-

Posts

707 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Texas_3D_Customs

-

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

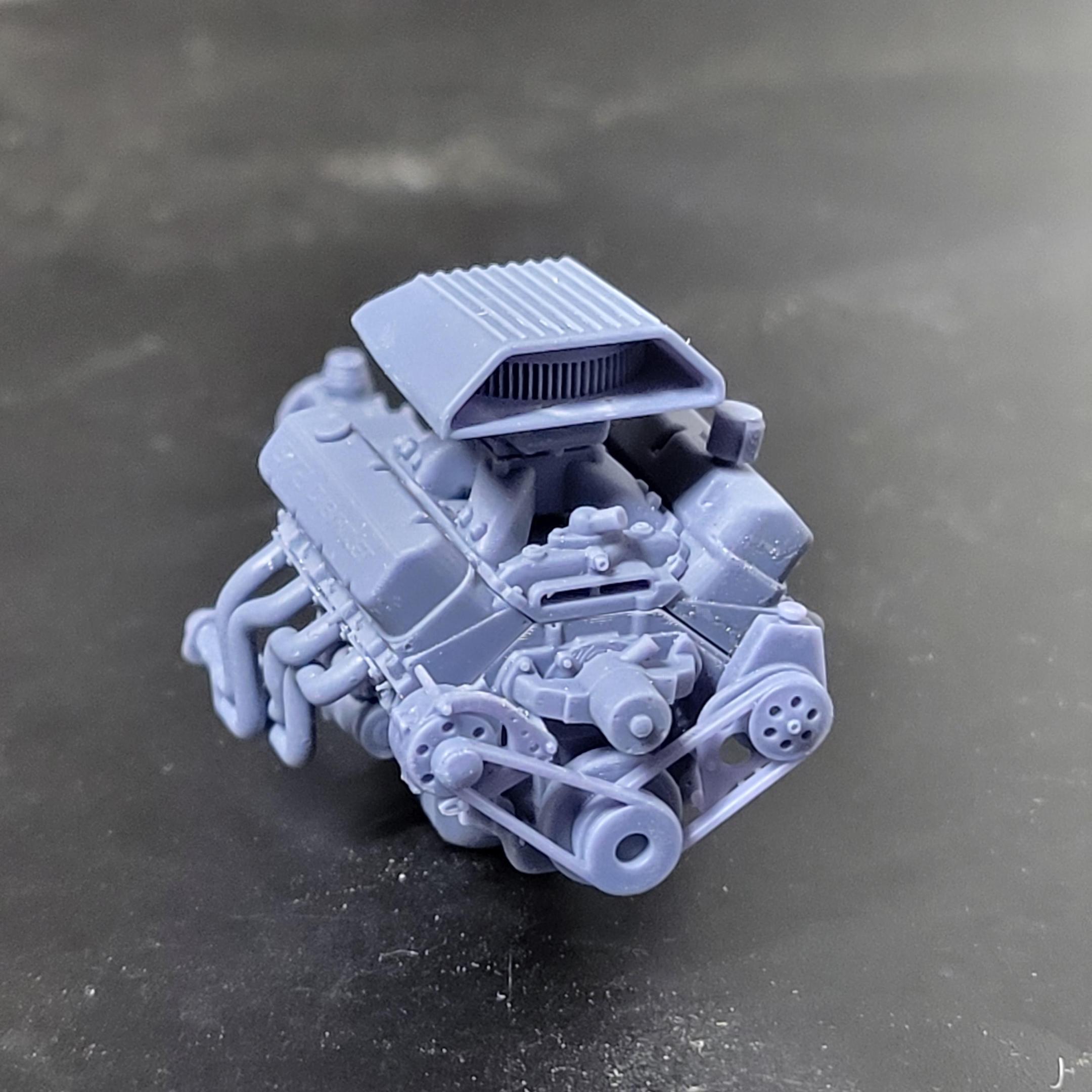

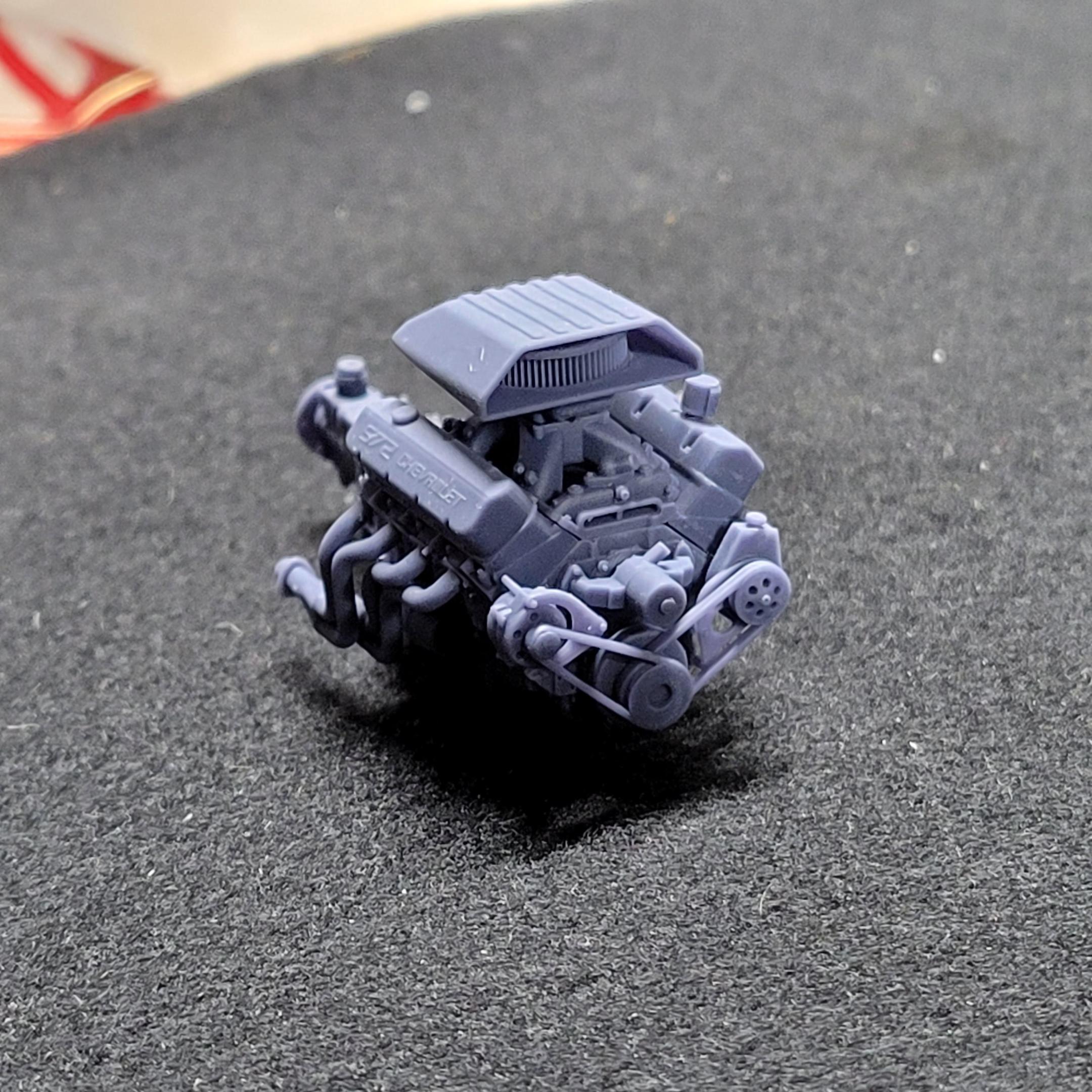

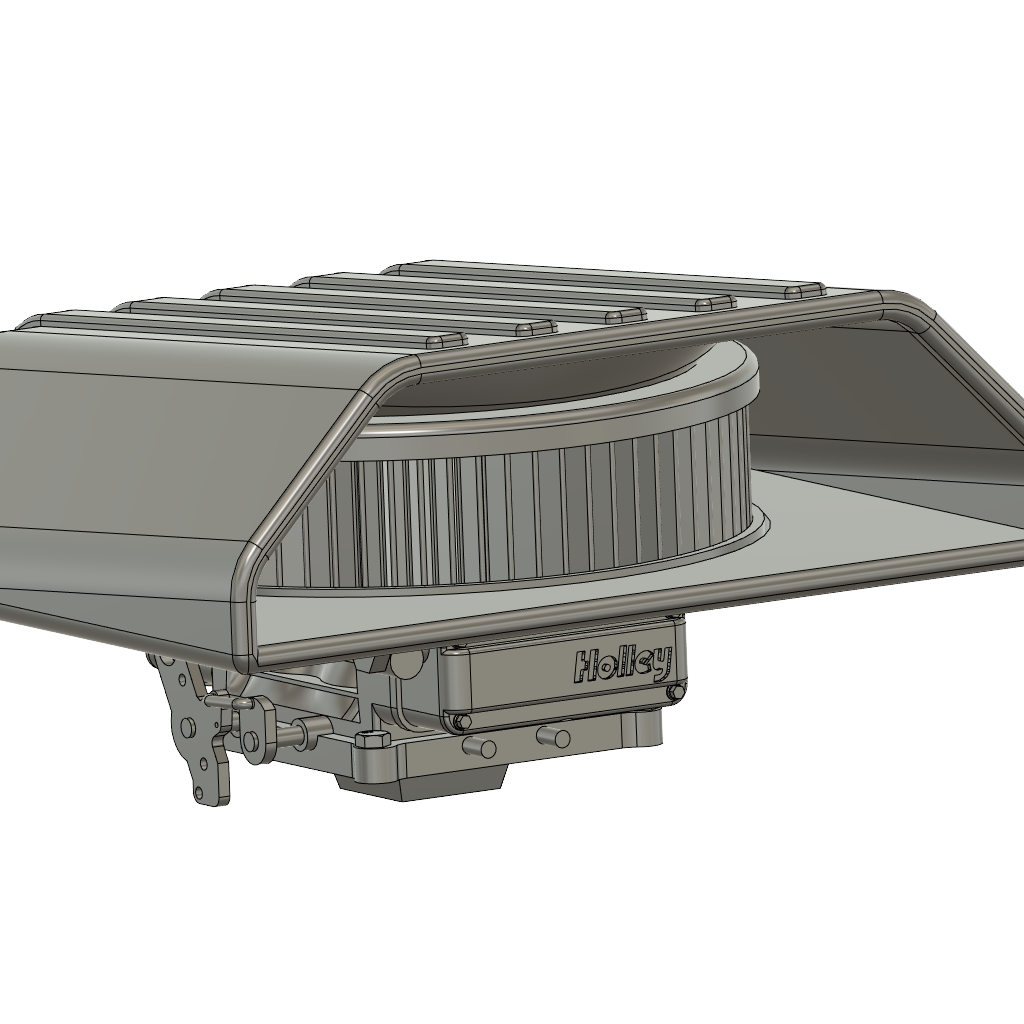

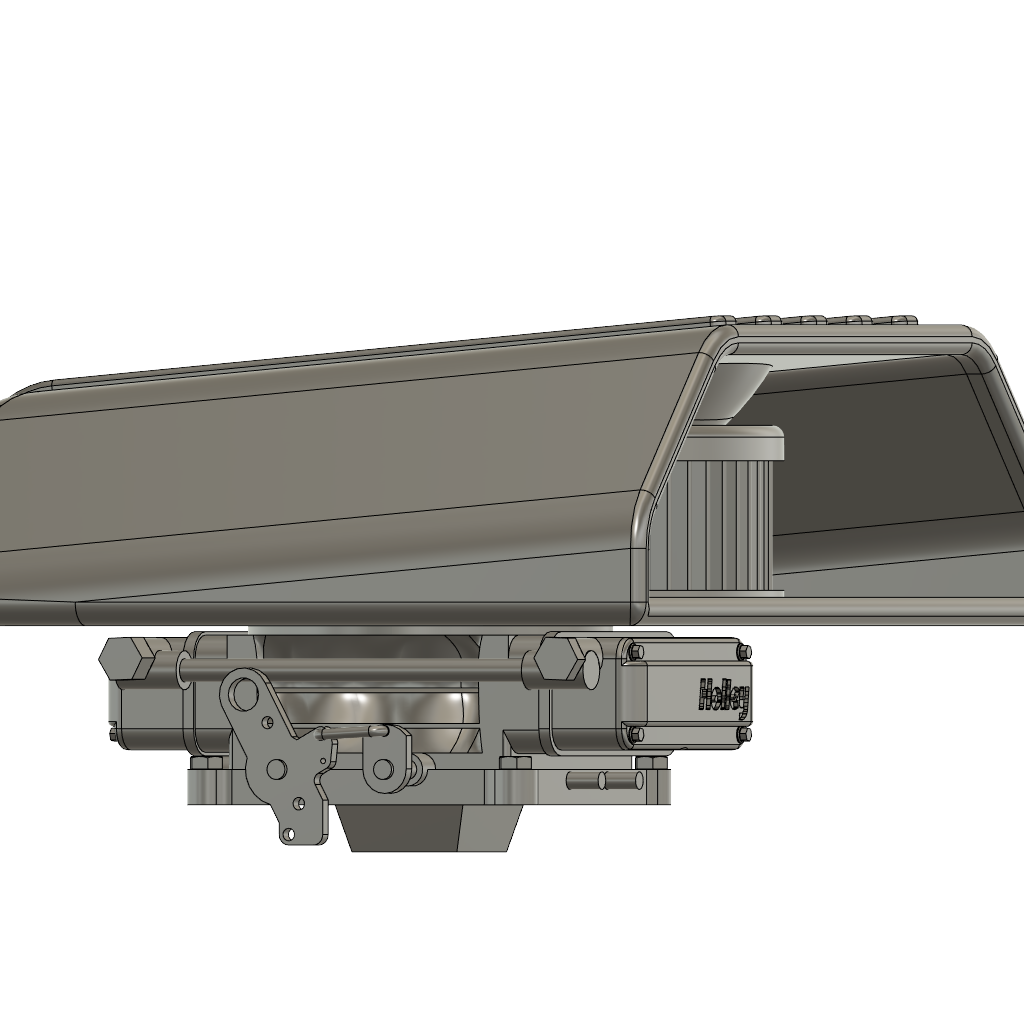

This is the version I will be listing it is two pieces the filter and the scoop are two separate pieces and while I know the filter is not properly shaped and you'll understand when you see the pictures of the parts it makes it fit all together well -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

I just designed it after you asked -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

-

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

-

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

So there are a couple issues there One that's extremely thin which extremely thin and resin prints usually means extremely hard to make without falling apart The other problem is there's an air filter inside there and people notoriously love to complain at me about the air filters inside my scoop for my 572 so you try to print an air filter that you can insert into the scoop or make the scoop where just kind of sits on top on a very thin ledge on the carburetor but the air filter can still fit through It's not really ideal making things in sheet metal for a car is a lot different than 3D printing. Now I could probably make something that resembles that that was two pieces but I'm not going to sell it with an engine If I do it it'll be a separate item and generally speaking separate items It's kind of a lose lose situation either I charge a lot to kind of make up for making these little fiddly parts for one off orders or I spent a lot of time making something that gets me no profit and I know it's not all about profit but this is not my side hustle that's just for fun anymore. That is one of the bad things about quitting my job and doing this as my income now. -

what is the best way to remove....

Texas_3D_Customs replied to oldr-n-drt's topic in Car Aftermarket / Resin / 3D Printed

Best way to remove supports is directly after washing it removing supports before the cure process will keep them a little more pliable so if you remove them just after washing a break off nice and clean -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

Sorry I didn't mention it but it's released -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

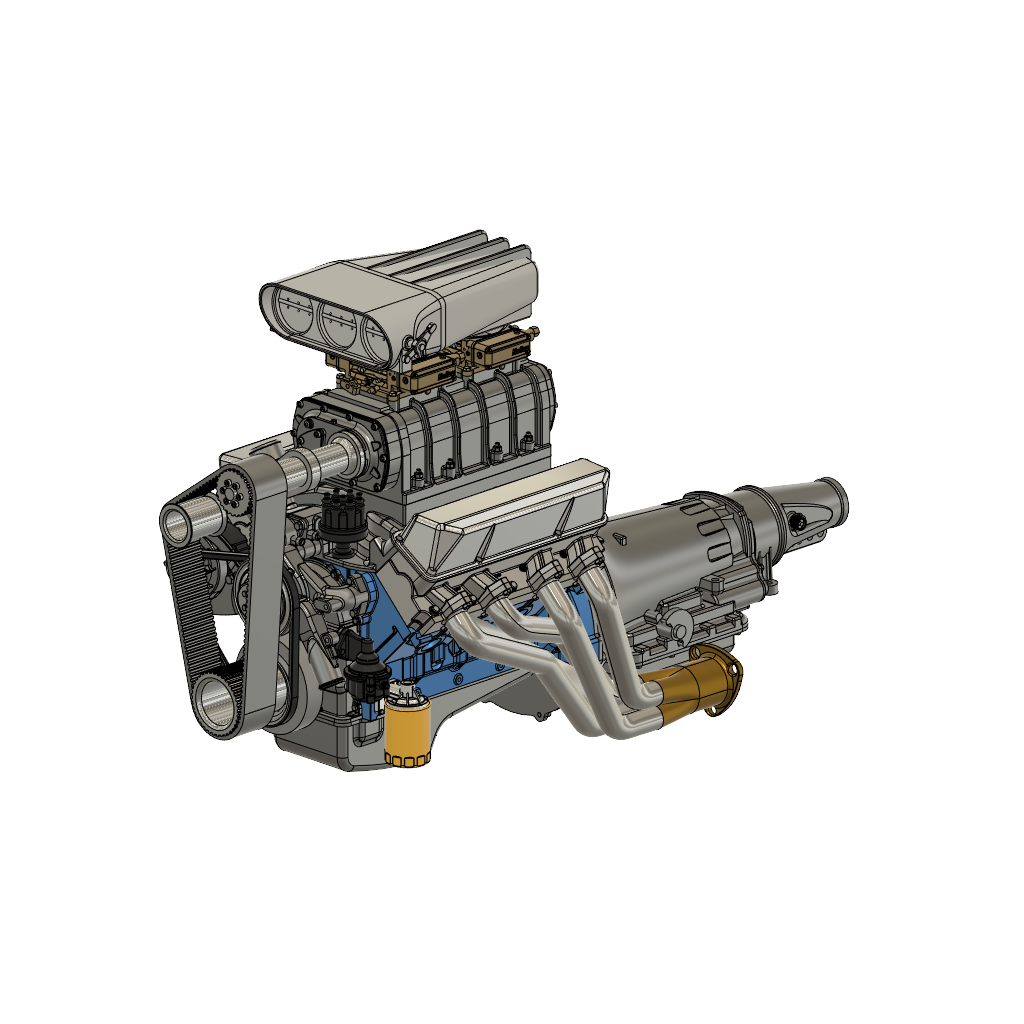

So was going through my FE engine doing a favor for someone and I realized I never fully completed my Blown Setup, I mean it was close really close, so I finished it off and am printing a small batch of both variants now. Transmission is selectable I am talking about the hats more than anything on the variation. -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

Sorry I don't see that in my future offerings. -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

Motivational speech is not one of my products I offer -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

The surfboard can be found at https://tx3dcustoms.com/products/modern-style-surfboard -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

-

Reliable Suppliers

Texas_3D_Customs replied to Joe Lange's topic in Car Aftermarket / Resin / 3D Printed

I disagree with casting takes longer, it's just different. You can cast a mold with 50 carbs in it in minutes, printing takes hours per batch, but you have to make molds for casting, but printing requires screen time to make the models, the time spent modeling makes a big difference in the outcome. I am not against casting so don't take it that way, it's just different. -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

-

AMC V8 engines

Texas_3D_Customs replied to Sportabout's topic in Car Aftermarket / Resin / 3D Printed

No it's just a place to buy files, but IMHO that model is a joke -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

The bigger issue with the surfboards is that you can go find a surfboard that's probably around the right size and a cheap toy and get it cheaper than I'm going to make it for I'm not dumb even though it's a popular item to put say on a beetle or a bus or maybe the back of a truck people aren't going to want to pay me to resin print one when they can go buy a cheap plastic one from some toy cheaper not going to make it most likely -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

Oh and they won't sell I'm not naive and I already know that -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

I'm going to make it scale 6 ft long because that's already more than I want to do It's going to take 7 hours to make them Not a lot of resin but 7 hours because of how big they are and it'll be your job to clean up the bottom where the supports are -

Odds & Ends you'd Like to See

Texas_3D_Customs replied to Calb56's topic in Car Aftermarket / Resin / 3D Printed

Fine I will make some surfboards, how long is a real one 1:1 typically -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

Well I did it based on a completely different reason it was all based on availability and partially it is the correct year we all know that the movie car was a 67 GT500 GT350 GT500 really the differences are very minimal and I'm replacing all those anyway. I think you're saying I made the right choice but What year are the kids were made in inadvertently may had something with it but really it was about finding me easiest to acquire. For example the F1 truck that has that pikes peak look old smoking It's great kit but it's impossible to find and sales suffer for that reason I did not design that one so that's how it came to be but on the other hand really what would be the other option other than the foose truck. -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

I'll be honest I bought the AMT to do it because it's one of those kids that's really easy to find it's the right ear and it already had the right tail lights. Same thing with a bug I bought the Revell because you can find it anywhere I know they're not the best kits but I really like making things for kits that are easy to get a hold of. -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

But you could just go out and buy that AMT kit and mount it to whatever chest you want It's really not that bad of a kit -

Texas 3D Customs

Texas_3D_Customs replied to Erik Smith's topic in Car Aftermarket / Resin / 3D Printed

I have no idea I don't have one I bought the most rarely available kit to do this from and that's why I did it and the year was right