-

Posts

2,503 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Gary Chastain

-

I have been debating over my next build and decided I like the Watkins kit the best. Plan: sleeper, updated Cummins engine with intercooler, 5&4 with twin stick shifters, maybe oversized turbo, custom wheels, air ride rear suspension, rear fenders, 12 scale inch stretch, better exhaust , all subject to change. Medium dark blue with a little sparkle, TS-50 Tamiya with lotsa chrome. Mockup below

-

Restorod Autocar

Gary Chastain replied to Gary Chastain's topic in Model Trucks: Big Rigs and Heavy Equipment

Thanks Steve, appreciate the inputs. -

Restorod Autocar

Gary Chastain replied to Gary Chastain's topic in Model Trucks: Big Rigs and Heavy Equipment

Thanks Chris -

Restorod Autocar

Gary Chastain replied to Gary Chastain's topic in Model Trucks: Big Rigs and Heavy Equipment

Thanks Brian, and thanks for sending me advice on this one. -

Restorod Autocar

Gary Chastain replied to Gary Chastain's topic in Model Trucks: Big Rigs and Heavy Equipment

Thanks Landon -

Restorod Autocar

Gary Chastain replied to Gary Chastain's topic in Model Trucks: Big Rigs and Heavy Equipment

Thanks guys, for the kind words -

Peterbilt 359 (full custom)

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Agree, good spot for ideas -

Peterbilt 359 (full custom)

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

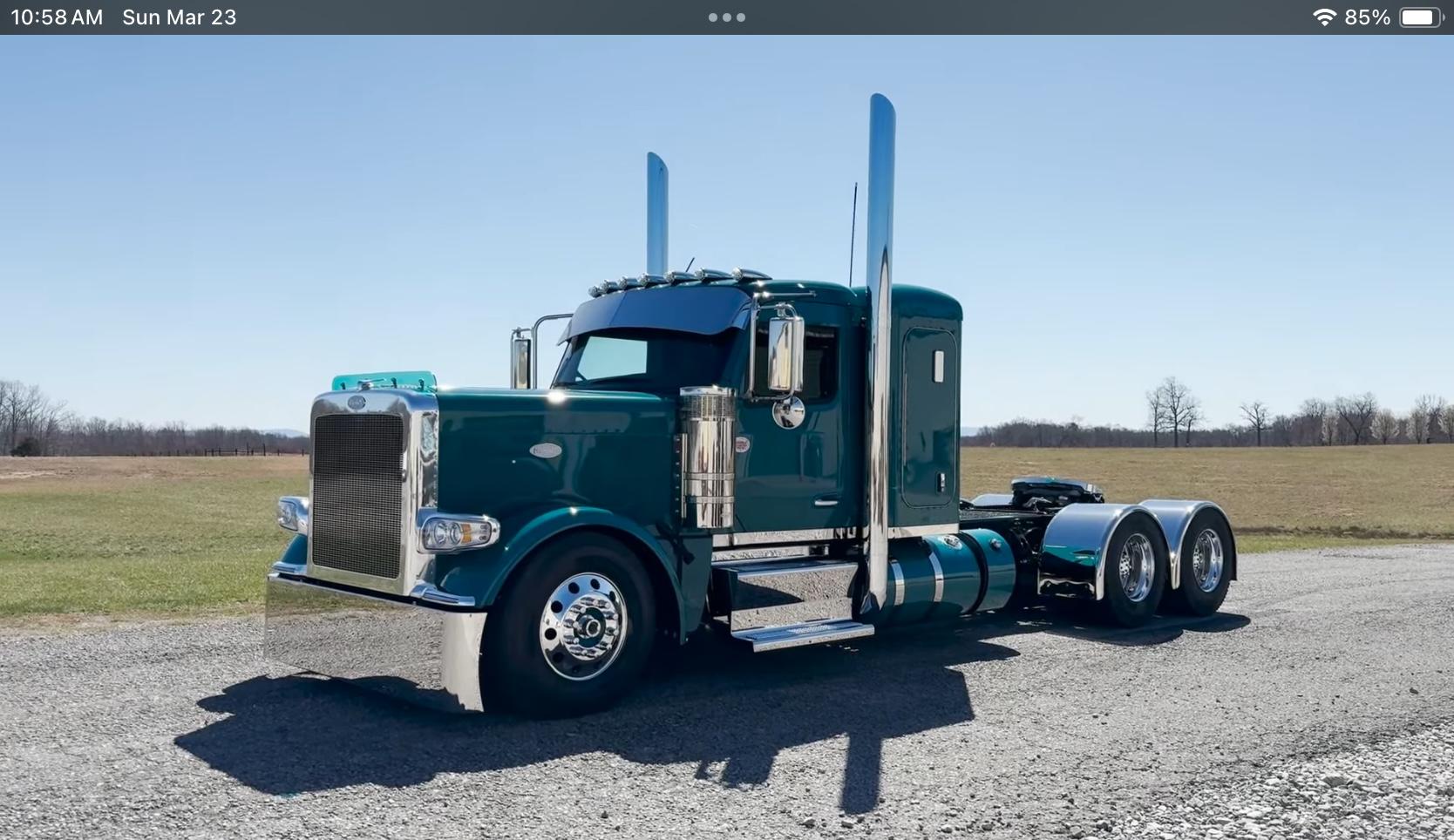

Doing some homework on my next build, I really like this mild custom from a company called Semi Causal -

- 40 replies

-

- 12

-

-

-

Mack Superliner

Gary Chastain replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice addition, helps add some realism to a cool build. -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

This will be last post in WIP for this truck. Next post for the Restorod Autocar will be under glass. Just put the last coat of chrome paint on the bumper and antennas, will attach and post, tomorrow or the next day. -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Steve, a lot of ideas I stole from you😄from your builds -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Jurgen, means a lot coming from a builder with your skills. -

I buy from Paul all the time, great guy/business to buy from. Little curious what the tariff impacts will be.

-

Exciting news, I still have a few of those lots rat holed.

-

New Upload Limits

Gary Chastain replied to Dave Ambrose's topic in Forum News and Questions (formerly: How To Use This Board)

Ok, I thought I was having problems on my end, not allowed to load pictures. I lost the paper clip (add picture). -

Mack Superliner

Gary Chastain replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Sweet, I’ll be watching your trailer build. -

1974 Peterbilt 352

Gary Chastain replied to DRIPTROIT 71's topic in Model Trucks: Big Rigs and Heavy Equipment

Wow, that is a sharp truck, well done -

Fruehauf Flatbed

Gary Chastain replied to DRIPTROIT 71's topic in Model Trucks: Big Rigs and Heavy Equipment

Looks great, like the wood deck. -

Peterbilt 289

Gary Chastain replied to Rbray47's topic in Model Trucks: Big Rigs and Heavy Equipment

Very cool build. -

Johnny Cash 1972 C60 Chevrolet

Gary Chastain replied to DRIPTROIT 71's topic in Model Trucks: Big Rigs and Heavy Equipment

This build sure tells a great story, well done.