-

Posts

4,794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

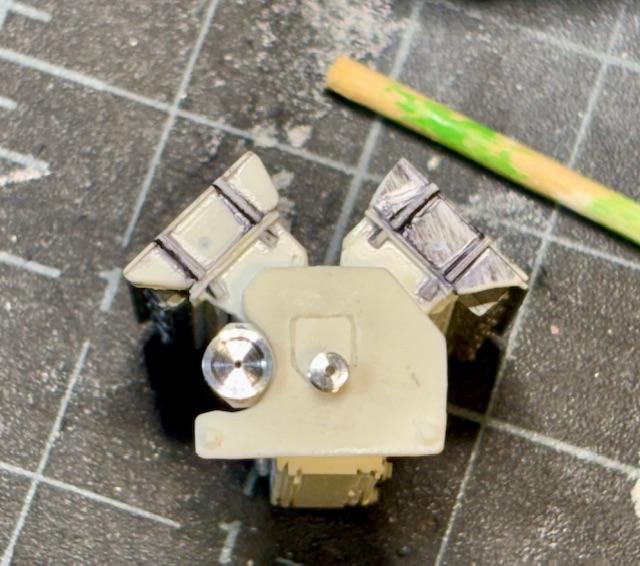

Needing a fuel pickup break - these are the front engine plates - the left hand is the 20th sc plate for the fuel injected Climax engine in the Tamiya kit - with the water and oil pumps - good stuff - the right hand plate is the simpler on that i made for the ‘62 Climax engines - which sported Webers …

-

Michey Thompson's wynn's spitfire

absmiami replied to johnyrotten's topic in General Automotive Talk (Trucks and Cars)

-

Michey Thompson's wynn's spitfire

absmiami replied to johnyrotten's topic in General Automotive Talk (Trucks and Cars)

Alrighty then - did Calvin cast the offset on his Thompson Harvey Aluminum kit ?? -

Michey Thompson's wynn's spitfire

absmiami replied to johnyrotten's topic in General Automotive Talk (Trucks and Cars)

And in fact, this car is a survivor [against all odds] here it is at the Amelia Island concourse two years ago i think the livery is fr its last year of competition - which i think was '64 the offset is still in place .... - cool .... -

Michey Thompson's wynn's spitfire

absmiami replied to johnyrotten's topic in General Automotive Talk (Trucks and Cars)

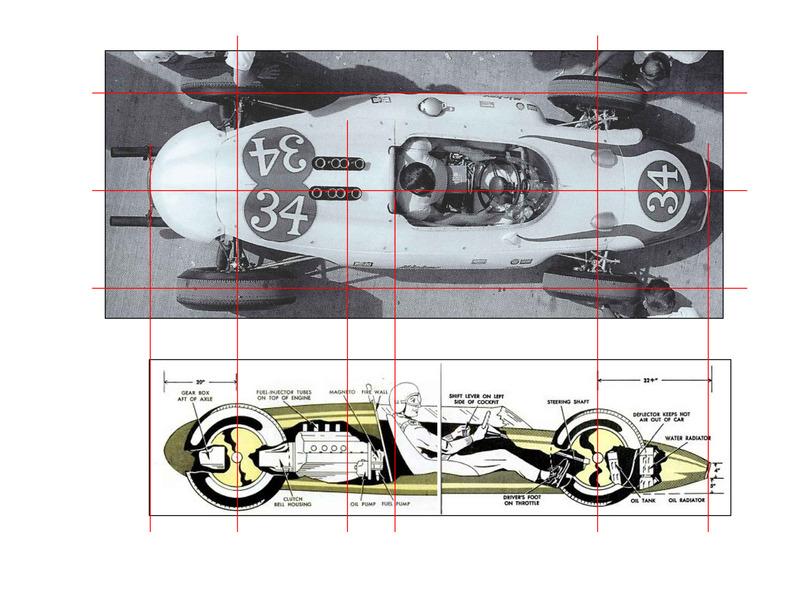

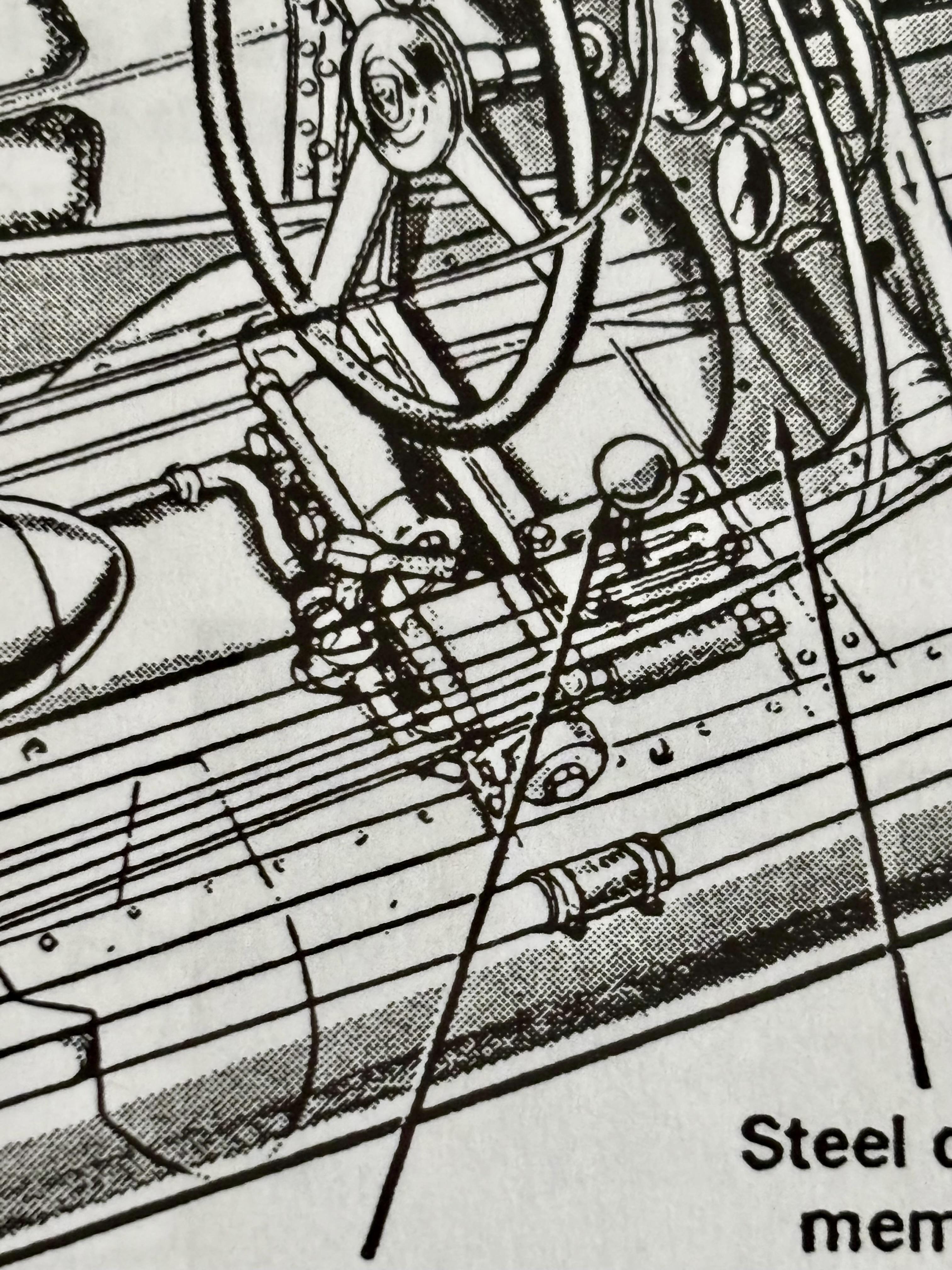

HERE'S A GOOD ILLUSTRATION OF THE OFFEST - I had forgotten about this feature - but - here it is ... -

Michey Thompson's wynn's spitfire

absmiami replied to johnyrotten's topic in General Automotive Talk (Trucks and Cars)

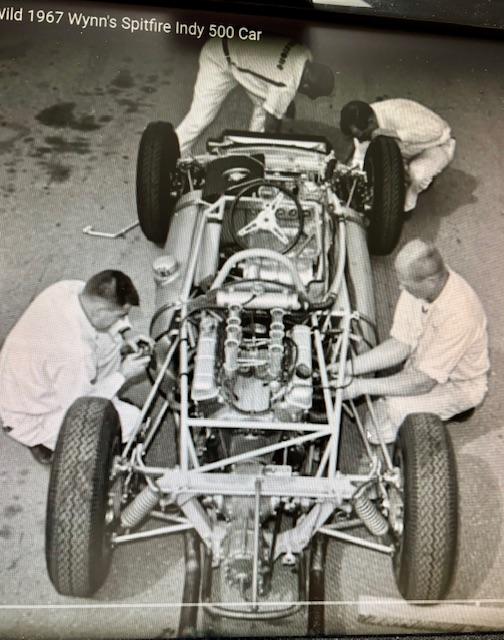

This is a still shot from the video of the ‘62 Gurney car - notice the engine offset - this sent me back into research I had collected on this car … -

Michey Thompson's wynn's spitfire

absmiami replied to johnyrotten's topic in General Automotive Talk (Trucks and Cars)

damn - that was great - and I scarfed up the great body off chassis photo of Gurney's '62 entry - which was casted yrs ago in resin - thank you Calvin ... -

cheetah reboot

absmiami replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Alu soldering - a black art … -

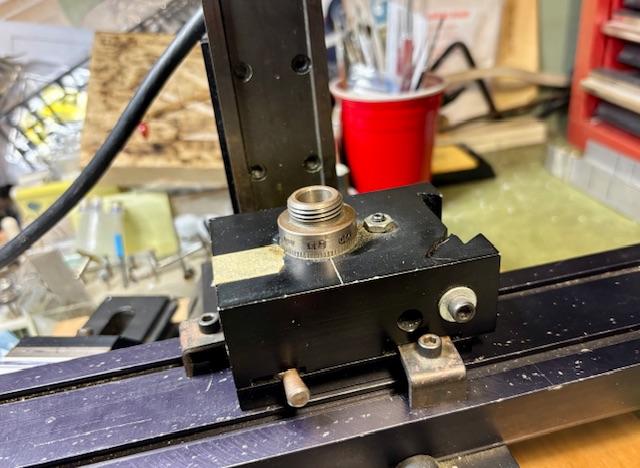

Pg - this is the sherline indexer that i’ve used for these milling ops - the chuck screws right onto the tool - they also sell a more expensive indexer for radial milling - its a better tool - but not needed for what I’m making …. The fuel filler collar on the Indy Lotus 38 is up next - while i’ve got the mill machine on the w bench …

-

formula 55 chevy

absmiami replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Oh Charlie ... Do you have a fractal mini bench vise ? didn't know what it was til 30 minutes ago there's one for sale on Amazon for 100 bucks - called a white rhino mini vise or your could spring for the $2,997 model - and I could borrow it ... -

1937 Bugatti 57G

absmiami replied to TC's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Nice