-

Posts

3,058 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by AmericanMuscleFan

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks for the info Daniel, I'll go check it out, it'll be funny or rather intriguing to see you working on something other than a drag racing project! 😊 -

1:16 FED, brass, current project

AmericanMuscleFan replied to Mike Holland's topic in WIP: Drag Racing Models

Great to see you working on another one of these superb FED Mike, it's always a pleasure to see an eternally young man aligning brass rods to make a convincing and perfectly straight frame. 👌 -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Brian, I don't know if the update worth the wait but it feels good to get back to the hobby after a long break, I'm re-energized and I have a lot of work ahead of me, many complex parts are on the menu for the coming months! Thanks Brian, more to come in the following months, the fuel system looks like an interesting challenge, among other things! Thank Daniel, you're absolutely right, the standard Sherline configuration is excellent and perfectly suited to almost all common uses. Switching to a pulley system to rotate at 10,000 rpm is an option when you want to use tools that make cuts as wide as a hair... among other things! I haven't managed to catch up yet, do you have a new WIP project ? Thanks Pierre! Of course! I've seen how easy your projects are, my friend! It's not the tool that does the work, but the hand, and you prove it well! There are many talented people on this forum; it's just a lack of time to appreciate their achievements. 😉 Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Tim, I don't want to make you feel guilty, but you bear some responsibility for my madness; it takes fuel to feed the fire, and you own a fine refinery! 😉 Thanks for the meme Hank, you made me laugh on this cold Monday morning, a great way to start the week! Thanks for the kind words Rich, I think a wedge engine is less spectacular than a HEMI, I thought a little bit of fancy might make it more attractive. However, I do like the aura of mystery behind these heads developed during one of my favorite eras of the NHRA. -

Superb photo of such an inspiring subject (your legendary and sadly deceased Henry J 😭), but we must move forward, and that's exactly what you're doing. I'm sure we'll have a lot more fun following the making of this famous brass frame. I'm taking notes, my friend! 😊

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

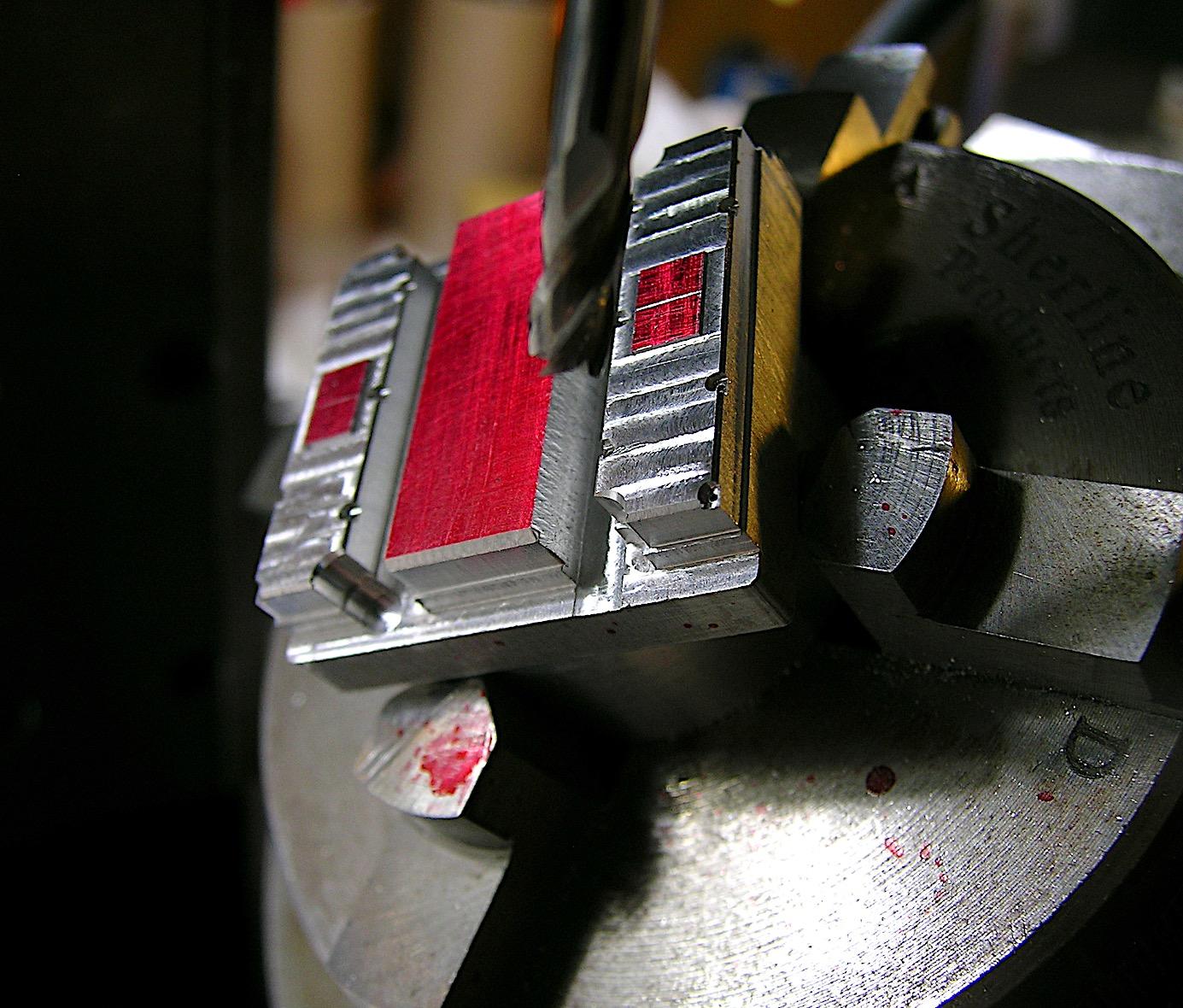

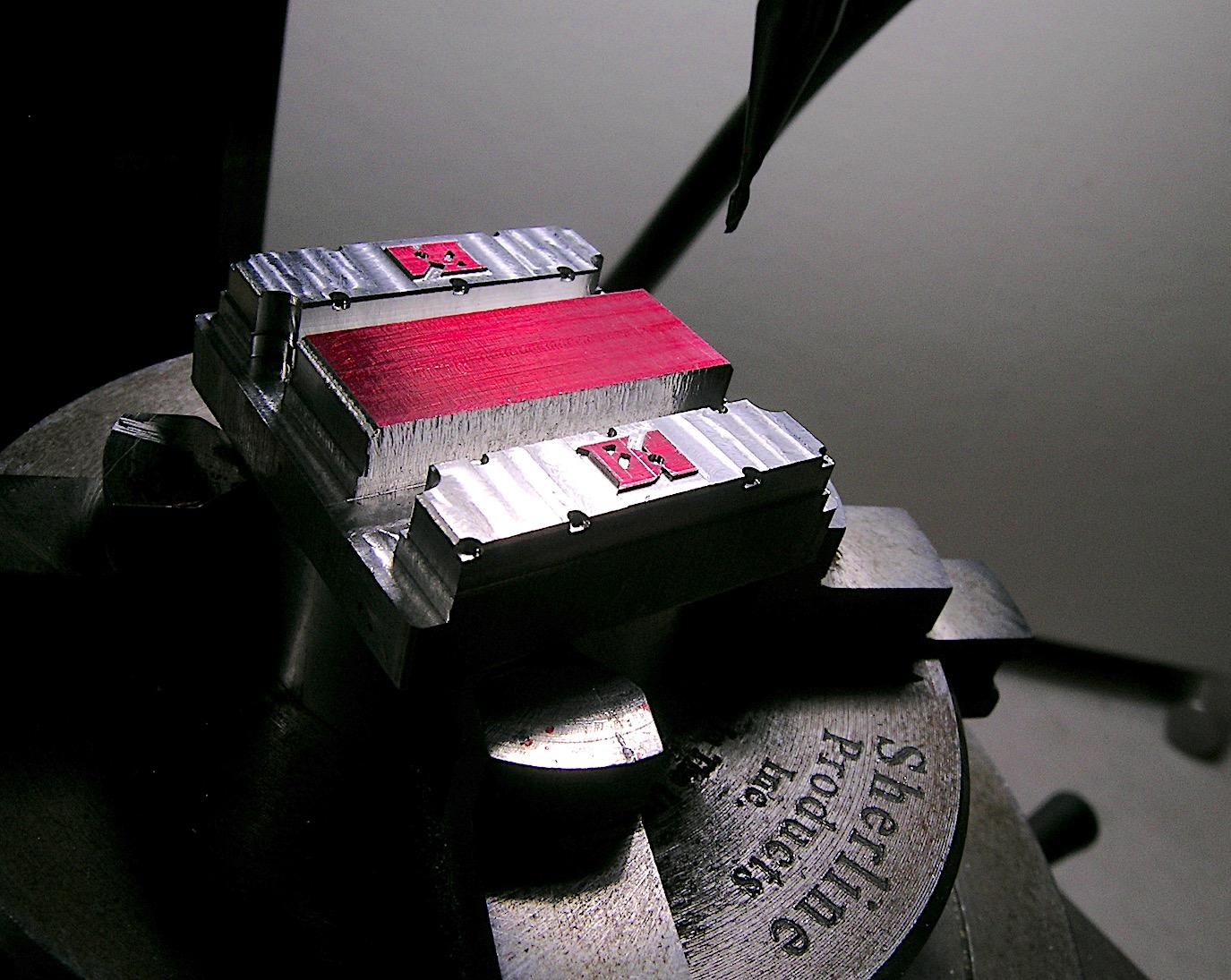

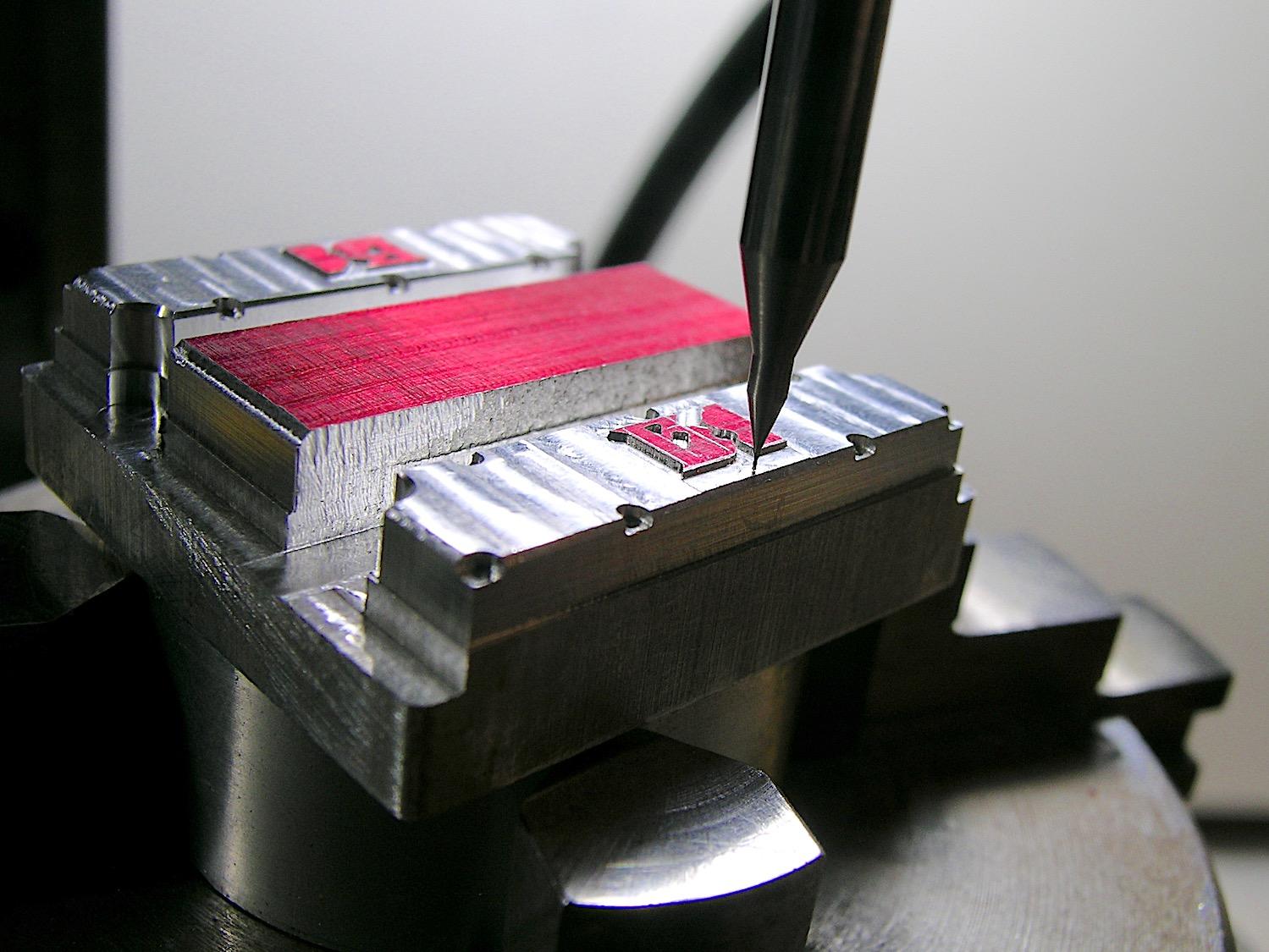

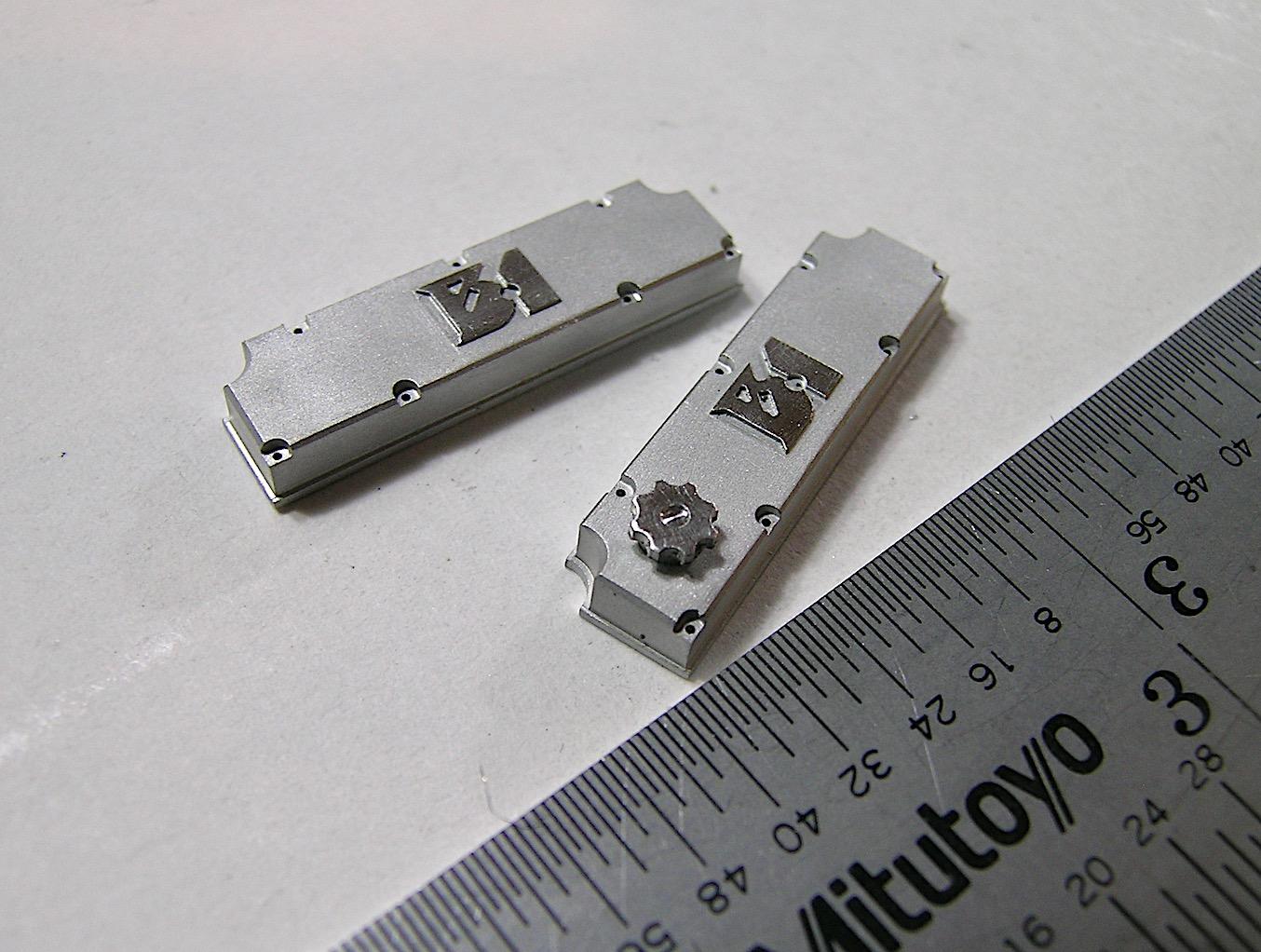

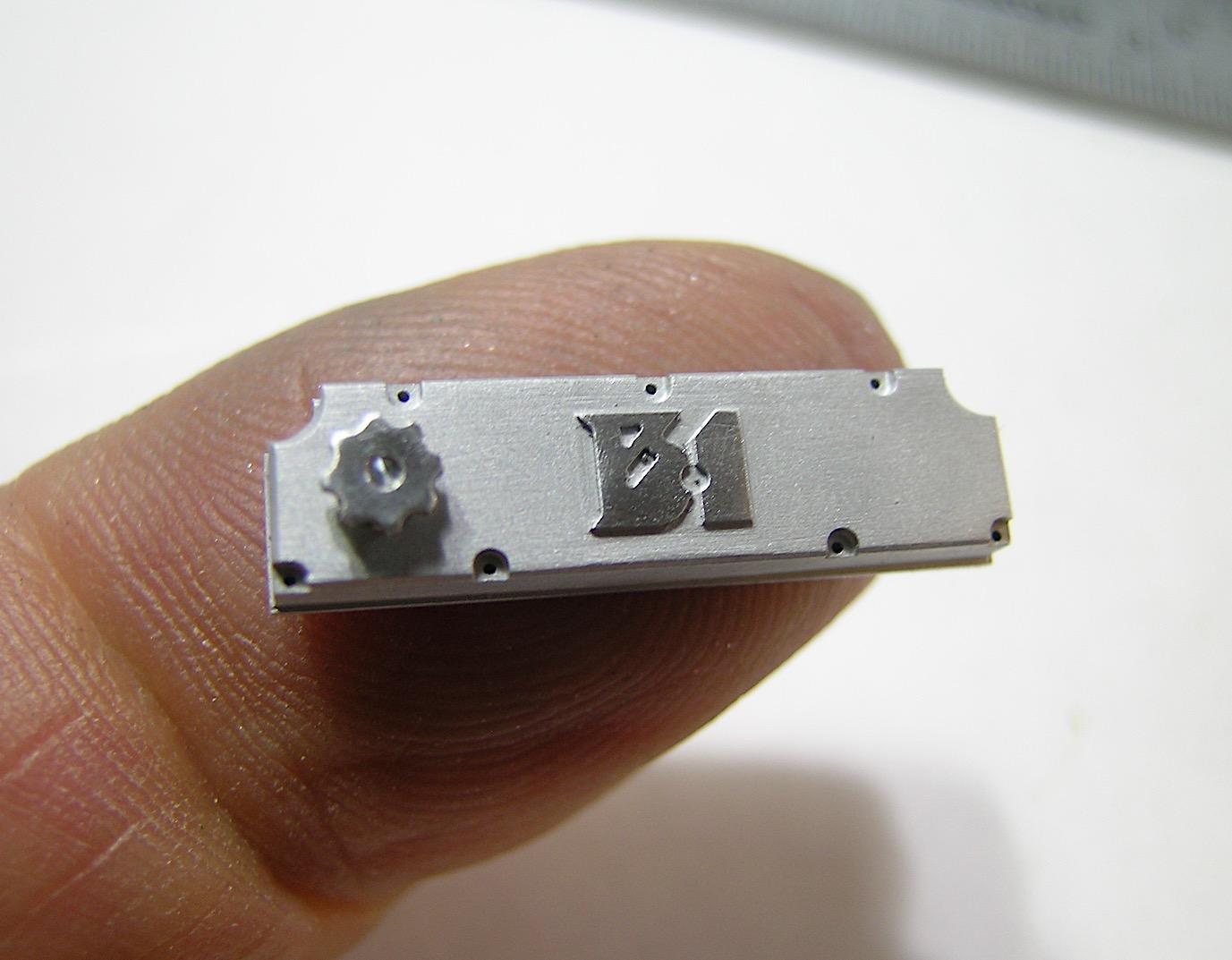

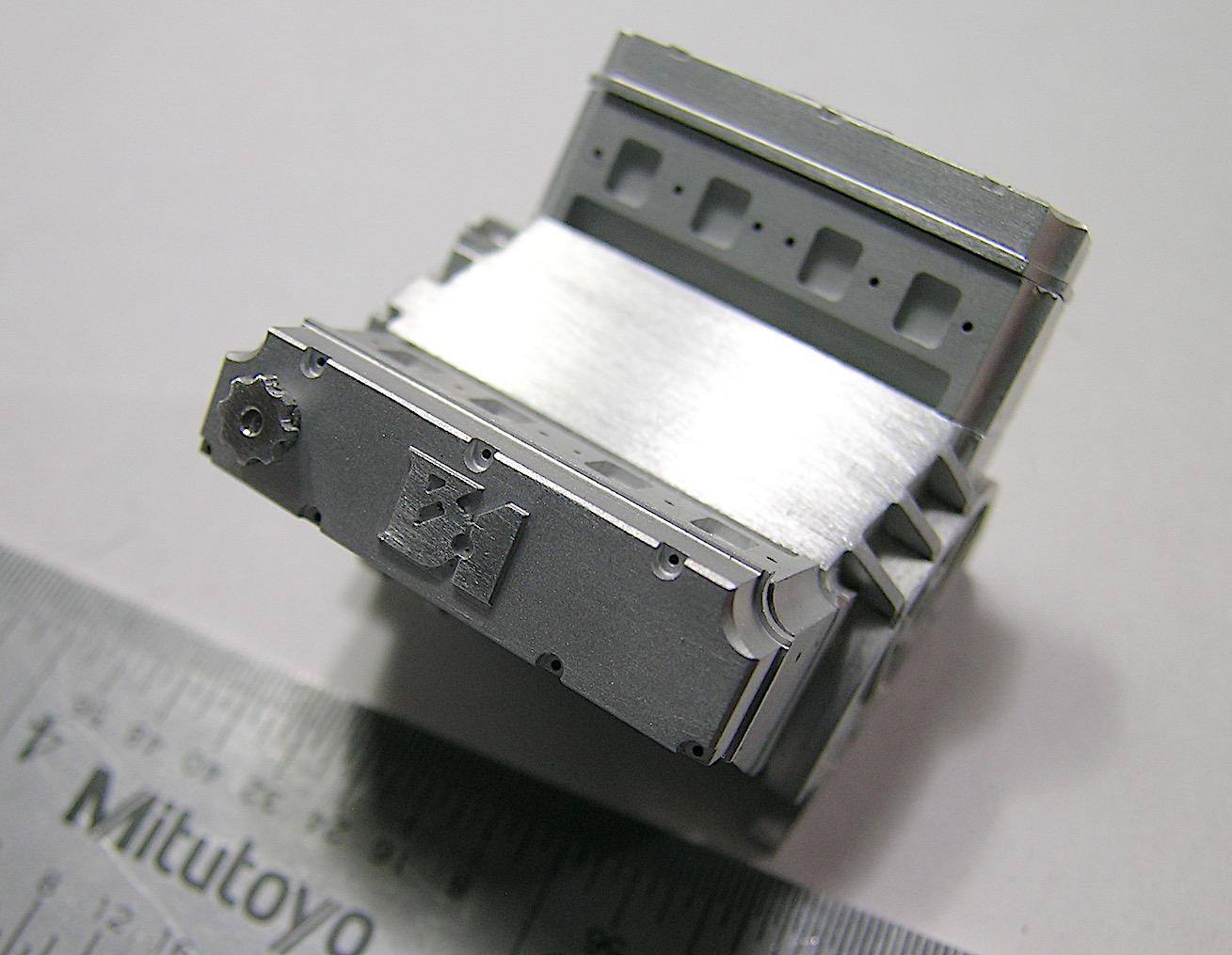

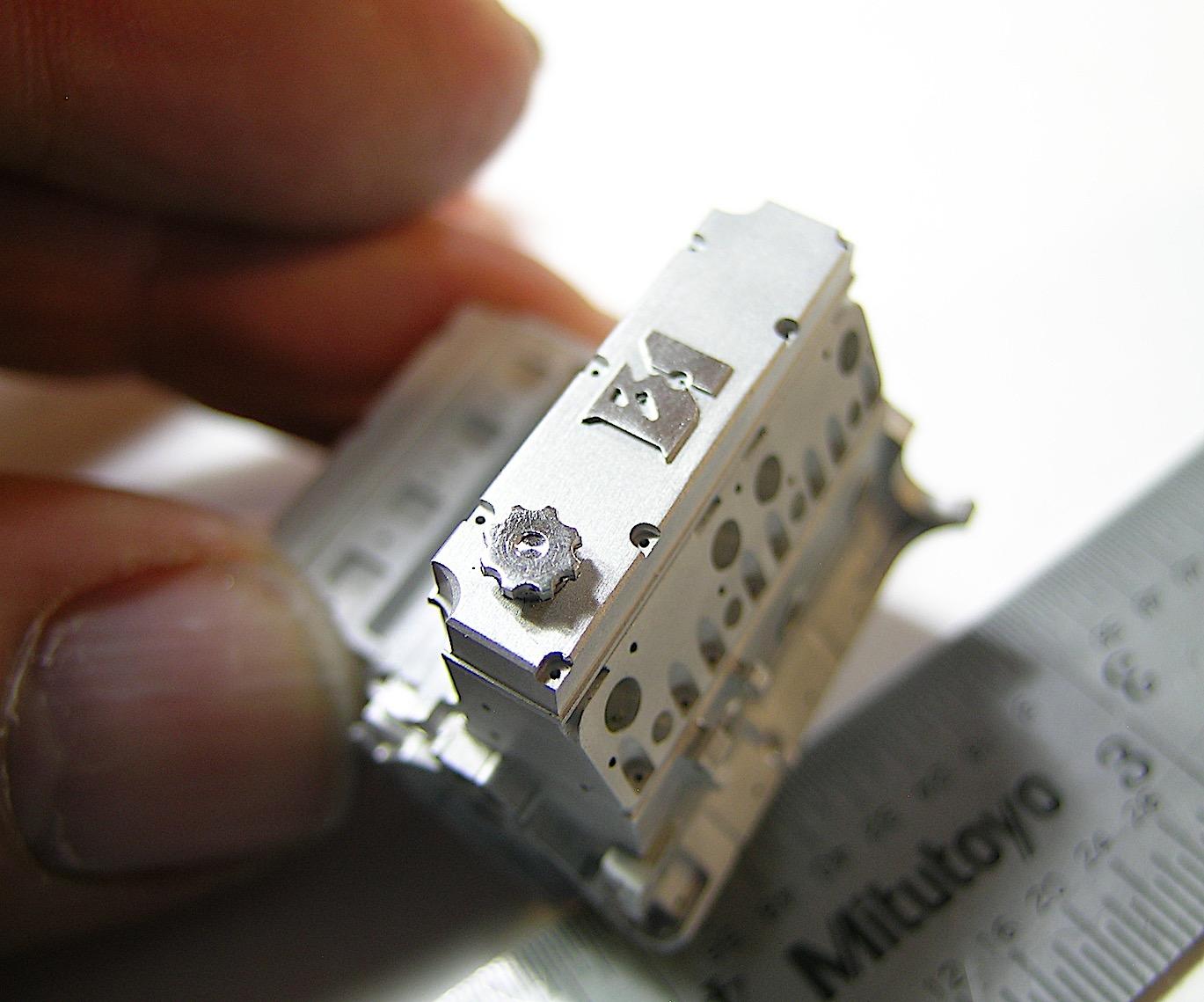

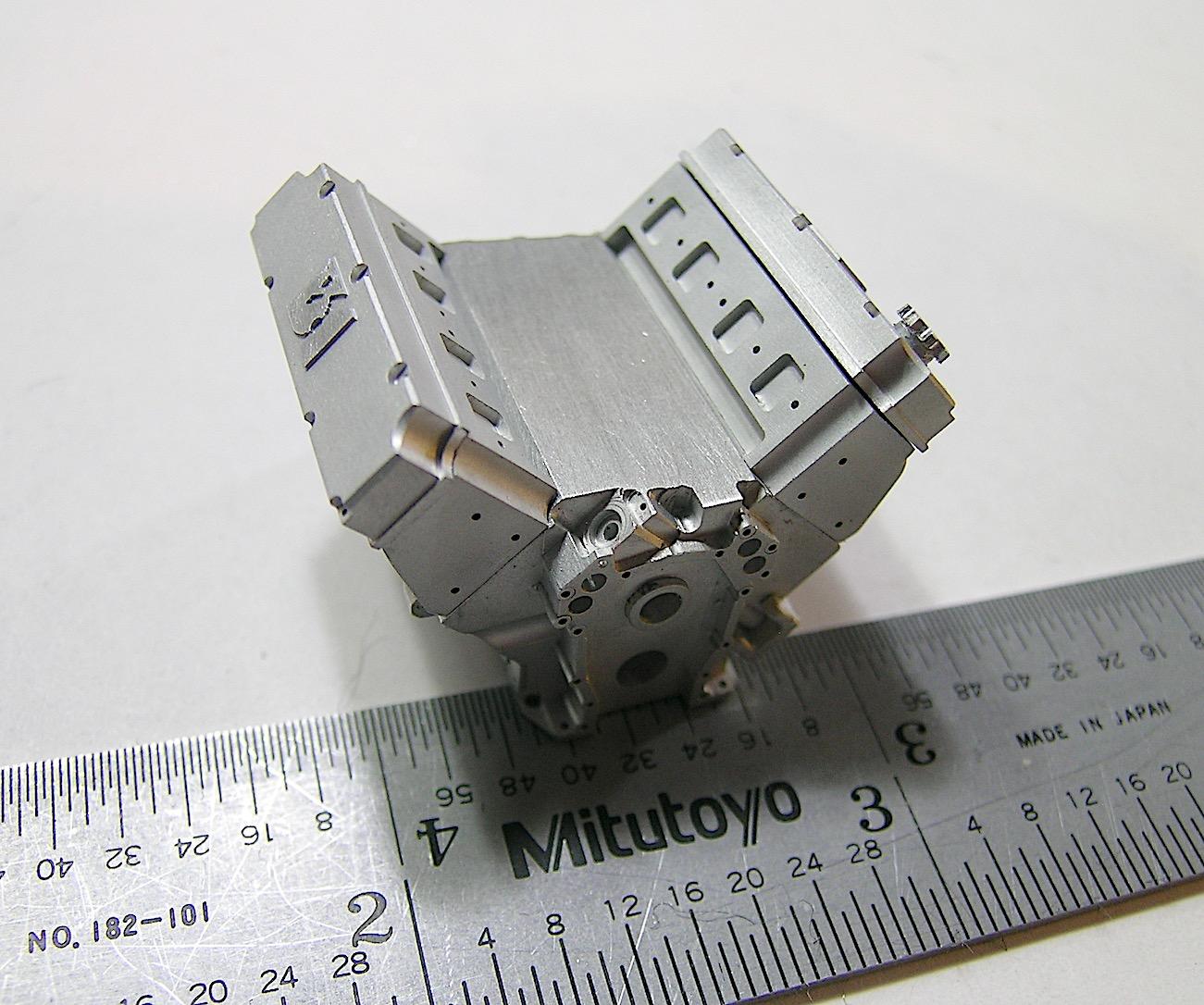

Hello everyone! It is a great moment of pleasure and excitement for me this morning to return with new updates on this project. I feel like my summer break was longer this year than in the past, but my pleasure in returning to my favorite hobby is still the same! To make my latest parts, the valve covers, I was forced to buy new tools and accessories, as if I didn't have enough already... I had planned to engrave the B1 logo like on the original valve covers but I didn't have end mills small enough to do it, my smallest being 0.015". So I bought 0.006" tools, but this kind of ultra-small cutting tool requires very high speed rotation to avoid breaking on the first bite, so I had to get a pulley set from Sherline to be able to push the machine to 10000 RPM. Thanks Tim (Codi), you were right again and I followed your advice, I think I won't regret my purchase. I'm posting the photos without adding any further comments, but feel free to ask if you have any specific questions; I'd be happy to answer them. The only advice I can give you is to buy quality end mills from reputable manufacturers, especially for such small sizes. They are extremely fragile and patience is essential, otherwise they won't last long... I'm happy to be back! Francis The easy part! And the rest! Satisfaction and relief! -

70 Plymouth HEMI GTX 1/25 Scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thank you Robert and Hank, it's a great surprise for me to see this project reappear after 4 years this morning when I logged into the forum and I really appreciate your kind comments! This one has been one of my greatest successes at every exhibition where I entered it in competition; it has brought me many first places and I am very proud of it! I think my last creation, the '64 D100 Pro Street pickup, was superior in terms of complexity, but as they say, beauty is in the eye of the beholder! Some projects age better than others, but my goal is the pleasure of building them, and that's what I felt throughout these projects. Thanks again for bringing back some good memories of these somewhat forgotten builds. Francis -

Fantastic job Mike, what a pleasure to see you back with your magic touch and your natural way of creating with brass, you are an example to follow! Age is just a number and you prove it well, I hope to still have as much drive as you when I reach... that number! 😉

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks for your kind words Mike, I hope to continue to make you smile with my next update; I have the basics done and the tools for the details have just shown up at the post office. I hope to do my first update in months very soon before I forget how to do it! 😔 -

Great work Claude, you really have a natural gift for this kind of racing car, it's always my favorite of your creations, I must have a weakness for speed and muscle! I was immediately surprised to see you in the WIP Drag Racing Models category and I realize it was a simple mistake, but that doesn't take away from the genius and passion that drives you! Perhaps one day we will have the honor of seeing your secret magic happen before our eyes in a WIP thread, who knows? 😊

-

You're so well-organized and prepared, Tim; that's certainly one of the reasons for your excellent results. I'll have to follow your example one of these days; my notes are a pile of unstructured drafts. Calculation is worth the effort, as one of my math teachers once told me!

-

Hello Claude my friend! It's been too long since I've visited the forum in depth and I still have a lot of catching up to do. However, some things haven't changed, like your ability to turn anything into art. Knowing that the basic eelements cost you the exorbitant sum of 5 Canadian dollars, I can simply state that in addition to having crazy talent you have a flair for a good deal. They say that a good cook only needs a few ingredients to make a great dish, you are certainly the Grand Chef of model making and good taste! 👌 Thank you for continuing to amaze me! Francis

-

The body fits like a glove Mike, your excellent work on the chassis is paying off! 👌

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Randy, I'm working on it! 😊 -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Why didn't fate bring you into my life sooner? I guess everything happens for a reason, as the saying goes! Winter gives me a little more time, but my priorities remain the same. I can't wait to see you again, my friend (and our other mutual friends), but I'll have to put in some extra time... in front of my tools... I need to post photos, not just text! I'm waiting for some new, very small cutting tools to complete the next step; I feel I'll have other purchases to make, it's a process that unfortunately doesn't seem to want to end! Francis -

I have to say that I've been struck by the same illness... 😁 Your last statement only adds to the merit of your project; the machine alone does nothing more than what the hand and imagination can do! You clearly have talent and dexterity, sir! 👌 I'm coming on the trip!

-

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thank you for your kind words, gentlemen! As you have read in my recent post, I am back on this project after a far too long summer and autumn break. HankinWisconsin: There's still a lot to do, check back from time to time for more of the crazy things that make this project seem endless... I am easily influenced and there are some little magicians on this forum (who recognize themselves...😉) who push me to try to do better and better, it doesn't look good for the future! I see that I have the honor of your first post, so thank you again and welcome to the forum, don't hesitate if you have any questions or suggestions! Ian: Thank you for your continued support and expertise in the world of drag racing, and your positive feedback makes me think that I make fewer mistakes and that my parts are more realistic over time. Francis -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thanks Tim, I really appreciate your comments and your invaluable source of motivation! However, I think there are several Santas on the forum, and your license seems to be in good order. I'm really looking forward to seeing the new gifts you have in store for us, my friend! 🎅 -

’72 Dodge Demon Drag Racer 1/25 scale

AmericanMuscleFan replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hopefully soon Daniel, I've ordered some very small cutting tools for the next step, I'm putting pressure on myself... As if I wasn't slow enough, I'm hooked on your project and the time I spend marveling at it reduces the time I have available for my own. I'm going to have to concentrate! Thanks Pierre, Is it a trend for modelers north of the border to take long breaks? Ultimately, I don't think so, or perhaps our friend Claude is the exception that proves the rule! 😉 I started with a good dusting, I'll get back to it very soon! Thanks Rich, I've been thinking about the next step since I closed shop at the end of spring, it's time to make what I had in mind a reality. -

Great job Ian awesome build, It seems to me that we have enough of a challenge in this hobby without the postal service getting involved! There's a French expression that says: Everything comes to those who wait! I don't know if it translates word for word, but I imagine you see what I mean! 😉

- 75 replies

-

- 3d printed

- scratch built

-

(and 2 more)

Tagged with:

-

Maserati A6GCS Spyder

AmericanMuscleFan replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

No, still on the ground, good news for the northern model car builders! 😁 Playing with paint is what I like the least, I think you're doing rather well, my dear! -

Maserati A6GCS Spyder

AmericanMuscleFan replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

I've noticed you have some nice toys too, Andrew... and you know how to make the most of them, from what I can see! However, talent can't be bought, but it seems that nature has blessed you! It's motivating to work on a Maserati, isn't it! 😉