-

Posts

4,845 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by absmiami

-

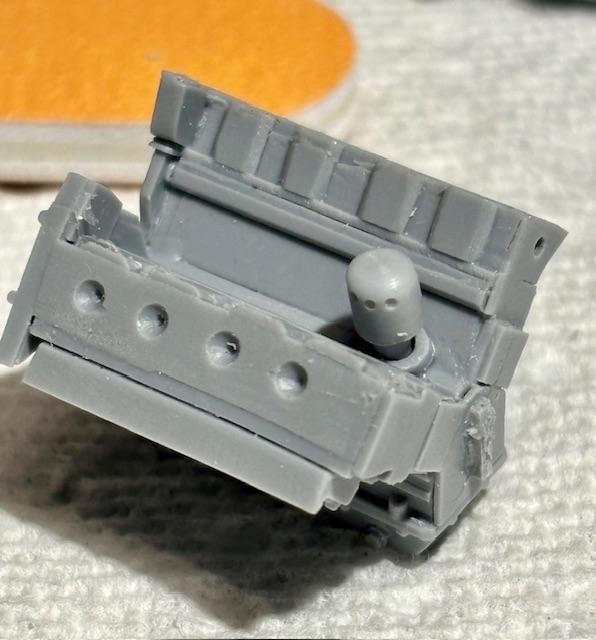

Was sort of hoping you mite look at some 24th sc subjects for a transkit - can we tempt you to do a proper 24th sc Jag engine ? The Tamiya 6 cyl Jag engine in their saloon kit is good - its about half way there -

-

Ooph

-

Can we see some scratchbuilt frames?

absmiami replied to OldNYJim's topic in General Automotive Talk (Trucks and Cars)

-

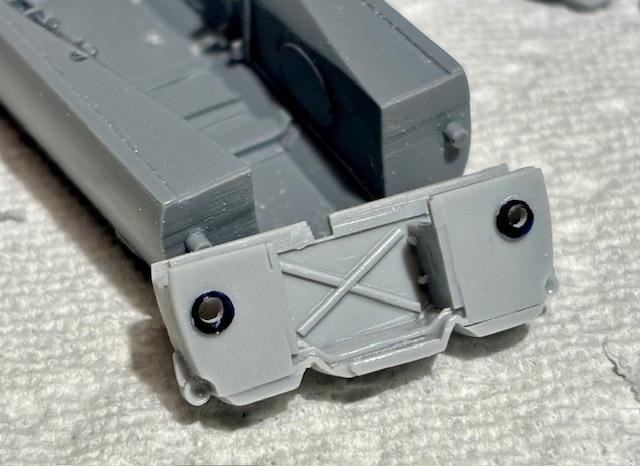

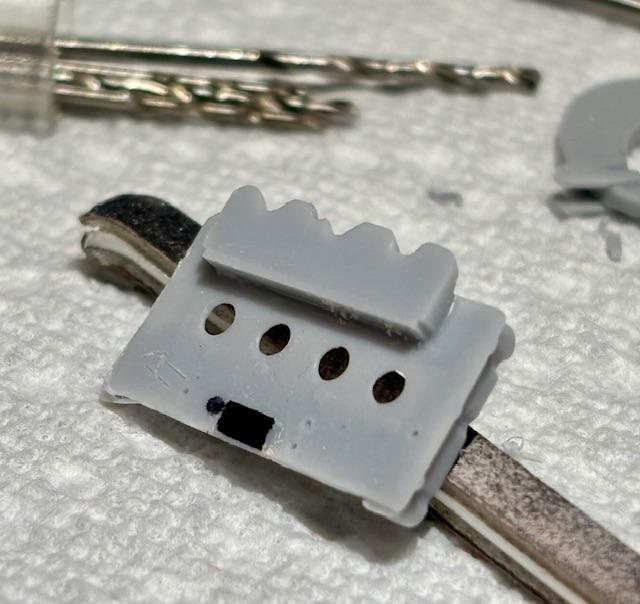

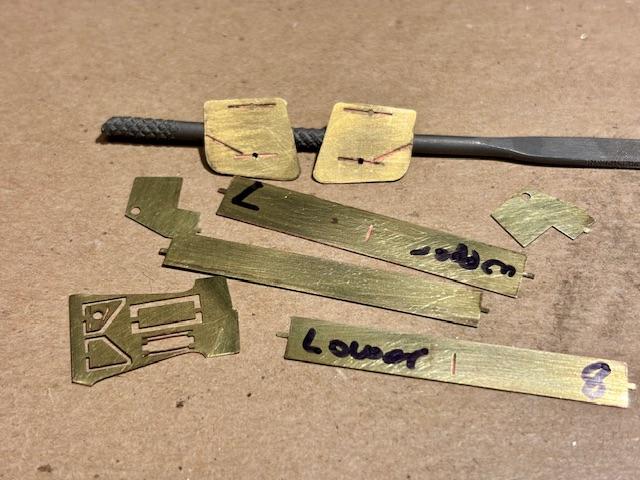

Early nineties IMSA cars all had this neat rear wing - Jaguar did this too - the side panels are relief etched to place the wing elements - but glueing will be sloppy and uncertain - so I’m leaving the fret tabs on the edges of the wings in place and drilling corresponding holes in the side plates - will attempt to solder everything together upon my return to Fl -

-

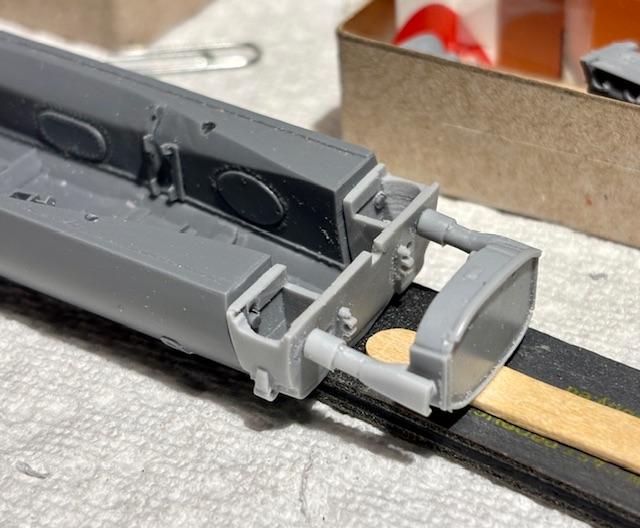

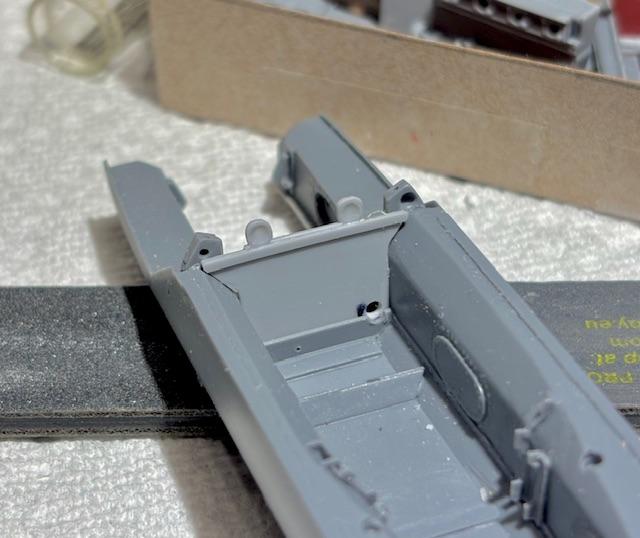

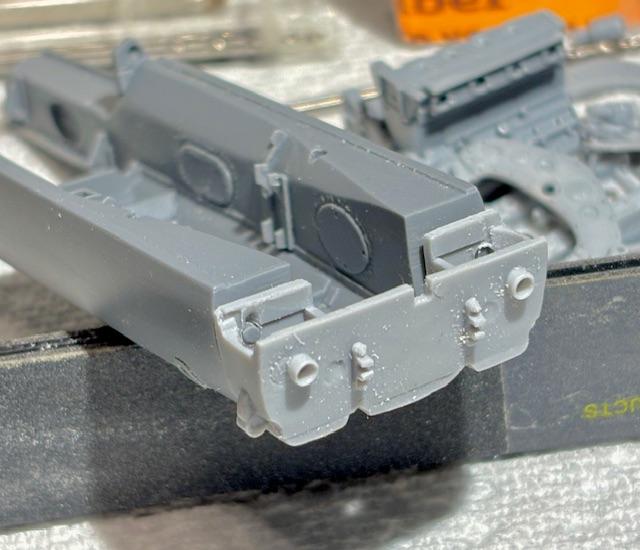

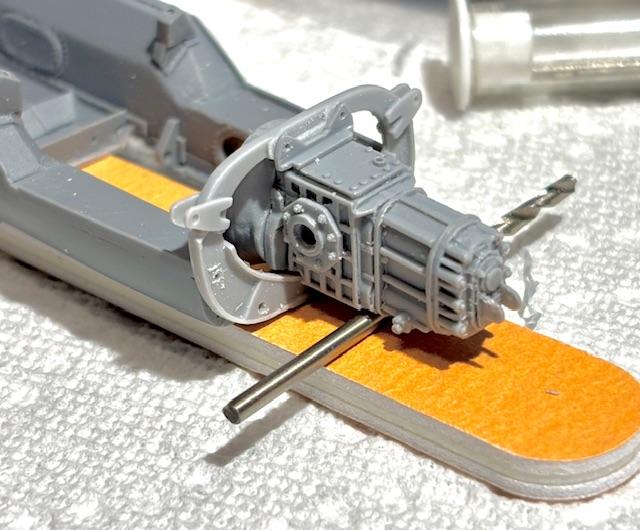

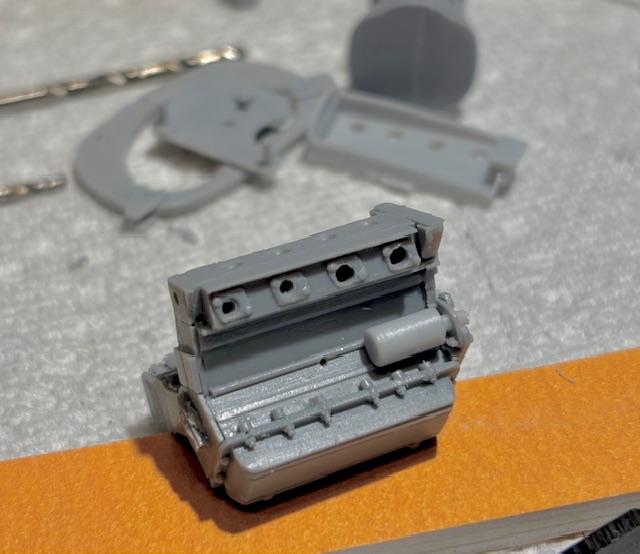

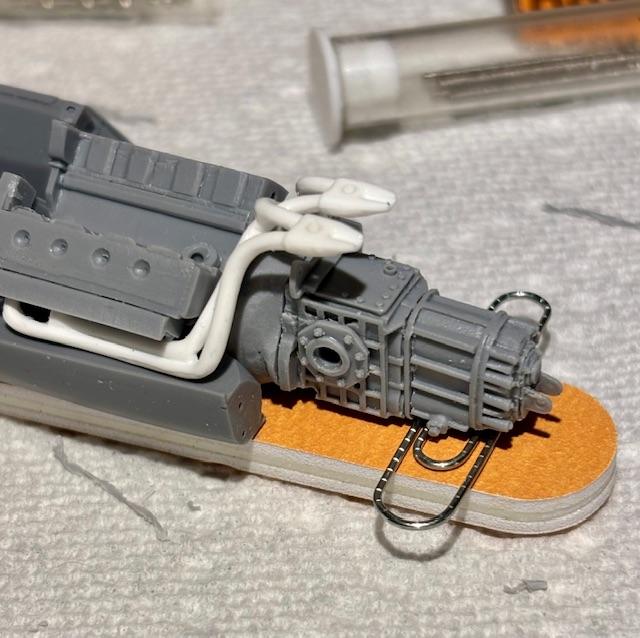

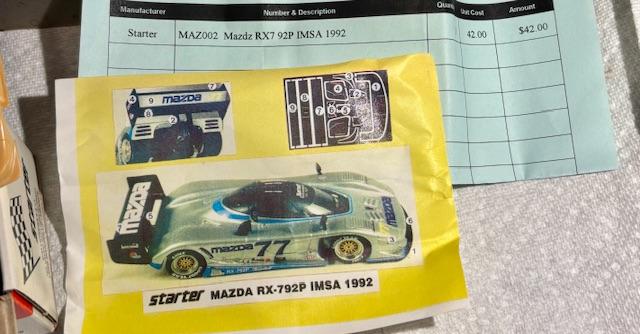

This is Starter’s IMSA Mazda 792P kit - i bought it from Ultimodels in Cali for 42.00 about 30 yrs ago - i never seem to get around to building any of my few 43 sc kits - so i thought this would make a good holiday basement build - this was the follow-up to Mazda’s Lemans winner - not very successful - wonderful lines - but not a good real-world racer - Mazda’s IMSA team never figured out how to manage the issues caused by the insane exhaust header heat …