-

Posts

2,743 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Chariots of Fire

-

Western Star 4900 FA plow truck

Chariots of Fire replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Funny thing about keys. I have 2 keys to my GMC Canyon. Tried the spare today and it would not start the truck. Turns out the key itself has to be programmed! No simple info in the owner's manual. Had to go to the GMC dealer to find that out. Started truck with older key, turned it off, inserted the spare and it got programmed immediately and the truck started. Talk about overkill!! -

Western Star 4900 FA plow truck

Chariots of Fire replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That's got to be one of the most detailed models I have ever seen. And superbly done to boot! Don't forget the key for the ignition!🤣 -

AITM is back

Chariots of Fire replied to PierreR89's topic in Truck Aftermarket / Resin / 3D Printed

If the resin of the Ford F-8 is as good as Dave's was, you should be able to scribe through the lines of the hood to separate it. I did that on the Reo Gold Comet that Dave cast so I could do a model with an opening hood. Worked fine. -

Welcome to the forum! Plenty of neat stuff to see and lots of great info to take in.

-

Those last photos should be of some help. When you compare the height of the cab to the wrecker frame there is some consistency. If you can find one or two dimensions that are relatively proportional you might be off to a start. Other pieces that you can see in the closeups can be made to fit pretty close.

-

M543 Wrecker

Chariots of Fire replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice work, Warren. I was going to suggest washing all of the 3D parts in detergent and warm water first but you beat me to the punch! Going to be a BIG truck even for 1/35 scale. The basic M52 is a 5 tonner, I believe, and this one looks similar. -

Ok. Fenders have been attached along with panels for underneath. The engine is in and secure. The hood latches have been completed along with the hinges. I brush painted portions of the cab interior that would be hard to hit with a rattle can. Overspray on the outside will cover any unevenness of the brush work inside. Makes it so much easier to do when it comes to paint. The frame has been given a coat of OD. Still some washes needed to highlight the various details. Tires and wheels are ready for mounting. I made the hood hinges out of pieces of door hinge stock, a piece of small brass channel and some plastic. The hood latches are made of brass tubing and common pins. They are glued in position and have a small U-shaped piece of wire on the sides of the hood as latch catches.

-

Transporting Completed Models

Chariots of Fire replied to Ralphie's topic in Tips, Tricks, and Tutorials

I use plastic storage containers. Models are placed on a padding of paper towels or something similar. Then more paper towels are placed in between models and around the edges of the container to keep them from rubbing up against each other or against the container. Thin, soft foam stock works as well. No need for extra protection against cold or hot if you are not going to be in such environments for long periods of time. -

Got a little more done on the cab. Doors were cut free by scribing and then hinged to open. A small rare earth magnet was set in the edge of the door and a piece of wire in the edge of the cab which will hold the door closed. The engine was basically finished up and can be installed once the paint on the frame is done. The hinges were glued with CA into notches cut in the edge of each door with a similar notch cut in the edge of the cab. Then holes were drilled in the doors and cab for small nails to add strength to the hinges. The heads of the nails were ground nearly flat so that the doors will close without binding. A new drip edge at the top of each door will be done to replace the ones that were partially removed during the scribing process.

-

Got a bit more done. Engine detail has been started. The plugs were drilled out and brass tubing was inserted. These will be painted white for the ceramic of the plugs. The distributor was also drilled out for the wiring. Additional details were added to the frame including brake lines, fuel tank, front shocks, and steering arm and pitman. The cab has been set on the frame and is held in place with small screws that project from the frame cross members into the floorboard. With that set the fender locations can be determined. The cab can come off for painting and I still have to open the doors.

-

More to go, Bob. Got the brake lines in place along with the main canister and master cylinder. Working on the gas tank shape and details to put it in place. Will have to move the drive shaft from the transfer case toward the rear differential down a bit to get it fit into position. I think it will improve the look as well.

-

Much of the hard stuff chassis work is done now. Wheels are mounted on the axles but can be removed for painting. 3D printed U-joint ends were mated with brass tubing and attached. The one connecting the transmission to the transfer case is loose for final fitting. The front axle steers. The tie rod was made of 1/16" tubing and smaller solid brass rod. As with the other builds, the wheels were drilled for 6 lug nuts using wire and hex beads. Much more realistic than the cast in place ones that can sometimes be difficult to cast without bubbles or holes. Locking rims for the tires need to be cast as well for the rear tire set.

-

Blue Rig Completed

Chariots of Fire replied to Chariots of Fire's topic in Model Trucks: Big Rigs and Heavy Equipment

Not sayin' 😎 -

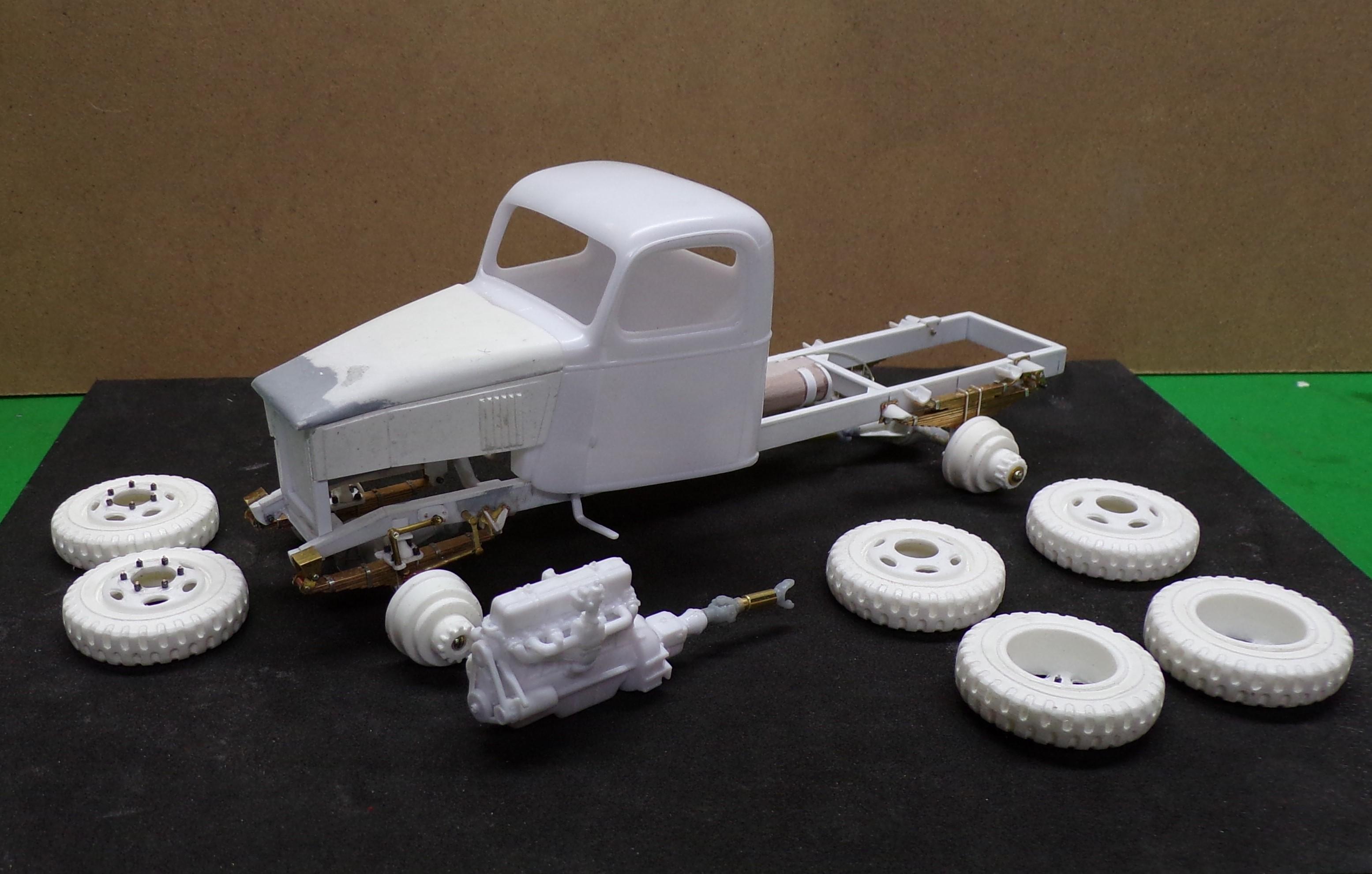

So far I have built two of these World War II fire pumpers that were done by several fire apparatus manufacturers on Chevy 1.5 ton chassis. The first went to a Vet in Hawaii while the second one went to a friend of his in Belgium who also happens to have a full size one that is restored. This time around the build is for my shelf to compliment some of the other WW II rigs that are there. Here's the start of the build. I got one more Revell '41 Chevy kit (the cab and engine are identical to what was used to produce the Class 325) and began casting more of the parts that I had done for the other two projects. The reconfigured hood fits the kit cowl and has separate side pieces. Tires and wheels are resin castings as well. The frame has been altered from the pickup frame in the kit utilizing the front end and straightening the rear portion. I also reinforced it to make it slightly deeper using Evergreen strip stock. Springs are made of brass strip stock soldered together at the ends. Separate hangers were made for each spring. Clips for the springs are made of flattened solder wire. Now I am working on the axles to get the proper tread width for the front and back. Then the wheels can be secured to each axle. In the photos are also the grill guard, made of strip brass and brass wire soldered together. The parts next to the grill are the components of the steering knuckles for the front axle. They are made of brass channel and tube stock, again soldered together. Both are now made up and will show in a couple of future photos. The aluminum turning is the master for the Barton American pump that will be mounted on the front of the truck. The mold is ready for a pour so that the pump can be built up.

-

Dodge L-700 stake bed

Chariots of Fire replied to Sam I Am's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Good rig for a lumber yard. I have a couple of those L-700's. Make sure the cab sits straight on the chassis. It was one of the little quirks in the mounting process. -

I typically download to a file on the computer. Then while in MCF hit the "choose files" button down below and then select the photo to insert. Comes up every time.

-

Where are you taking the photo from, a camera, documents file??

-

Mack B-61 Dump Body

Chariots of Fire replied to Scott Eriksen's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

With a Maxim built aerial ladder!