-

Posts

5,117 -

Joined

-

Last visited

Previous Fields

-

Scale I Build

1/25

Profile Information

-

Full Name

Christian Pamp

Recent Profile Visitors

19,256 profile views

Junkman's Achievements

MCM Ohana (6/6)

-

Yes, all these components would require being retooled, we know that. Round2 has surprised us with much more elaborate re-toolings in the recent past.

-

1/12 Lancia Fulvia teaser from Italeri?

Junkman replied to The Creative Explorer's topic in Car Kit News & Reviews

Plus, the European sales tax would be deduced if the kit is exported. -

Apparently the Trophy Series custom parts have not found their way back into the Fairlane kit.

-

Revell GMC Van "Stranger things"

Junkman replied to Luc Janssens's topic in Truck Kit News & Reviews

Don't worry, it'll be on sale early in the new year. The ST Blazer, Camaro, and VW Bus kits are already marked down everywhere and still don't sell. I don't think this series is doing too well for Revell. -

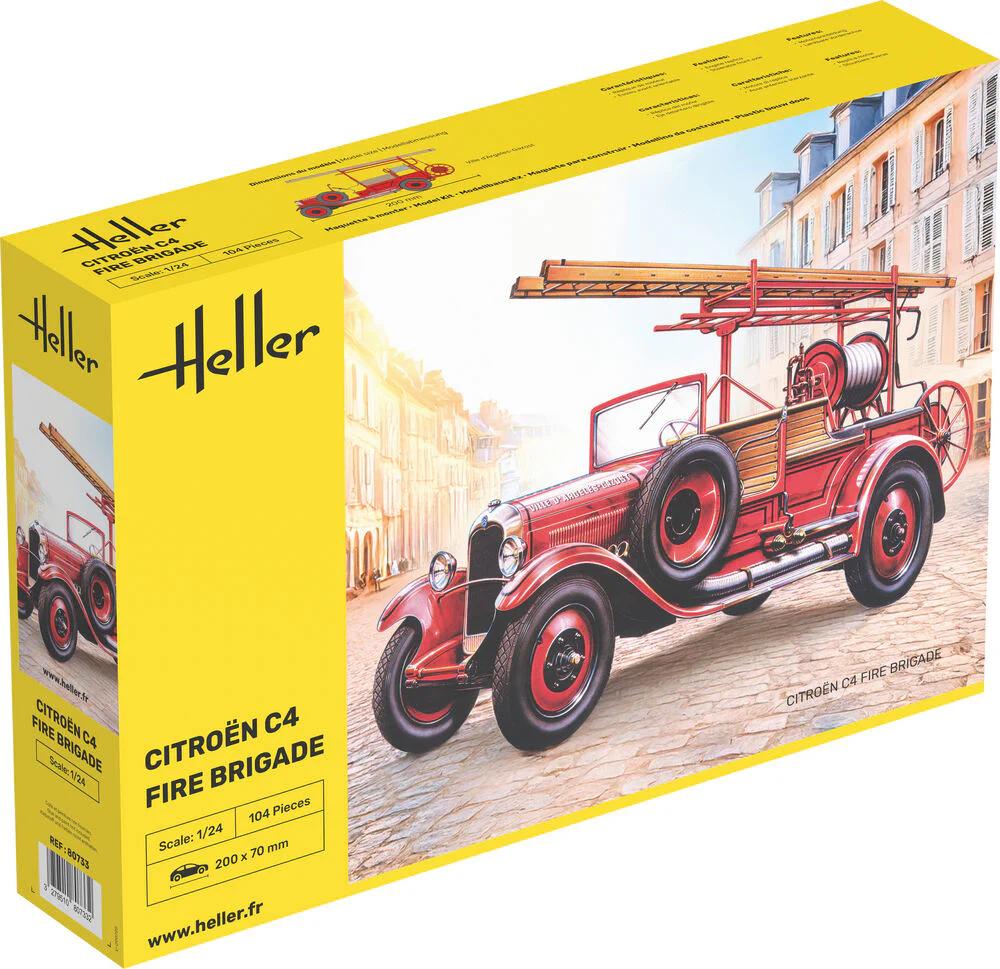

Heller. Or shall I say Hell-Err? So I just took delivery of this kit: I'm not sure whether this has been mentioned before (nothing showed up on my search), but the kit has some serious and not so serious issues. The serious one is that the inner structure of the loading box sidewalls is very prominently repeating itself as sink marks on the outside surfaces. This doesn't show very well on my photos (sorry, can't do any better), but it means you either have to to do a lot of putty work, and I do mean a lot, or cover them with thin styrene sheet. The other one is less severe, but still annoying. The body parts tree that's not moulded in white, is moulded semi translucent: Please take this into consideration when you decide to buy the kit. You have been warned. I'm not responsible.

- 1 reply

-

- 1

-

-

I'm really happy to have it back. I ruined one forty odd years ago and originals have become pricey. I also always wanted to make a tow truck out of one, so I'll buy two.

-

-

I know the kits are not related. But they would be a nice continuation once sitting next to each other built on the shelf. That's what I meant.

-

The El Jefe/Big 6 Wheeler is a nice continuation of the MPC Rolling Thunder.

-

If unit sales are so critical to profitability, one has to wonder why the American companies aren't keener on increasing export sales. American model kits have been increasingly hard to come by over the past two decades, now it became almost impossible to obtain any. Their increasing navel gazing at the domestic market is costing them sales through their noses. American kits were widely available in the 1970s/80s, my generation grew up with them, and we would more than welcome the reissues of the kits we ruined back then. Talk about round 2. In this time and age, where more 3rd party companies than ever before exist that can be tasked with handling your export business, it is inexplicable why the American manufacturers don't make use of that. Most produce in China anyway, so the merchandise could be exported directly from there to a market reaching from Scandinavia to Italy with millions of potential customers.

-

1/20th Revell Fendt 728 Vario Gen7

Junkman replied to Luc Janssens's topic in Truck Kit News & Reviews

I completely agree. Some old and the odd new American tractors wouldn't go amiss. They were/are surprisingly common in Europe, too. Kubota not so much, but definitely JD and IH. -

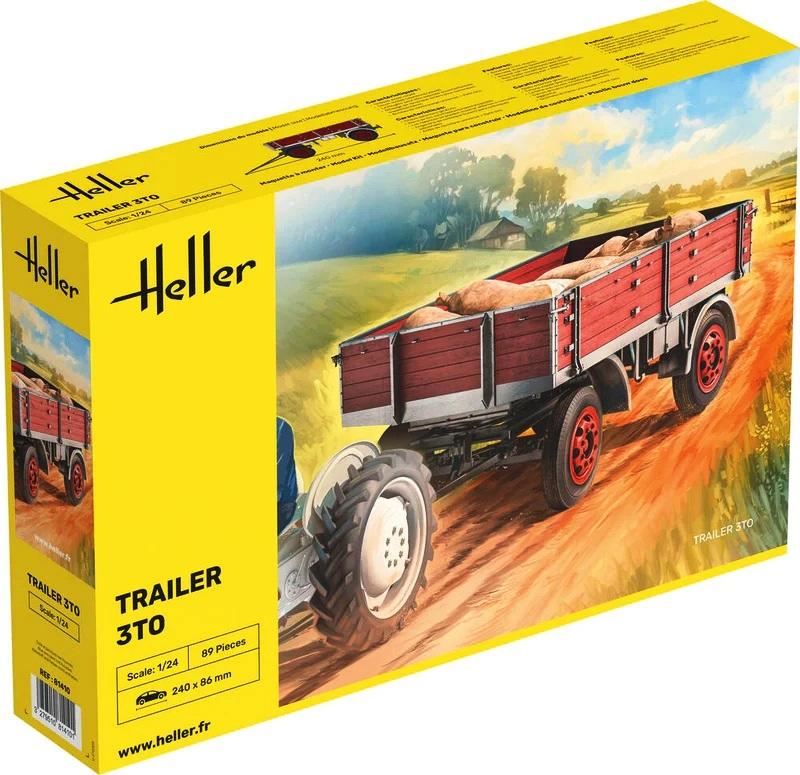

Heller announced a German standardised 3 ton trailer of the kind that was in use from the 1930s to the 1950s, with some surviving much longer on small farms. The pattern was built by numerous manufacturers, such as Blumhardt, Kaessbohrer, Kögel, and many others. They were also widely exported throughout Europe. It's pretty perfect for all the vintage tractors that have emerged lately, but also wouldn't look wrong behind an Italeri Opel Blitz.

- 1 reply

-

- 2

-

-

1/20th Revell Fendt 728 Vario Gen7

Junkman replied to Luc Janssens's topic in Truck Kit News & Reviews

Yeah, I was thinking that, too. The implement part. We also need these for the vintage tractors that have cropped up everywhere as of late. A start for at least the old tractors will be Heller's upcoming universal 3 ton trailer you can use for anything from the 30s onward.

(1).thumb.jpg.e371d4579f83ee021ff22f9ad4b79bbc.jpg)