-

Posts

39,241 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

Query, query little star, how I wonder what you bees.

-

"Gone but not forgotten" is what all those folks I owe millions to will say 'bout me when I'm pushing up daisies.

-

Bingo.

-

"Perfected" is something the self-driving-car mavens thought they would have achieved some time ago, but it turned out to be one whole jelluva lot harder than most folks thought, even engineers who should have known better

-

Time to pour somebody into a taxi...

-

1/43 Cobra Coupe Seen Today

Ace-Garageguy replied to Straightliner59's topic in General Automotive Talk (Trucks and Cars)

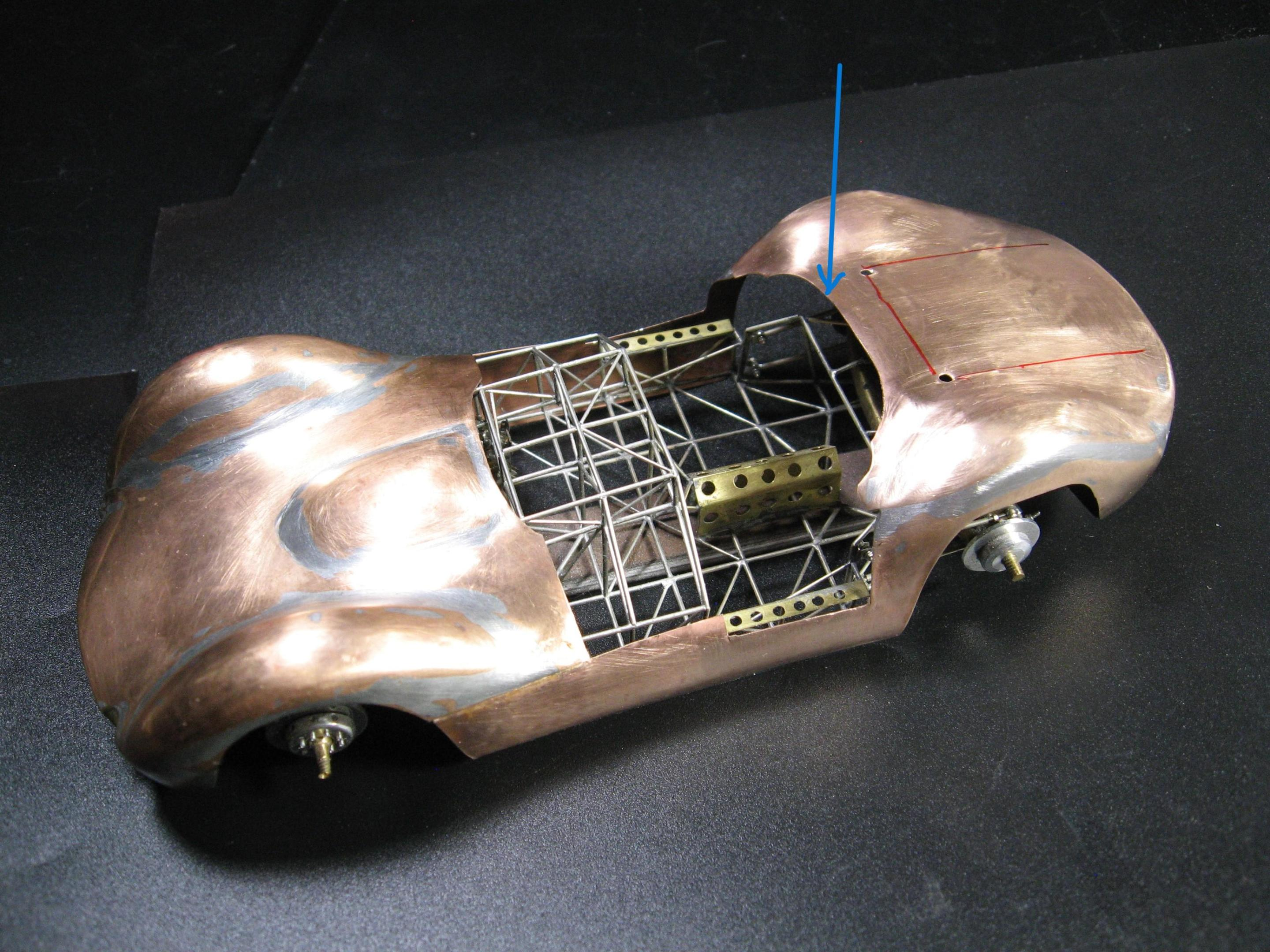

Just in case you (or anybody else) missed it, Randy Ditton has done something similar on his Birdcage Maser build... -

Privileges are often assumed that simply don't exist, along with other ridiculous ideas, like believing all business-owners have boxcar-loads of cash sitting around.

-

Finally learning not to rise to things that tend to provoke my ire, staying calm, standing my ground without anger, and walking away when it becomes obvious the provocation is from the clueless who will never get it. It sure took long enough to get to this point, but better late than never.

-

What Did You Have for Dinner?

Ace-Garageguy replied to StevenGuthmiller's topic in The Off-Topic Lounge

Spaghetti w/ homemade tomato sauce made with ground beef and chorizo, heavy on the garlic and onions and peppers, topped with fresh basil and feta, and a decent Merlot. -

Sore feet and hips and back can often be caused by carrying excess poundage.

-

Flies' cute cuddly little babies are known as maggots.

-

Stupor-charged is when you get the bill for a long night of partying.

-

On the subject of what constitutes a "sentence", there appears to be a lot of misunderstanding.

-

Summer just means I sweat a lot more, I have to mow the lawn more frequently, and if I'm not careful, the house gets full of bugs, mold, and mildew.

-

What would a car modelers Hades be like:

Ace-Garageguy replied to GLMFAA1's topic in The Off-Topic Lounge

Yup...occasionally a portal to another time-space continuum opens up either on my workbench or under it, and phfffffft...a small part or drill bit is lost and gone forever. Sometimes happens wherever I put my keys down too, but so far, they've always winked back into existence exactly where I put them. -

"Bartender...there'sh a pig in my glash" said the feller who was looking at his own reflection on the surface of his drink.

-

"Ago" being the opening word again, I'll pass.

-

What non-auto model did you get today?

Ace-Garageguy replied to chunkypeanutbutter's topic in The Off-Topic Lounge

Thanks Steve. Honestly, I wasn't aware of the new PIKO model until this one came up sor sale, when I researched what else was out there before deciding how high I'd bid to get it. The PIKO model is beautiful, with a level of detail that far surpasses the one I have...but at less than 10% of the cost of the new release, I can live with the old one...and of course up-detail it at some point, maybe. There are a few people out there offering the model I acquired for almost as much as the PIKO version, and if you really have money to burn, which I don't, there's a brass Korean-made one from Overland at well over $500, and a later "hood unit" version from the same maker currently bidding at $750. Model trains have become a "rich man's hobby" in the minds of a lot of people, due to prices for top-line equipment and the space required to build a big layout, and that's kindof sad. While even at its most cost-conscious it's more expensive than collecting string, if one knows what one wants to do, has realistic goals, and has an understanding of the options, a whole lot of fun can be had with a 4'X8' layout running salvaged "toy-train" equipment that can be upgraded cost-effectively to look and perform almost as good as the cost-no-object stuff, and scratch-building is still an option too, of course. It's a lot like the way that building a hot-rod is perceived as something only a rich guy can do by those who forget that, for a while at least, it's still possible to build a very nice rod from mostly junkyard parts...just like it was in the beginning. -

1/43 Cobra Coupe Seen Today

Ace-Garageguy replied to Straightliner59's topic in General Automotive Talk (Trucks and Cars)

Thanks for posting and bringing it to my attention. What a beautiful model, whether scratchbuilt or not. I've never seen the process of building an alloy body over a wooden buck modeled before. -

What non-auto model did you get today?

Ace-Garageguy replied to chunkypeanutbutter's topic in The Off-Topic Lounge

Pretty stoked about this pair of Roco/AHM/Rivarossi/Model Power HO scale "sharknose" diesels in the old Delaware and Hudson livery, one powered and one dummy, in quite nice condition...both of 'em for about what one dummy in incorrect colors usually trades for. The really interesting thing is that the D&H only ever had two of these, both bought used, and only kept them for 4 years. They are now the only two surviving Sharks on the planet...still in the D&H livery minus the lettering and heralds, and slated to go to a railroad museum when the current owner, who saved them from the scrapper's torch, dies. Kinda hard to believe that somebody at the model company that produced them knew as much about these two particular locomotives' obscure history, and cared enough, to have them factory-finished in these colors...and to even get the unit number of the last one to run, 1216, put on the side. I also snagged this pair of runners in an equally sweet deal. The gray one is an HO scale Rivarossi Krauss-Maffei ML-4000 diesel-hydraulic locomotive, in Southern Pacific colors. SP bought several of the German-built ML-4000s in 1961 as an experiment. Most US locomotives at the time were (and still are) diesel-electric, with the diesel engine driving a generator supplying electricity to drive the axle motors, rather like a hybrid automobile (without any batteries). But the ML-4000 Krauss units are diesel-hydraulic. The engine drives a hydraulic pump that transmits power to hydraulic axle motors, more like some earth-moving equipment than conventional locomotives. The German diesel-hydraulic locomotives didn't work as well as was hoped in mountain service, and as American diesel-electric locomotives began offering more horsepower and reliability, the Krauss units were phased out in 1967 and most were eventually scrapped. None were saved in original form, although in 2017, the one that had been converted to a camera car began a lengthy rebuild by mostly volunteer labor, with salvaged mechanical parts and a newly-fabricated cab to return it to its original appearance. It made its first run in 2019 pulling a railfan excursion train, and the restoration work is still ongoing to the best of my current knowledge. The green and yellow one is an HO scale EMD E7A passenger locomotive, also from Model Power, in Chicago and North Western colors. The EMD (part of General Motors at the time) E7 was among the first diesel passenger locomotives built following WW II, and the first of the E-series to share the "bulldog" nose of the wildly successful F-series of EMD freight locomotives. C&NW had 26 of them. Though I haven't run it yet, the Model Power E7 is reputed to be one of the strongest pulling locomotives in HO scale, being equipped with a large motor suitable for O-scale locos, a geared 12-wheel drive...and it's heavy. Of all the 429 EMD E7 A-units built, only one escaped scrapping. It has been cosmetically restored, and lives at the Railroad Museum of Pennsylvania. These four models appear to have come from a collection of someone who loved vintage, historic, and obscure machines as much as I do. They also appear to have been owned more recently by someone who viewed them as children's toys, and let then get a little dinged up. But they'll be well cared for as long as I have them. -

Citroen/Funny

Ace-Garageguy replied to Holeinthehead2's topic in Model Building Questions and Answers

Similar to what Phil said...I'd cut the rear pillars just to the point your roof clears the cage, then lay the front pillars back by whatever amount it takes to get the roof level with the body side, or maybe angled down, but very slightly. -

That's a real beauty. Wonder if it's still there.

-

I tend to complain and moan frequently about people not returning emails, or just not bothering to do their jobs with any sense of responsibility. This week I had TWO suppliers who messed up, one with a ridiculously poorly packed order that was subsequently badly damaged in transit, and another one who shorted an order bigtime, and one of the parts that did arrive was of poor quality. HOWEVER, BOTH of these responded immediately to my emails, and have already or are working towards making things right. Everybody makes mistakes. It's how you deal with and correct them that counts in the end...and these two suppliers have top marks for follow-up so far.

-

I tend to complain and moan frequently about people not returning emails, or just not bothering to do their jobs with any sense of responsibility. This week I had TWO suppliers who messed up, one with a ridiculously poorly packed order that was subsequently badly damaged in transit, and another one who shorted an order bigtime, and one of the parts that did arrived was of poor quality. HOWEVER, BOTH of these responded immediately to my emails, and have already or are working towards making things right. Everybody makes mistakes. It's how you deal with and correct them that counts...and these two suppliers have top marks for follow-up so far.