-

Posts

2,495 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Gary Chastain

-

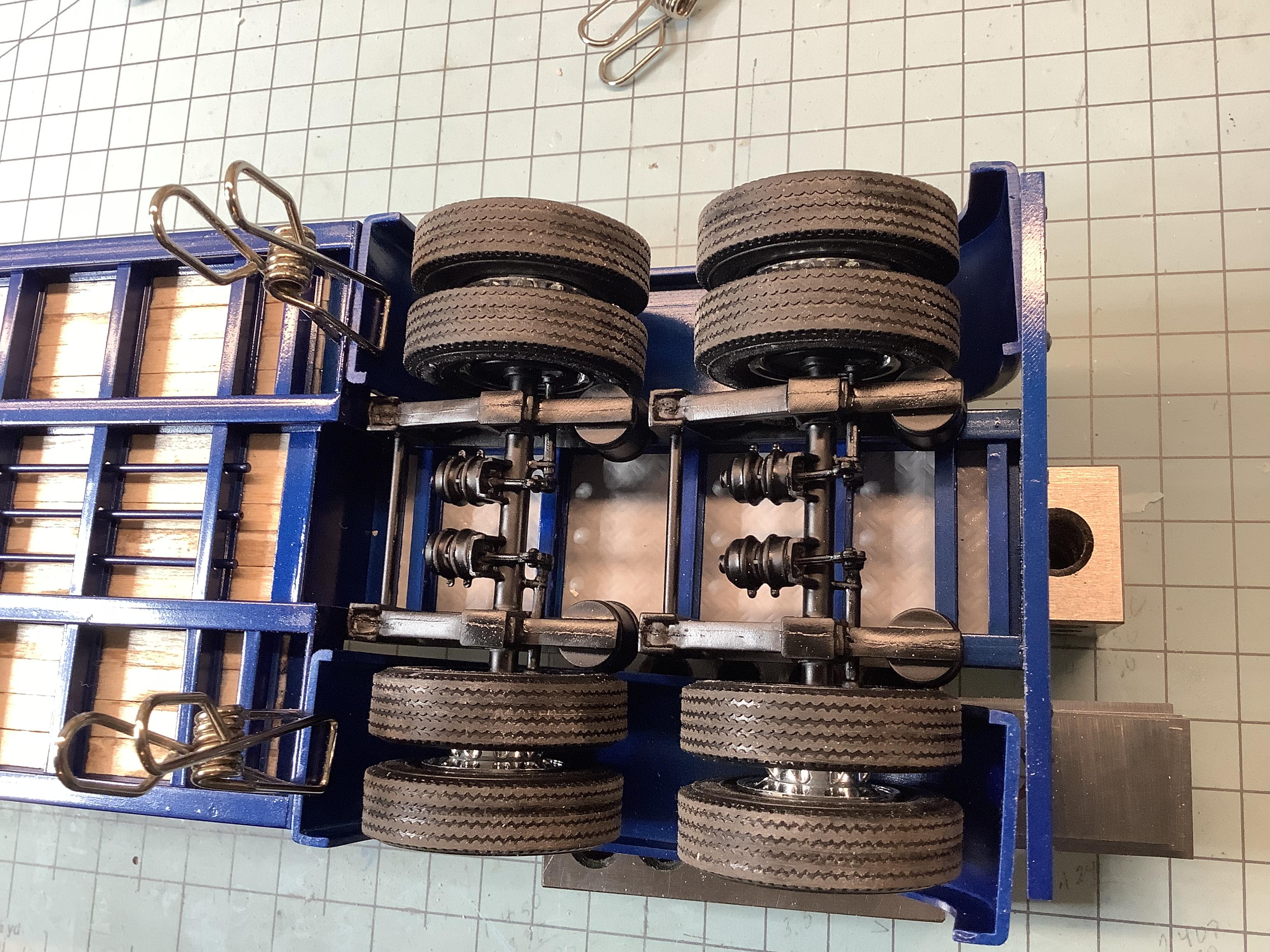

Aligning these 3D printed fenders is proving to be a challenge due to slight warp. The axles are attached, wheels attached and aligned, rear light panel glued in place. The fenders will attach to the trailer frame (clamp locations) after epoxy sets, then I will try to align the rear of fenders to light bar with epoxy. But they are fighting me.

-

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Found my last exhaust kit from Auslowe, they look good on the truck but I will need to make mounts off the back of the cab as the doors could not open, very limited space. While I was digging for parts, I found this headache rack (not sure where I got this), but it’s too tall, think I will try to make shorter stands to lower it. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

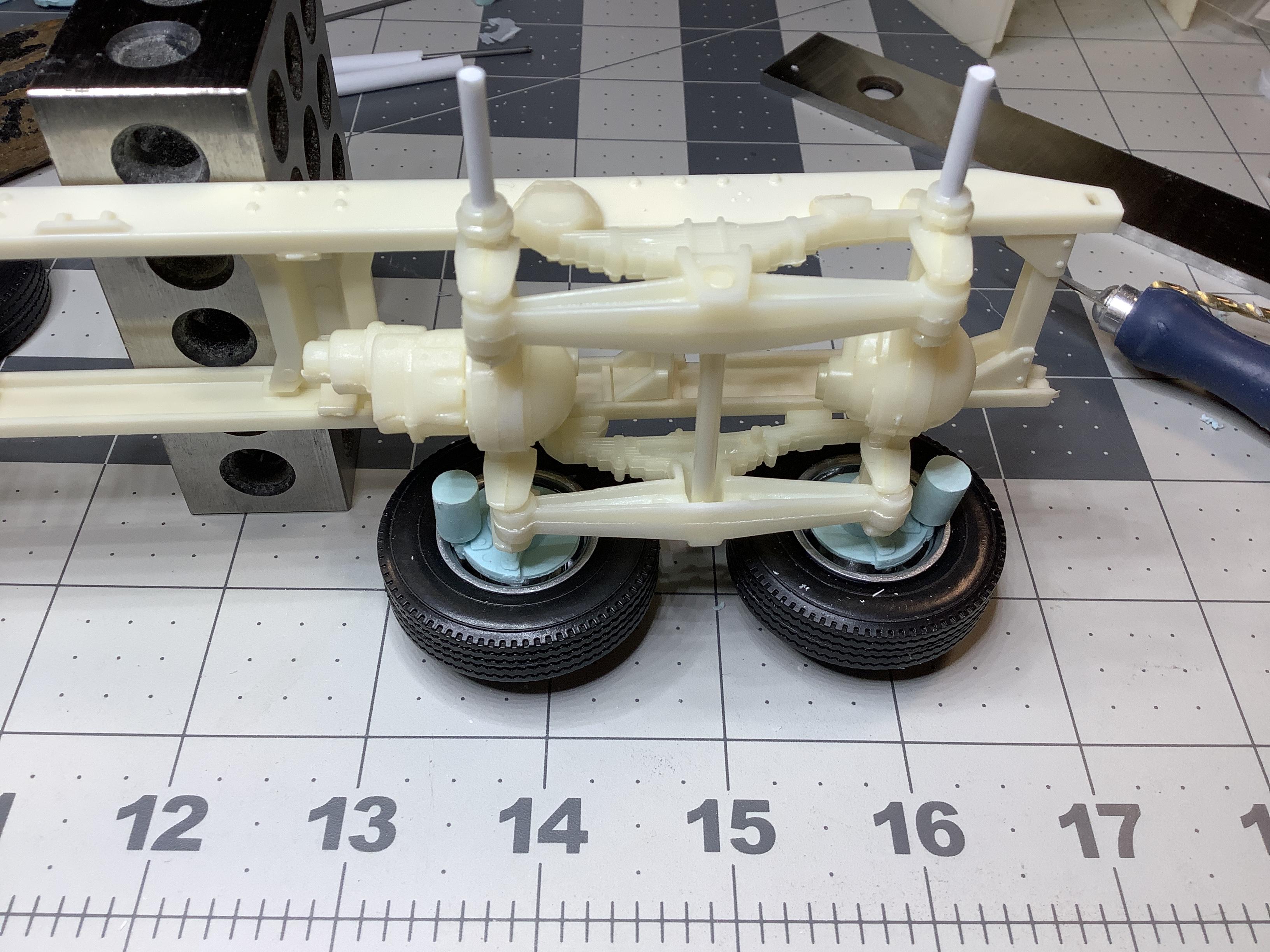

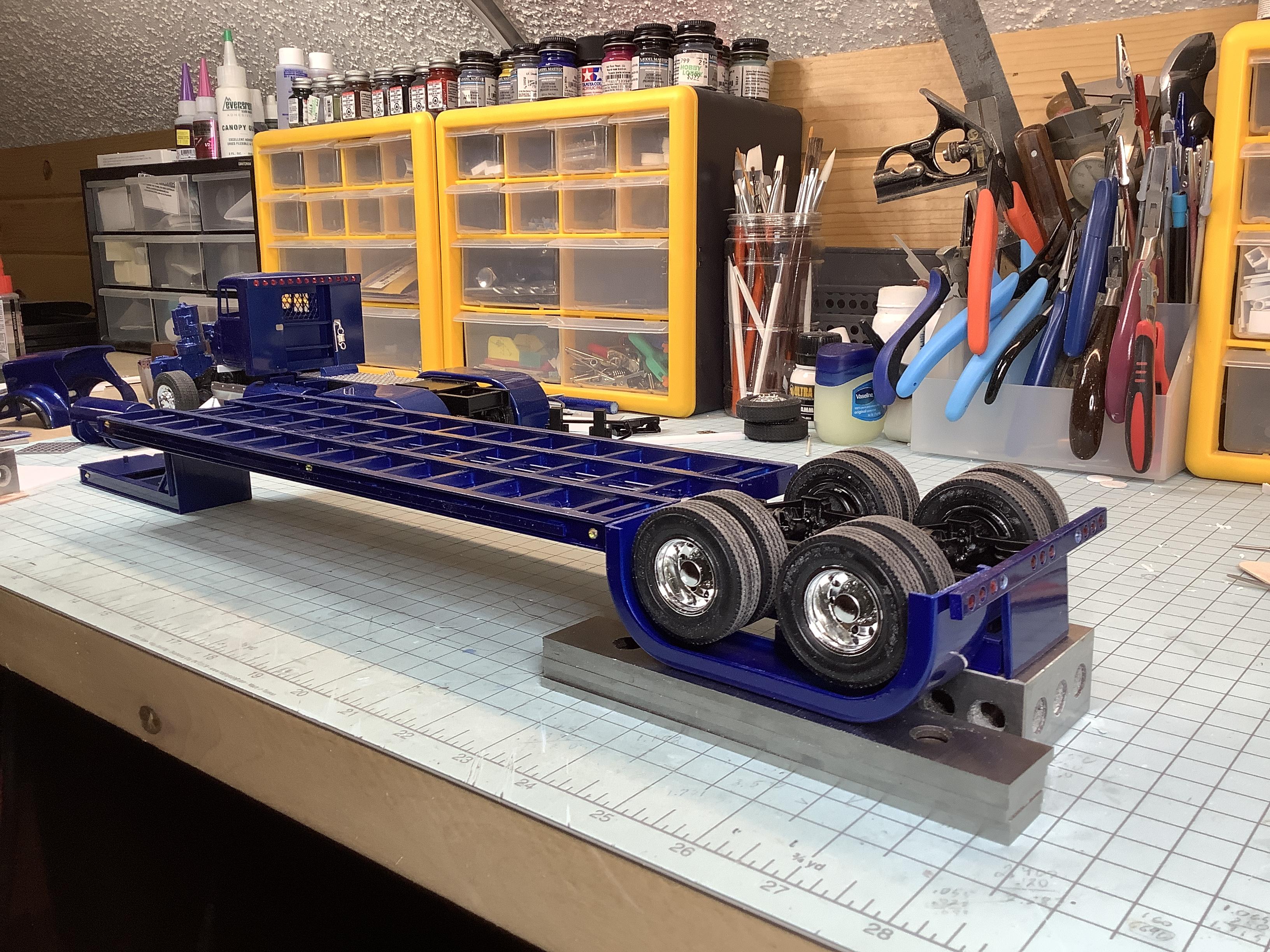

Finally got the rear disk brakes fitted and the track width corrected. Built these fenders up for the KW925 and ended up using different fenders on that build. I think these fenders look good on the Road Boss. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Made up a set of front wheels that would clear the disk brakes. The tires are a little wider than the back. Had to dig thru my boxes of junk until I found a set of outer rings then sanded them down to .200 to narrow them up a bit and fit the tires better. these rims don’t have great detail, but using them tires come right to the edge of the fenders -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Good catch, everything is in mock-up yet, so adjustments can be made. thanks -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you, the one thing bugging me about any sleeper on this truck, is how close the sleeper is to the rear tires and fifth wheel plate. It’s really begging for a short frame stretch. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

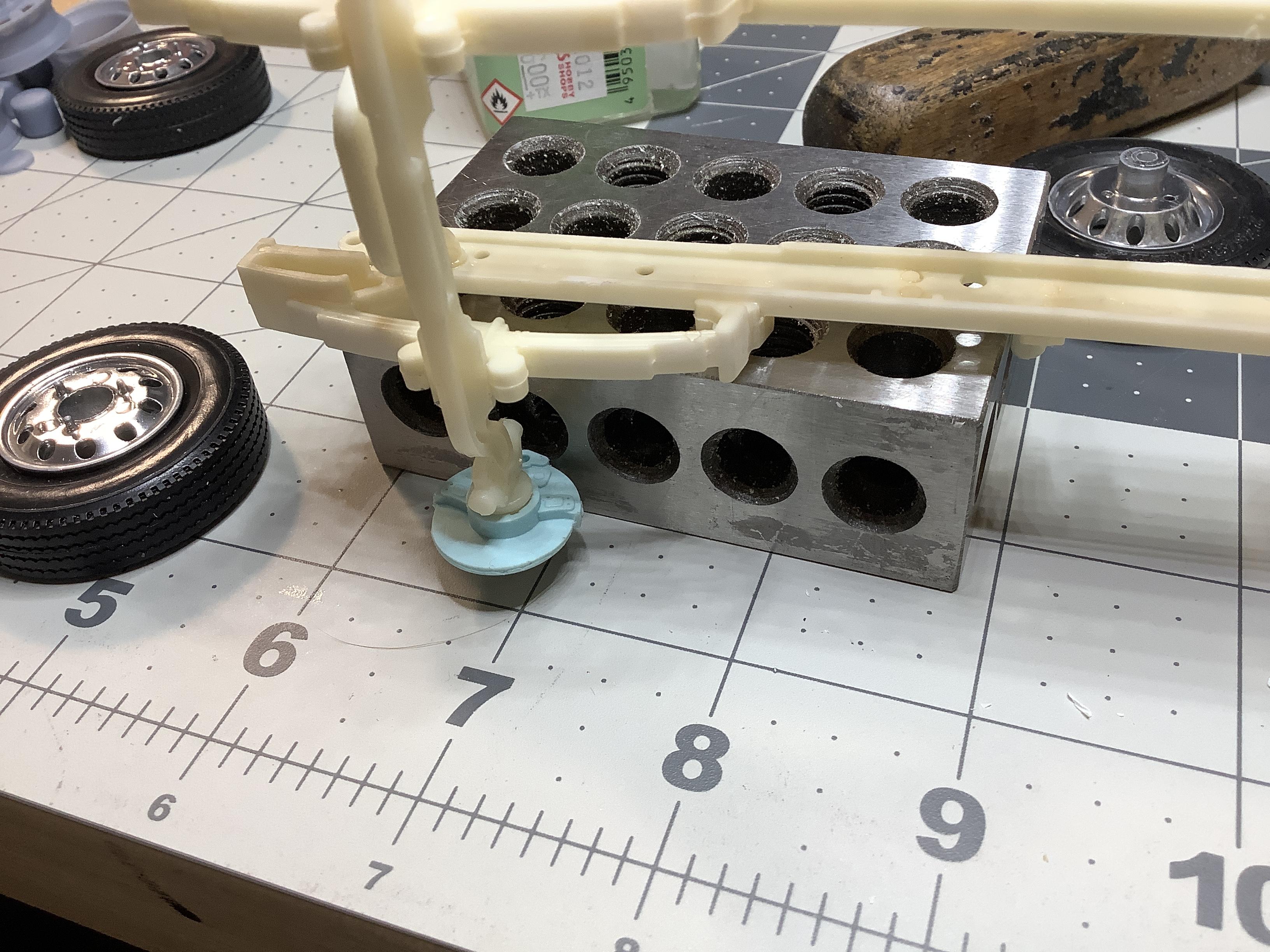

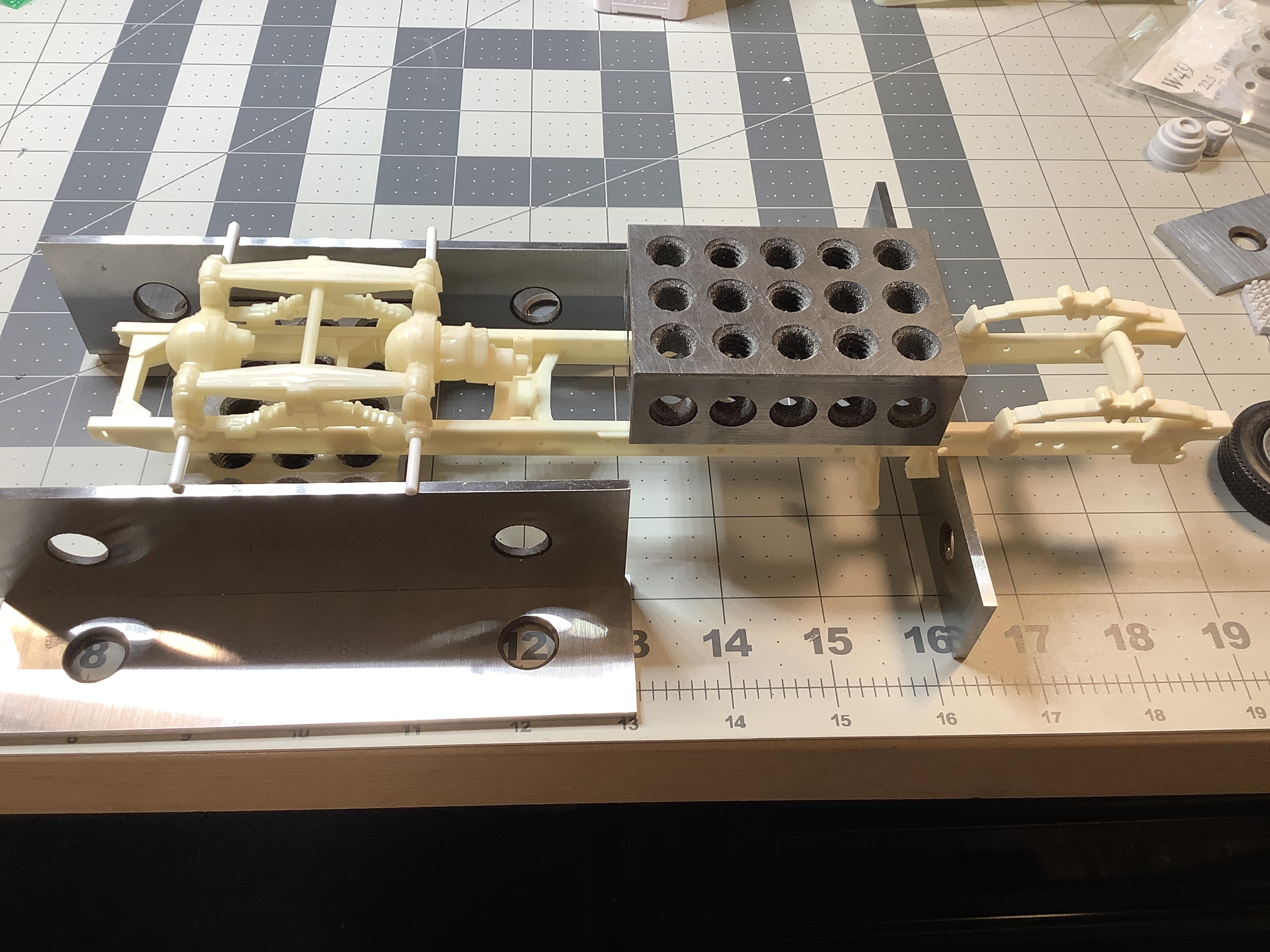

With a couple modifications, looks like the disk brakes will work on the front as well without increasing the front axle track width. I need to find a smaller air chamber for the front by looking online at disk brake equipped trucks. Wanted to test fit all this before committing to this modification. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

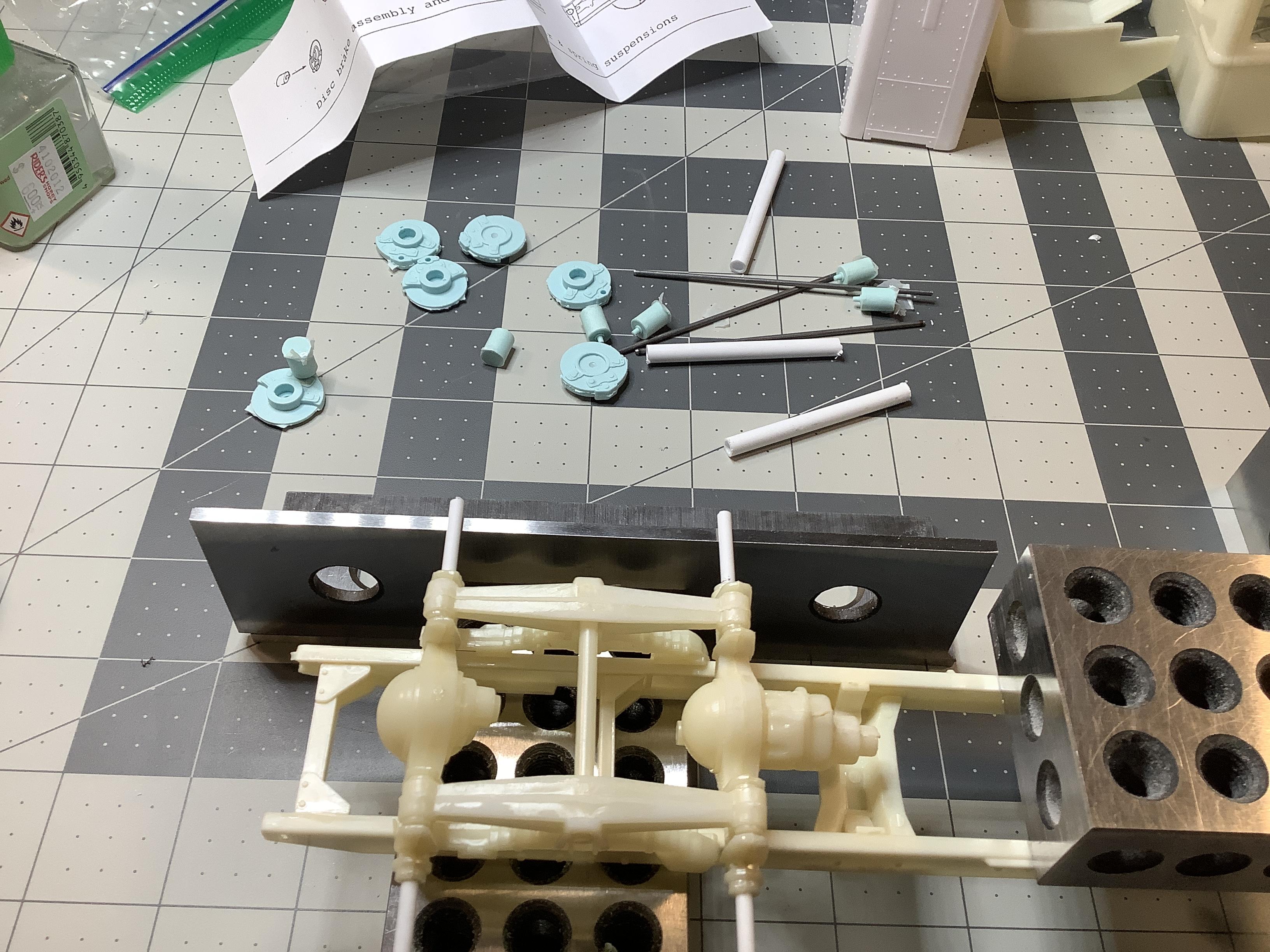

Fitting and doing a mock-up for the disk brakes. The disk brake kit is from Auslowe and they do fit very well, clear all the suspension, fit the axle housing well. this will alter the vision of this build, to more of an updated old truck -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks for the pics Scott, great inspiration, not sure mine will look that good, love the light amount of weathering -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

This is great information guys, complete history lesson. I find it interesting how the trucking industry functions and sharing resources/ materials. In reality I believe this is still the strategy today with many brands. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I have about 6 or 8 truck kits where something went wrong or broke and I just steal parts from those boxes. Kinda makes truck parts inventory🤣😂😆 -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That is actually kinda cool, I had forgot he did that. Jeff suggested that the wedge brakes were not that good. Maybe an opportunity here, more research. -

TIGERCAT SKIDDER 3D PRINTED

Gary Chastain replied to Swamp Dog's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Ok David, is this kit? Or are you scratch building this one? Either way, wow, what a cool build. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

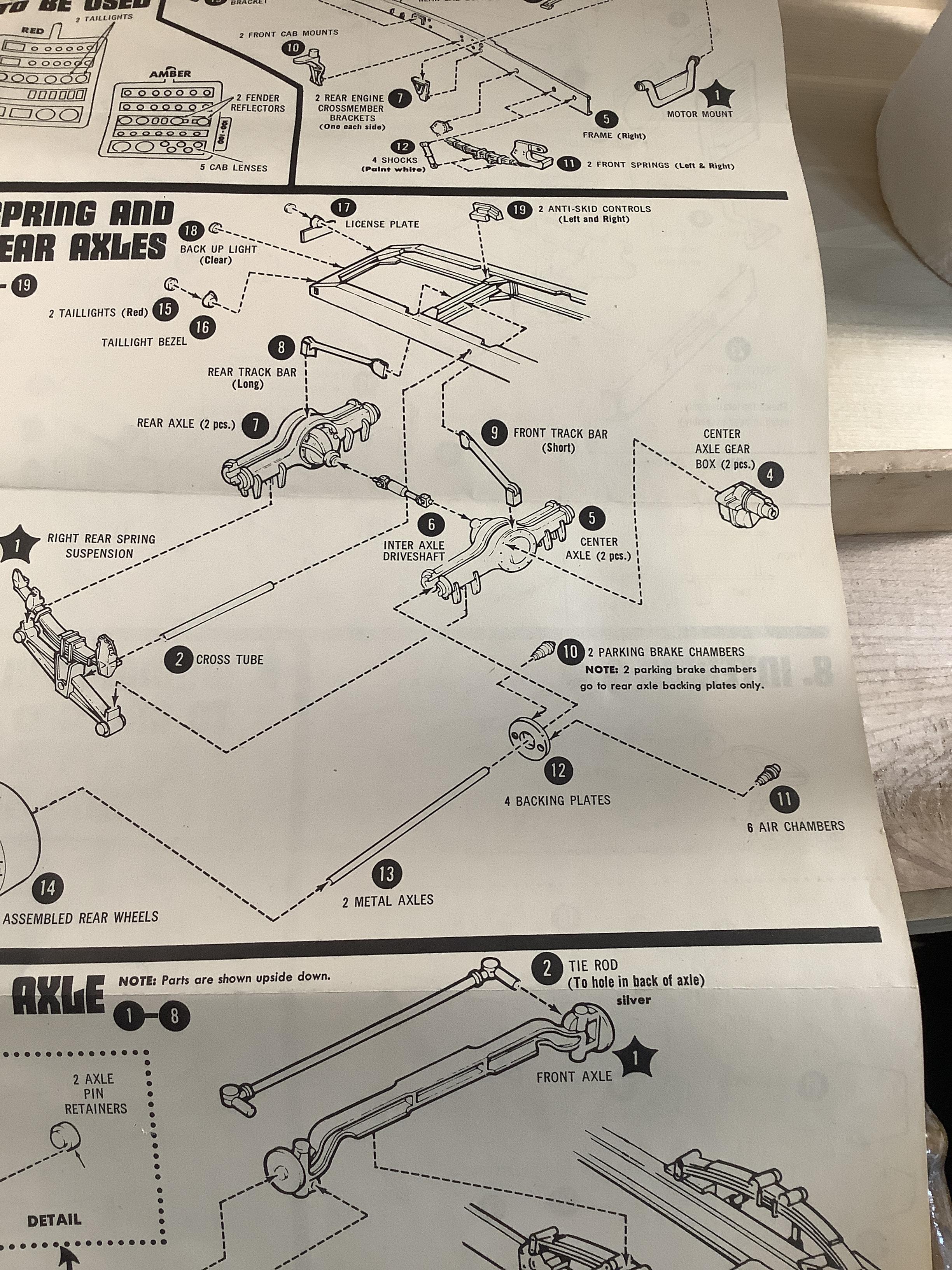

This what you are talking about? I seen parking brake chambers, first thought was then where are the air brakes. We can see where my knowledge stops -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Oh my, this kit has no brakes……anywhere on the rear axles. Non of the air brakes I have will fit. I have a full set of air disk brakes, not sure if anyone has ever upgraded a truck to disk brakes. What the heck…..why not. Kinda changes the scope of the truck but that’s ok, see where this goes or I get to add another bad idea to my growing box of bad ideas. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

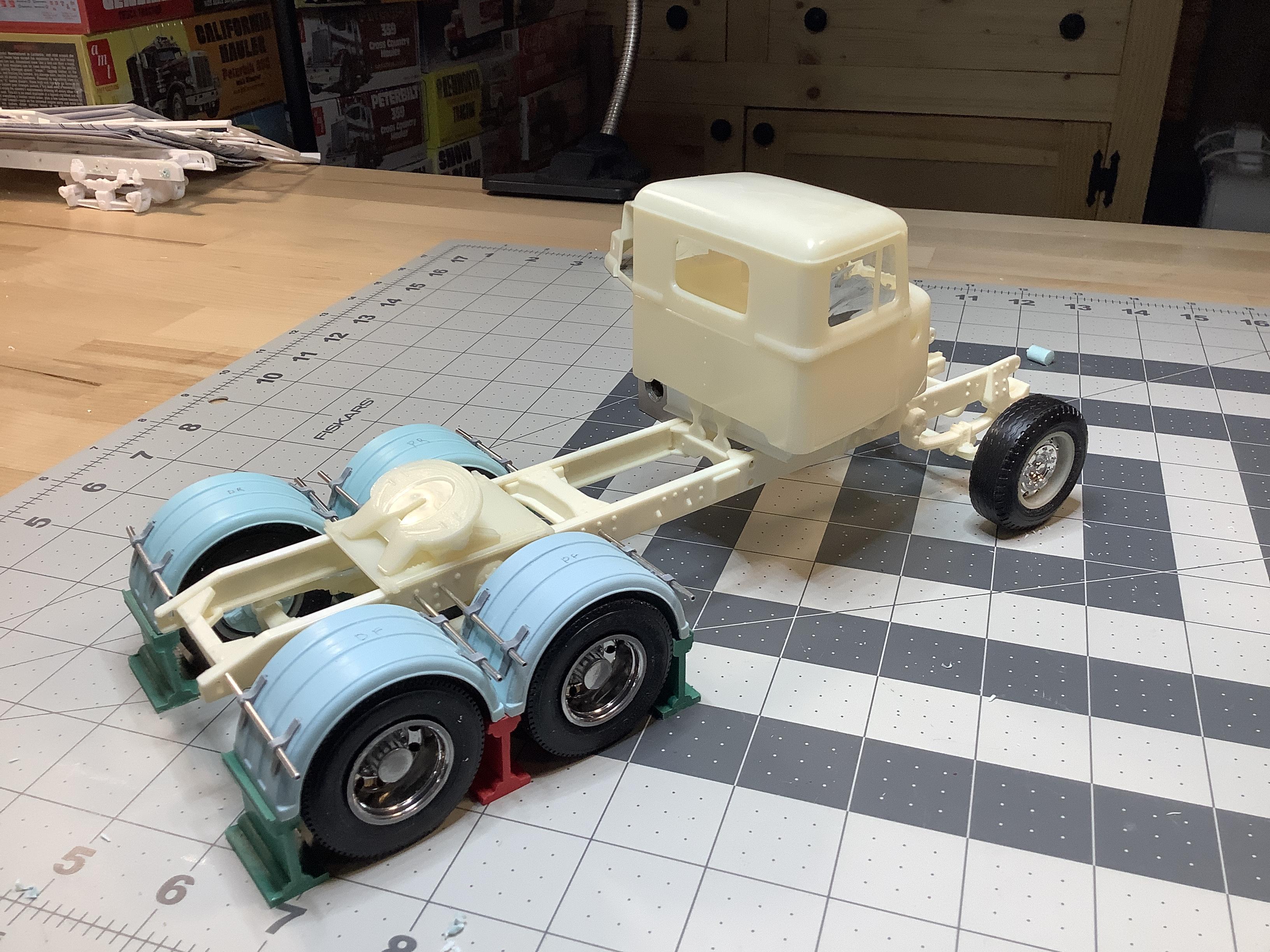

Well I have never gone to this extreme just to align rear axles. This poor old kit needs lotsa love to assemble it, or age has taken its toll on the parts. Now I now why it got stuck back in the box. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Well that answers alot of questions , thanks Brian. And that manufacturing process still lives today, amazing. -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Jurgen -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Well that’s interesting, did not know this. Is this an AMT thing or was this real life of manufactures sharing truck bodies? First cab is from the Autocar, second cab from White Road Boss, third cab from Diamond REO, all exactly the same cab. -

Western Star 4900 FA plow truck

Gary Chastain replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

First, get to feeling better, hope it is nothing serious. Second, I think you are posting pictures from the real truck buddy, your not fooling us. 😂🤭🤣🫣 -

White Road Boss

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Just a nice road truck with some simple updates -

This is a really old kit that I have had for many years. Bottom right hand corner says I gave 25 bucks for the kit. I started this build several years ago and it ended up back in the box, not sure why other than….squirrel. I promised myself that this winter I would finish up three started kits, so this is number one. The instructions have turned very yellow and crunchy. I may take photos of the instructions in case they self destruct. The plastic seems to have yellowed as well or maybe it was molded in this color. Like to build this as a road truck with maybe a couple custom goodies, I have these custom wheels so they are going on, changing the sleeper. See how carried away I get.