-

Posts

324 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by mountaindewd

-

sleeper question

mountaindewd replied to clavender17's topic in General Automotive Talk (Trucks and Cars)

I've known some to use .040 for the shell walls and it may be ok. I use .080 as I like the stiffness of it and that would probably be more accurate to the 1;1 walls. This is one I built a few years ago. Walls, floor and ceiling are made with .080. All interior parts structures are .040. Cabinet doors and drawers are .020. -

Wow! Your masking skills alone is art! I can't imagine getting the symmetry with the curves that you have done. Very nice!! And then there's the paint........fuhget about it!! Beautiful!

-

Kenworth Adrodyn 31770

mountaindewd replied to shirtlessmoe's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Good golly, that's a lot of truck!! You'll need hydraulics and a scissor lift to tilt that cab! -

Very nice work!

-

Peterbilt 379-119 "Outlaw" style

mountaindewd replied to ghoodii's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

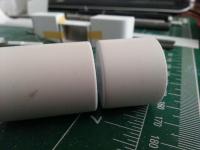

You can use sheet styrene for tank end caps. Cut a piece larger than the diameter of the pvc, glue in place and sand it to fit. I usually use .040. -

Looking really cool! Nice paint. Had a good laugh at this phrase. "Sadly, the Plastic Jesus hit the windshield and had to be re-located...." Decking the rear window area, think Fiero, would've looked cool.

-

The name's Pete!

mountaindewd replied to mountaindewd's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks for the comments, y'all! I got a little more done to this one. I've made two different bumpers and not yet sure which one will be used though I am leaning toward the bigger one. Cut the kit sleeper up and using it as the fuel tank/storage box. I still have to finish sanding the roof of the sleeper tank and scribe doors into the upper portion of it. Interior has been started also. This is all in mock up, nothing is glued yet. -

I'm diggin' that groove! What are the white walls from?

-

im going to do it in 1/16

mountaindewd replied to dabelltoller's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I agree with Tony. You might be surprised how rigid and strong it will be with plastic once assembled. The sheet plastic for sides would act as the frame, much like modern van trailers. They don't have frames. Their design is the structural integrity. .060(1.5mm) will be quite rigid or you could up it to .080(2mm). That should be more than adequate to resist bowing or sagging. 2mm = .080 1.5mm = .060 1mm = .040 .75mm = .030 .5 = .020 -

Mack Superliner

mountaindewd replied to MoparWoman Jamie's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

^^LIKE^^ :oP -

Tom, is there a thread for this WIP? That is cool!

-

Just an idea. You might be able to take the kit floor pan, cut it at the same point you did the frame, raise the back half and add a connector piece. More or less, z'd like the frame was. You may have to do some adjusting to the pan to fit it inside the body.

-

Jolly Roger Merc - back on the bench 8/30/15

mountaindewd replied to Jantrix's topic in WIP: Model Cars

With the pointy end?! Stay away from the bench or I'll stick you! -

Pete Rebilt! I've been whittlin' away at this for a couple weeks. Not sure of its future yet, but, on its way no less. Started with the AMT 359. So far I've chopped it, scalped it, dropped it and performed rhinoplasty, narrowing the hood and scratchin' a new grille. Will be constructing a frame soon and see where it goes from there. One thought is possibly hauling the toys around in the 44' Galaxy gooseneck or even leaning towards a wrecker of sorts. We shall see as it progresses.

-

I can't say anything that hasn't already been said. Well, without Gregg or Harry grabbing me by the throat that is. It is almost a shame to think all of your work is going to be surrounded by plastic. Very nice!! BTW, if those wheels are to be cast, I would be interested in a set or two.

-

"CRANKENSTIEN"(a small tribute to the "doc") DONE! 11/13/12

mountaindewd replied to bryan_m's topic in WIP: Model Cars

Doc, you wearin' this to ACME tomorrow? -

Wow, that is sharp!!

-

Helicopter turbine. Springer in da front n Mickeys in da back! Or, start with a title and go from there. Somethin' like Apocalyp-tique. Gas lights and machine guns.

-

Revell Lonestar

mountaindewd replied to griffin's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice build, Christiaan! I really like the painted tanks. -

Tamiya 1/12 scale ENZO with upcoming Scale Motorsport decal set

mountaindewd replied to David Thibodeau's topic in Model Cars

Regardless of fitment, Harry, I'll bet, is gonna steal these pics for a future Real or Model. Nice build! -

Autocar Sleeper Cab

mountaindewd replied to 20dakota04's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

James Secor was selling those tires. They might have come from him. I don't think he is casting any longer. I wanna say they are modified steers from the Can Do kit, among others. -

Autocar Sleeper Cab

mountaindewd replied to 20dakota04's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I have an idea for tires I would like to make a master for, but, it would require work I don't have the means to do. Removing treads from existing tires, cutting and splicing, making slug for tread to mount to, casting that, cleaning up gaps, etc., recasting final tire. A lot of work. I have removed some of the tread. Cutting, splicing I shouldn't have a problem with. The slug I may be able to manage, at least try. The casting is the part I can't do. No materials or experience doing that and don't want to waste the money practicing it. Maybe someday.