-

Posts

1,360 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ian McLaren

-

Thank you Francis, I'm really having fun building the Mageau fleet. Between the Thunderbird BB/FC and the Prospector N/FC Belair and Corvette bodies I have wandered into several new areas of modeling challenges and feel I'm better for it. I do feel I'll be a little less ambitious on the next project. As per usual this one just flat got away on me (my fault).

-

1/16th 55 Thunderbird BB/FC Funnycar "GIRL TROUBLE"

Ian McLaren replied to Ian McLaren's topic in WIP: Drag Racing Models

Thank you Francis, Yes dealing with USPS has alwys been interesting, but add in this Canada Post nonsence and the costs involved, it is becoming increasingly, just not worth the the effort. It's so much easier to print (or machine / scratch build) your own parts or even produce custom decals in all but the most extreme cases, (Girl Trouble). It's too bad as I would really like to do business with some of the extremely talented people out there but I just can't justify the costs involved (both monitarily and time wise).- 63 replies

-

- 3d printed

- scratch built

-

(and 2 more)

Tagged with:

-

’72 Dodge Demon Drag Racer 1/25 scale

Ian McLaren replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

I just wanted to add my voice to all of those that welcomed you back to the forum. You were sorly missed my friend!! -

’72 Dodge Demon Drag Racer 1/25 scale

Ian McLaren replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

I just wanted to add my voice to all the others welcoming you back to the forum, you were sorely missed my friend! -

1/16th 55 Thunderbird BB/FC Funnycar "GIRL TROUBLE"

Ian McLaren replied to Ian McLaren's topic in WIP: Drag Racing Models

The Prospector funnycar is headed to the back burner for now, as the final decals for the 55 Thunderbird are now available, and after a marathon battle with USPS and Canada post lasting the better part of six weeks and is still not fully resolved, I have what I need to finish the body. Then will come final assembly on the Thunderbird and on the Prospector funnycar as well. It has really been a long haul on this project- 63 replies

-

- 3d printed

- scratch built

-

(and 2 more)

Tagged with:

-

Update on the progress on the Prospector funnycar and its two bodies, the bulk of the decals have been drawn and installed, a trolly for the body not currently in use has been built. Body tins for both bodies are roughed out and need only detailing, braces and injector dog houses to be added but that requires that the windshields be finalized. The adjustable headers are installed and work as required. Scratch built all metal magneto is wired and ready to be installed. That required a modification to the Corvette body the same as on the real car. Corrected valve covers and fuel pump are printing now and that will allow the engine and plumbing to be wraped up. The end is in sight, with either body fitting correctly on the chassis with no changes other than header length, again as per the real car. ress

-

Some more progress on the 57 body, side chrome and hood V decals created and installed. As they were paint on the original car they will go under the clear to replicat that. also the Corvette body has also seen some progress

-

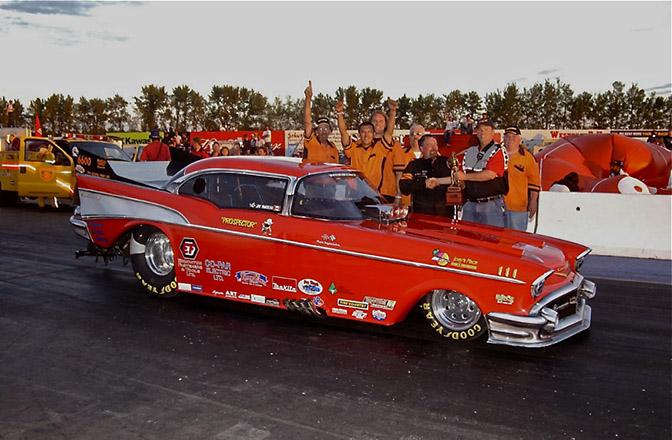

Thanks for the tip. I talked to Jay last night and here is the whole story. The "Wicked Quick" car is not the same vehicle or body. Jay has met them and it is a big inch alcohol car. Jays body was the sixth body pulled from the mold (not the second as I previously stated) and has been all red from the begining. When the NHRA (National Harassment Rundaround Association) ruled that the 57 body was too old for NFC racing? The decision was made to get a 69 Camaro body instead. Which Jay did but there were three other racers in the area with the same idea. Jay sold one of them the Camaro body (shown just sitting on the chassis) and ordered a brand new Corvette body as shown earlier in this thread.

-

I don't know for sure, I'll ask Jay, but the rear wing fences are quite different, and no front bumper bullets.

-

As far as I know the Mageaus purchased this body new and ran it as the Prospector with essentually the same livery from that date untill now. Jay did tell me he asked McEwan if he had any problems with the all Red scheme, and was told in as much as it was going to be a Division Six car and unlikely to tour too far from here, there was no problem.. The above car does appear to be out of the same mold that I believe was made by Steve Davis and Bill Loper. Base on a 7/8th scale Thundercarft body, it was cut and modified to a stock looking although somewhat lengthened profile.

-

-

Yup, it looks kind of like a stock 57, but that not Toms car. This was the second body out of the same mold. It's called the Prospector and was built and run out of Edmonton Alberta as an AA/FC, with Toms blessing as I understand it. There is also a 57 Black Widow street car in the fleet along with these three.

-

Yellow base coat on to allow laying out and masking the Yellow graphics on the body, also working on the chassis to add all of the major areas where clearance issues migh arise when mounting the two different bodies.

-

OK here comes the twist on this one. The real car runs two different bodies, one for nostalgia events and another for match races, the 57 Chev for nostalgia and this for match racing. So I'm doing both bodies and they will fit the chassis without having to make any changes to the chassis to fit either body just as in the real car.

-

Jim thank you so much!

-

Thank you John, stay tuned for a twist on this one.

-

-

I'm really liking this project, as per usual your fabrication is spot on, love the front struts. I'm also enjoying your finishes clean, appropreate and scale looking, not too much bling. Well done!

-

Got this STL file from New Zealand, and the body printed very well with few issues as did the chassis from another source. Not absolutely sure which car I'm going to do.

-

1/16th Vega Funnycar With a difference

Ian McLaren replied to Ian McLaren's topic in WIP: Drag Racing Models

The Vega has not been forgotten, parts have been printed and or built, Chassis has progressed and the new wheelsare inpaint right now. Another update shortly. Very , very rough draft of the graphics.- 17 replies

-

- 3d

- scratch built

-

(and 1 more)

Tagged with:

-

1/16th 55 Thunderbird BB/FC Funnycar "GIRL TROUBLE"

Ian McLaren replied to Ian McLaren's topic in WIP: Drag Racing Models

- 63 replies

-

- 4

-

-

- 3d printed

- scratch built

-

(and 2 more)

Tagged with:

-

1/16th 55 Thunderbird BB/FC Funnycar "GIRL TROUBLE"

Ian McLaren replied to Ian McLaren's topic in WIP: Drag Racing Models

NOT DONE, waiting for decals (no ETA) and clear coat, also front bunper guards, parachutes and mounts and bare-metal covers for front and rear bumpers. a- 63 replies

-

- 1

-

-

- 3d printed

- scratch built

-

(and 2 more)

Tagged with:

-

1/16th 55 Thunderbird BB/FC Funnycar "GIRL TROUBLE"

Ian McLaren replied to Ian McLaren's topic in WIP: Drag Racing Models

- 63 replies

-

- 2

-

-

- 3d printed

- scratch built

-

(and 2 more)

Tagged with:

-

1/16th 55 Thunderbird BB/FC Funnycar "GIRL TROUBLE"

Ian McLaren replied to Ian McLaren's topic in WIP: Drag Racing Models

Chassis is for all intents and purposes, completed' waiting for the body to be finished and for the decals to arrive- 63 replies

-

- 4

-

-

- 3d printed

- scratch built

-

(and 2 more)

Tagged with:

-

So here you are, quite a change of pace but still great results. Small changes that make a big impact, I like it. In a presious comment on this thread you mentioned a Nova?