-

Posts

38,173 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

Glue Gun Glue Bomb.

Ace-Garageguy replied to oldcarfan's topic in General Automotive Talk (Trucks and Cars)

For what ti's worth, I tried hot-glue for model mockups a few years back. I'd often used it in the real-car work with excellent, easily removable adhesion on metal and fiberglass. I used a HOT one, not the wimpy little ones they make for low-temp glue, as I should have. Long story short...the hotter of the hot-glues melts into the surface of styrene much as solvent-based glues do. It's the absolute devil to get off, and usually requires careful surface scraping with an X-acto chisel-tip blade, or something similar. IF...big if...you can immerse the model in HOT water, it WILL soften the stuff enough to ease disassembly. But remember...the CRITICAL temperature (Tg, or "glass transition temperature") for most kit "styrene" is right around boiling, 212F, 100C. It you get your model that hot, warping is a real possibility. -

Yeah, I bought a supremely clean '60 built-up within the last 30 days for reasonable money.

-

^^^ Man is that a classic profile. Absolutely perfect.

-

NICE job on that.

-

How do I lower the Revell 41 Willys?

Ace-Garageguy replied to Tuffy's Garage's topic in Model Building Questions and Answers

Exactly. The online instructions (I don't have that kit in stock to look at) show the front spindles to have stub-axles molded in about the center of the spindle. Carefully cut the stub-axle free from the spindle and re-glue it UP in relation to the chassis, as far as you want the car to go DOWN. OR...perhaps an easier way...file material off the TOP of each spindle, and add a spacer (of the same dimension as you removed from the top) to the BOTTOM of the spindle. Re-create the mounting pins with rod stock, if you want to retain the "steering" ability. Either method duplicates in scale exactly what you do when you replace stock spindles with "dropped" spindles on a real car. NOTE: Exactly how you do it depends on how low you want to go. To lower the thing even more, the upper control arms can be cut loose from the chassis and raised relative to it with spacer blocks. This will move the spindles up relative to the chassis, and you can either add spacers of an equal thickness to the lower ends of the spindles, or file the crossmember mounts to allow it to move up as well. Careful measuring of the stock ride height, and a mockup of the ride height you want, is essential to determine how much you cut...and where...BEFORE you start modifying. -

A good friend of mine was at Kadena in the late '60s supporting Blackbirds, and another one was at Naha in the mid '60s.

-

I paid P-bucket from the beginning, so I could use Adblock (which eliminates all the complaints of slow-loading, etc. that co many "free" users complained about) with a clear conscience. When the big blackmail debacle occurred, they grandfathered my account in, and I never lost access to anything. Now, with the new management, my account is still working just fine at the price I was paying back in 2012. I didn't have to waste days transferring images and replacing the new addresses all over the web either. it's been my lifelong experience that anything you get for free is usually worth exactly what you paid for it.

-

AMT and MPC Please Put Out Significant Kits

Ace-Garageguy replied to regular guy's topic in Car Kit News & Reviews

Very true, and in the case of the XR-6, anybody who really wants one can find one. Though a little spendy, they're not in the stratosphere yet. The vast majority of modelers working today probably don't even know what it is, and wouldn't be interested much even if they did. I have two. -

AMT and MPC Please Put Out Significant Kits

Ace-Garageguy replied to regular guy's topic in Car Kit News & Reviews

Some actual factual knowledge of how injection-molding tools are made, and how they function during the molding process, is always useful to have when indulging in the endless they-should-do-this-or-that opinions. Costs are often overstated by some manufacturers as excuses, but costs CAN be prohibitive if the company doesn't have hands-on machinists and toolmakers with a can-do attitude on staff. And all dies are not compatible with all injection molding machines. Again, knowledge of the subject is a big plus when discussing it, or criticizing. -

You can find brushes for just about any old electric motor online. I'm lucky here, as there's a hardware store that's been around for decades close by, and they have a cabinet chock full of small motor brushes. Naturally, nobody but me ever seems to buy any, and they don't get restocked. I probably need to go buy them all.

-

From what I see, just about everyone who makes "cordless" anything is on the same train. It's maddening to have shop tools that function perfectly fine, but can't be used because there are no batteries...other than offshore knockoffs that rarely hold a charge for very long. Someone who had some mass-marketing savvy and cash to invest could probably make a large pile of money developing plug & play lithium ion packs (and chargers) to replace all the nicad packs you can't get anymore. I've converted some of my old tools with cobbled-up rigs, and they work just fine.

-

Lotus Seven Replica - diary of a build F I N I S H E D

Ace-Garageguy replied to da Speedinger's topic in WIP: Model Cars

Wow. Beautiful. -

Agreed.That's quite a machine.

-

How do I lower the Revell 41 Willys?

Ace-Garageguy replied to Tuffy's Garage's topic in Model Building Questions and Answers

It depends on whether you have the straight-axle "gasser" version or the independent front suspension "street rod" version. -

Bethlehem Steel & The People Who Built America

Ace-Garageguy replied to Ace-Garageguy's topic in The Off-Topic Lounge

Interesting that your father was there, Bill. Obviously, Bethlehem and companies like it were the real backbone of the American economy. To me, it's just so sad that America didn't value it's heavy industrial base, and gladly let it slip away rather than staying competitive by dealing with labor and environmental issues head on, and by implementing new processes earlier. The "information" and "service" based economy so loudly touted by "experts" just doesn't have the muscle to sustain the robust middle class that was America's strength. The six-year payment cycles you mention, now common when buying a new car, are indicative of the majority of buyers not really having as much buying power in adjusted dollars as they once did. -

Agreed 100%. I bought one a while back to hack into something else, but seeing how good yours looks, I'll have to get one just to build. Nice piece of GM history. Did you adjust the stance at all? Yours seems to sit a little lower than the one I mocked up, IIRC. Looks great.

-

What other Model As were made in 1/25

Ace-Garageguy replied to junkyardjeff's topic in Model Building Questions and Answers

I've got '29 AMT fenders I'll never use. PM me your address and I'll send you an assembly if you want it. -

Childhood Becomes Reality

Ace-Garageguy replied to Badluck 13's topic in General Automotive Talk (Trucks and Cars)

That's quite a toy. I've always really liked the back end, still waiting for the nose to grow on me. All around pretty cool in its crazy way. -

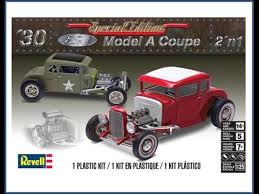

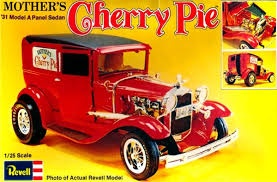

What other Model As were made in 1/25

Ace-Garageguy replied to junkyardjeff's topic in Model Building Questions and Answers

-

What other Model As were made in 1/25

Ace-Garageguy replied to junkyardjeff's topic in Model Building Questions and Answers

The Revell sedan delivery was based on this kit, split up and reissued. Revell also did several release versions of the '28-'29 body style A pickup. NOTE: All of the Revell kits shown above will work on the AMT '29 chassis. BUT...due to different architecture, with frames molded to the fenders, the other AMT kits Art mentions will NOT work on the AMT '29 frame without considerable surgery. -

Need Some Help With A Couple Things

Ace-Garageguy replied to regular guy's topic in The Off-Topic Lounge

For welding, Motorbooks Performance Welding Handbook is outstanding. For soldering, the Antex The Basic Soldering Guide Handbook is an excellent introduction. DO NOT buy the Kindle version. You can't see anything in the low-res photos. For Corvair engines, Bill Fisher's How to Hotrod Corvair Engines is the bible. Get a FACTORY service manual as well. For the '78 Volvo 242 GT, just buy the FACTORY manual. For Tamiya Elecraft, buy the kits, follow the instructions, learn as you go. https://www.tamiya.com/english/products/list/elecraft/kit75001.htm