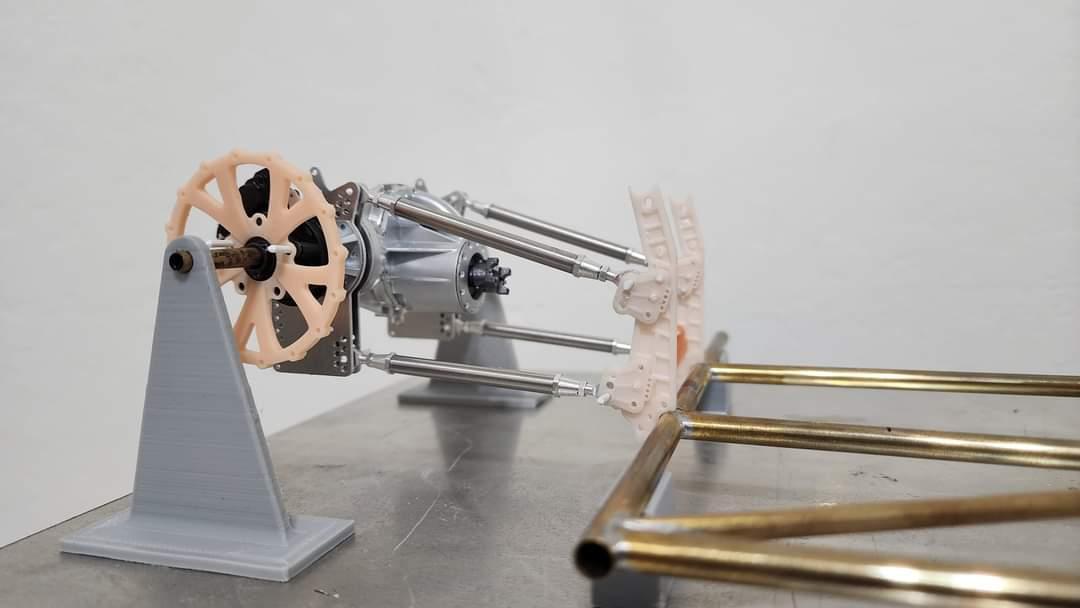

Officially off the deep end..... Articulating heim joint in 16th scale....🤪 20250518_225033.mp4

-

Coming Soon from Atomic City's JoHan line of new kits

mr68gts replied to thatz4u's topic in Car Kit News & Reviews

As we all have for years while people make bold promises with no outcome? Yeah no thanks. I honestly wish them luck but not only moving on with an old name and even one that's already being or has been used feels kinda like dirty pool. -

My question is why restart an old beaten horse name? Everyone knows the history that is Jo-han. It's written as lore for anyone to research literally everywhere! While some of the accounts may be inaccurate and some factual information missing due to people holding it close to them like the ern of a long-lost grandmother, there is so much more than CAN be done by anyone and everyone. 3d printing isn't for everyone. Takes different techniques to build. It's not as easily hacked up into something else anyone wild imagination dreams up. However, those of us that utilize every tool available can do damn near anything. Those that can't, there's a whole world of files available that can be printed. Just gotta search for them! And some may need work to make printable. Guys like Bill Greary, have taken to 3d and moved it into their era of building. And he's probably done more with 3d files than anyone I know! The fact that the files of many vehicles exist can significantly cut down the costs for tooling. The files are done, purchase the file for probably less than paying someone to develop it. It's digitized. Send it to a pattern maker to cnc and polish. There are your molds. For probably less than the 250k everyone touts. With all that does come the licensing issues, and they'd need to be addressed before hand. All this has to be done with backing. No small feat. I'm not sure of the 3 resurrecting an old name. I know Okey had grand visions of returning an old beaten-up war horse to battle with little to no luck. Perhaps it's time to let the war horse rest in peace. And from the ashes resurrect something embracing the digital technology that is there and use it to an advantage, with a NEW name rather than an old tired one that's left a bad taste in people's mouth for one reason or another. Doesn't have to be 3d printed. Can 3d print for resin masters, minor parts or just not at all and make actual tooling for injection molding. Heck, there's ways to utilize 3d prints as Injection molding too! Kind a like an old movie remake, lets leave the old BLAH_BLAH_BLAH_BLAH in the ground where it belongs and move on into a new era of modeling. Let the classics be classic!

-

Thanks Tim, I actually reprinted the tires in a different resin as I am trying different resins with the new printer. I bought a larger format printer with better resolution which has made my prints come out far superior to my previous efforts with the old 2k! Paul

-

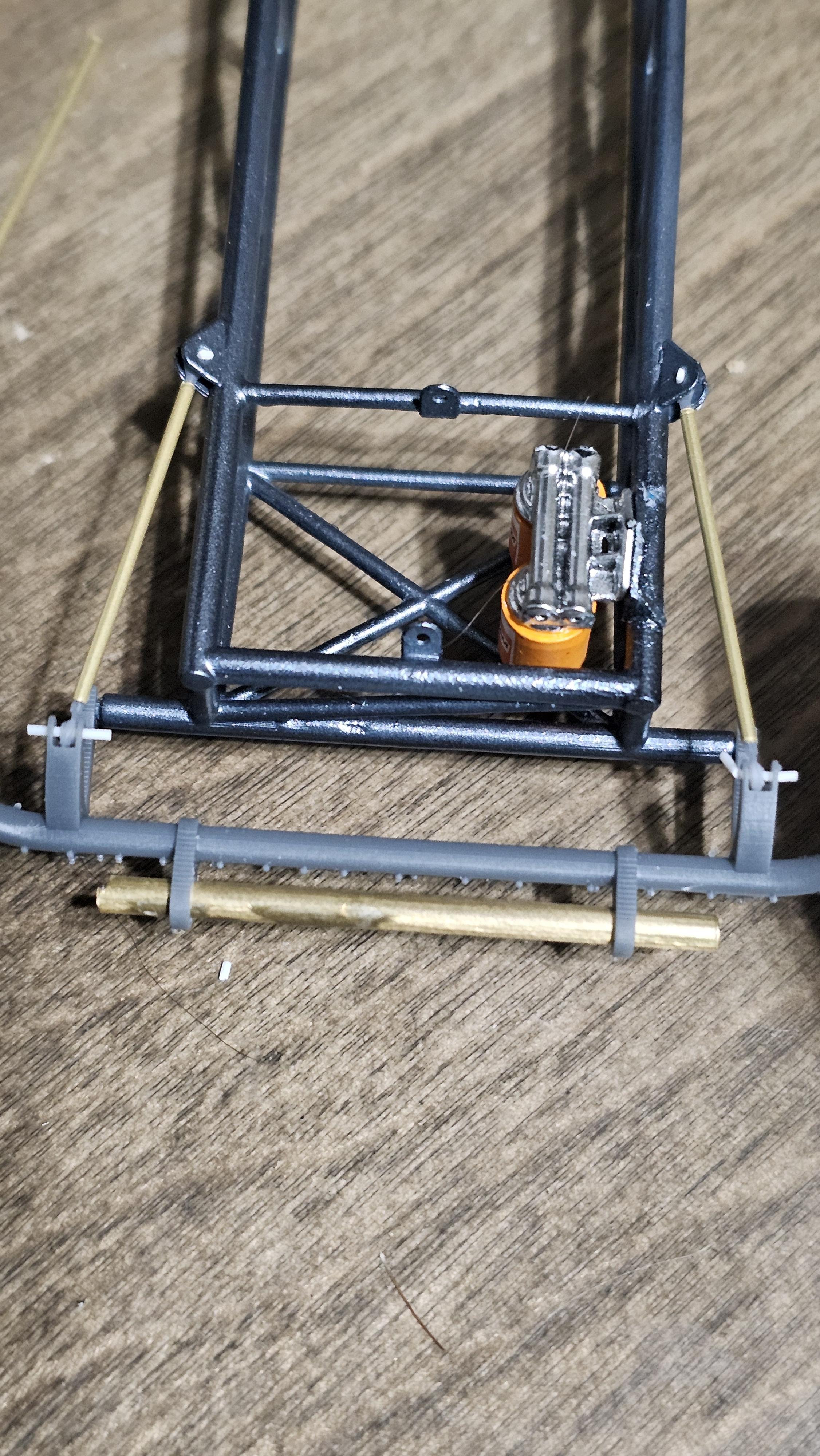

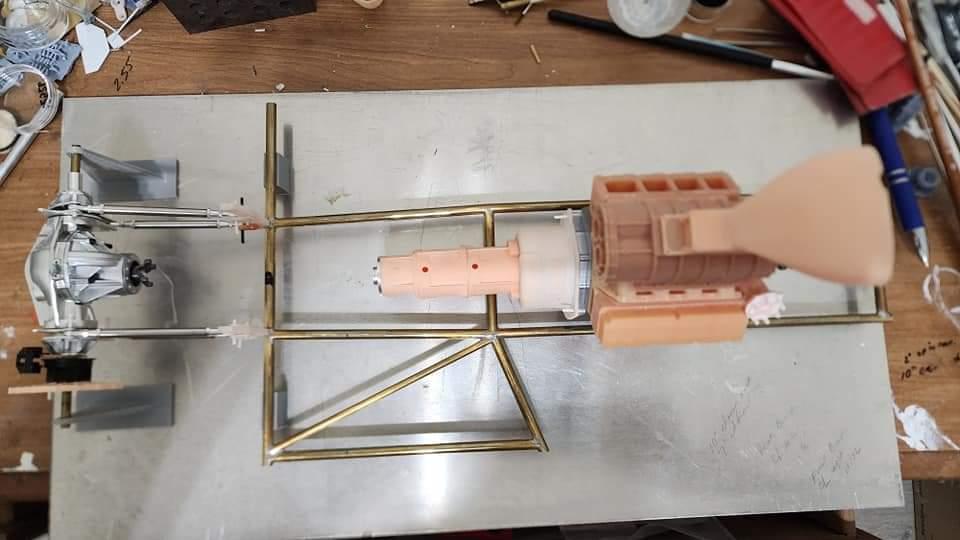

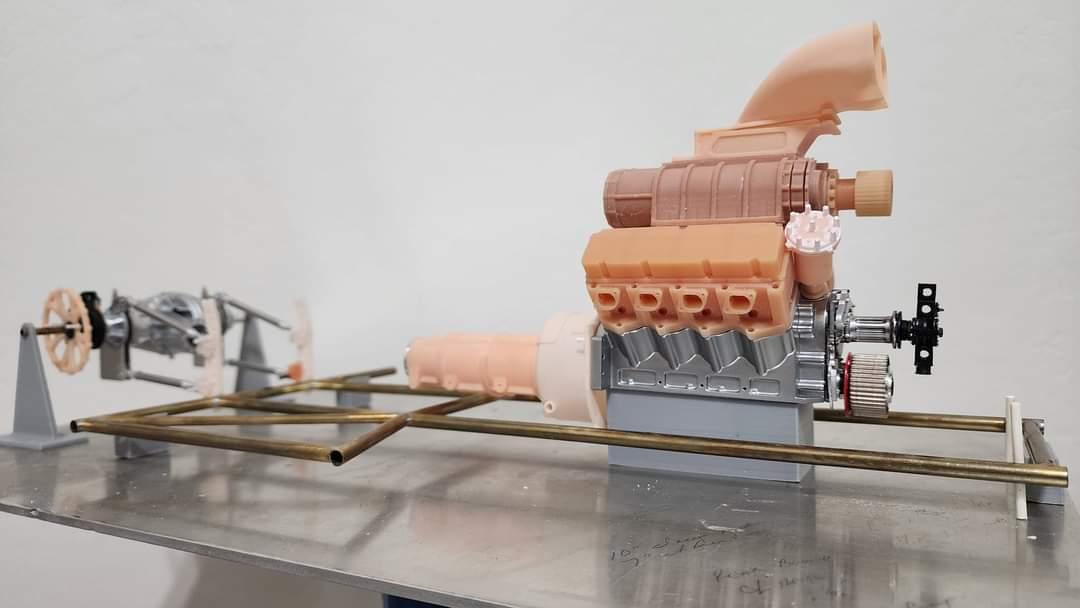

Newly printed front axle with brass tube for a "weight bar". I also printed the spindles. New 5 spoke spindle mount centers. Just need to make the heim links for the upper bars and the steering components.

-

Steve, Welcome to the nuthouse of scratch building, good luck with your project and if you need help with anything, let us know! There's plenty of people here knowledgeable on Pro Mods, myself included! Paul

-

Try Albion tubing. they make very small tubing is brass and aluminum.

-

If my noodle still works correctly the 4 spd cars got the Dana and the Automatics got the 8 3/4 originally. Now that's not to say that the racers didn't update to the Dana later on. Also, that 74 Duster of his actually ran Modified Production. Even has it on the windows btw. Car is still around and has been restored by HemiDenni on Facebook. (spelling?) Quite a lot of work was done to it. not to the level of the Missle wire car but there was some stuff done to fit bigger tires yet retain the chassis rails for example. Paul "I’ll use one of the spare rears from the Hemi Dart kit. Trying to find out if this car had an 8.75, or a Dana? I might have it mocked up tomorrow. "

-

-

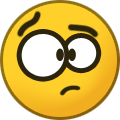

Printed a dual filter setup. Had to add a bracket to the chassis to mount it and touch up chassis color. Re alcladed the rear end. Machined bolt head pins to hold it to the chassis. Threaded the "studs" into the hub to check fit with the rim. Onto the next portion of this project....

-

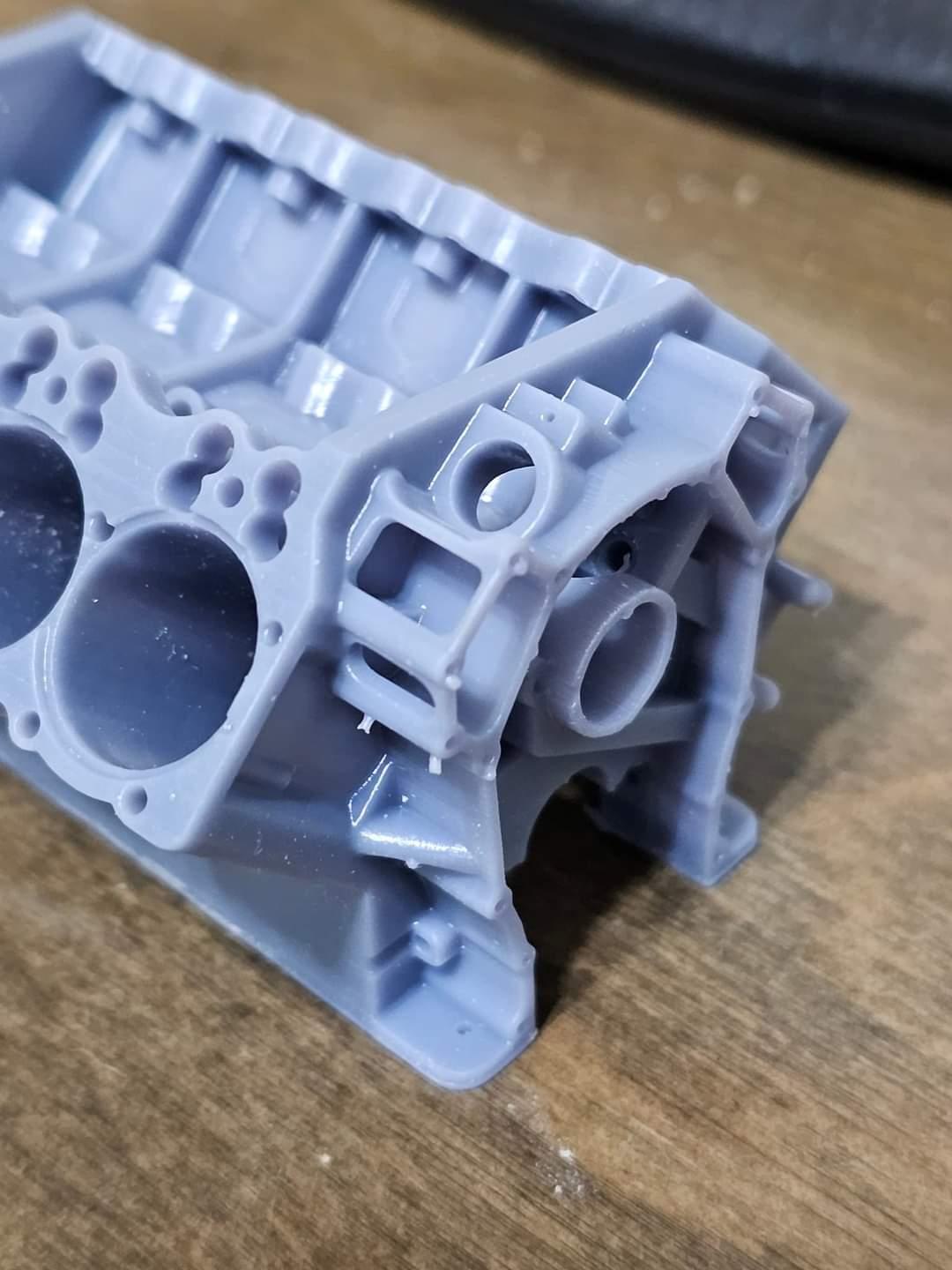

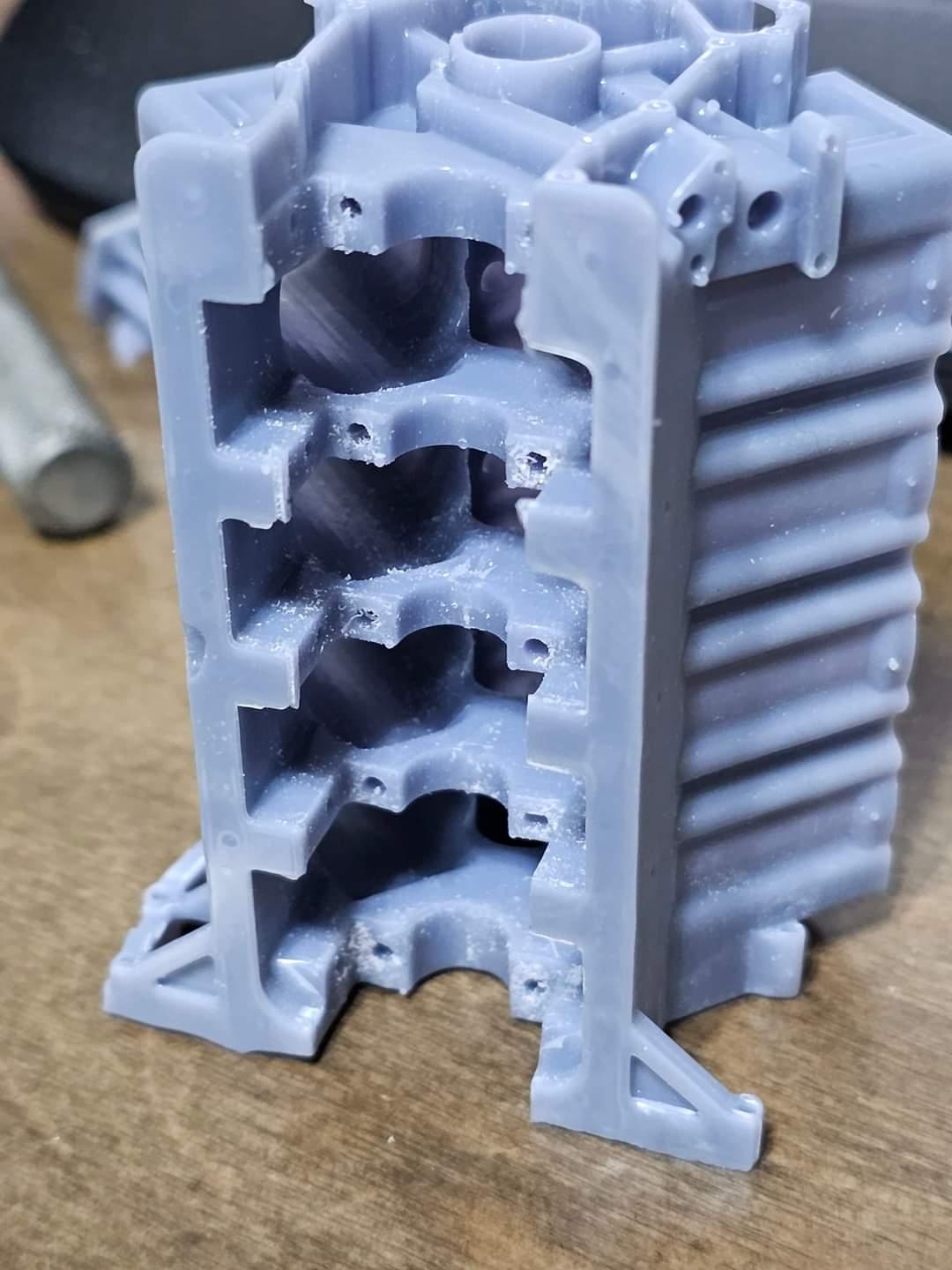

Thanks Tim, I've had a lot going on lately, so it's been nice to be back building even for a little bit. I was pretty disappointed in the old chassis color which set me back a bit. While a cool color it wasn't what the real one wore so I set it aside. I really would like to finish this by the end of the year. Still, lots to do. In fact, I just ordered a bunch of 1:1 scale AN fittings in various sizes, so I can model them up in SolidWorks. (What the hell was I thinking.... HAHA) I need to cad the fuel tank and I think that's it. Sadly, the only kit parts are the severely hacked up body, the bellhousing, oil pan and the brake calipers from the old Aurora FC kit. The rest is all 3d printed or aftermarket lol. I hadn't planned on going this far with it, but one thing has led to another. At this point the last thing is the gas tank as mentioned and everything, but detail bolts and fittings/hoses are done! All that's left to do is build lol. Thanks for checking it out! Paul

-

Minus the hardware, the front of the engine is done. Need to add a bracket to the chassis for the filter block so I'll touch up the chassis once thats done.

-

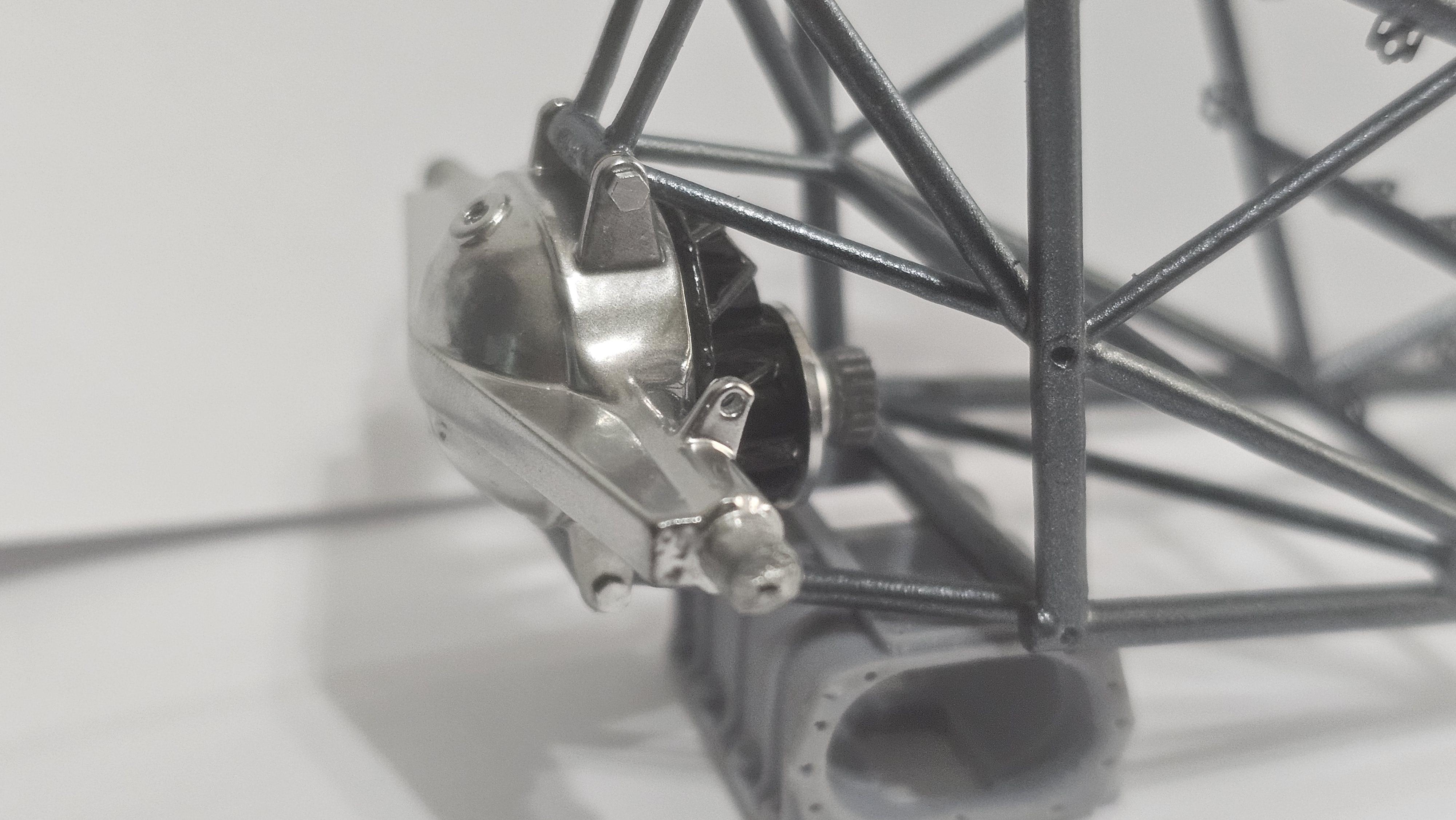

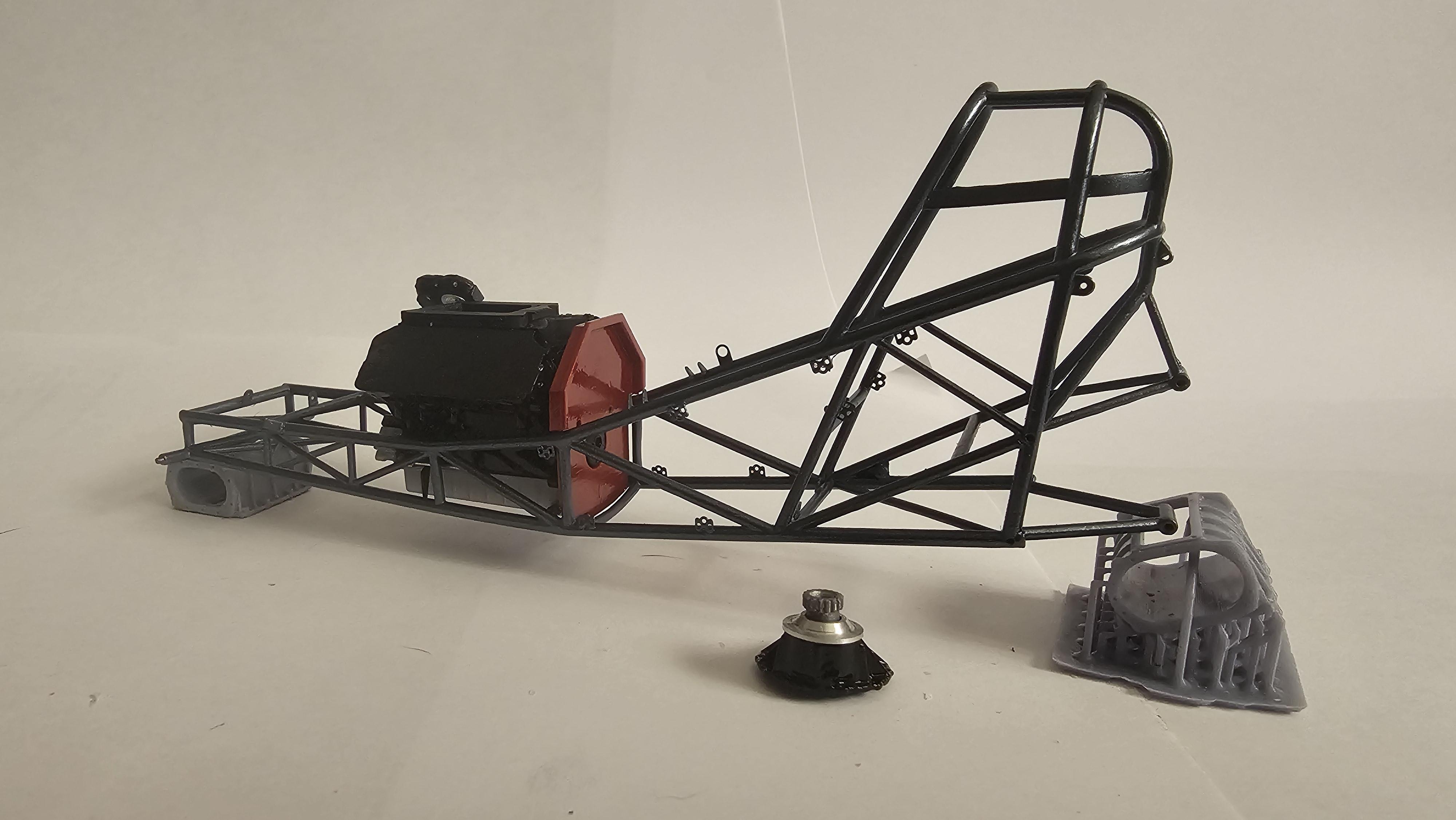

Pulled this one out of moth balls lol. Repainted the chassis a more correct grey color. Resprayed the long block and finally painted the midplate

-

Nice job! The kit is a pain in the behind to build but with some patience and lots of cleanup it buids up nicely! Paul

-

Nice to see you back on and on this thing again Tim! what did you use for the bead roller? I have an idea for one, I just have to proof it out first!

-

Nostalgia Fuel Dragster--Blower Manifold (01/28/23)

mr68gts replied to Straightliner59's topic in WIP: Drag Racing Models

Yeah, I started going though projects started myself and taking stock of what's what. A few have been moved so many times that all the pieces aren't even together with the model anymore lol. It's definitely time I take care of old projects or get rid of them. Not getting any younger here haha. Anyway, can't wait to see this thing finished! -

Nostalgia Fuel Dragster--Blower Manifold (01/28/23)

mr68gts replied to Straightliner59's topic in WIP: Drag Racing Models

Really outdone yourself with this build Daniel! On top of it it's really nice to see this ancient build moving along at a steady pace with updates. I remember when this project start oh so long ago. Like many of my builds that have been moth balled lol. Paul -

Nothing to my mail box in AZ yet either..... I'd hoped it would be here when I got home from our Thanksgiving trip since it was hitting the mail at the beginning of the month supposedly.

-

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

Some might think this thing has been forgotten but nope.... Working on the Penske shocks to 4 link mounting. Have some pieces I need to machine to make it look proper but it's otherwise exactly what I was looking to do! -

They can be either male or female. We ran a male on the Lenco altered we ran in comp Elim when I worked there.

-

69 pro mod chevelle, chassis started mock ups

mr68gts replied to mr68gts's topic in WIP: Drag Racing Models

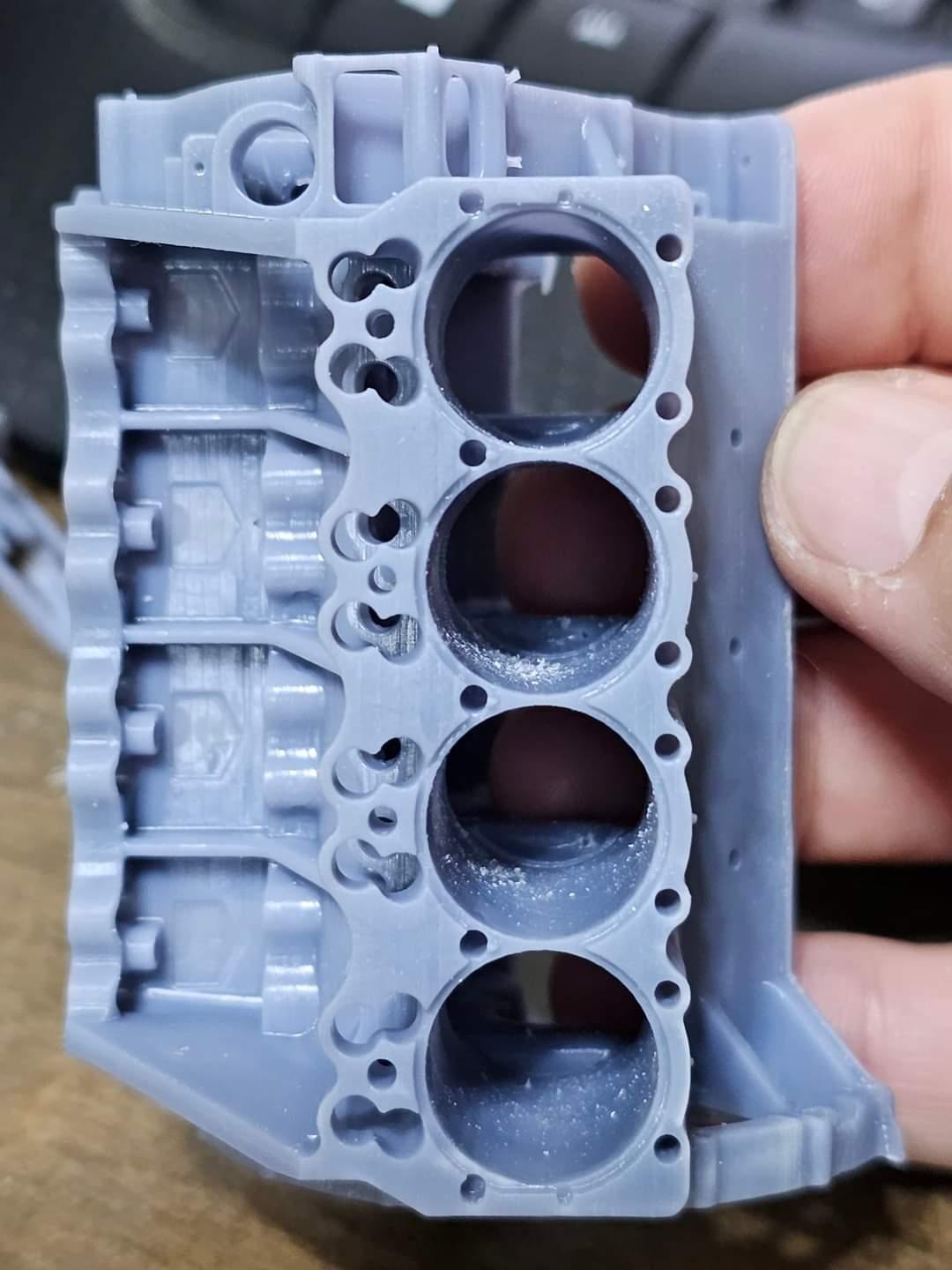

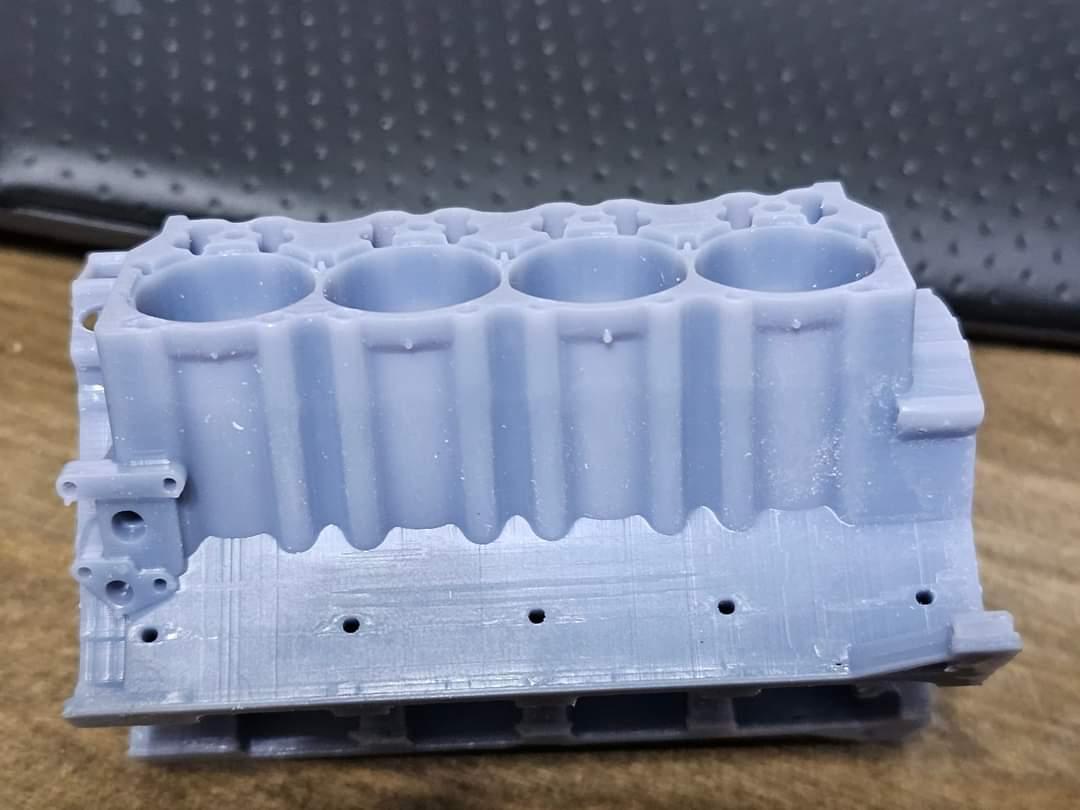

I've gotten the chassis back on the "jig" so I can start to continue on with this monstrosity. I need to update a few files but I can still plug away in my free time between this and Radici & Wise Vega FC now that the madness has settled down a bit around here. Now to find the model room again....lol And while this model will stay 481x powered, I did add this to my list of files thanks to Dave! Who knows what will happen down the road! Meet the 1 cubic inch BAE Hemi! (in 1/8 scale!) Still working on the rest of the files for it but I have a start anyway! -

Some. The body is ready for paint, just need to make it to the paint shop and get some. I do need to change the color of the chassis as it's too blue from all the research I've found online. For now it's been sitting in the display cabinet on wheels though awaiting me to get un busy enough to paint the body. Paul