-

Posts

1,881 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Randy D

-

What a great build you have going here my friend!!!!! Love the teamwork. You're showing some real skills working with the printed goodies as that is a whole different animal. Randy

-

Western Star 4900 FA plow truck

Randy D replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Hi Brian, Spent some enjoyable time this afternoon getting caught up on this masterpiece !!!!! The cab interior is flat out amazing. All the detail wiring, monitor, levers and gauges look spot on. Can't wait to see your paint job. Randy -

Western Star 4900 FA plow truck

Randy D replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Well my friend, so much awesome modeling to take in here. Love the shot from underneath showing all the detail you built up with the hood and floor framing. The dash is looking like you shrunk the real thing!! The mast and control tower , with the monitors and levers is really shaping up. Great idea using those RB Motion boots. What have you found for a glue that works with the silicone? Randy -

’72 Dodge Demon Drag Racer 1/25 scale

Randy D replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Well you sure knocked the radiator out of the park Francis. Beautiful machining and soldering. Simply a feast for the eyes my friend!!!! Randy -

You've got to be kidding, 14 perfectly spaced cuts on a rod that is 1/16th of an inch. I am sometimes just flabbergasted at what you achieve my friend!!!! Randy

-

Western Star 4900 FA plow truck

Randy D replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Glad to hear that the quake was not more destructive up there my friend!!! Great idea on the cab mounting. Your work building up the hood and hinges is a masterclass in scratch building. Randy -

WOW, paint really brings out all the extra work you are doing here buddy!!! That is a monster of a motor that was used in these things. Randy

-

Peterbilt 379 RV

Randy D replied to vincen47's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Victor, This rig looks spectacular in paint!!! You are one talented builder Sir. That Series 60 looks great😁 Randy -

Kenworth 925 - Strato Models

Randy D replied to carsntrucks4you's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Hello Michael, Love the metalwork. That hood you created is awesome! Randy -

Mack Superliner

Randy D replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Hello Jurgen, As always, fascinating to watch you design, print and build your trucks!!! Randy -

Steve, Got to echo what Jeff said. This is one special build Sir. Wonderful creation of parts and details. Randy

-

Hey Tim, I am way behind here. The seat frames came out great. Very successful plating! The Lenco is shaping up to be another of your machining masterpieces my friend. That is so cool that you have an reference source for the chassis!!! Randy

-

FDNY Wrecker

Randy D replied to Scott Eriksen's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

The whole front end looks spot on Scott! Question if I may, where did you find the great looking winch? Randy -

3rd PR Open Model car and Collectibles Show

Randy D replied to Mad Slammer's topic in Contests and Shows

Hi Roberto, really enjoyed going thru your album. Lots of outstanding models and what a wonderful venue. Car show, model car show and all sorts of shopping !!!! Thanks for posting this, Randy- 1 reply

-

- 1

-

-

Farm Floater Truck 1/24th scale

Randy D replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you Brian for the comments! Working on more details in the cab.... ref. pics... Making up the mast. Turned a top and base, soldered up the arm.. Soldered up a box to hold some toggle switches... Top Studio provides the switches... Making up a monitor..... Most of this subject to change and additions. Will finalize layout when I build up the seat and more of the interior.. Thanks for looking in. Randy -

Farm Floater Truck 1/24th scale

Randy D replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

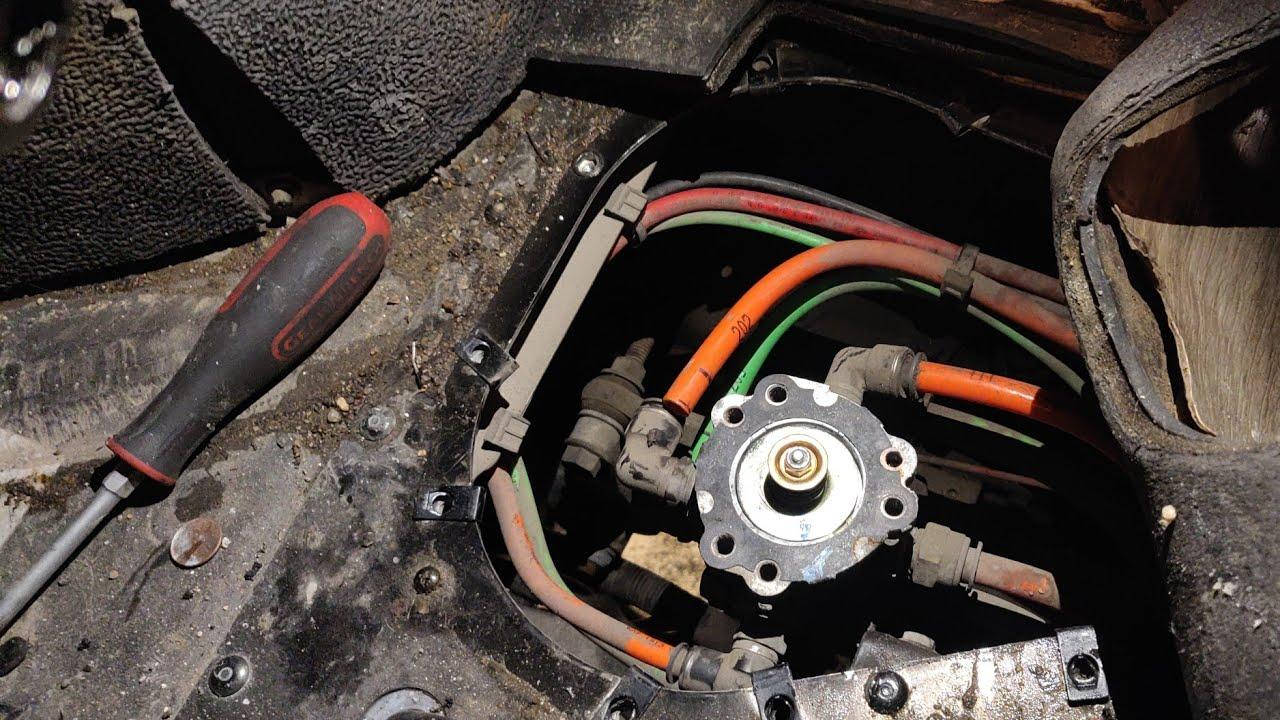

Thanks Steve, Having trouble keeping pressure up🤣 More concerned when I mocked up the clutch on those last couple of pics. Not sure how the linkage will line up to the tranny. Might have to shift over. Will know more when I line the cab floor up with the motor/trany. Randy -

Farm Floater Truck 1/24th scale

Randy D replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Brian K. ...Thank you my friend. Sometimes it seems like my progress is painfully slow🤔 Brian S. glad you like it ! Steve McNally, thank you and I do seem to have hoses dangling all over the place! Steve, Thank you! Victor, Thanks and I know we are all waiting for your next update. Hello Francis, Yes, a little different area for me. Thank you for the kind comments. If you folks want a treat for your eyes, check out Francis's miniature machining work in the Drag Section of this forum, truly spectacular. Appreciate it Ron!! Jim, thank you and that is so cool that you are working on a Pete!!! I will be bugging you😀 Some progress... Trying to finish up the brake pedal this time... Pics of pedal and treadle valve my efforts... here we have all pedals mocked up ... Thank you for looking in! Randy -

Western Star 4900 FA plow truck

Randy D replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Simply some of the finest modelling on this forum my friend!!! Randy -

Hey Jeff, Just checking in and have to say you are doing a great job on this kit!!! Randy

-

Peterbilt 379 RV

Randy D replied to vincen47's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Always enjoy checking this build out Victor!!! Randy -

Service Truck Kitbash

Randy D replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Understand about the frustrations Paul, but really like the end result you have working here!!! Randy -

Kenworth aerodyne cabover

Randy D replied to Bronzekeg's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Great build Ken!!! Randy