-

Posts

39,239 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

Status-seekers used to tend to drive flashy cars and build big houses on lots with no trees so everyone going by could marvel at how much money they must have spent, but phone apps make self-validation much easier (and cheaper) for the personally insecure.

-

"Anal-retentive" can be spun positively into "strongly detail-oriented".

-

Roll-bars and anti-roll bars are very different things.

-

Cesspool baths might tend to boost your immune system over time, if you live long enough after the first one.

-

Half of six, a dozen of the other...or something...you know...what?

-

That's really weird. I live on a wooded lot, and have at least 4 species of woodpeckers because of several bug-infested dead trees, and trees with dead limbs. I've never ever heard one after dusk.

-

You might want to consider that some woodpeckers are federally protected species, you could get in a fair bit of unpleasantness (including very stiff fines) if you destroy or maim one, and that it's generally illegal to intentionally kill most wild birds without a permit of some sort or another.

-

Double post due to site hanging up.

-

Very cool little race truck. Glad you decided to stay with it.

-

What exactly is lacquer paint?

Ace-Garageguy replied to D.Pack's topic in Model Building Questions and Answers

There sure is a whole lotta TLDR in this hobby. Paint is actually kinda complex, and if you want to understand what you're doing rather than just muddle through with often disastrous results, it takes a little intellectual effort. People who are happy relying on tried-and-true materials and techniques...fine. But why bash those who want to understand...or explain...some of the chemistry? There's a whole lotta misuse of terminology and misinformation bandied about too, both by modelers and manufacturers. Much of it can lead to ruined paint jobs or spoiled effects, and can sour somebody on building models. The more complete and accurate understanding you have of anything you use, the more likely you won't be making avoidable mistakes. EDIT: A little off topic, but the bottom line comes down to, as usual, if you're not certain that specific products and techniques will work together, don't rely solely on what you "heard" or what advice you get here, or even what it says on the products themselves. TEST TEST TEST TEST and VERIFY before committing to using ANYTHING on a model. -

"Clean habits" aren't always what single geezers are most known for.

-

Deterrent won't getchur clothes kleen.

-

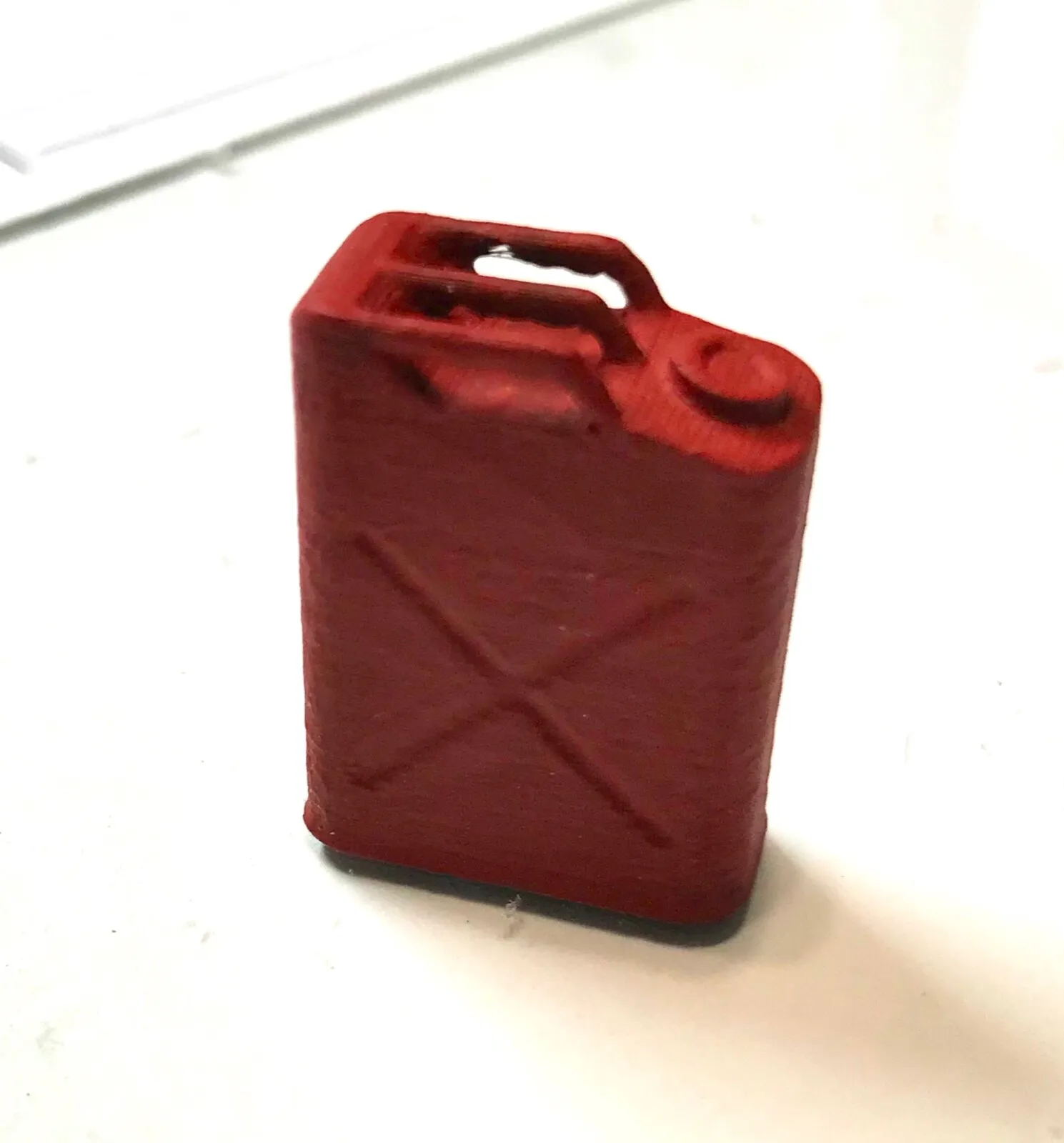

1/25 Scale Jerry Cans.

Ace-Garageguy replied to stavanzer's topic in Model Building Questions and Answers

These are better quality...but "NATO" style https://www.etsy.com/listing/1347729959/scale-jerry-gas-can-16-18-110-112-114? -

1/25 Scale Jerry Cans.

Ace-Garageguy replied to stavanzer's topic in Model Building Questions and Answers

Yup. Shape looks good, but the print quality isn't the best possible. https://www.ebay.com/itm/255197634132 https://www.etsy.com/listing/844025145/g-scale-jerry-can-gasoline-container-rtr -

1/25 Scale Jerry Cans.

Ace-Garageguy replied to stavanzer's topic in Model Building Questions and Answers

I'd bet there are some in G-scale model railroad accessories. -

Very attractive model, and that fine-grained silver really brings out the subtle sculpting of the body. The interior colors work very well with it, look European.

-

"Feet off the dash !!!" I've found myself snarling on more than one occasion to folks who have no respect for others' possessions.

-

Pads on a cat's feet make characteristic prints when they walk through the black paint they knocked over on the bench.

-

"Special" was often part of the name of one-off race cars in times past...like this one sponsored by Grant Piston Rings.

-

"Lad" he said, "if you keep it up, I'm going to throw you out yon window".

-

Almost every winter, I grow a beard. I've found it to be easy enough to keep it trimmed with scissors. If that's not an option, some trimmers made by Wahl and probably others have interchangeable heads.

-

House flies are almost as annoying as some internet influencers.

-

It's a very simple kit. Instructions at the link below: https://public.fotki.com/drasticplasticsmcc/mkiba-build-under-c/monogram-instructions/show-rods/monogram_hurst_hair/lastscan.html#media

-

Sound financial planning when you're young will allow you to be a comfortable old geezer with money in the bank.