-

Posts

4,857 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

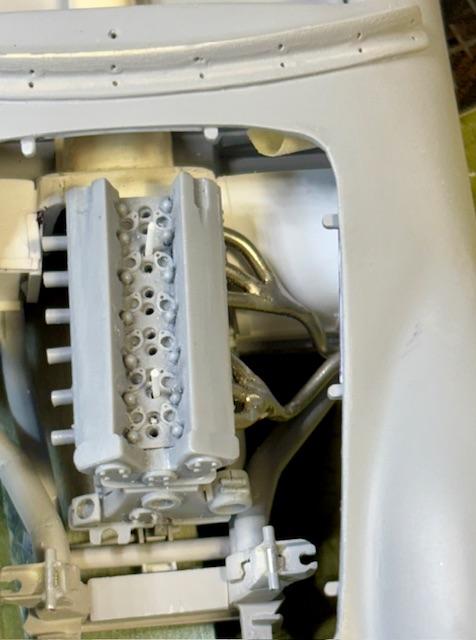

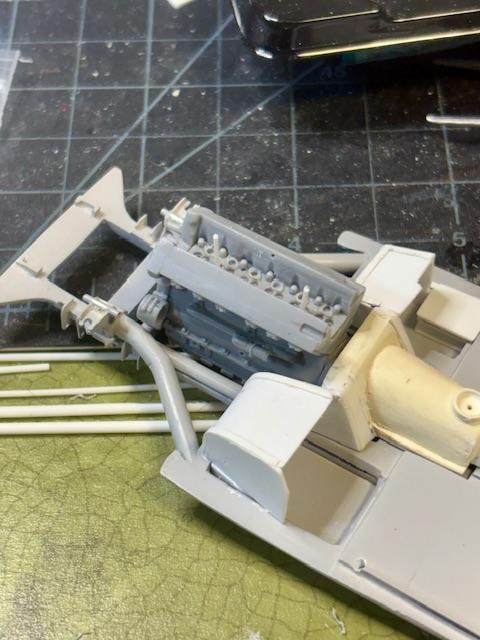

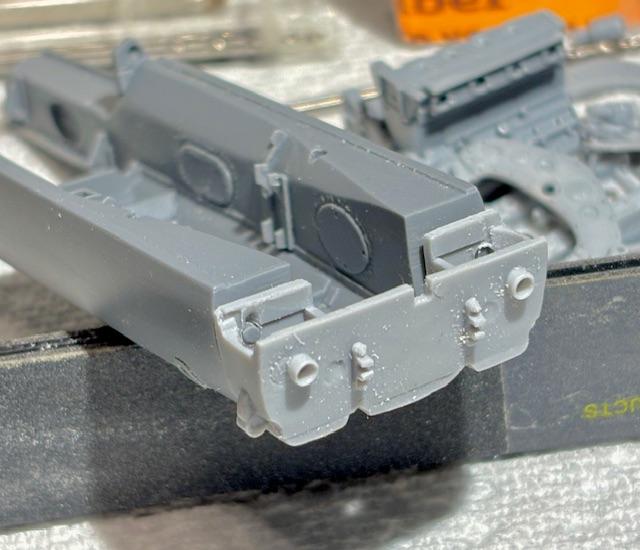

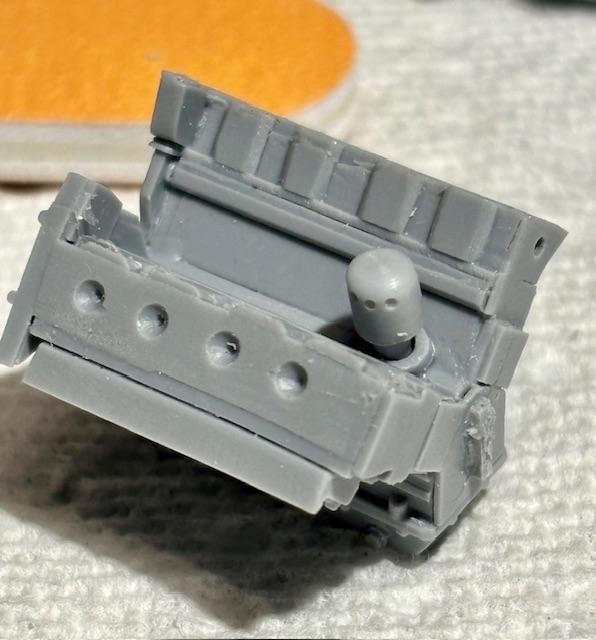

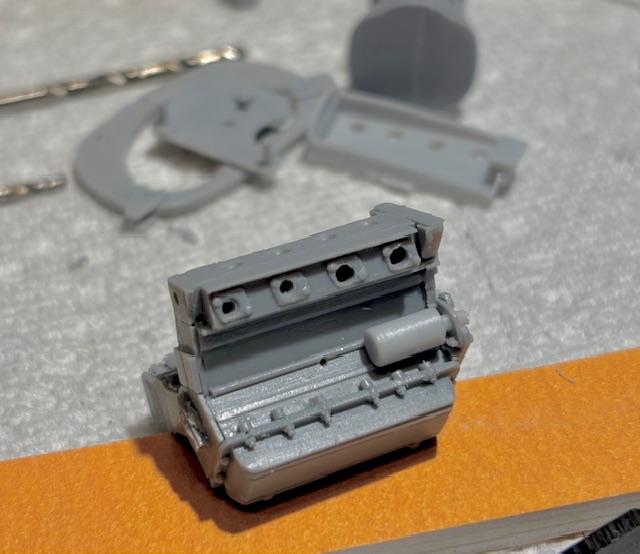

I had made brass plug wire looms - my caster took the trouble to add tabs used to attach the looms to the valve covers - thats a difficult job - but the tabs line up just right - the slender parts wont be as strong as the brass masters - but i think i can use them … -

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

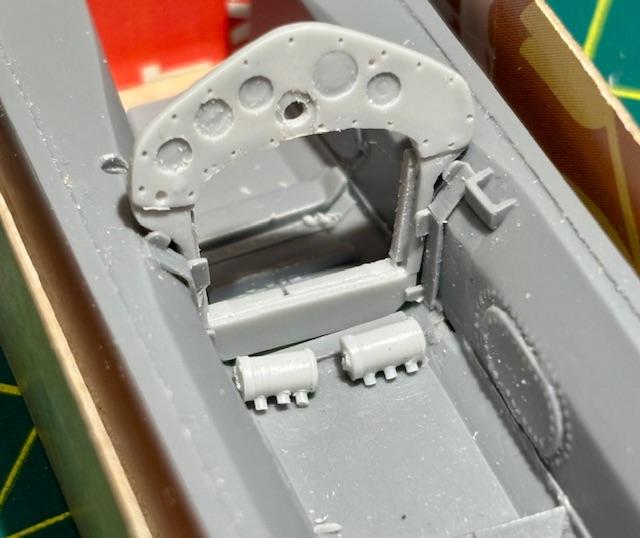

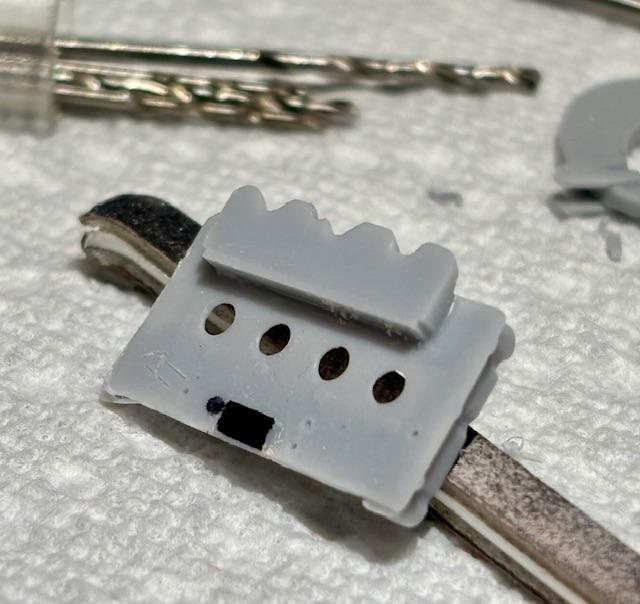

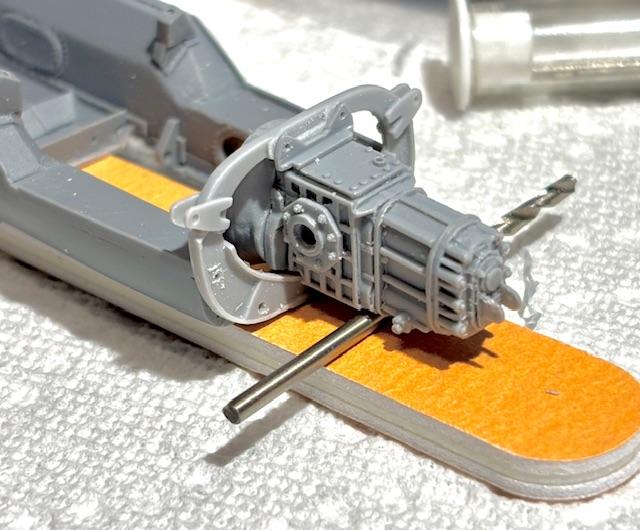

The starter is a short length of .093 alu tube with some bits and peices of Evergreen rod for detail - -

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

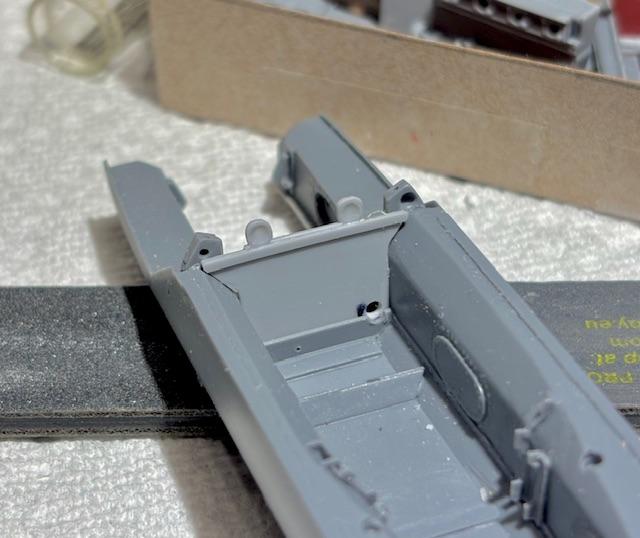

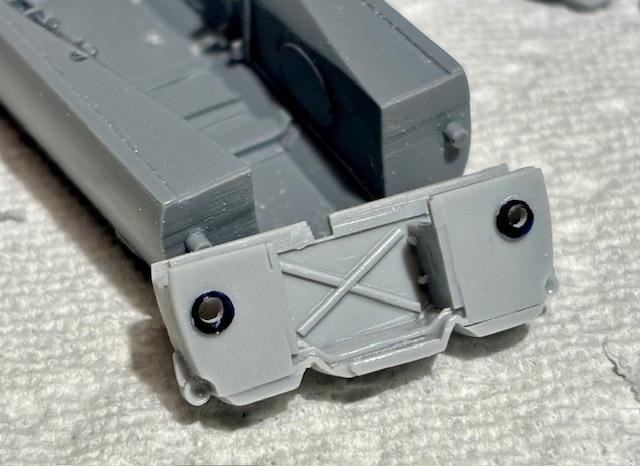

I’ve now made enough parts to paint and assemble my engine … nearly all the parts have been casted by the HOF resin caster that casted my Lotus Climax engine … the white casting in the group pose is the trans casing - even though i’ve scratched the frame and the engine - i’m finding that many of the kit’s castings are useful once modified … -

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

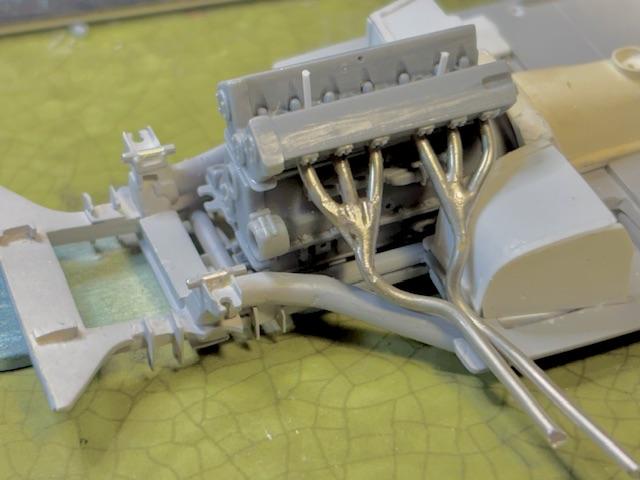

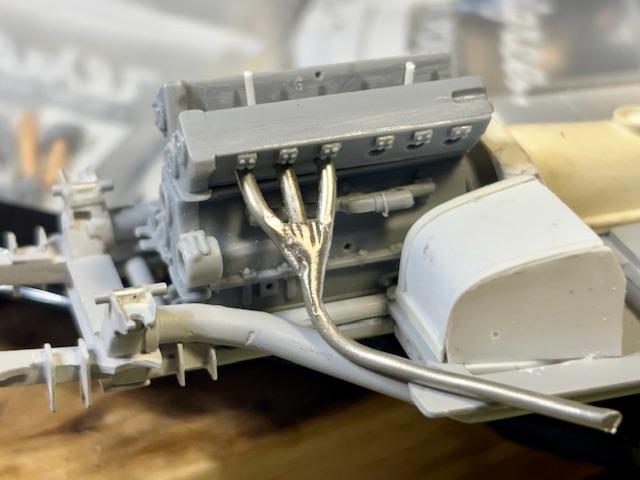

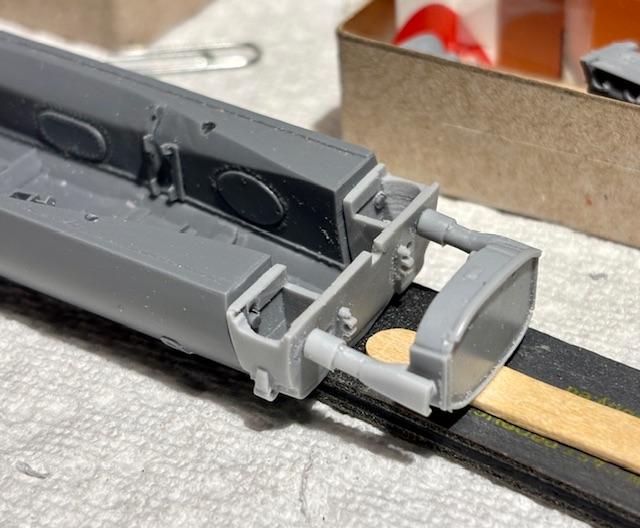

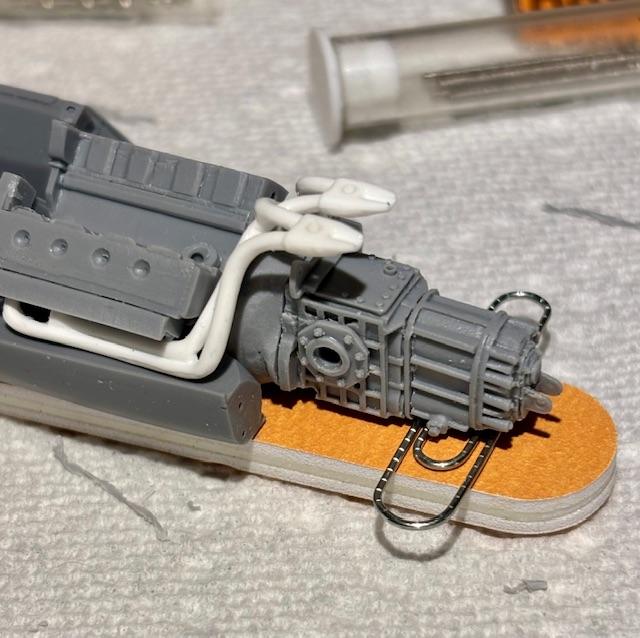

Not done yet - the manifolds don’t yet line up as neatly as they should - but the silver solder remains soft enough for some more adjustments - will do this later - i’m … exhausted … -

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

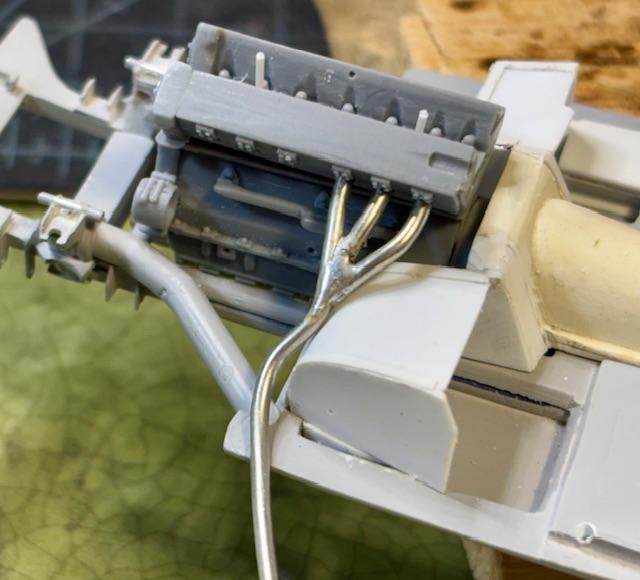

Ground a cutout into the left fender - which is exactly what the factory appears to have done - for the manifold pipes’ exit fr the eng bay … -

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

-

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Which gave me a manifold that i can bend and adjust in place in the engine bay - the white casting is the kit side pipes - this part is pretty good - plan to use it - -

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

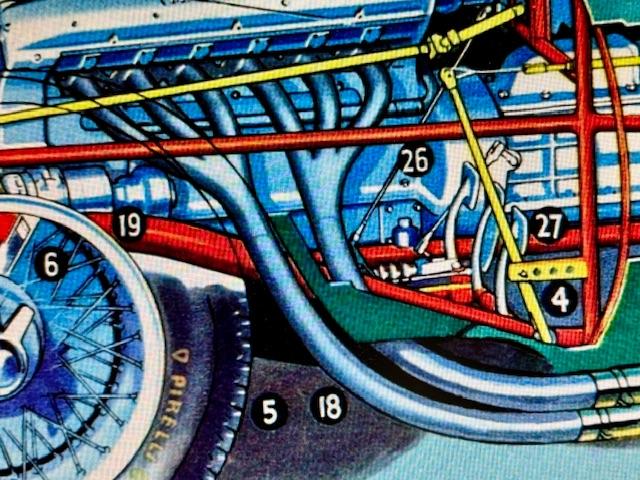

Dont want to use copper or brass - because both will “work harden” after repeated bends to route the pipes - and once I’ve soldered the 3 into 1 pipes - i can’t repeatedly anneal the assembly - so i’m using silver solder - .060 for a scale 1 1/2 pipe - while working on parts for the Lotus 25 I sourced some low temp solder fr GB - using it to solder white metal - it dawned on me that i could use it on silver solder because of its higher melting point … -

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

-

Maserati A6GCS Spyder

absmiami replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Exhaust manifolds - this is the last thing in the engine bay to tackle - two 3 into 1 pipes that exit under the fender and then into side mounted mufflers … -

Was sort of hoping you mite look at some 24th sc subjects for a transkit - can we tempt you to do a proper 24th sc Jag engine ? The Tamiya 6 cyl Jag engine in their saloon kit is good - its about half way there -

-

Ooph