-

Posts

2,503 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Gary Chastain

-

Brockway 459

Gary Chastain replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Great progress, love the color combination -

Resin big truck cabs

Gary Chastain replied to junkyardjeff's topic in General Automotive Talk (Trucks and Cars)

https://www.sourkrautsmodeltrucks.net/modeltrucks?offset=201 https://jimmyflintstonestudios.com/Car-Bodys_c_30-21.html https://globalscalemodeltrucks.com/ try these guys out -

Farm Floater Truck 1/24th scale

Gary Chastain replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Impressive building right there. -

1970 Ford C 600

Gary Chastain replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Just keeps getting better, well done. -

Farm Floater Truck 1/24th scale

Gary Chastain replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Glad to see this back in progress. -

New project Chevrolet dump

Gary Chastain replied to Repstock's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I drove one of those trucks with a grain bed and a rear spring tag axle, got stuck everywhere. It had the 366 big block with 5 spd and 2 speed rear axle. -

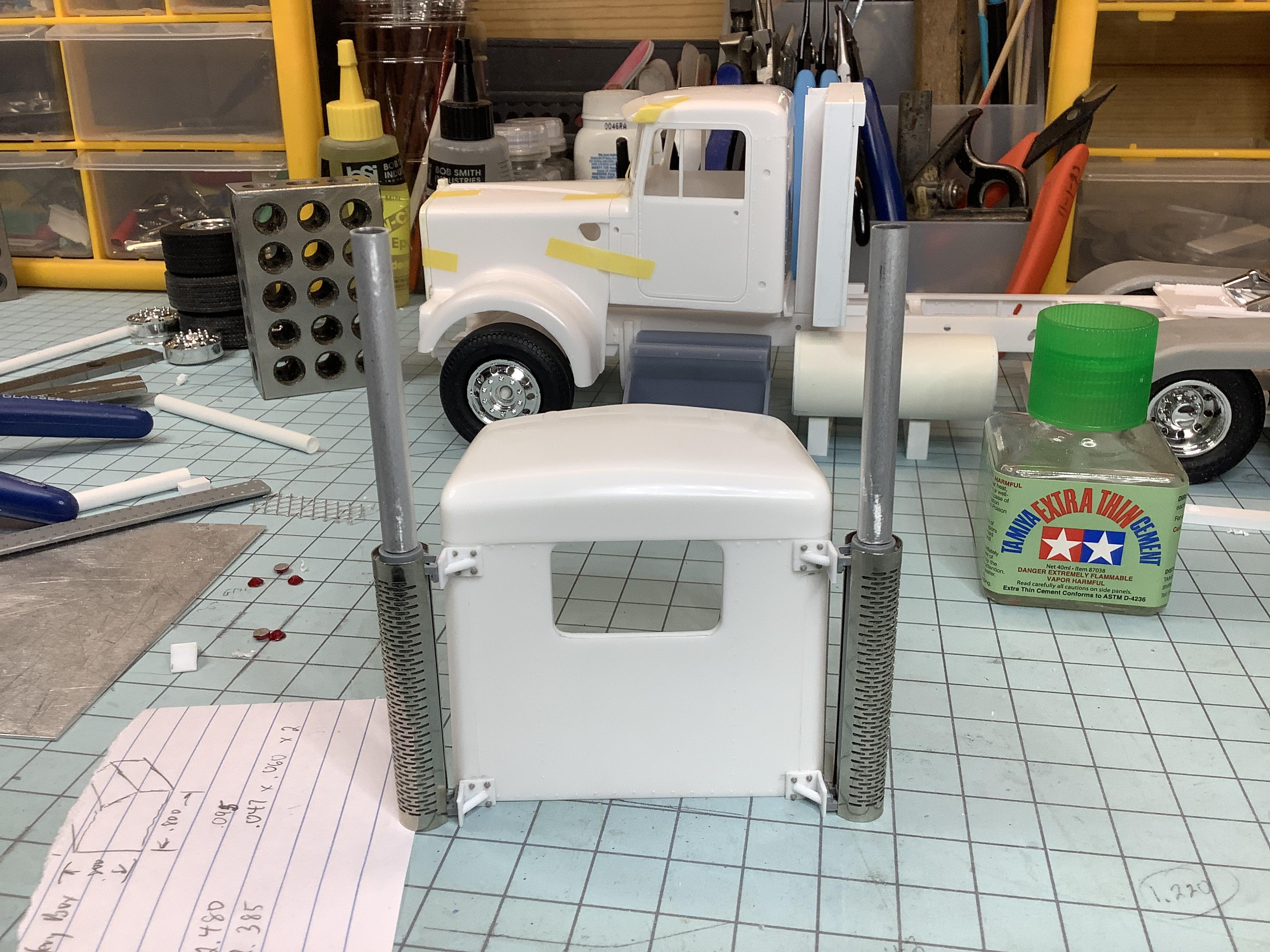

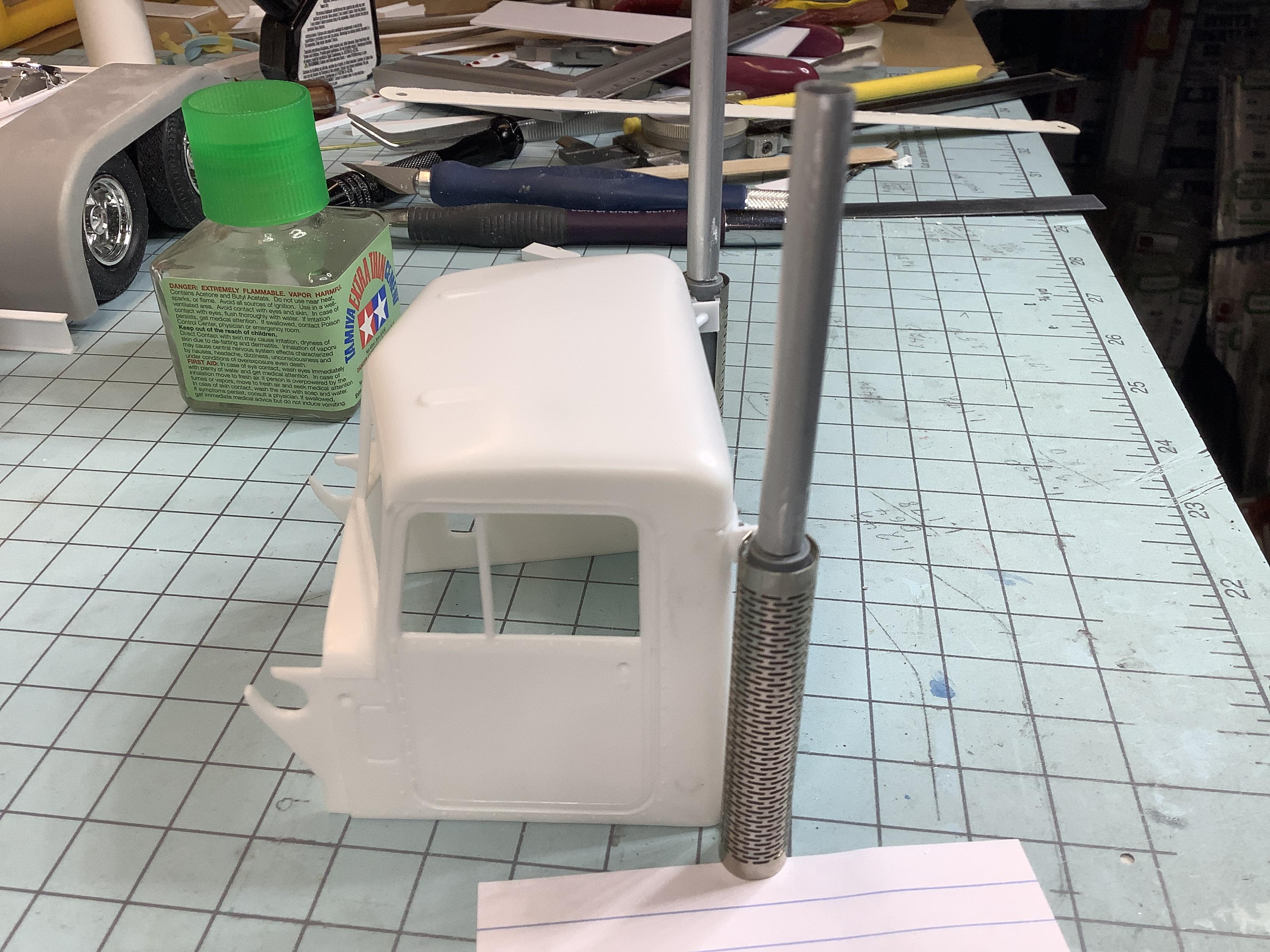

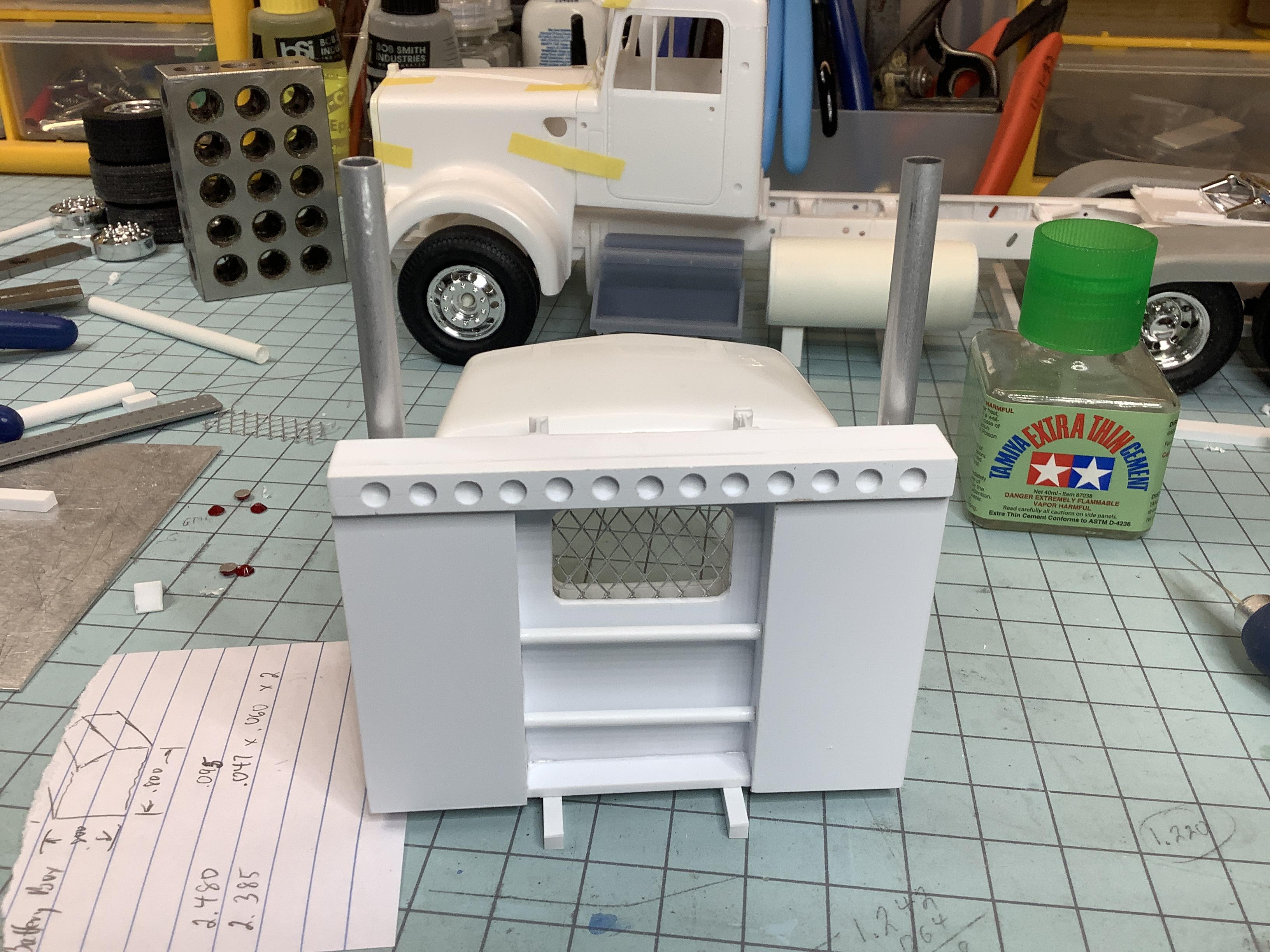

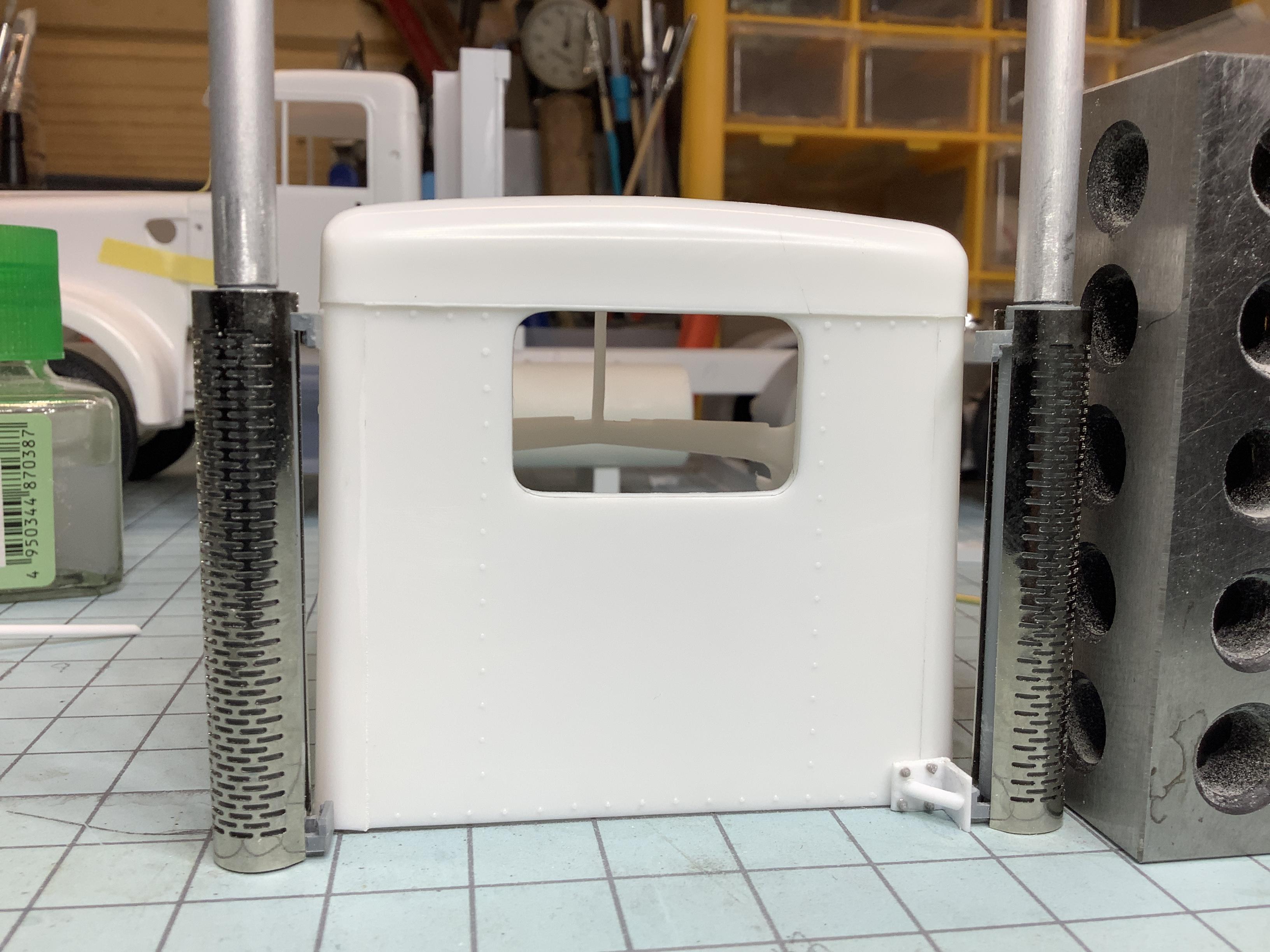

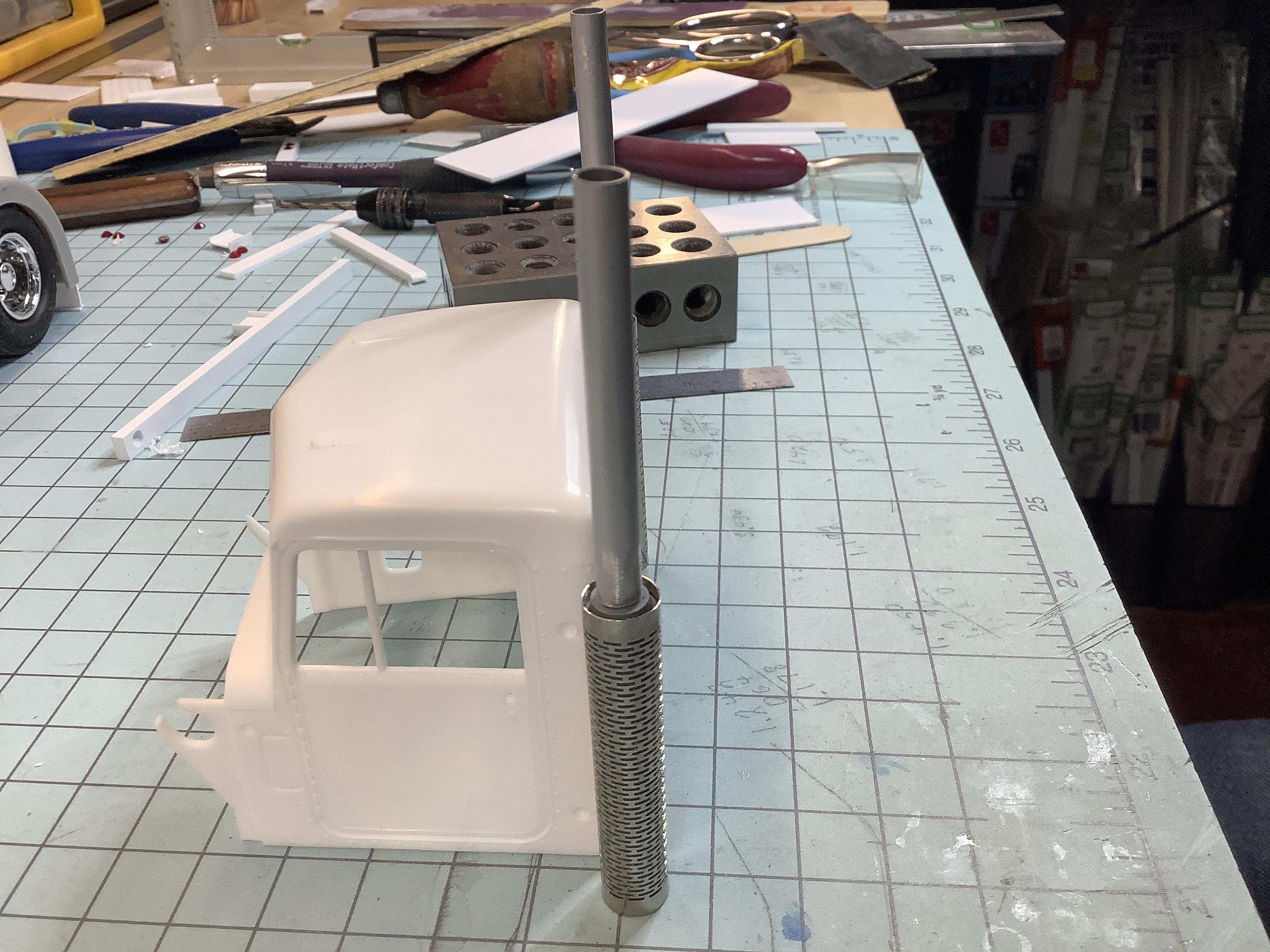

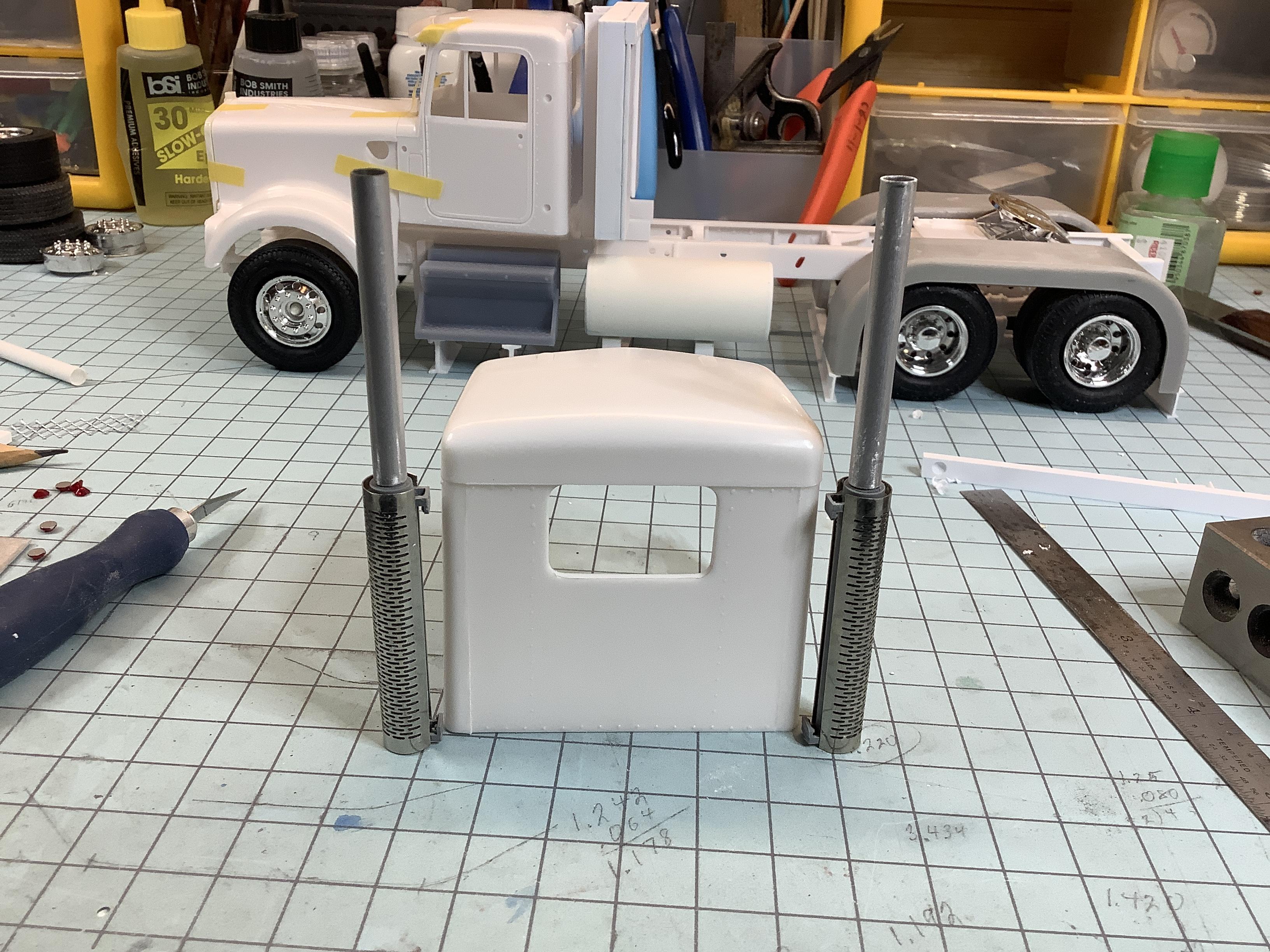

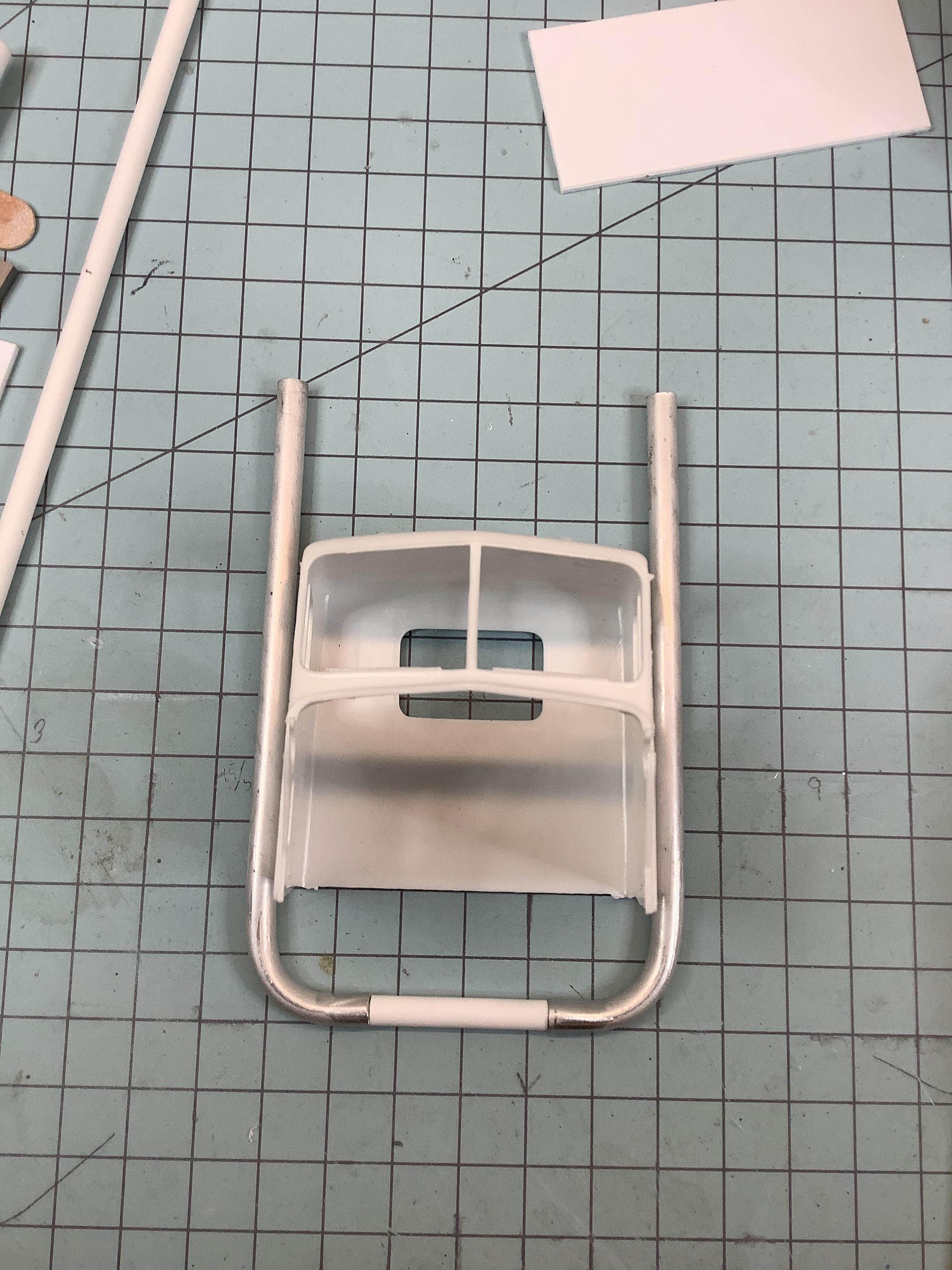

Did a quick mock-up to find a new problem to solve. I purchased these after market battery boxes from Truck builders model forum and they have good detail, so I want to use them but as you can see the exhaust mounting holes are not in the correct place, so need to plug those four holes and make exhaust mounts off the back of the cab. Will switch to Auslowe exhaust, which was the original plan. I can still move the fuel tanks back a bit for exhaust clearance

-

Brockway 459

Gary Chastain replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Now that’s a cool paint job, love it. -

Brockway 459

Gary Chastain replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Great subject matter, will be watching. -

De-snapping

Gary Chastain replied to Rockford's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Wow Steve, huge improvement, well done. -

1970 Ford C 600

Gary Chastain replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Those details will pay off big time, well done. -

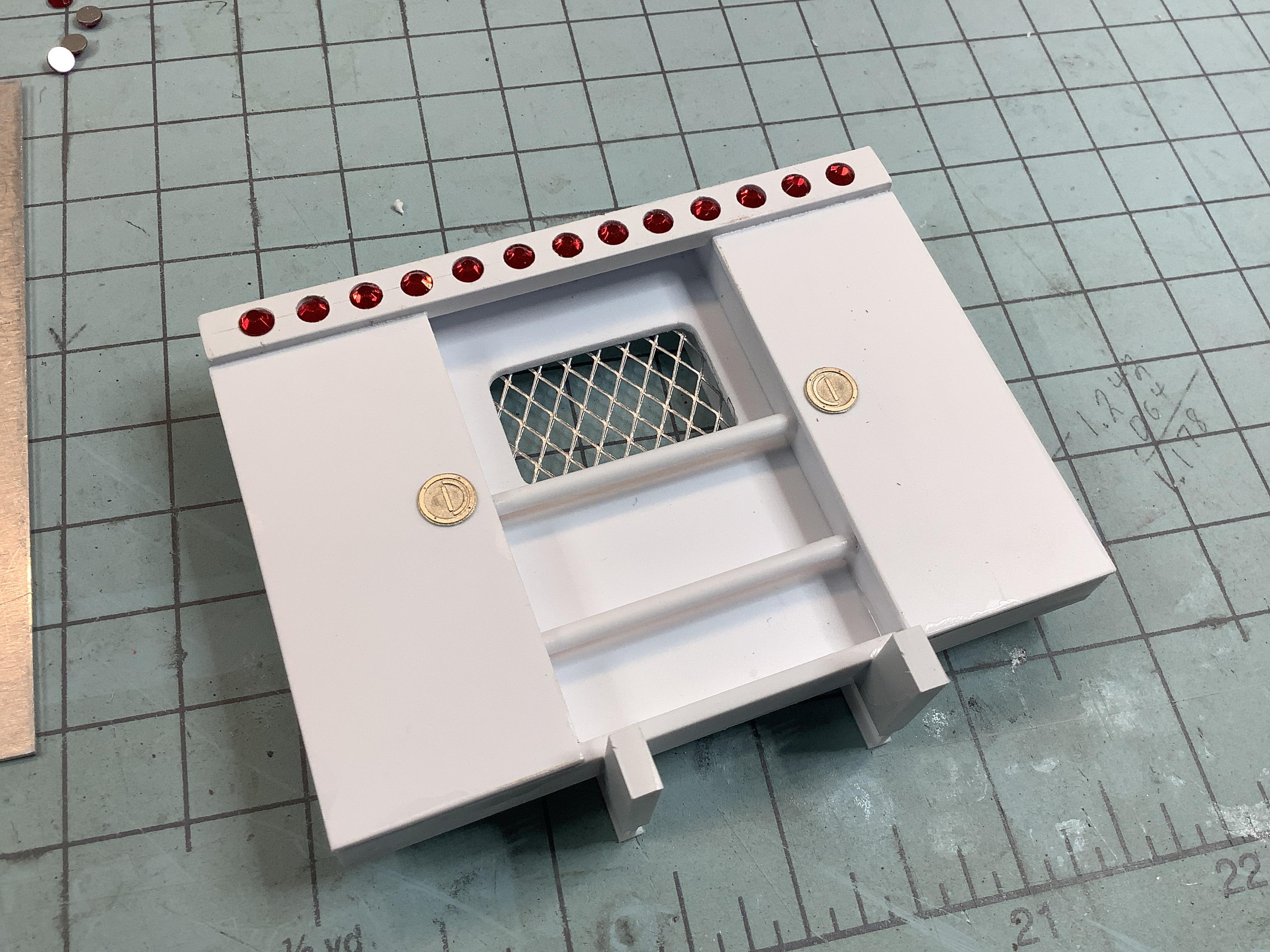

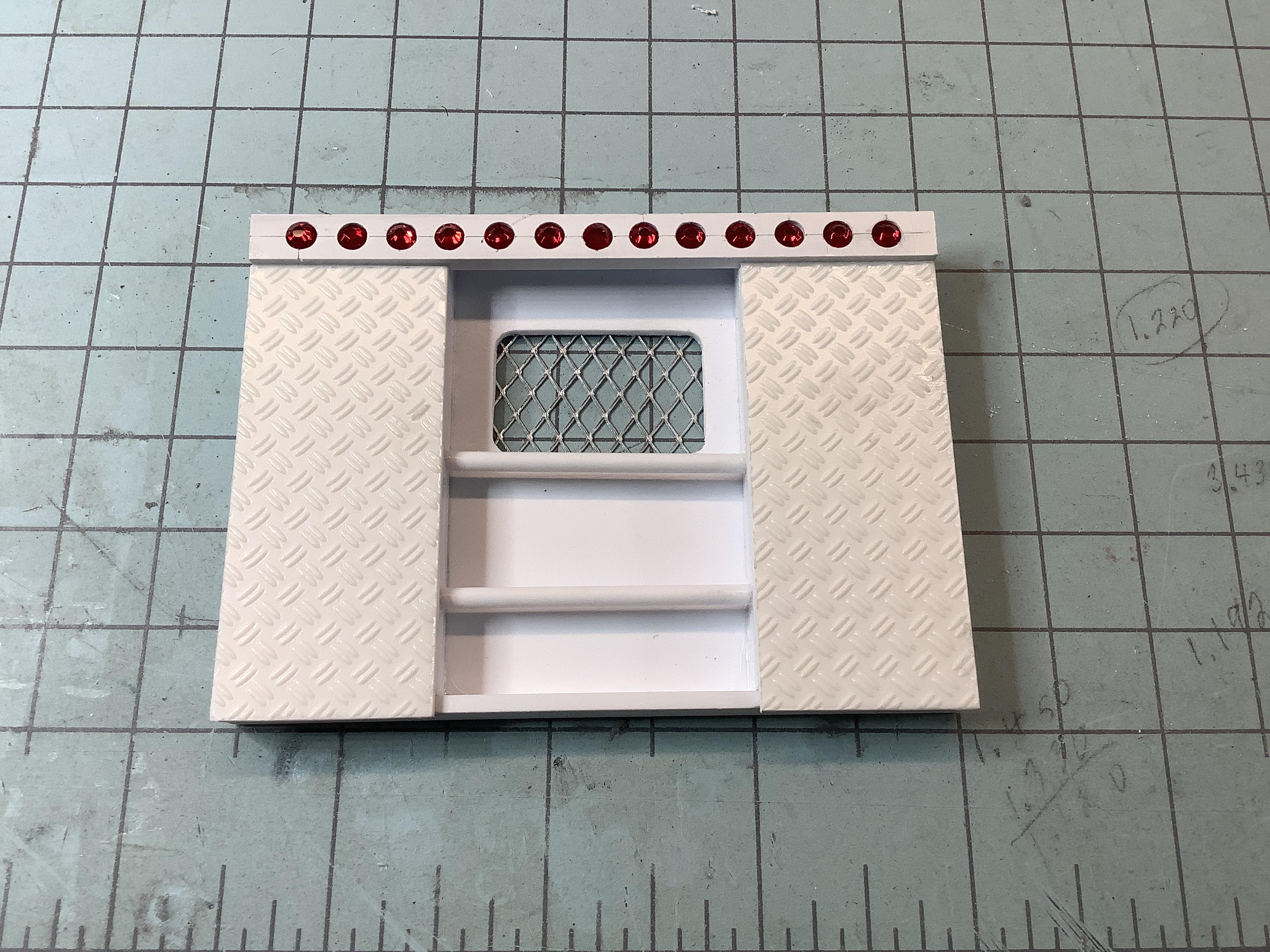

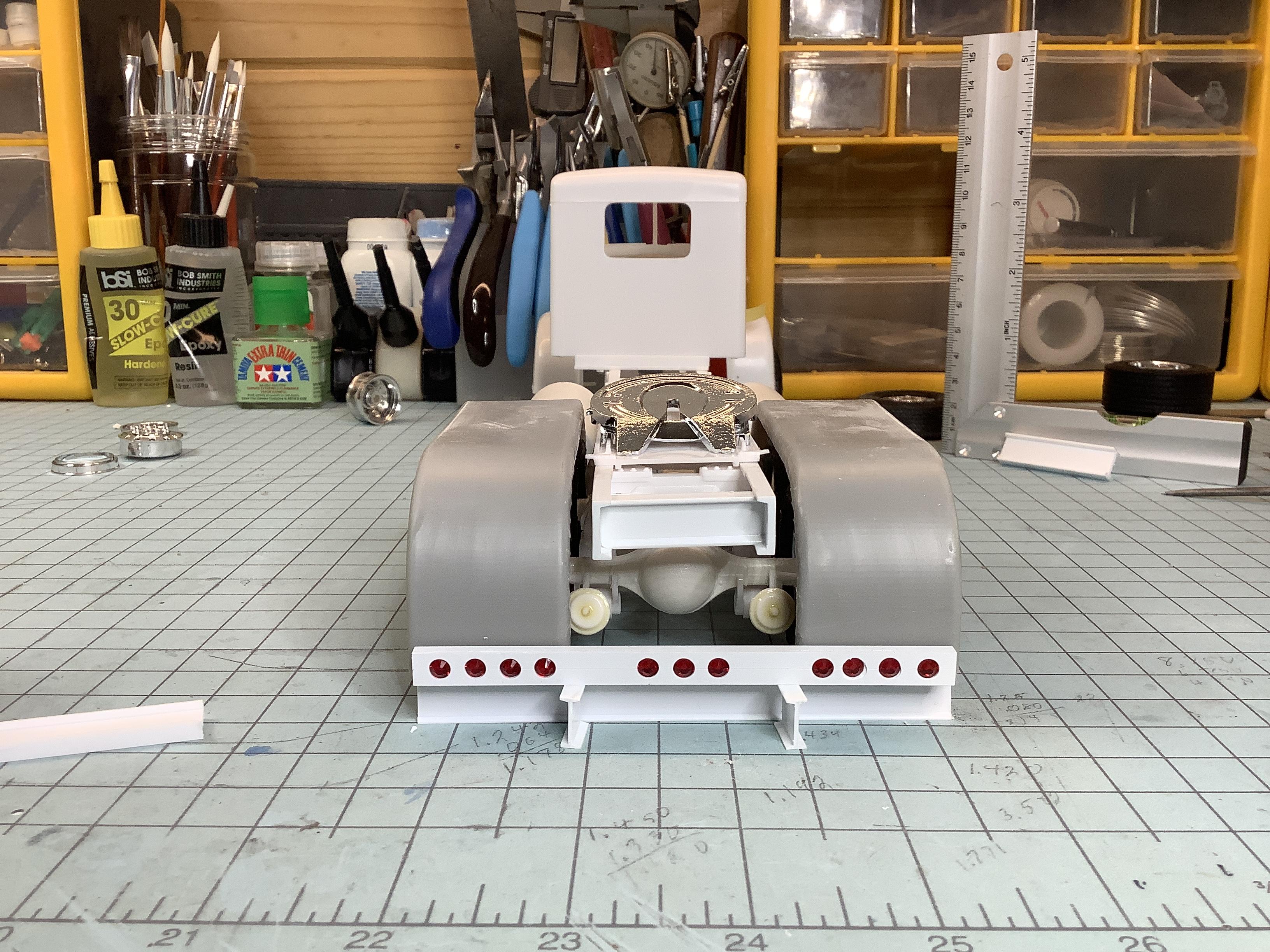

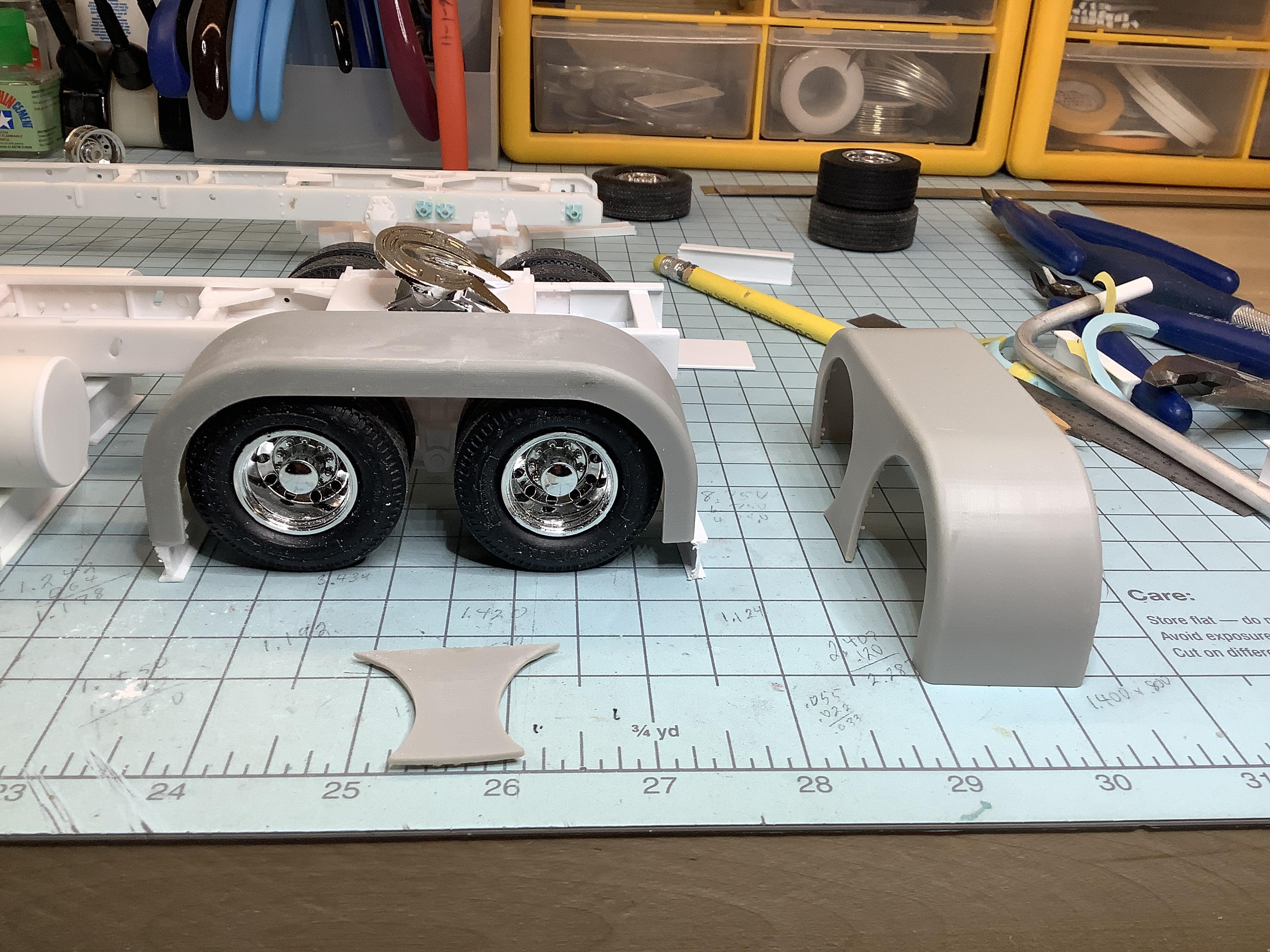

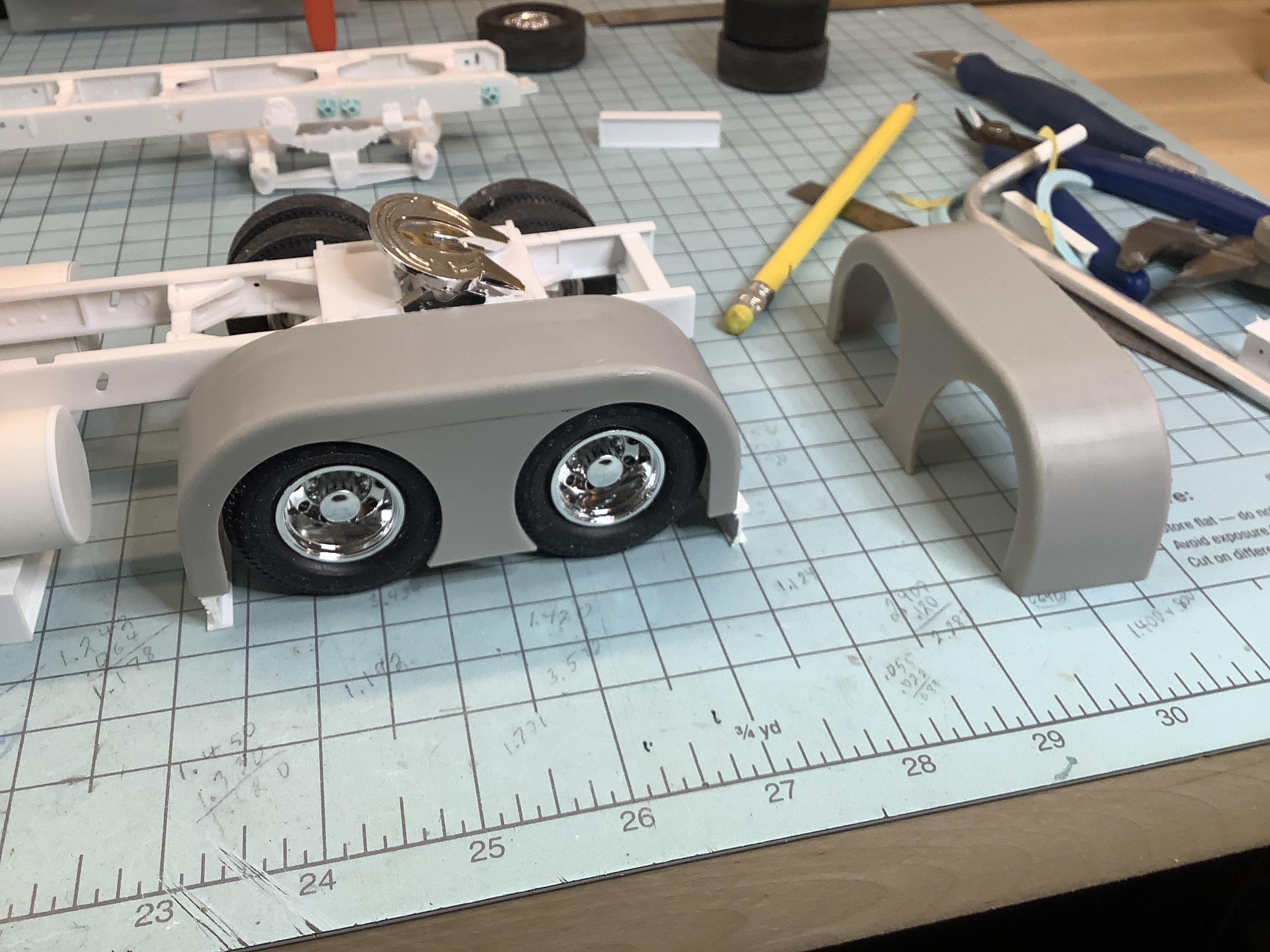

Finally got the bench done and all organized (well mostly, I keep seeing more to organize) so getting some bench time. Couple changes to this build and keeping with the mild custom vision. First I decided to use the stretched frame that I built first. Second is the rear fenders. I purchased a set of 3d printed fenders but they are warped and seem to not be able to straighten them, so I modified them for this truck by removing the center piece that was warped. You can see the warpage on the uncut fender. I think this will work.