-

Posts

38,171 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

If I Ran Revell....

Ace-Garageguy replied to Snake45's topic in General Automotive Talk (Trucks and Cars)

Pretty much agreed on all points...HOWEVER... I believe the reason we've been seeing all manner of dimensional and proportion errors in bodies, mechanical parts that are clunky blobs bearing little resemblance to anything real, large klugey alignment pins that belong on toys rather than precision scale models (look at what's standard quality in the HO scale model RR stuff today, and compare it to the typical car model), the same parts (like engines) from the same manufacturers in the same scale, but in different kits, that are somehow magically of different dimensions after having been scaled down to 1/25, stupidly designed wheel and tire retention systems, front and rear "glass" that doesn't even come close to fitting the openings correctly, bumpers that droop, grilles that don't fit, cylinder heads that are WAY too short for the engines they go with...and on and on...is because there are simply too many fingers in every kit development pie belonging to people WHO DON'T APPARENTLY KNOW ENOUGH ABOUT CARS...OR BUILDING MODELS...to get things right. Scanning a real car and developing CAD data from that is just dandy if you've got mostly computer-jock clean-hands-never-held-a-tool mouse-clickers on salary to manipulate a bunch of data, misinterpret some of it, and you want to pay for multiple tooling changes and test shots and corrections because the whiz-bang tech wizards fouled up, and, of course, translating everything into Chinese, we're told, is difficult. Costs skyrocket. Endless meetings addressing unnecessary problems, while making sure nobody is actually responsible for any decision, add thousands of dollars to projects. Time passes, no product, re-do after re-do. So instead, you get a tiny team of a FEW guys who understand cars intimately and are world-class modelers...at least one on the team, anyway. Add some practical engineering knowledge, and require everyone to be fully cognizant of how injection molding works, what the goals are, what the tolerances are, and get it done without spreading responsibility all over the planet. One guy is the ultimate decision maker, period. No meetings, no discussion. And find an American company to cut the tooling. They're out there. You start with basic measurements like width, length, height. wheelbase, distance across door sills and door tops etc. Bring the body into spec...really only one side is necessary. Scan it. Mirror it. Do a rough tool design, close enough to know your material thicknesses on the body shell within a millimeter. Develop ALL the other parts from the dimensions you have from the body engineering. Check everything multiple times. Everything fits, no baloney, no excuses. This ain't going to the moon...and the REASON we don't go BACK to the moon is because middle-management spread and 100% reliance on tech and distributed blame rather than a core team of people WHO REALLY KNOW WHAT THEY'RE DOING just makes it too damm expensive. -

and warm beer

-

If I Ran Revell....

Ace-Garageguy replied to Snake45's topic in General Automotive Talk (Trucks and Cars)

If I ran Revell...or really wanted to get a bulletnose to production cheap, I'd probably get a VERY competent modeler to start with the Flintstone body (which is pretty bad) and see if it could be corrected and made symmetrical. Tough, but I'm certain not impossible. Get it dead-on. Then ship THAT to the tooling-designers and let them take every tiny little dimension directly from the thing. Better yet, just scan it. Industrial scanners exist with the requisite precision. Only scan one side, and flip it in the computer. Develop your CAD files directly from that data, and cut your body tooling. Ought to be a slam-dunk, right-the-first-time deal IF EVERYBODY DOES HIS JOB RIGHT. The chassis and guts can have the odd discrepancy and nobody will scream too loudly, but the body needs to be as close as humanly possible. -

^^^ Man, once you're carrying one of those on your tail, it makes it kinda hard to sneak home in the middle of the night. 3AM, Mr. Policeman sees one, you're doomed if you're cooked.

-

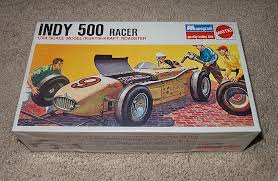

Thanks. I'm trying, a little every day or so. Me too. Closer and closer... Thanks for your interest and comments. The seat is from the old Monogram Kurtis Kraft Indy car, narrowed, with a few holes drilled to give it a surplus aircraft look. Trying. And thanks to you too for your interest and comment.

-

Mickey Thompson's Challenger One. Still alive, Feb. 8

Ace-Garageguy replied to Ace-Garageguy's topic in WIP: Model Cars

Thank you sir. Not yet. The water-based release agent I tried had an adverse reaction with the surface finish, and I didn't want to use a silicone-based product. There's another one I have used in the past that might work, it's a two-pert process, I've run out of the first part, and the new minimum quantity is a gallon...and it's not cheap. Still kinda studyin' on which way to jump. -

Holy cow. I saw the first version of this in November at the Atlanta ACME meet, and it was pretty danged impressive. But the NEW version is completely over the top. Fine, fine, fine. It reminds me of something I read from a model railroad scratch-builder-extraordinaire eons ago...if you can hold it, you can make it. Holding some of those little parts to work on them is just short of magic.

-

or jockey shorts

-

Мені це подобається.

-

how would you fix this?

Ace-Garageguy replied to gijoe's topic in Model Building Questions and Answers

Agreed. -

Ford big block ID help.

Ace-Garageguy replied to landman's topic in Model Building Questions and Answers

Just FYI, all the first-generation Olds OHV V8 engines built from 1949 through 1963/4 are pretty similar visually. 303, 324, 371 and 394 factory displacements, kit engines can easily be up- and back-dated to represent any of 'em. -

If I Ran Revell....

Ace-Garageguy replied to Snake45's topic in General Automotive Talk (Trucks and Cars)

Starlite coupe, business coupe, convertible, and one of the coupes in drag as a gasser. Yeah...that oughtta do it. -

crustacean in your

-

Oww....

Ace-Garageguy replied to Richard Bartrop's topic in General Automotive Talk (Trucks and Cars)

Unless, of course, the machine in question is the original product of one's own mind and hands. In that case, it's a symbol of EVERYTHING that matters. -

Oww....

Ace-Garageguy replied to Richard Bartrop's topic in General Automotive Talk (Trucks and Cars)

But you know man...time is like...so relative, man. Like when a dude says, like, everything old is new again...you know, man? I mean like, yesterday and tomorrow, like, all run together man. Like, you know what I mean man? -

without detonating it

-

Oww....

Ace-Garageguy replied to Richard Bartrop's topic in General Automotive Talk (Trucks and Cars)

The main-stream media is suppressing it. -

Agreed. My title was a little tongue-in-cheek in response to the somewhat overheated and breathless nature of the vid. Still, as you say, it's interesting to see lotsa whoopee-gee-whiz techy-doo "integrated into the design process". And as far as I'm aware, the tech doesn't yet exist to 3D fab a functional chassis using large-scale metal-deposition (sputtering). The vid looks as though the concept is essentially using a wire-feed welder, CAD/CNC/robotically controlled, to build up structure analogous to a tubular space frame. For now, I think I'll stick with plain old dinosaur-era seamless tubing.

-

knows how to

-

Not the class.

-

Head of tails.

-

on its head

-

through green Jello

-

to his ewe