-

Posts

14,971 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by StevenGuthmiller

-

I think Steve’s point is that foreign does not always equate to a better kit. It’s certainly not true when comparing the Trumpeter ‘60 Bonneville to that lowly old AMT article, and there are other examples. You really need to consider yourself extremely lucky that Tamiya even made a 90s Mustang.......If you’re a Tamiya loyalist anyway. Otherwise, who cares. Steve

-

Trumpeter 1960 Pontiac Bonneville

StevenGuthmiller replied to Sidney Schwartz's topic in WIP: Model Cars

Sidney’s comparison photos above are a comparison between the kit and the 1:1. But where the obvious discrepancies come in is when you view them from the top. The top on the Trumpeter kit is more than “a little” short. Haven’t done any measurements, but if I had to guess, I would say at least a good 3 or 4 scale inches short. Not a pittance by any stretch of the imagination. But with all of this said, I would never suggest that someone shouldn’t build the kit if they desire. Just one of those situations where I feel that people might want to be aware of the situation. I generally don’t let small discrepancies bother me a whole lot, but in some circumstances, they will bother me enough where I have difficulty getting beyond them. For instance, the shape of the side trim on the AMT 1958 Plymouth never really bugged me, but I’ll never be able to get past the shape of the rear quarter panels on the AMT ‘68/‘69 Roadrunner/GTX kits. Just my personal issue I suppose, as apparently AMT sold a boatload of those kits. Steve -

Trumpeter 1960 Pontiac Bonneville

StevenGuthmiller replied to Sidney Schwartz's topic in WIP: Model Cars

The roof is considerably too short, and as a consequence, the tulip panel between the rear glass and the trunk lid is way too long. Another glaring body mistake in my eye is the hood molding. Far too wide, short and stubby. Steve -

Trumpeter 1960 Pontiac Bonneville

StevenGuthmiller replied to Sidney Schwartz's topic in WIP: Model Cars

Yeah, they botched the roof pretty good.......among other things. Steve -

The problem is that some people don't see it that way. Apparently some will sacrifice their desires for "easy". I've never understood this mentality myself. If I want to build a that '65 Bonneville, I'm going to suck it up and go with the only available kit from AMT, and make it better if possible. I'm certainly not going to consider a Tamiya Volvo station wagon an immediate alternative. Steve

-

Trumpeter 1960 Pontiac Bonneville

StevenGuthmiller replied to Sidney Schwartz's topic in WIP: Model Cars

When I first came across this kit in my LHS some years ago, it was quite an exciting revelation. Initially, upon opening the box, it looked as if it was going to be a fantastic kit! Of course, as time went by and all of the kit’s short comings became evident, it lost it’s appeal pretty quickly. That said, I have one of the hard top kits, and if I ever built it, (which at this point is rather unlikely) I would absolutely be chopping off the top and doing a convertible. There’s no way that I can unsee the roof/tulip panel proportions of the hardtop kit. My opinion? That weird wheel/tire configuration is the coolest part of the whole kit!! ? Steve -

This subject comes up constantly, and I'll just offer the same opinion that I always do. I could care less who the manufacturer of the kit is, and the initial quality is of no consequence to me whatsoever. For me, subject matter is the ONLY consideration. If the kit has issues that bother me, or need attention, I'll fix them. The best engineered kit in the world means nothing to me if it's a subject that I have no interest in. I would rather use my skills to re-work a subpar 60 year old kit that interests me, than build a immaculate new kit that doesn't. It's that simple. Steve

-

Flocking

StevenGuthmiller replied to Sidney Schwartz's topic in Model Building Questions and Answers

The powders can be mixed fairly convincingly, although don’t expect to mix red and yellow to get orange. It works pretty well to mix similar colors to achieve certain results. In the case of this ‘65 Plymouth, I had no turquoise, so mixing blue and green worked fairly well. Otherwise, the powders come in a wide variety of colors, and if you need a color that you can’t find, the powder is easily painted after application. Steve -

Flocking

StevenGuthmiller replied to Sidney Schwartz's topic in Model Building Questions and Answers

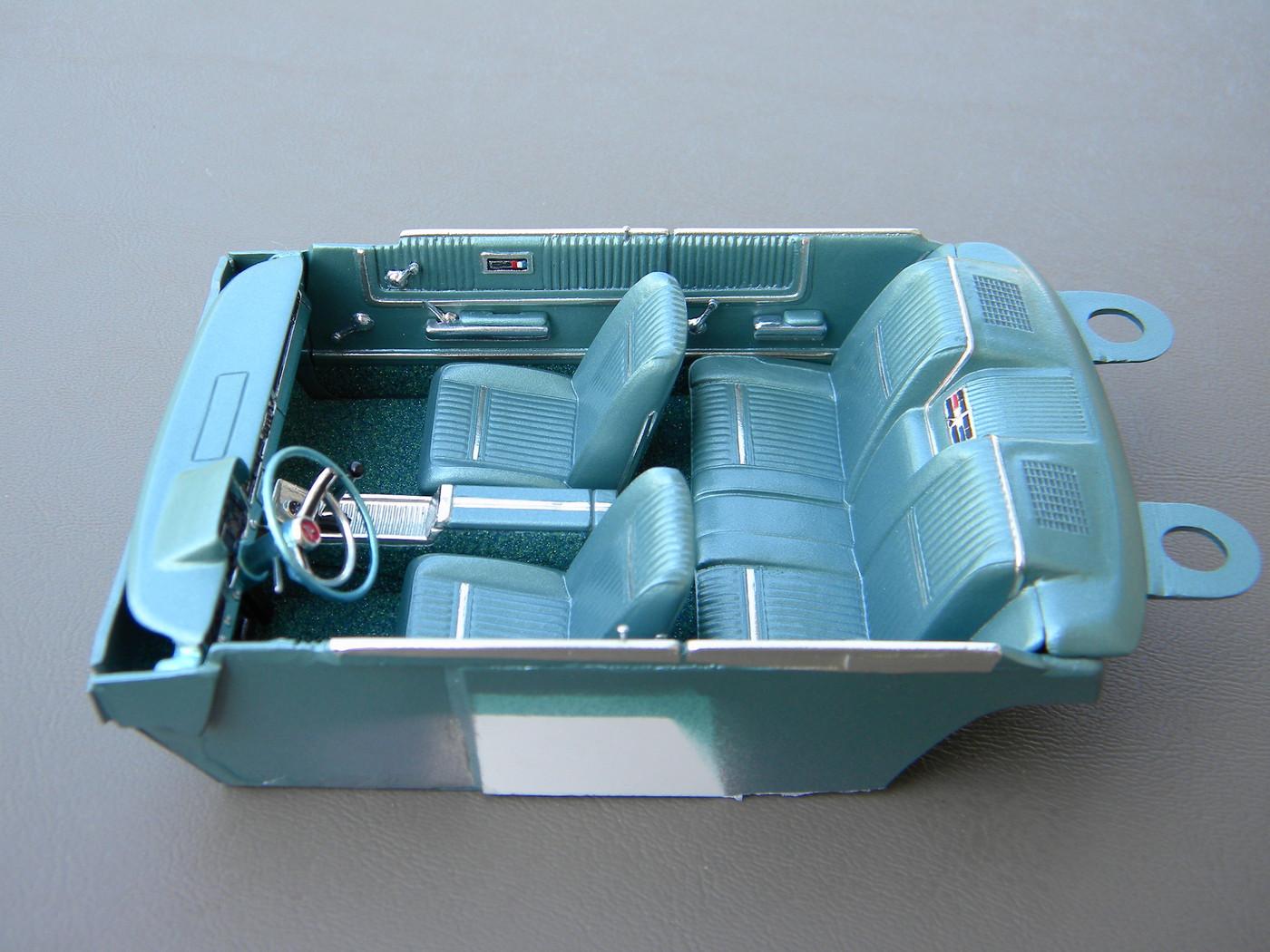

Flocking is very fine fibers. I've never had much luck with flocking. It has a tendency to float all over the place, and it's very prone to static electricity, making it want to stick to everything that you don't want it to stick to. It's long fibers make it look more like a shag carpet. Embossing powder is a very fine granular powder. Personally, I find it easier to work with, and it's appearance is more in tune with the cut pile carpet found in most cars. These were done with metallic embossing powder. Steve -

Flocking

StevenGuthmiller replied to Sidney Schwartz's topic in Model Building Questions and Answers

Do you want flocking, or embossing powder? Steve -

I may have posted this before, but I still have people ask me how I do this on occasion, so I figured that I would post it regardless. This is a pretty common technique that I assume many modelers have mastered, but here it is for anyone that may not be familiar with it. Steve

-

1964 Pontiac Bonneville Convertible.

StevenGuthmiller replied to StevenGuthmiller's topic in WIP: Model Cars

Steve -

1964 Pontiac Bonneville Convertible.

StevenGuthmiller replied to StevenGuthmiller's topic in WIP: Model Cars

Maybe this will help Bruce? Steve -

1964 Pontiac Bonneville Convertible.

StevenGuthmiller replied to StevenGuthmiller's topic in WIP: Model Cars

Thanks Bruce. I don't really no how to describe it other than to heat the sprue over a flame until it really starts to sag, and then immediately pull on both ends with very slow and steady tension. The slower you pull, the thicker the piece, the faster you pull, the thinner. I've learned to be able to stretch sprue pieces probably not much thicker than a human hair, and possibly as long as 3 feet long. Steve -

1964 Pontiac Bonneville Convertible.

StevenGuthmiller replied to StevenGuthmiller's topic in WIP: Model Cars

Thank you guys! I have been rolling some ideas around in my head for a few chassis details, (although, I don't think I'm going to go crazy with it), but I was thinking about one of the more visually obvious features, and how I should approach it. I was thinking about how to best throw in some emergency brake cables, and originally, the obligatory "wires" approach seemed to be the most likely solution. But then I started thinking, "I really don't want to start monkeying with trying to route these wires once the chassis is painted and in the finishing stages, and there's nothing that I hate more than trying to keep exposed wire details straight and free of bends and kinks during the assembly process, and after". In my mind at least, I figured that thin plastic would be more flexible and less likely to bend up on me as I progressed, and much easier to assemble and fit prior to the finishing stages of the build. Granted, it would be more prone to breakage, but as flexible as stretched sprue is, it would require some fairly radical forces to break it, so, I decided that there was absolutely nothing to lose by attempting to construct an entire unit that could be painted and virtually just slipped into place towards the very end of construction. It actually went much better than I anticipated, and installing it will require nothing more than a couple of seconds to slip it into place. Steve -

Agreed. Any clear that you desire will help protect the painted details. In many cases, I'll use flat paints for a lot of the base colors and details. That way, a coat of Testors clear gloss lacquer will give the parts a nice matte finish. Sort of killing two birds with one stone. Steve

-

Best Adhesive for Windscreens?

StevenGuthmiller replied to Bugatti Fan's topic in Tips, Tricks, and Tutorials

I don't want to call it "the best", but I've found that clear 2-part epoxy works better than anything else that I've tried, and once it's dry, that glass ain't goin' nowhere! I'll usually tape the glass in position in several places around the perimeter, and then apply glue to the open areas with a tooth pick. Once the glue has set hard, I'll remove the tape and apply more glue to the areas that were covered by the tape. I don't like thin glues, or ones with "capillary" capabilities, because I don't want the glue, "capillary-ing" all over the place, and, well, we all know how well some kit glass fits, so I find that a thicker glue works better for me. Steve -

Unique part question.

StevenGuthmiller replied to Geno's topic in Model Building Questions and Answers

If the stuff is that tough, just sand it as smooth as you can get it, prime the part, and send it off to the chromer. Apparently, it's not going anywhere. Steve -

Agreed. If it were mine, in retrospect, I would have drilled holes in the dash slightly smaller than the vents, and installed them prior to paint. But as that’s moot at this point, a very tiny amount of any kind of glue, or paint will work as well as another. As a matter of fact, if you want to avoid any glue “squeeze out”, an epoxy, allowed to set up until just barely still tacky before installing the vents should work well to keep that from being a problem. Steve

-

Looking for 68 Dodge paint match

StevenGuthmiller replied to Modlbldr's topic in Model Building Questions and Answers

I can vouch for both MCW and Scale Finishes!! Both produce EXCELLENT acrylic lacquers, and some enamels as well. But, unfortunately, I don’t think either one offers paint in spray cans anymore. But, I might be wrong, so check out their websites. If they do still offer spray cans, they come at quite a price! Let’s just say that for the price of 4 or 5 cans, you could buy a nice airbrush, and then your paint searches would be over! ? This is a shot of a ‘69 Coronet I did some years ago in MCW Mopar, F-Code, “Light Green Poly”. Steve -

But won’t the canopy glue dry to more of a gloss? With the dash being flat black, any glue overflow would show. I think if it was mine, I would tack them in place with whatever glue you want to use, and then give the whole dash a coat of whatever clear finish you envision, (ie, flat, semi gloss, gloss) That way there’ll be no finish variations, and the clear will seal down the vents. Steve

-

Looking for 68 Dodge paint match

StevenGuthmiller replied to Modlbldr's topic in Model Building Questions and Answers

If I recall correctly, MCW no longer offers spray cans. Don’t remember where I heard that, and it’s certainly worth checking into, but I believe it is the case. Steve -

Glueing evergreen to clear windshield.

StevenGuthmiller replied to NOBLNG's topic in Model Building Questions and Answers

I would use this approach. The acetate or clear styrene would look better, (thinner) anyway. If it were mine, I would add a molding around the perimeter of the window opening, using half round, plastic rod, stretched sprue, whatever you prefer, using a plastic cement, (I like Plastruct "Plastic Weld"), and then make a fresh windshield. Even if you opt to not make a new glass, I would cement the new molding prior to doing anything else to the body. Steve -

Scribing panel lines. How is it done?

StevenGuthmiller replied to conchan's topic in Model Building Questions and Answers

Agreed! Let the tool do the work, whatever the tool may be. Steve