-

Posts

39,255 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

Ground chuck is usually my first choice for taco, enchilada, and burrito filling.

-

Idea development is one of the more enjoyable parts of modeling to those of us who have an active creative streak.

-

Rhetorical questions can be the basis for thought experiments.

-

Does anybody really know what time it is?

-

One-Off Quiz #42 - Finished

Ace-Garageguy replied to carsntrucks4you's topic in Real or Model? / Auto ID Quiz

Oopsie doopsie. I finally figgered it out, but forgot to PM Michael... -

Why is my clear coat coming out textured?

Ace-Garageguy replied to Milo's topic in Model Building Questions and Answers

In a project to do a period build using period materials and parts, I used Ace Hardware black "lacquer" to paint the body shell. It looked great...until I had to go back into it months later. It lifted and cracked just like enamel. The photo below is as-shot the first time. Same thing with their white "lacquer" I used as a gloss surface coat on a set of masters for a custom lakester body shell. A relatively simple job turned into a nightmare, and frankly, ended up compromising the quality of the build so badly, I've had to re-do much of it. -

Why is my clear coat coming out textured?

Ace-Garageguy replied to Milo's topic in Model Building Questions and Answers

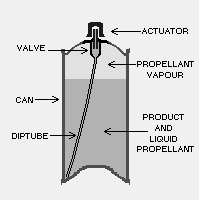

You would also kinda think that one of those paint-wizards would have heard of soaking nozzles in lacquer thinner. Clears 'em every time. Of course, more often than not, the clog is actually inside the can...the dip tube or the valve. -

I'm sick, at home, killing time perusing interdwerb stupidity. Quoting a male "influencer": "Some men put a woman on a pedal stool". EDIT: And a female talking about being "coat dependent". You can't make this stuff up.

-

DC-5 was the designation of an airplane built by Douglas Aircraft, intended for shorter routes than the DC-3 and DC-4 transports.

-

Flounder is good baked, especially when stuffed with crab.

-

Argument using logic and facts against someone who didn't arrive at their opinion using logic and facts is an exercise in futility.

-

Woke up with a miserable cold. Was kinda wondering why I was so tired yesterday. Now I know. Back to bed to read and snooze.

-

Russias answer to Tesla.

Ace-Garageguy replied to tim08's topic in General Automotive Talk (Trucks and Cars)

-

Buying kits we know we'll likely never build probably involves the same neural pathways as in the brains of women who buy closets full of shoes and clothes they know they'll probably never wear; I will, however, build all of mine, even if to do it I have to achieve immortality.

-

-

It is, after all, Christmas Eve...

-

Friends don't let friends drive if they're staggering.

-

Not the same, but reminds me of a time I had an air compressor that was constantly "burning" the points on the AC pressure relay. I kept cleaning them with the trusty old point file from the dim recesses of time, she'd run a couple of days, then burn 'em again. Prior to looking for some obscure electrical cause, the last time before I cleaned them, I examined the points carefully under bright light and magnification. There was a fried ant carcass making a nice insulator between the points themselves. I have no idea if ants are attracted to small magnetic fields (like the coil in the relay), but once I sealed the relay housing so they couldn't get in, the problem stopped. For all I know, they could have been playing some kind of ant "chicken", seeing who could get across the points before they snapped closed.

-

Beautiful. The middle one reminds me of several places I lived while growing up, but especially of Halifax when we'd visit while I was small. Thanks for triggering some good memories.

-

What color is this?

Ace-Garageguy replied to R. Thorne's topic in Model Building Questions and Answers

Looks like a darkish metallic gold to me. -

Trouble Is My Business is a short story collection by Raymond Chandler.