-

Posts

416 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by charlie libby

-

Tim your work always makes me jealous. But i always learn from you.radiator is just awesome.

-

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

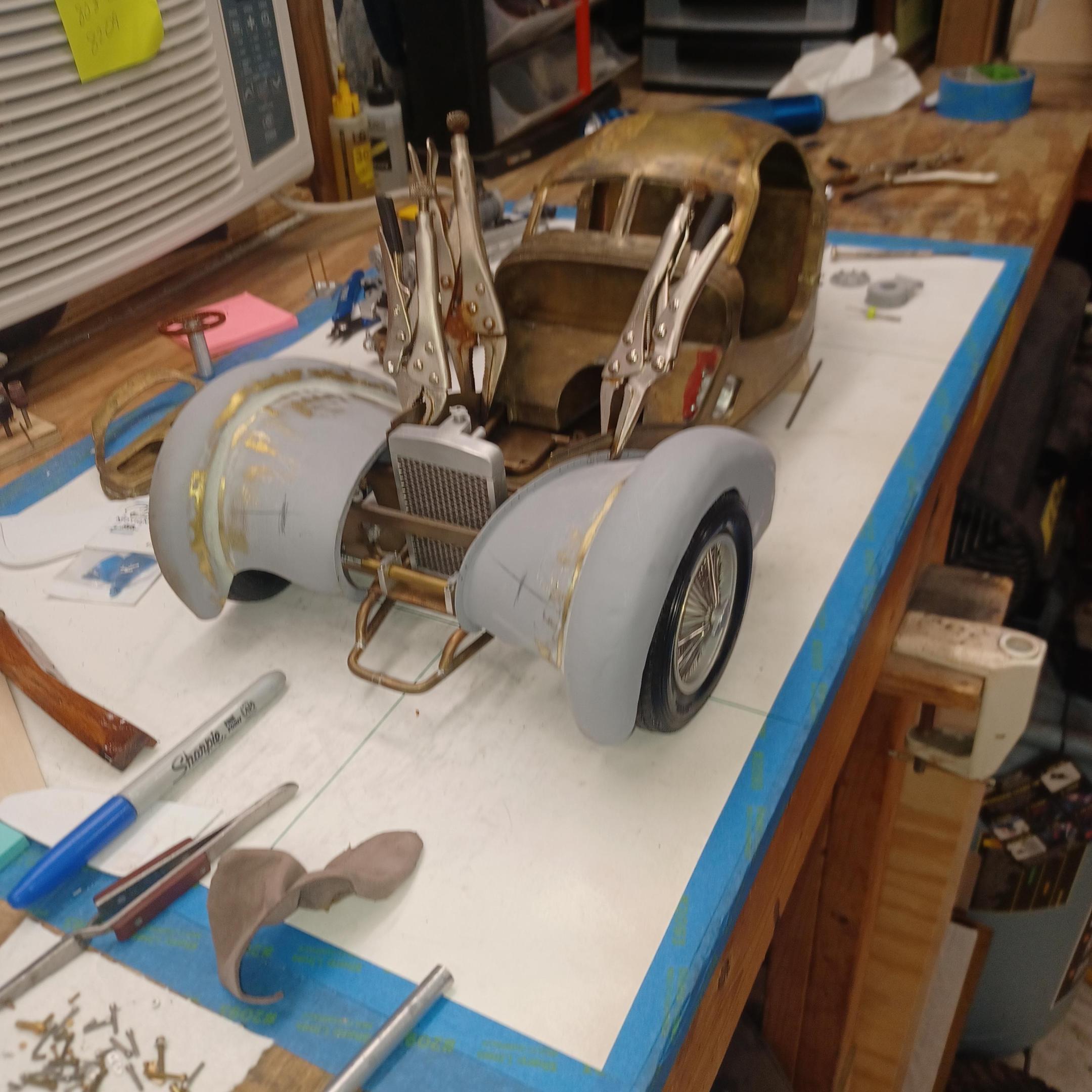

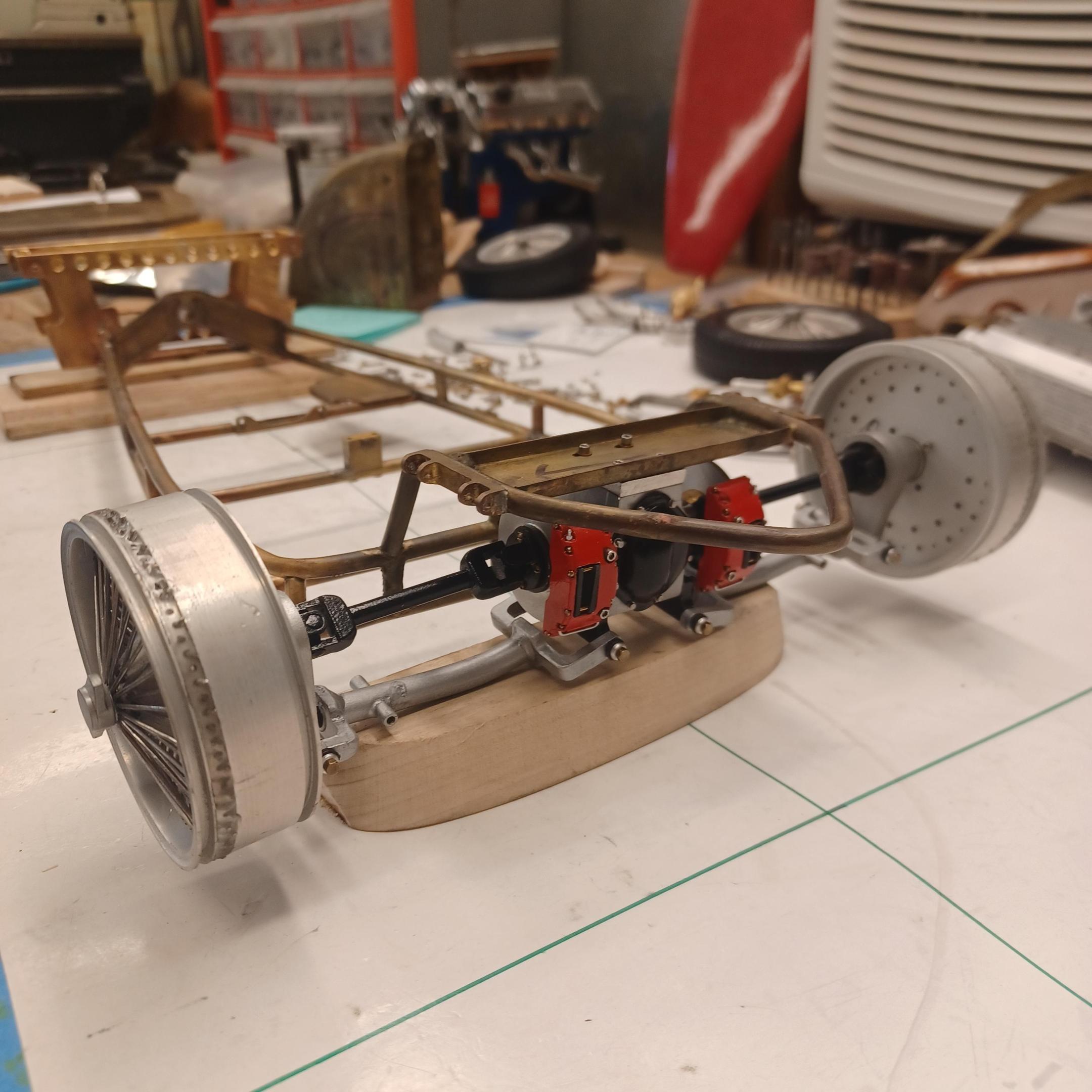

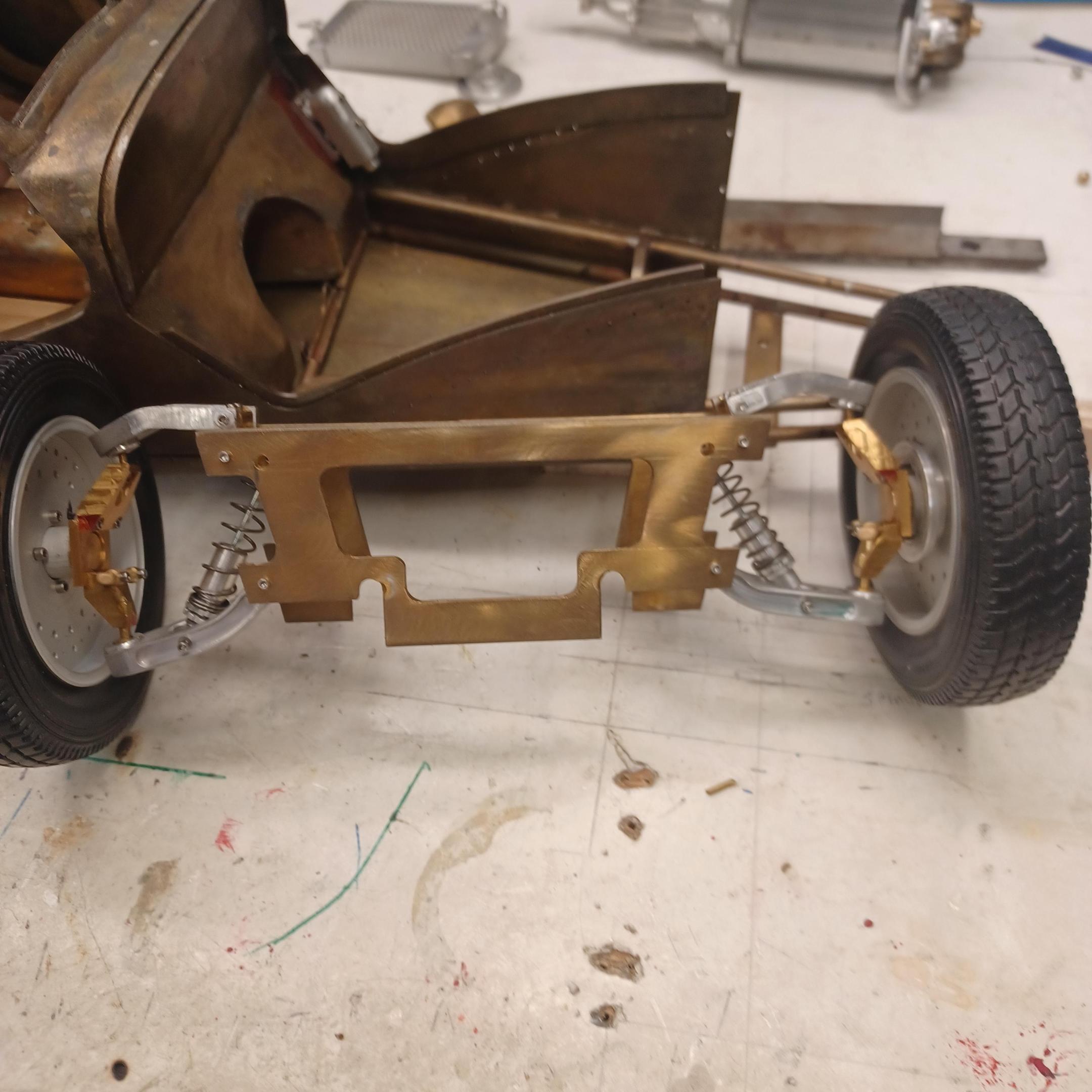

hi francis so glad to hear from you. bill glad you stopped in. hi pierre good to hear from you again. helmut thank you for the kind words. i have worked some on the interior , wood on the doors line up with the dash. the leather is very thin book binding leather which was a suggest from one of you guys on my last car. the front suspension and front crossmember are getting close . some finish work to do,sand and file. i lined up the front fenders and clamped them to make sure the front suspension is where it needs to be before soldering the crossmember in place. getting the rearend ready to temporarily install and do the same. the rear bolts in and its been in before but not with the fenders installed i dont think. maybe next week i can sandblast the body and get it in primer.to many things left to do. thanks again for your comments they are greatly appreciated. -

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

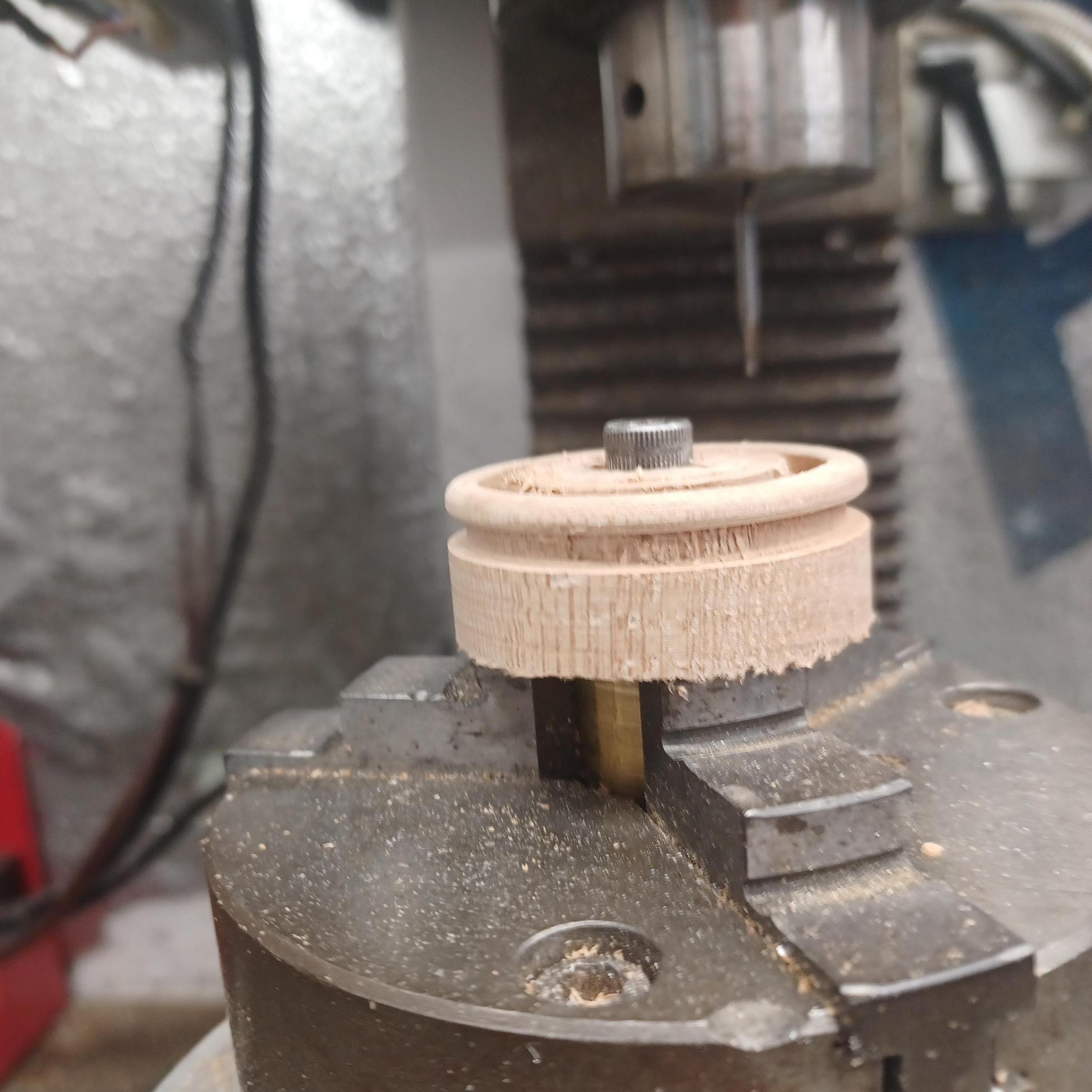

hi tim your maverick is looking great. hi mark thanks for your comments. hi bruce, nice to hear from you, your paint and your wheels look great. been put the edge around the window and doors .not sure the doors is what i want ,ill stare at it for awhile. started on the interior while i contemplate he doors . i now have the leather and am working on the wood trim and dash. the paint will be a tan body and navy blue fenders so i went with blue leather for the upholstery. hope it looks good. when i made the small trim for the center where the clock will be .drew it out on the mill so that i had something to go by. i have to put all the rivets in the wheel and stain it to match the dash. first i have to cut the finger grooves in the wheel , I'm a little nervous about that step. i did it on a practice piece but it di not have the brass in the middle. again nice to hear from you all. has anybody heard from francis? -

1/12 tamiya RA 273

charlie libby replied to Brudda's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Looks great.you do this for fun it doesnt have to acurate .thats why i build things that have never been built. Your talent shows in the finish. Keep up the nice work. -

gravity is not only a law its a good idea.

- 599 replies

-

- open wheel

- jim clark

-

(and 1 more)

Tagged with:

-

looking great .nice to see you back at it. tim you can use my mini bead roller if you would like.

-

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

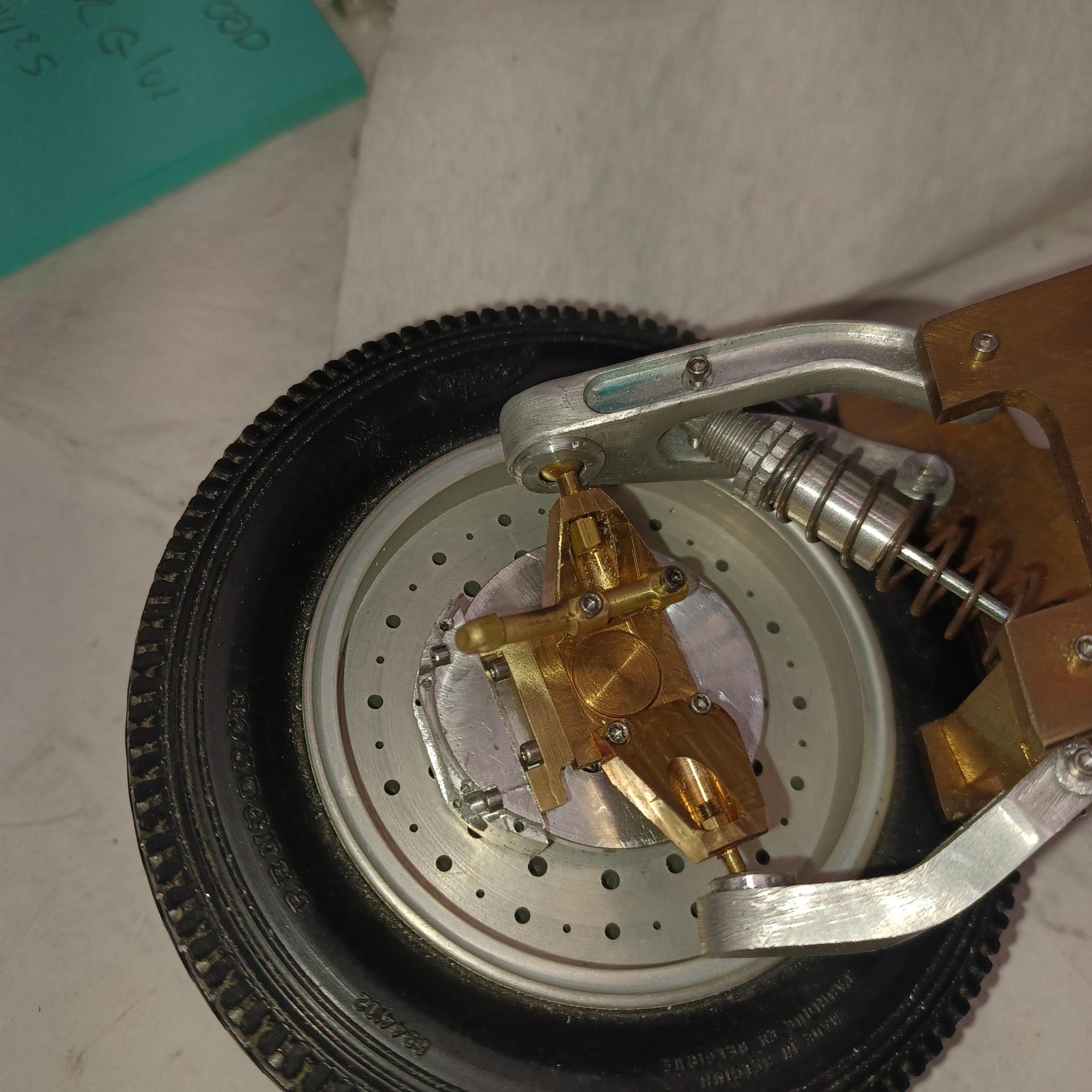

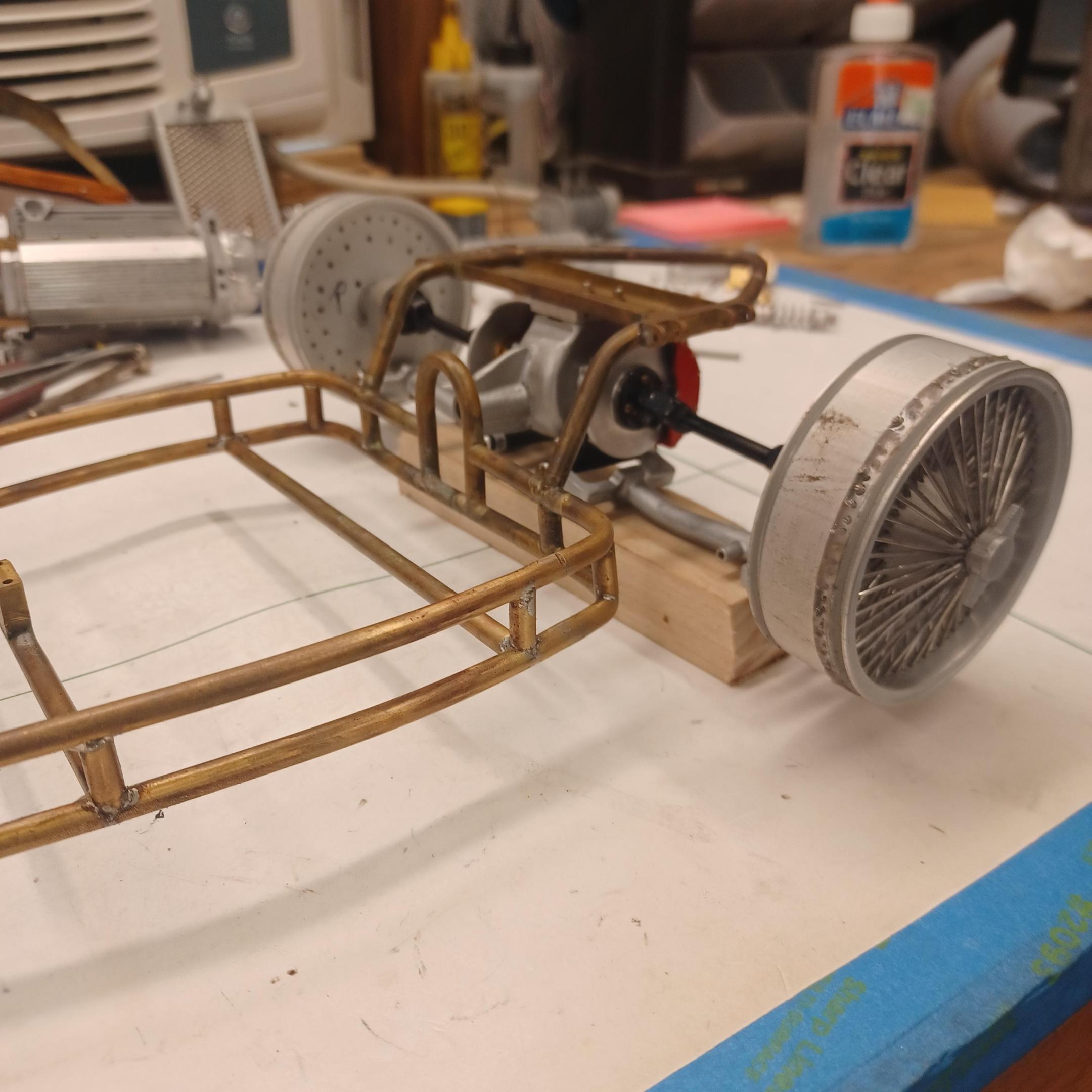

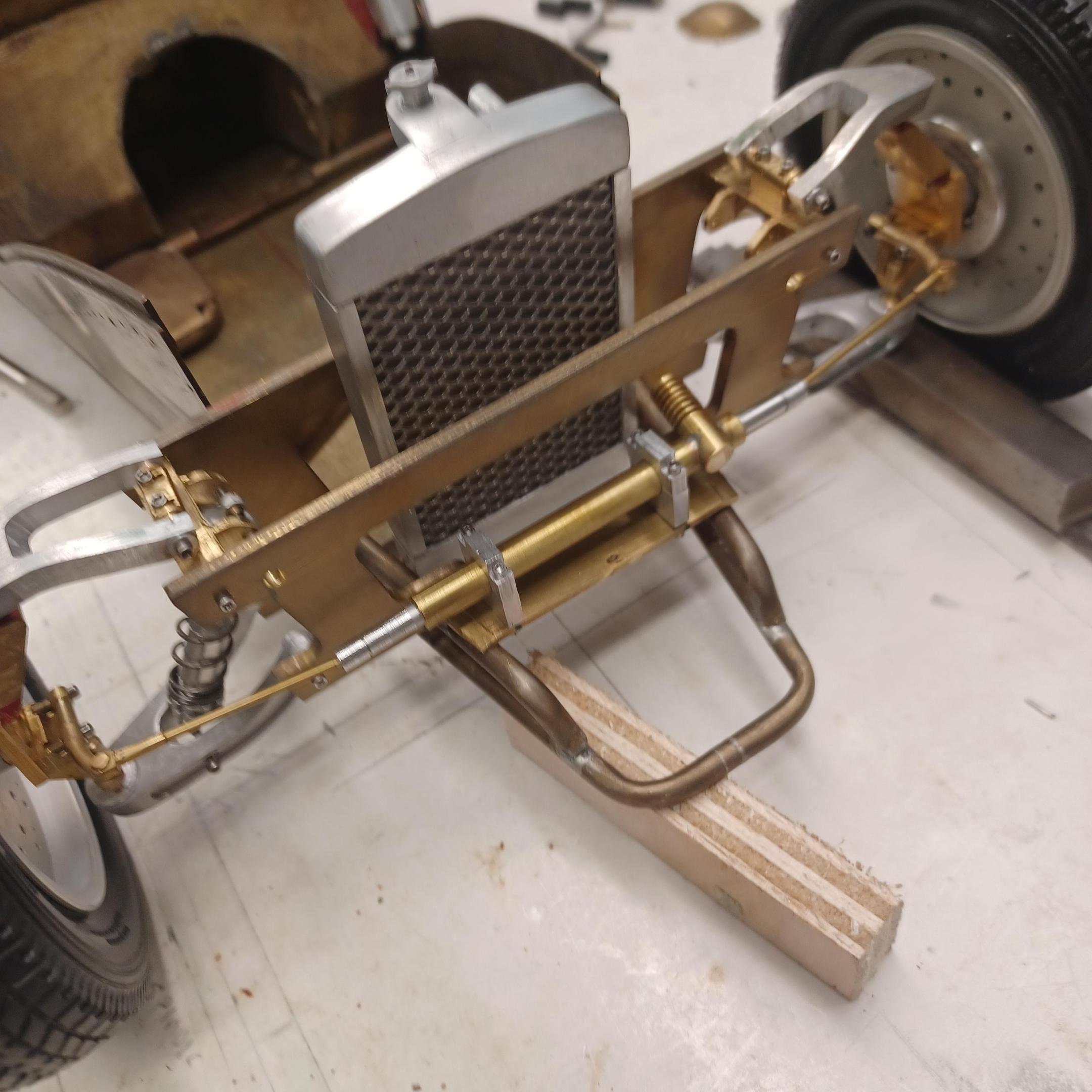

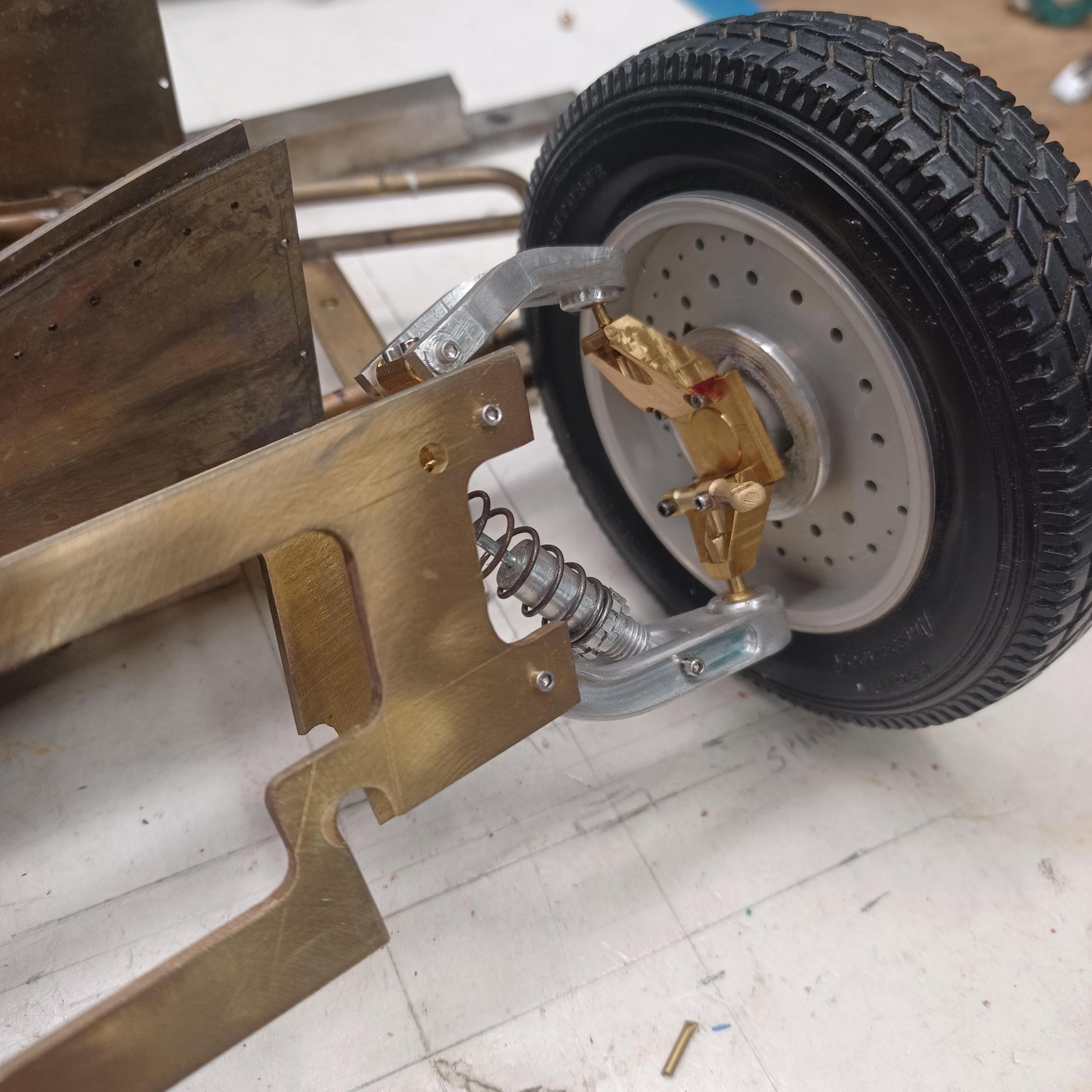

hi noel , thanks for your input. 3d printing is a great way to model if you are tech. minded. my mind doesn't go that way, im not tech minded . glad to hear from you mark . pierre thanks for coming back . andrew you will see by the pictures i am going the other direction ,3 piece wheel and nickel plated brass . got a few pictures of the front suspension . i believe it will look and work well with the rear suspension . the steering wheel is looking good. i made the wood piece from maple but i got some red oak to try tomorrow.to see if it cuts cleaner. did some research on the wood hardener andrew. most say it won't soak into good wood only rotted wood. still alot of finish work to do on the front end parts. temporarily mounted the front fenders to locate the head lites. thanks for looking -

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hi francis,that rear is so nice. I hope to get to your level.my next car is 1/16 scale,we will be looking at your car alot for insperation and technique.hope you are doing well. -

Your fabrication gets better everytime i look

- 599 replies

-

- open wheel

- jim clark

-

(and 1 more)

Tagged with:

-

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

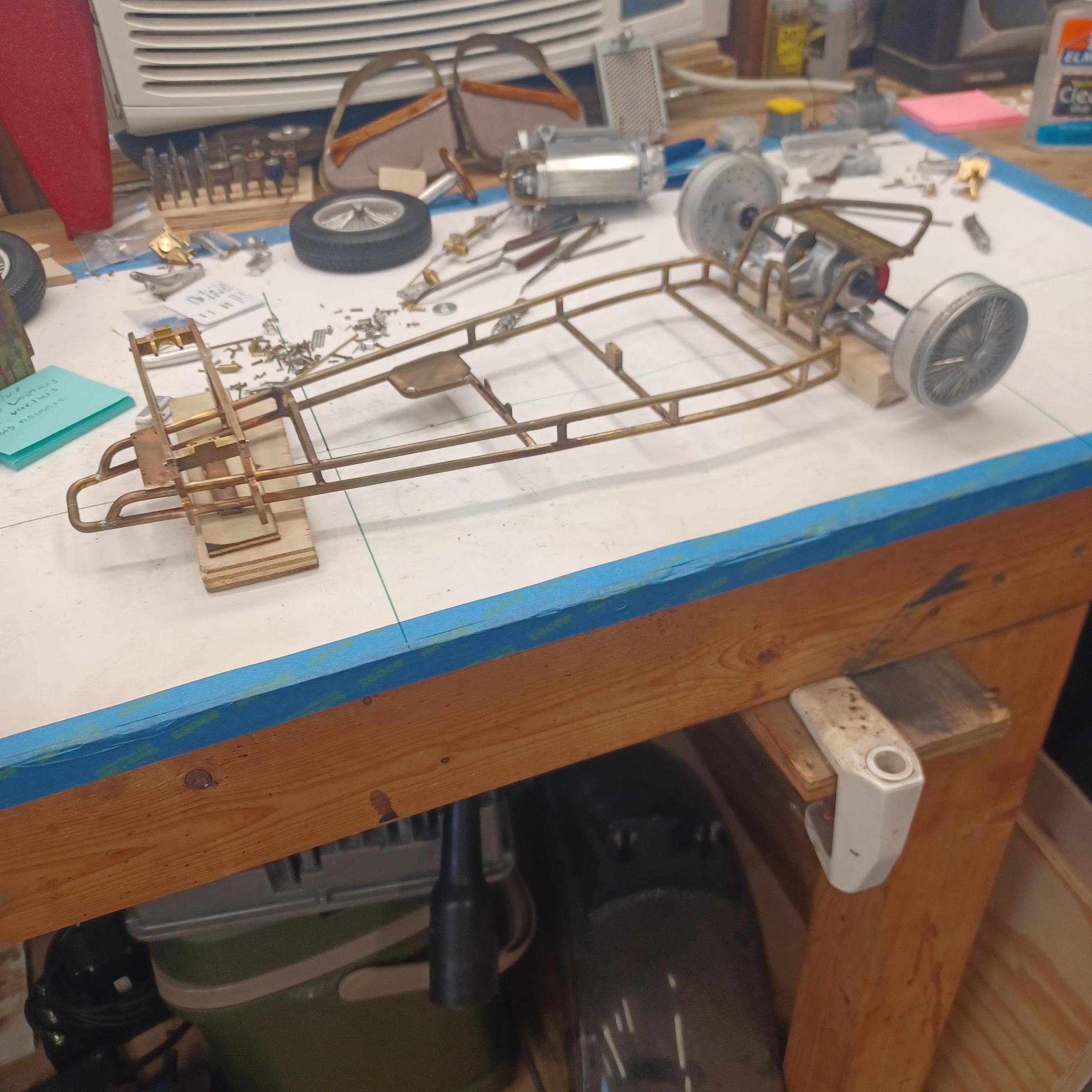

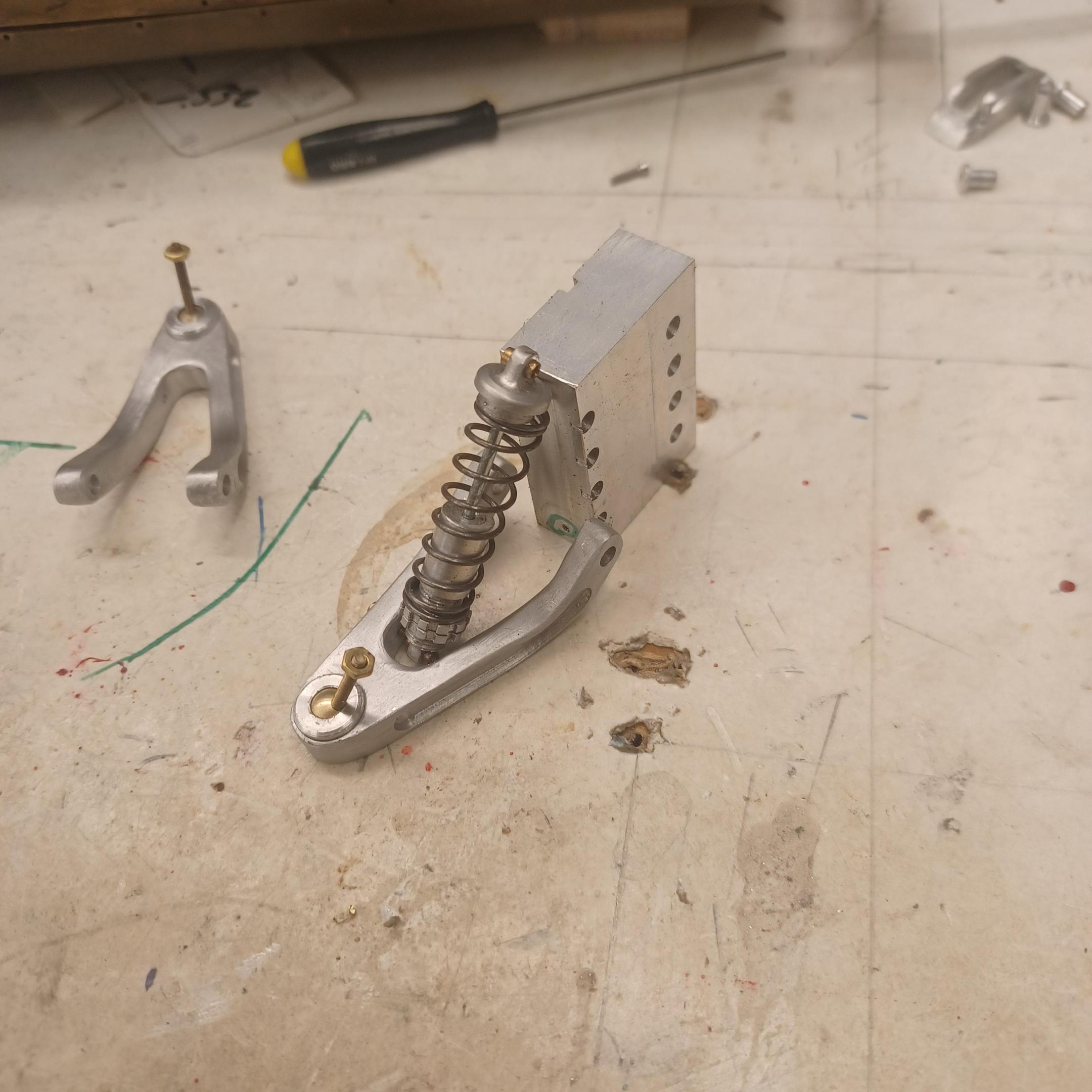

hi everybody ,thanks for looking ken great to hear from you. thanks for the comments bruce. nice to hear from you tim hope you are doing well. have been out of town to the great state of maine. relatives put a 50 th wedding anniversary celebration together for us and we had a really good time.back to my project again. i have been putting off the front suspension because i didn't know which way i wanted to go. finally made up my mind but its going to be difficult ,but i have started. not sure how it will end up but i have what i think i have some good ideas . the nose and front fenders are in the way. but we shall see. i have the lower arms and ball joint parts made. i made the shifter and the the floor location. andrew i am looking forward to the model car contest in a few weeks. never been to one. this will be a busy month. i am also a voting poll deputy sheriff and i will be busy with that allot thru august as well. thank you all -

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

you continue to get better everyday.gives us something to strive for -

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

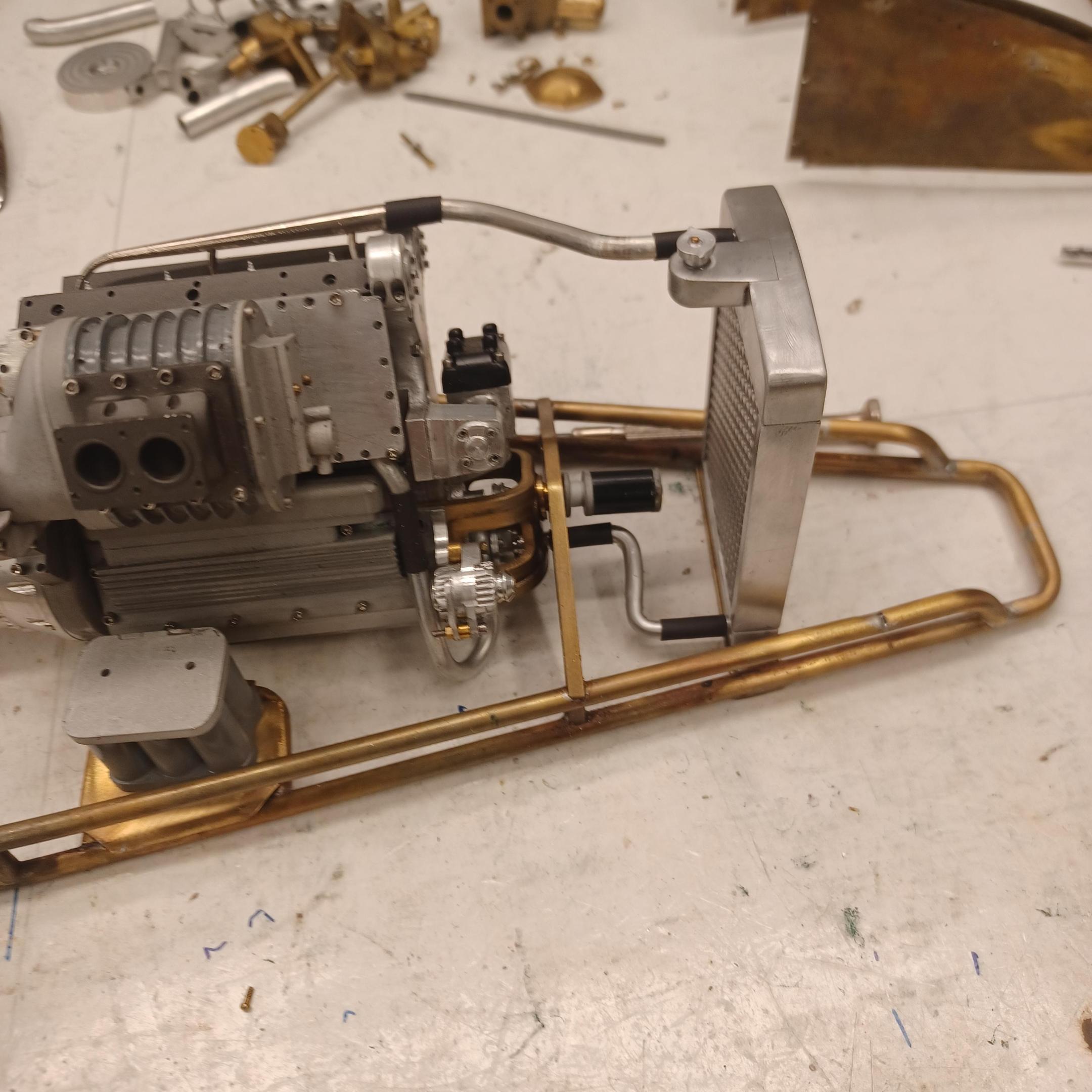

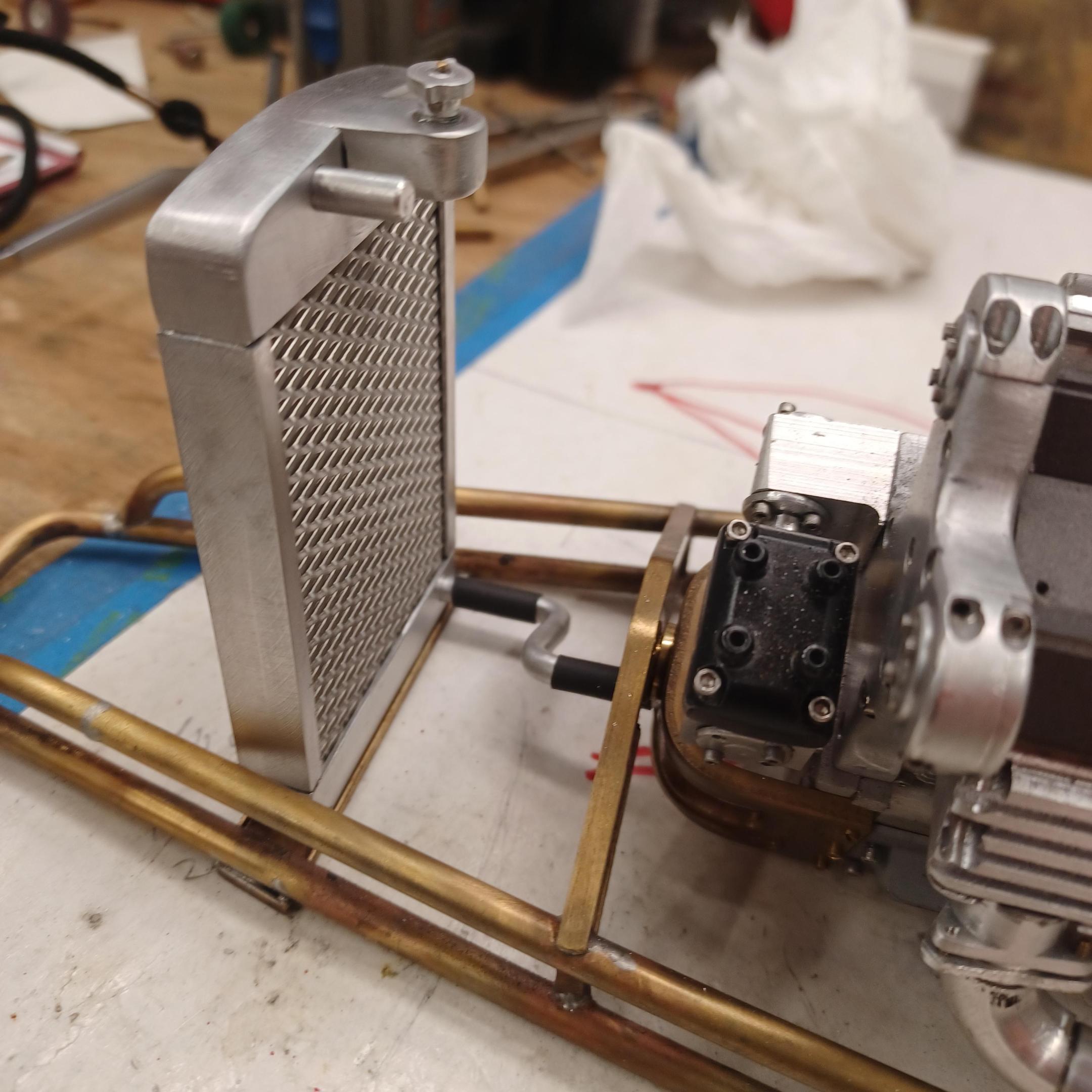

been out of touch for awhile. i have been renovating a bathroom for 2 weeks. finally its done.got back to the shop and made a few more parts. andrew ,look at what i added in the window of my shop! soooo nice. got the wires in the other 2 wheels and made the center nuts. working on the optima battery almost done .radiator is almost done . made the screen and trim for the nose. andrew are you going to the show in august. this will be my first model show. can you bring more than 1 car? looking forward to it. grill trim in brass, after plating and after polishing. alternator is mounted and needs a little finish work.i made an exhaust manifold instead of header.thanks for the cool pictures andrew -

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

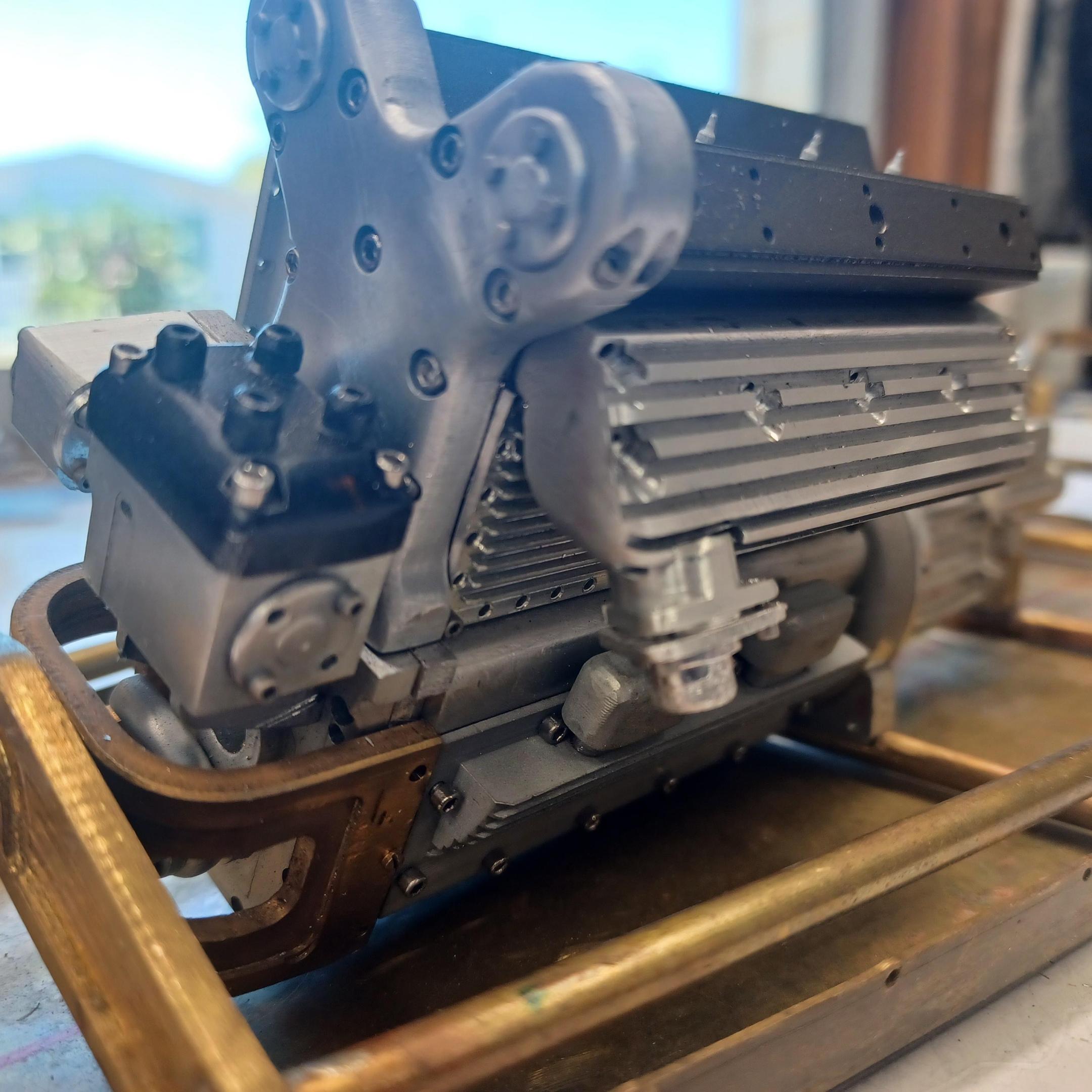

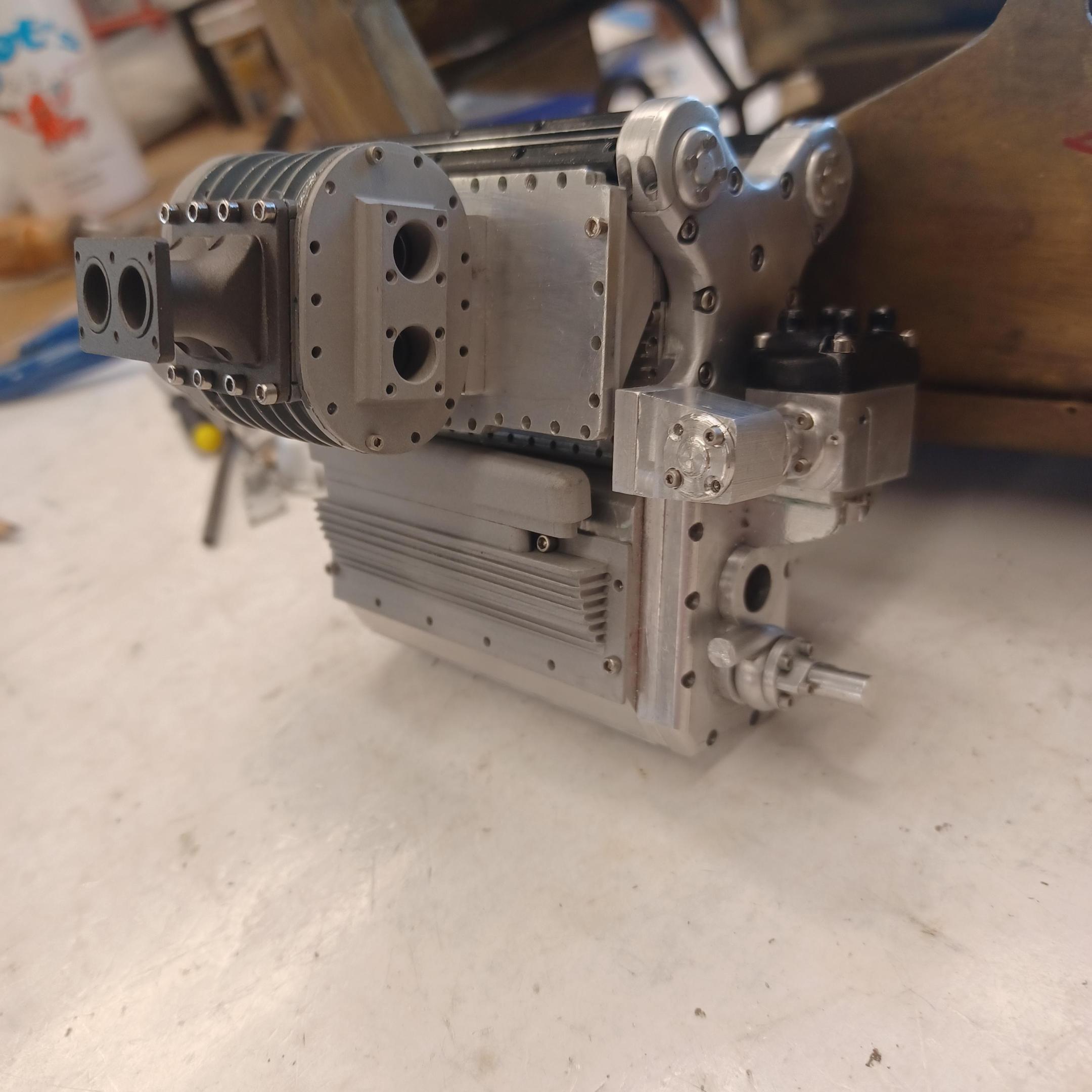

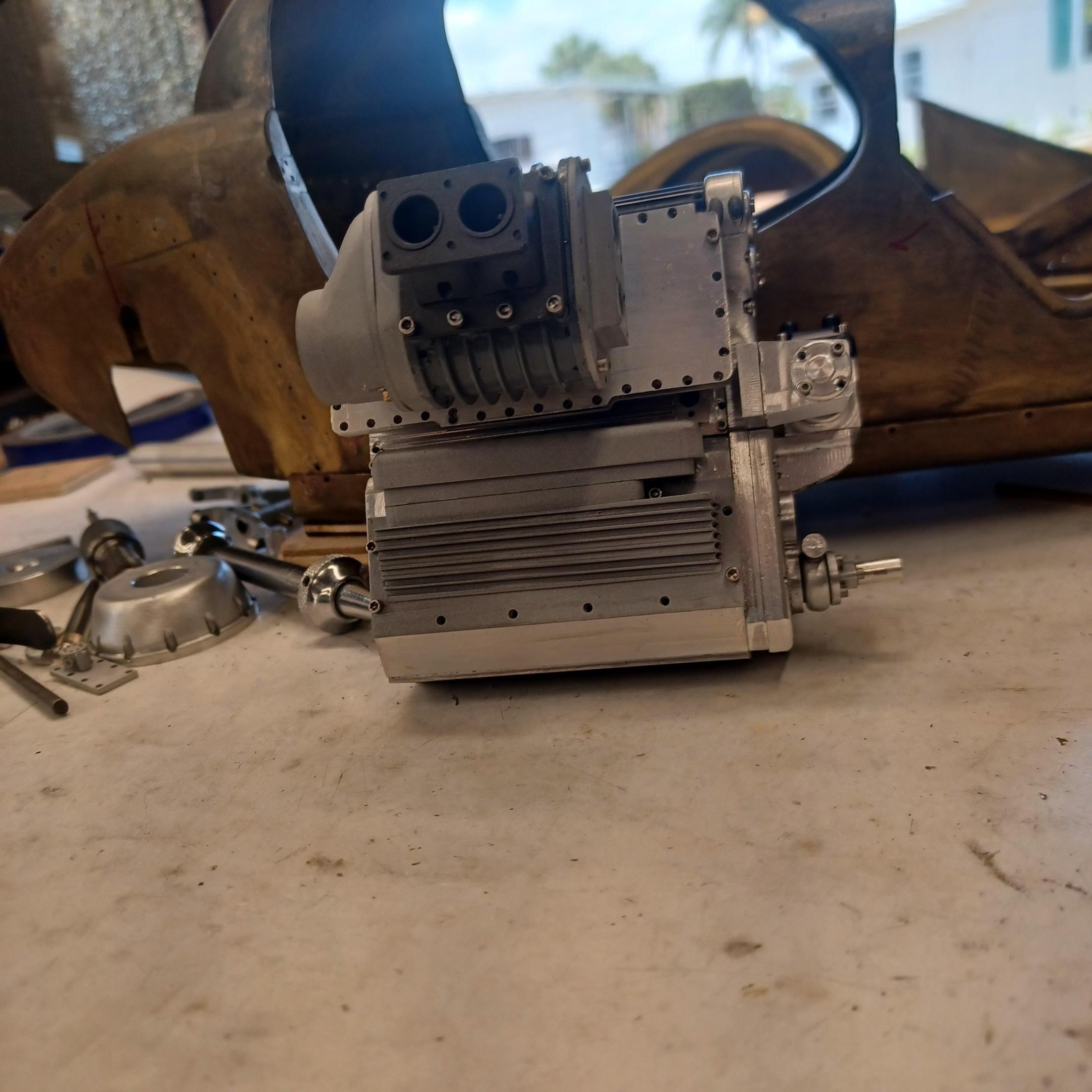

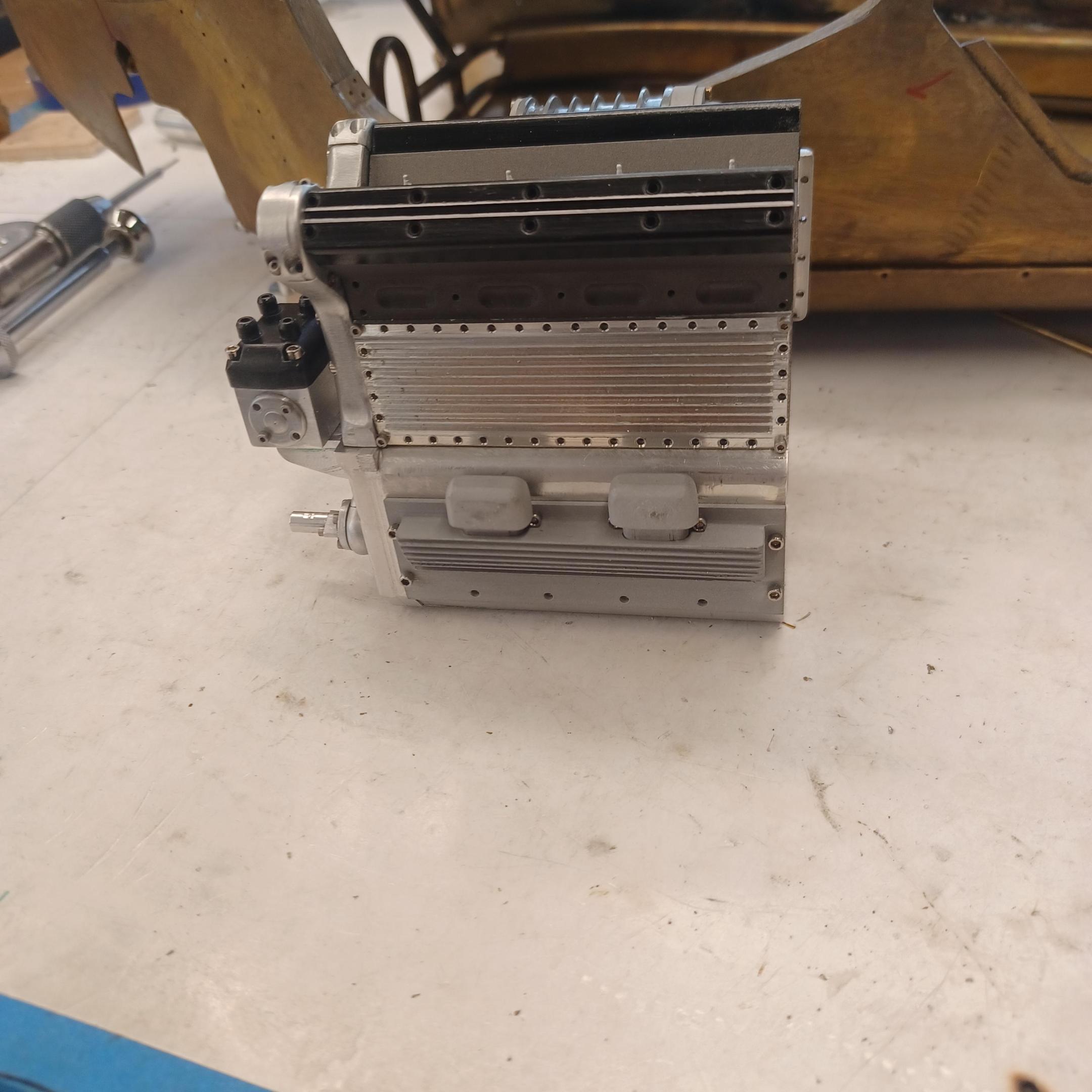

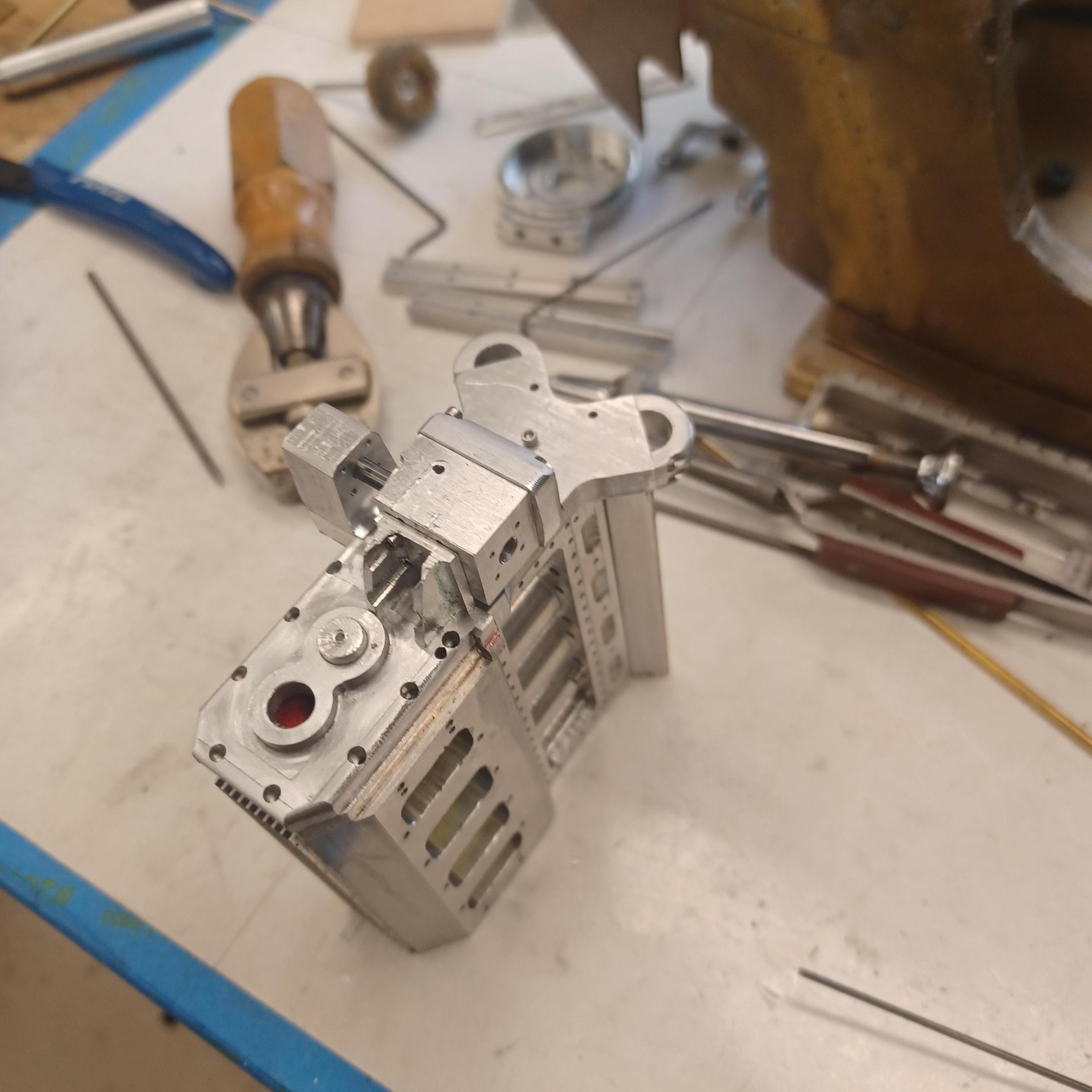

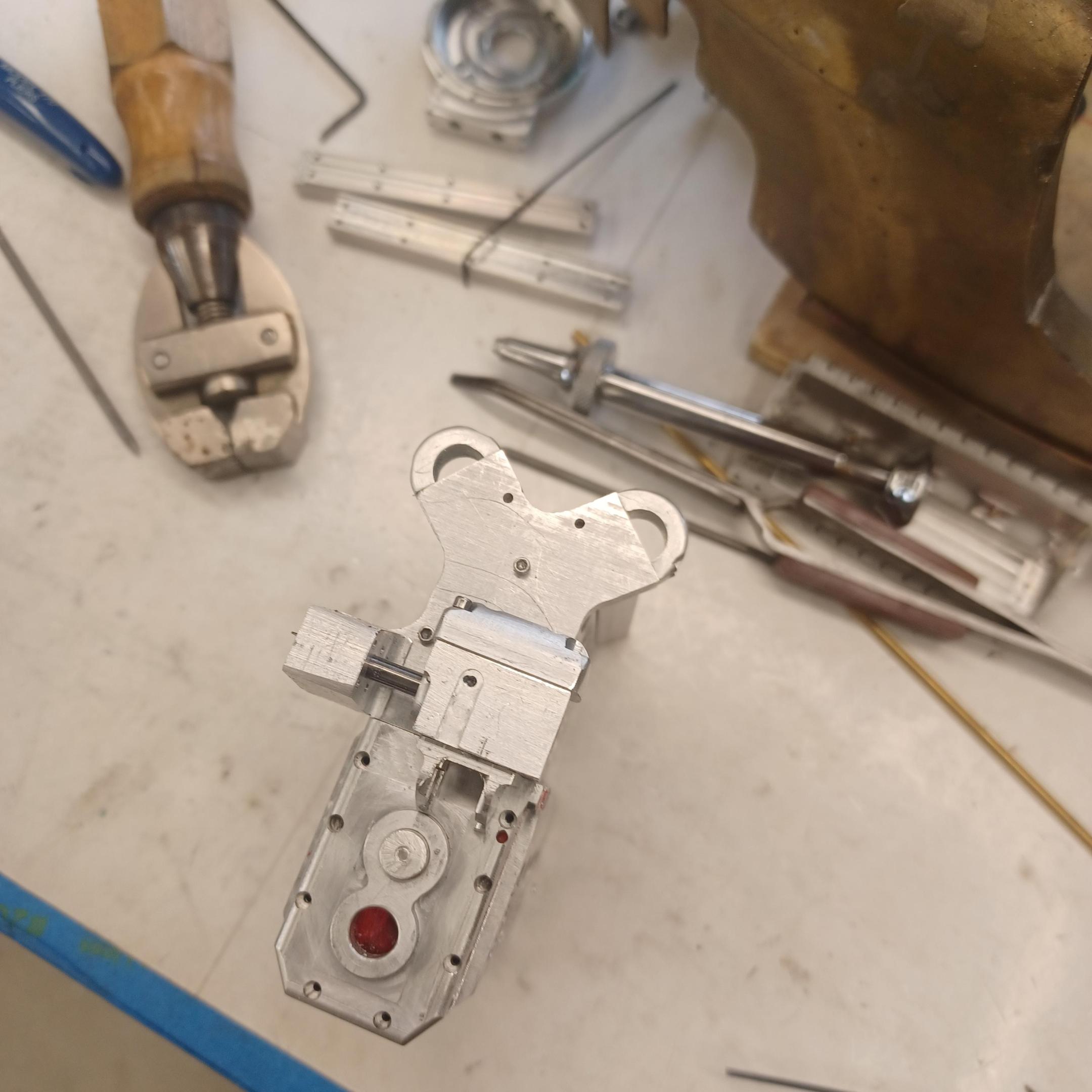

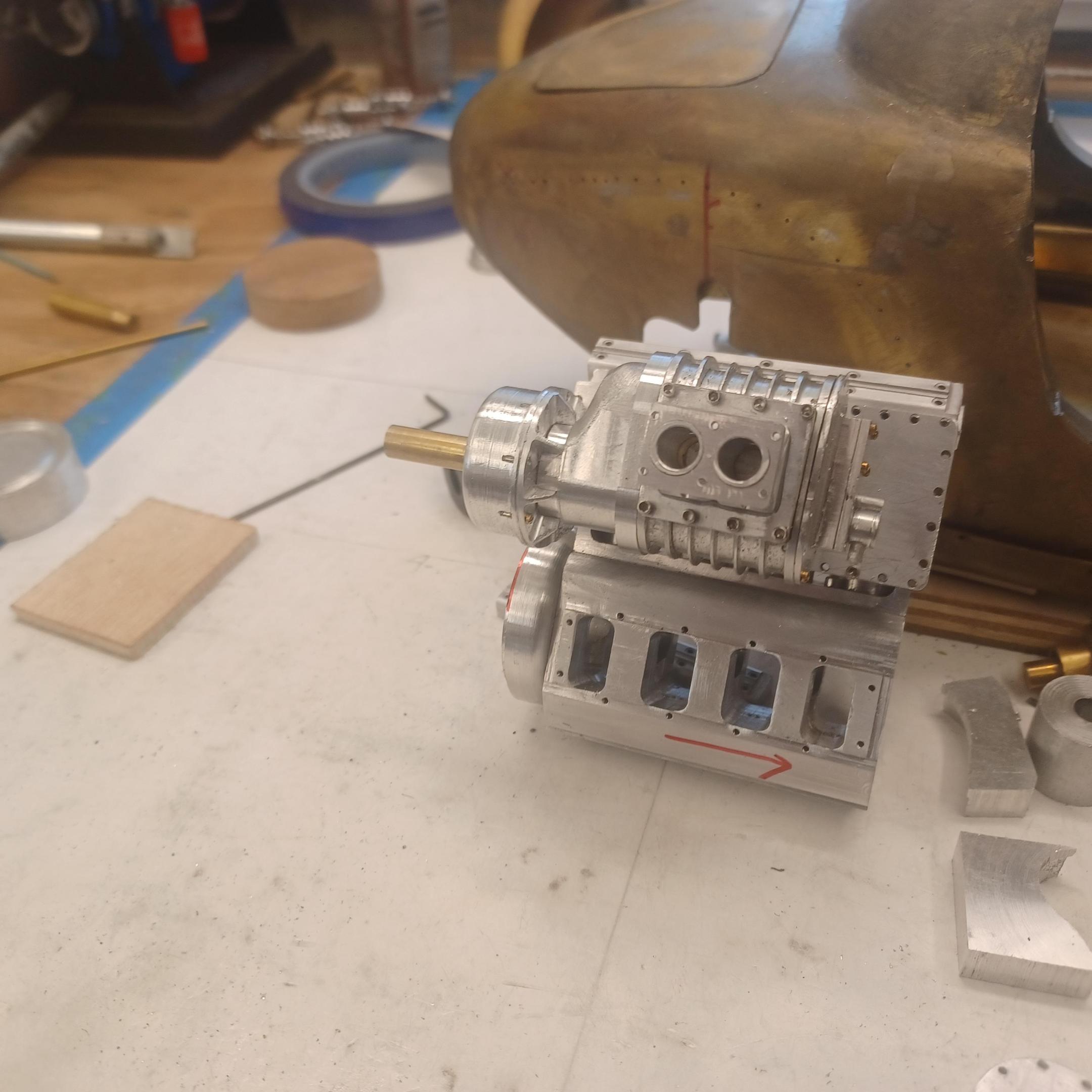

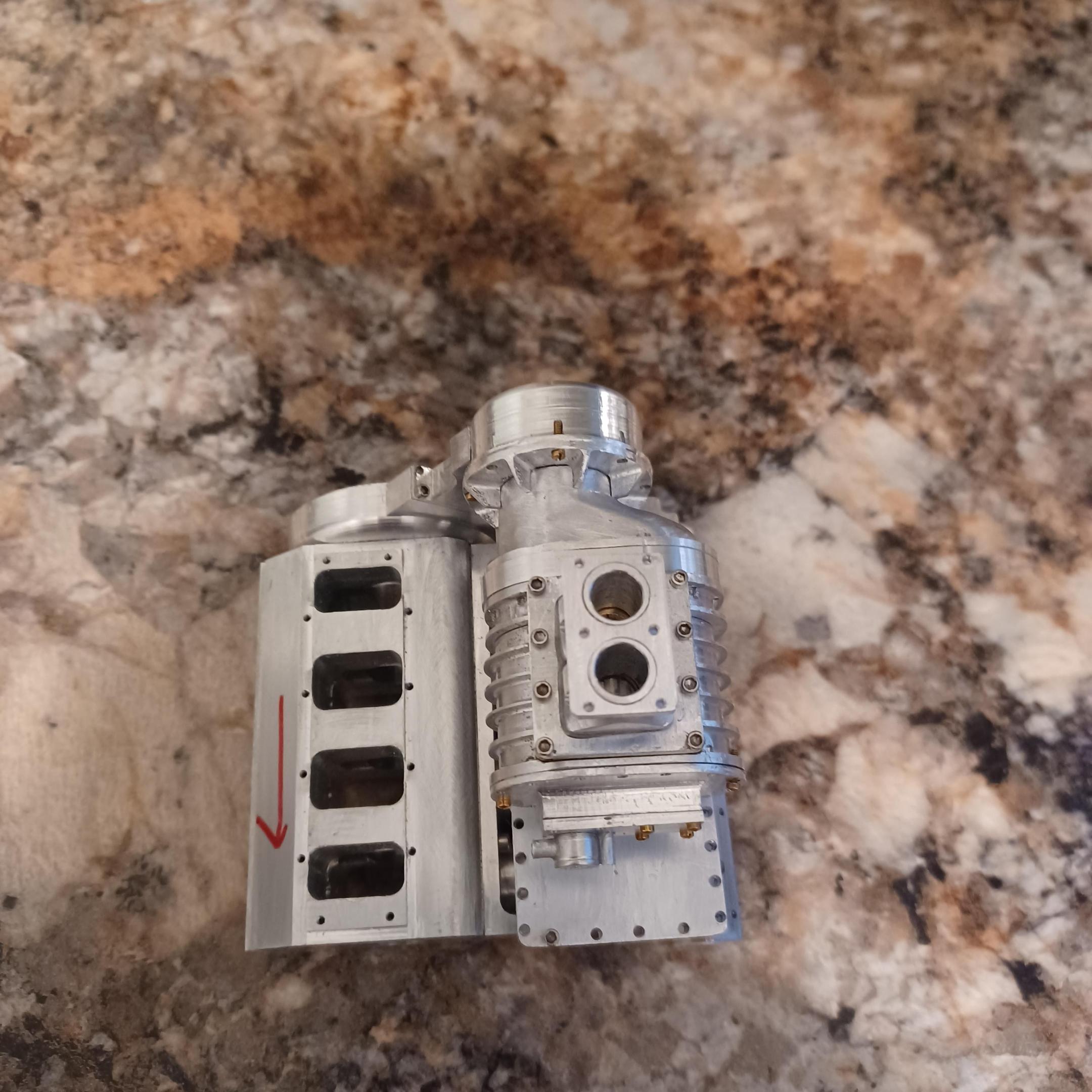

hi ken,many places, fastener express, ebay, model motorcars, minitaps .com, i am constantly looking. andrew, still good till about 2;30. hi noel,going to do the novi i 1/16 scale and put in in some crazy. it will be fun and different. working on the tranmissiom. its done except a little detail work. got the engine and transmission mounted and did the floor and firewalls. got the seats and some interior panels made. then i kept looking at the picture and just had to do the exhaust. making things fit is alot more difficult than just drawing the picture. alot of things get in the way of other things. here is the floor and the exhaust. i am going to make a finned aluminum exhaust manifold and a split the pipe ro go into the the dual pipes. -

T41 Bugatti sport coupe

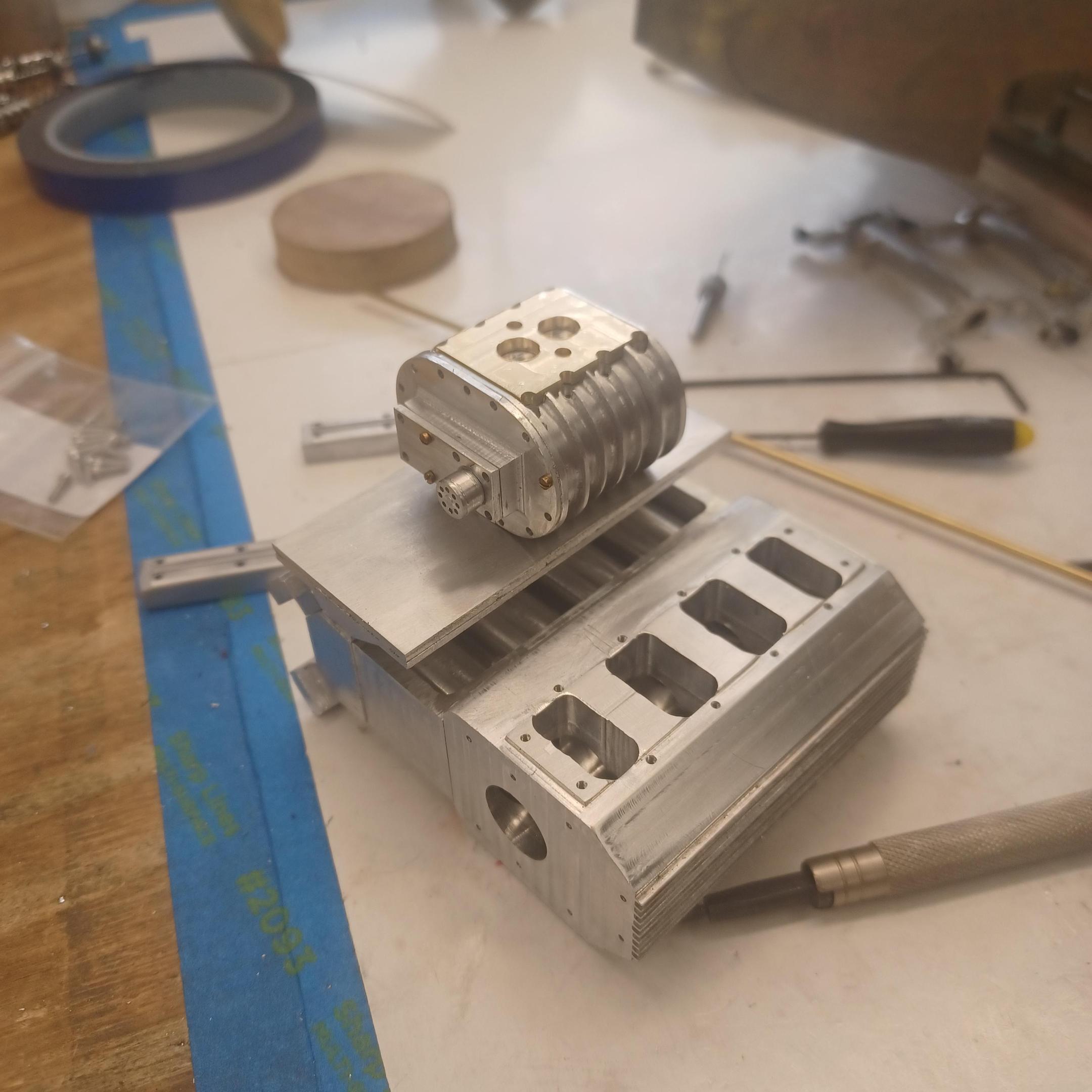

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

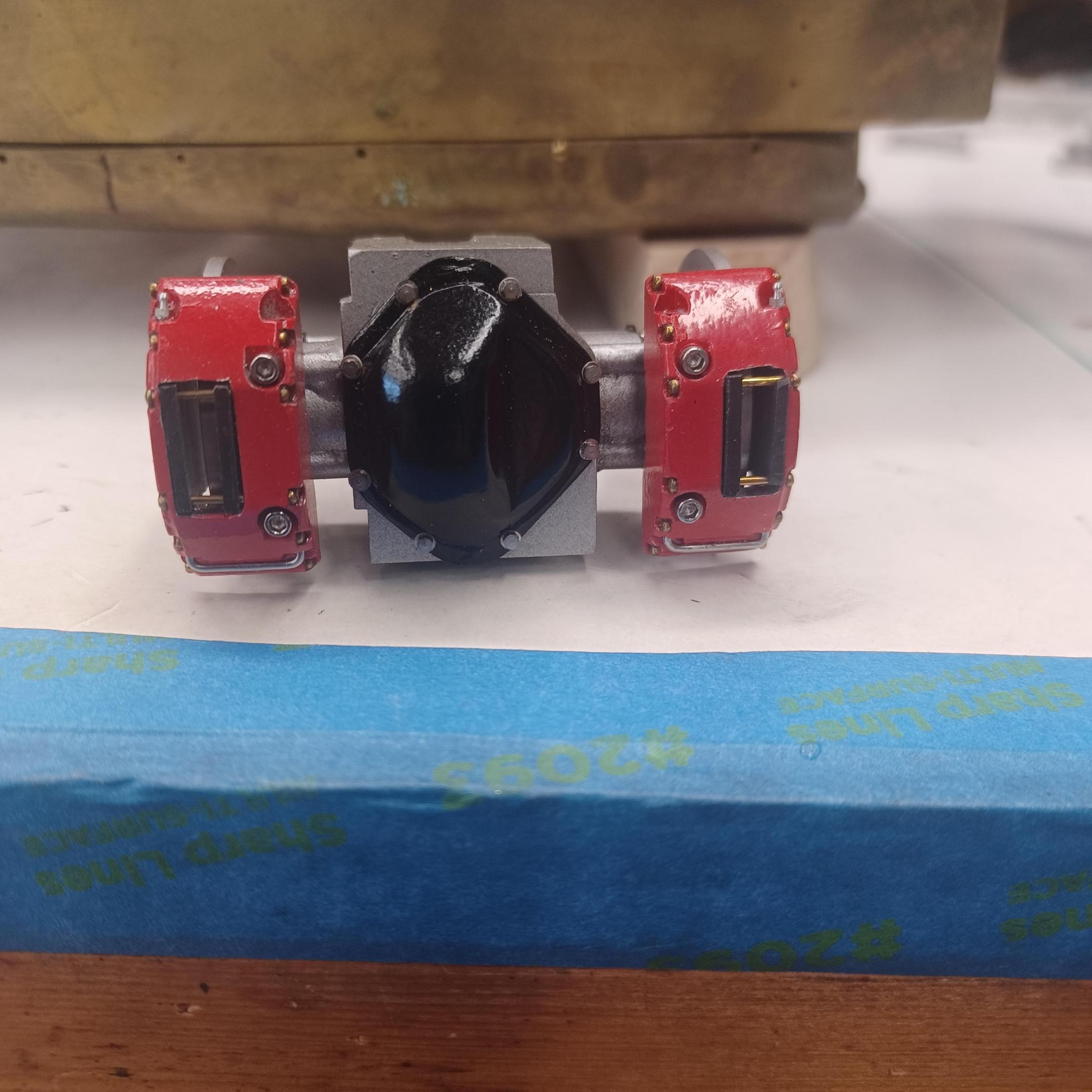

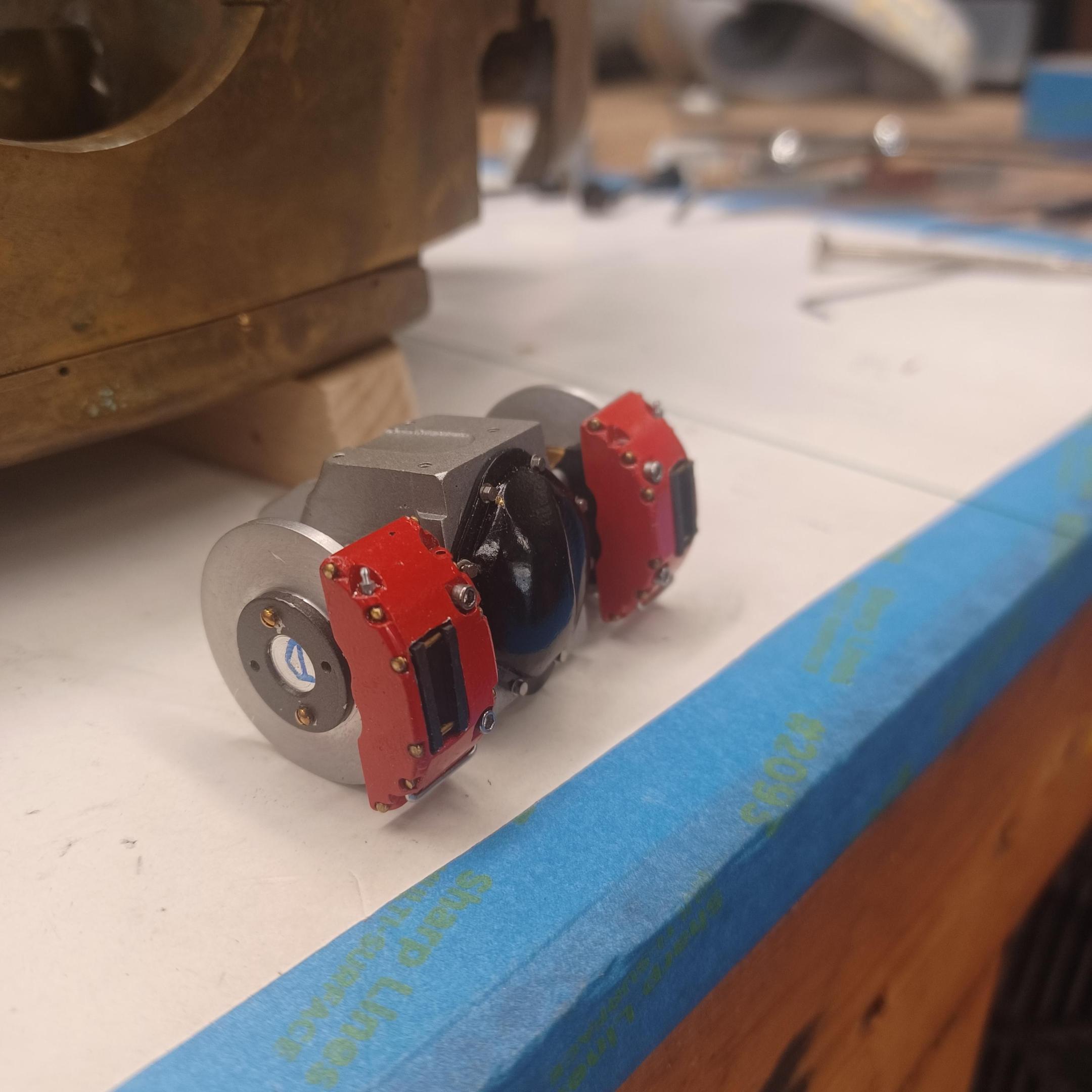

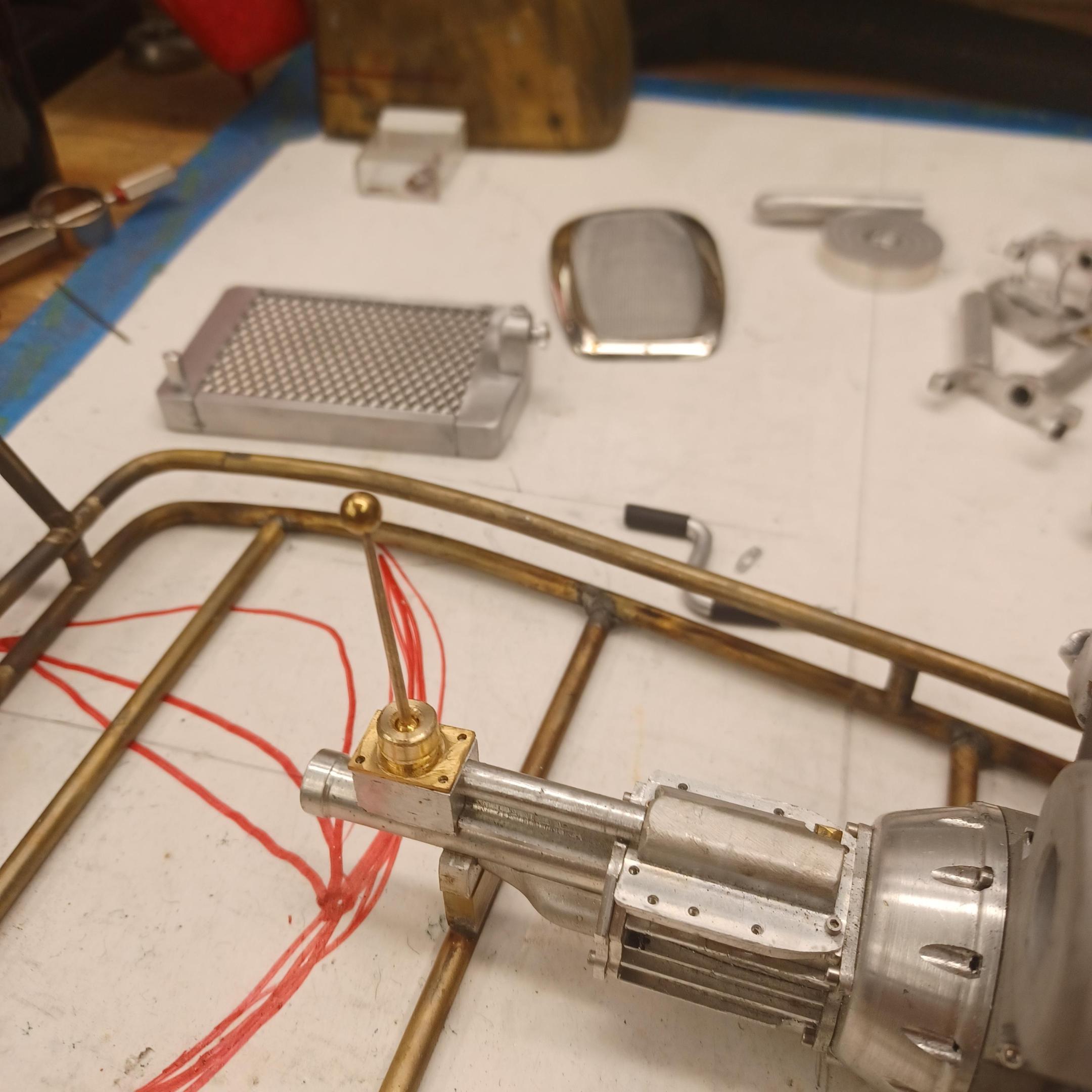

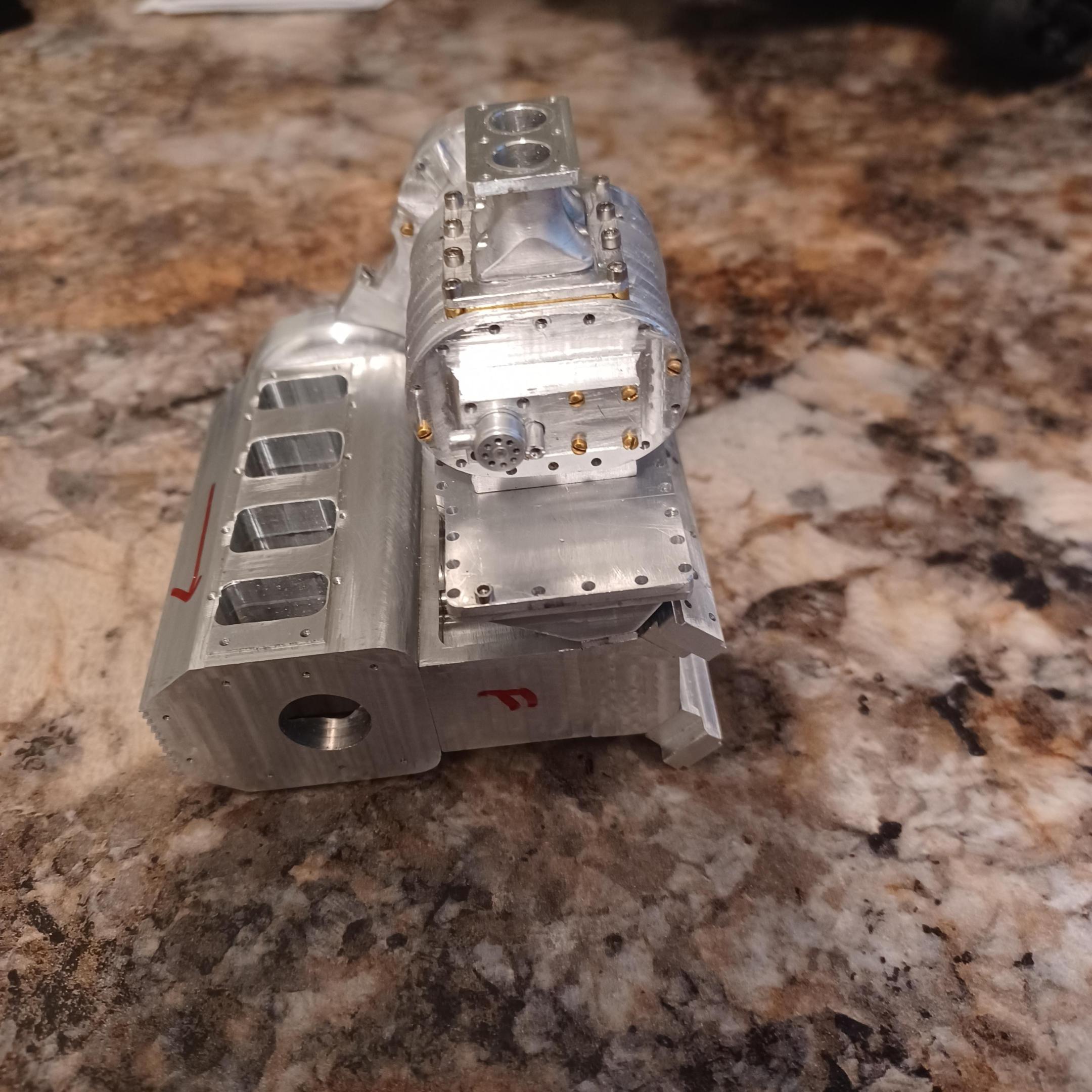

did a little assembly today .i just ordered over 200 screws to finish it. i have over 200 drilled and tapped holes in 4 different sizes,00-90 , 0-80 , ,and 1mm , 1-72. thank you all for your nice comments. i am looking forward to the novi also. long wats off. -

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

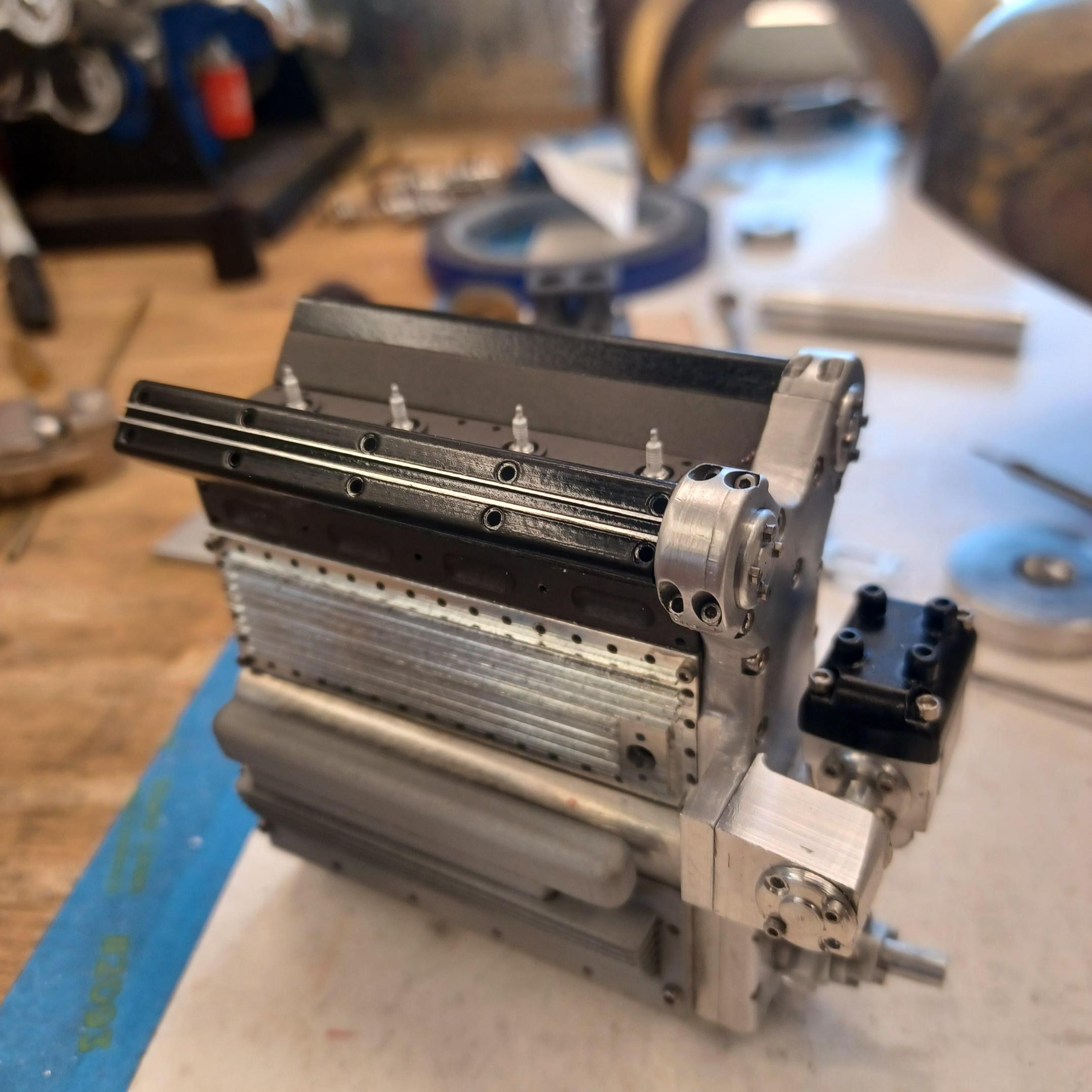

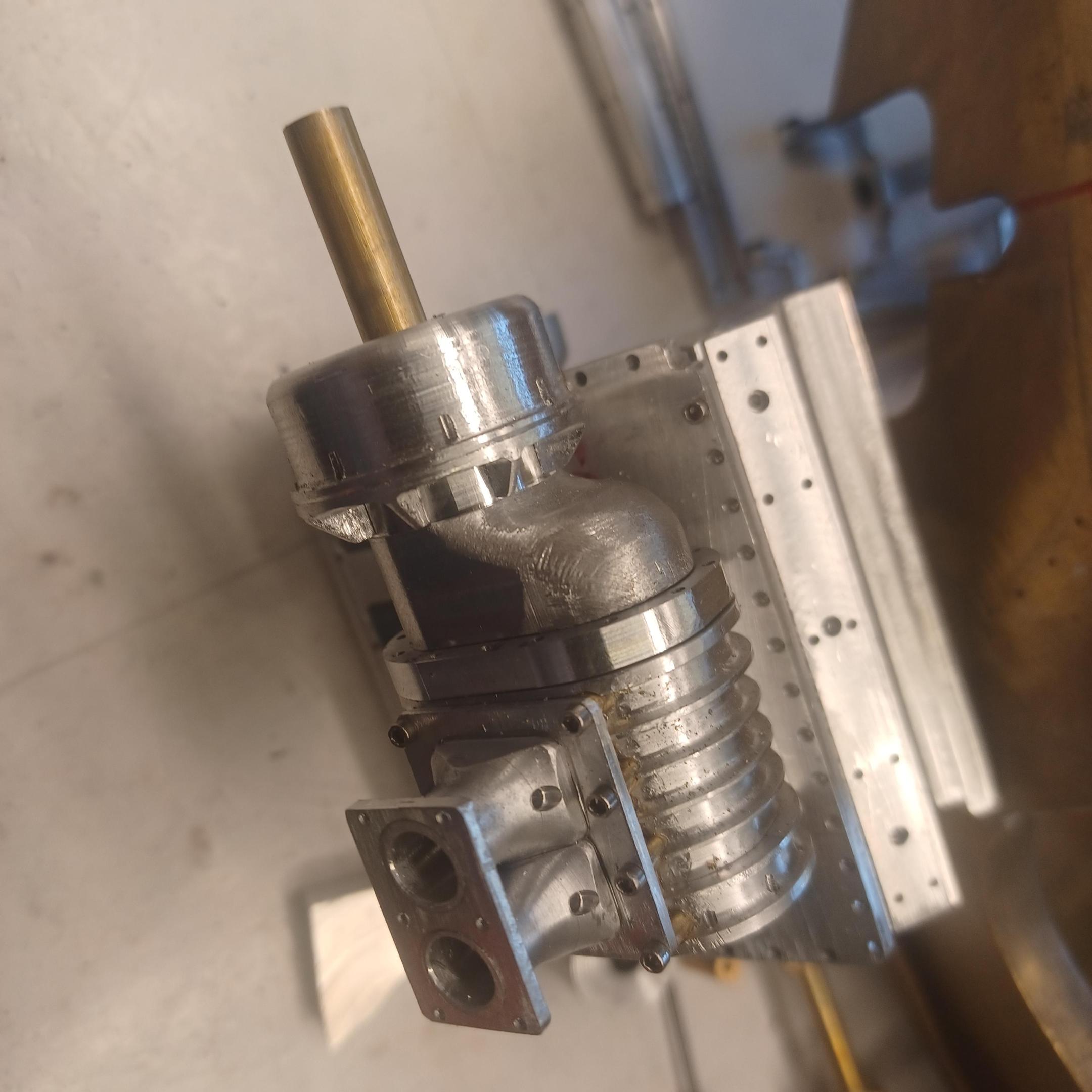

hello tim and randy , hope you are doing well. quick update. i haven't spent much time in the shop recently. other hobbies and honey do list ,but i got a few things done. still on this engine which is my favorite thing to make. i am going to do a novi v8 for my next project ,Andrews idea. i just received the brass to finish the body but i need the engine and transmission mounted to do the floor and fire wall. i am a little further along than these pictures show but forgot to take pictures. the engine is almost completed. more next week. thanks for looking and commenting ,I appreciate it. -

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

i was always afraid of sliting saws but i have been using them on this car.i always find new ways to do things by following your incredible work.just learned some to night.thanks francis -

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

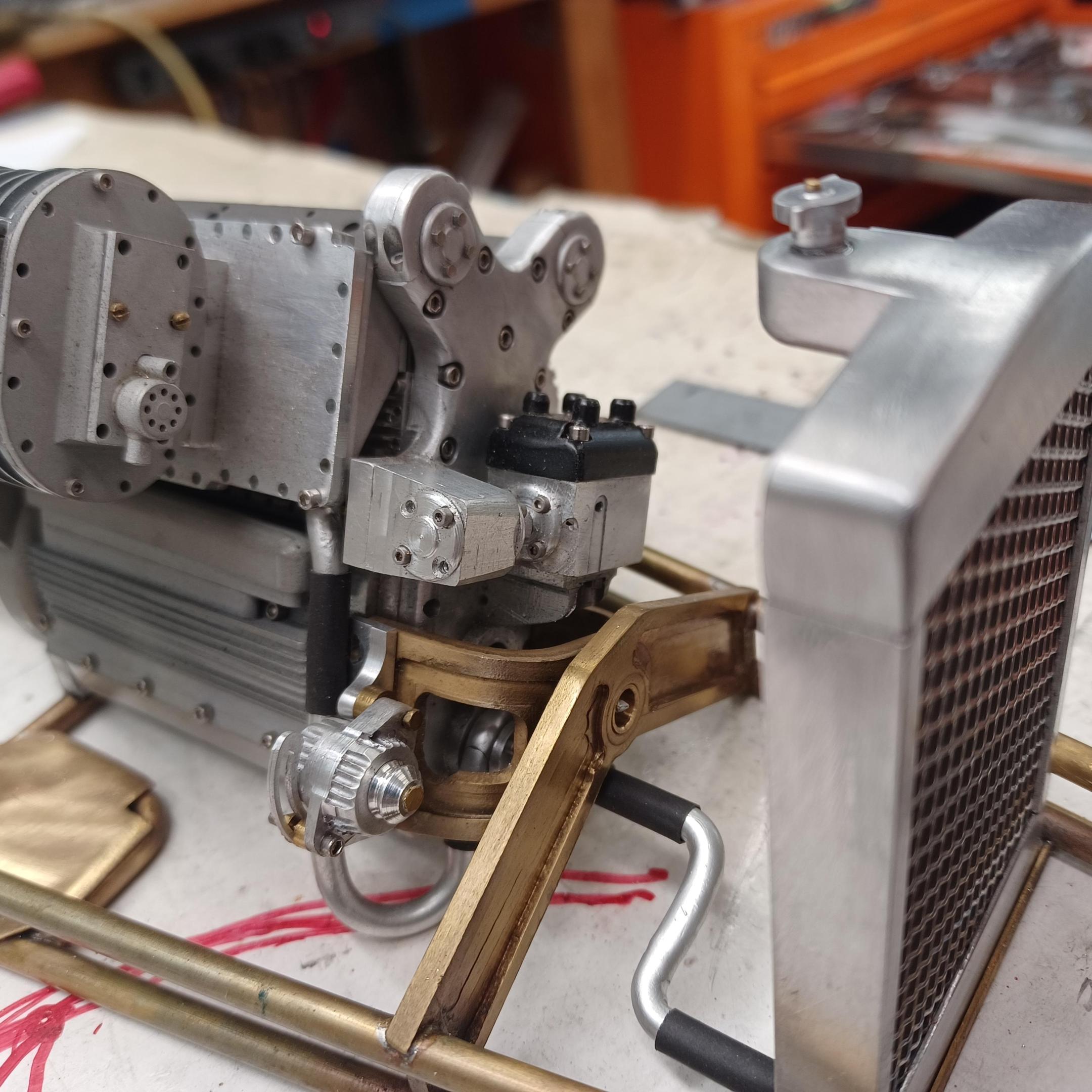

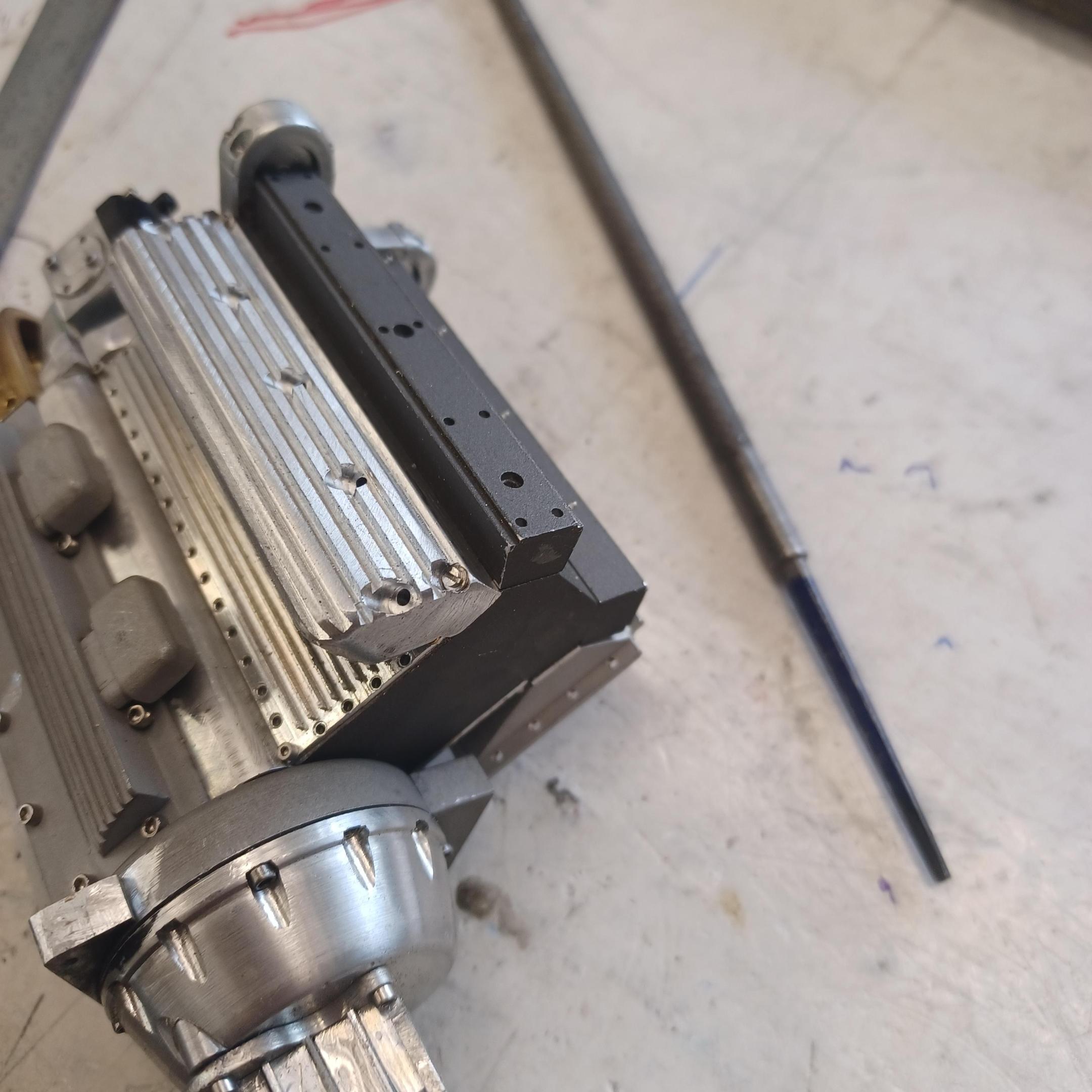

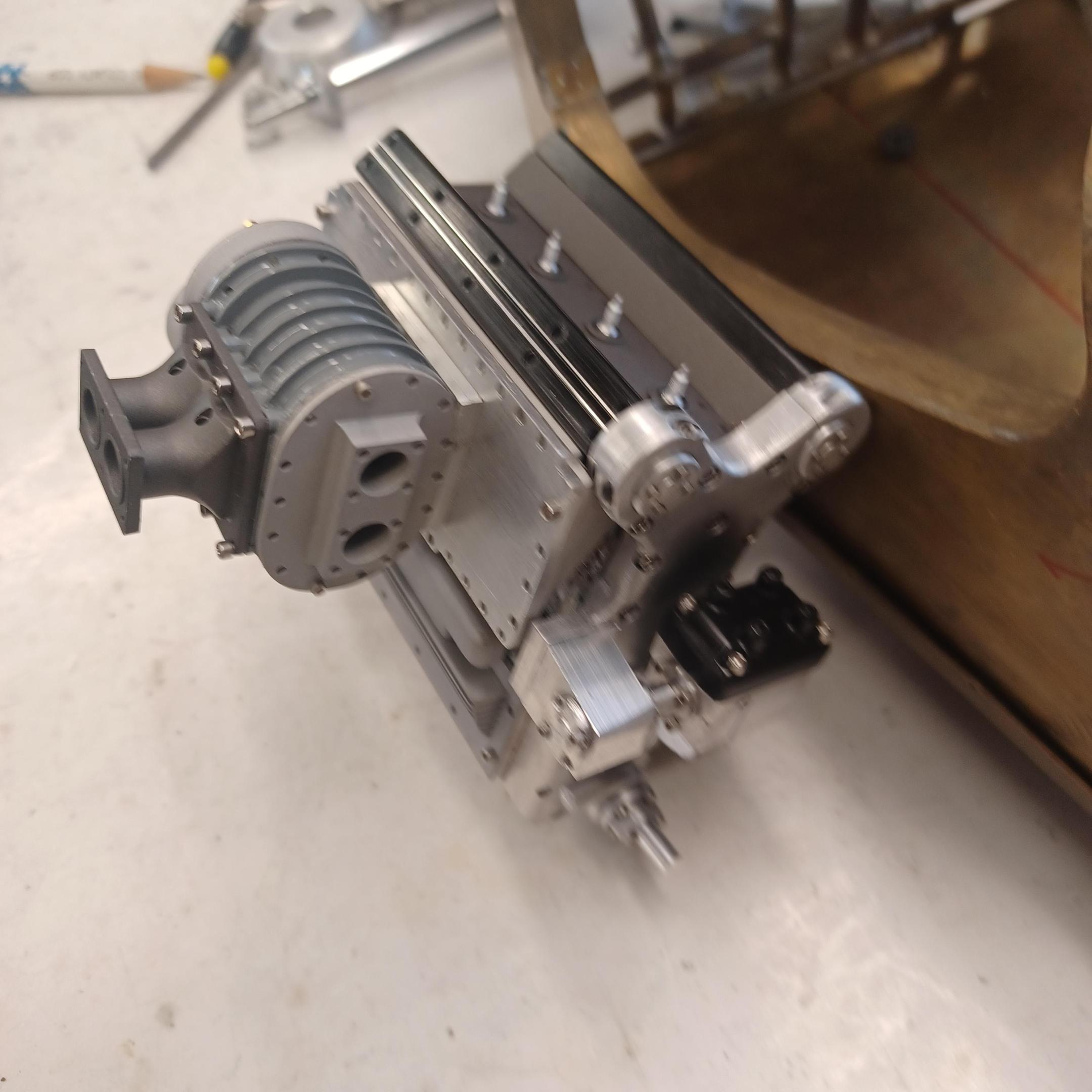

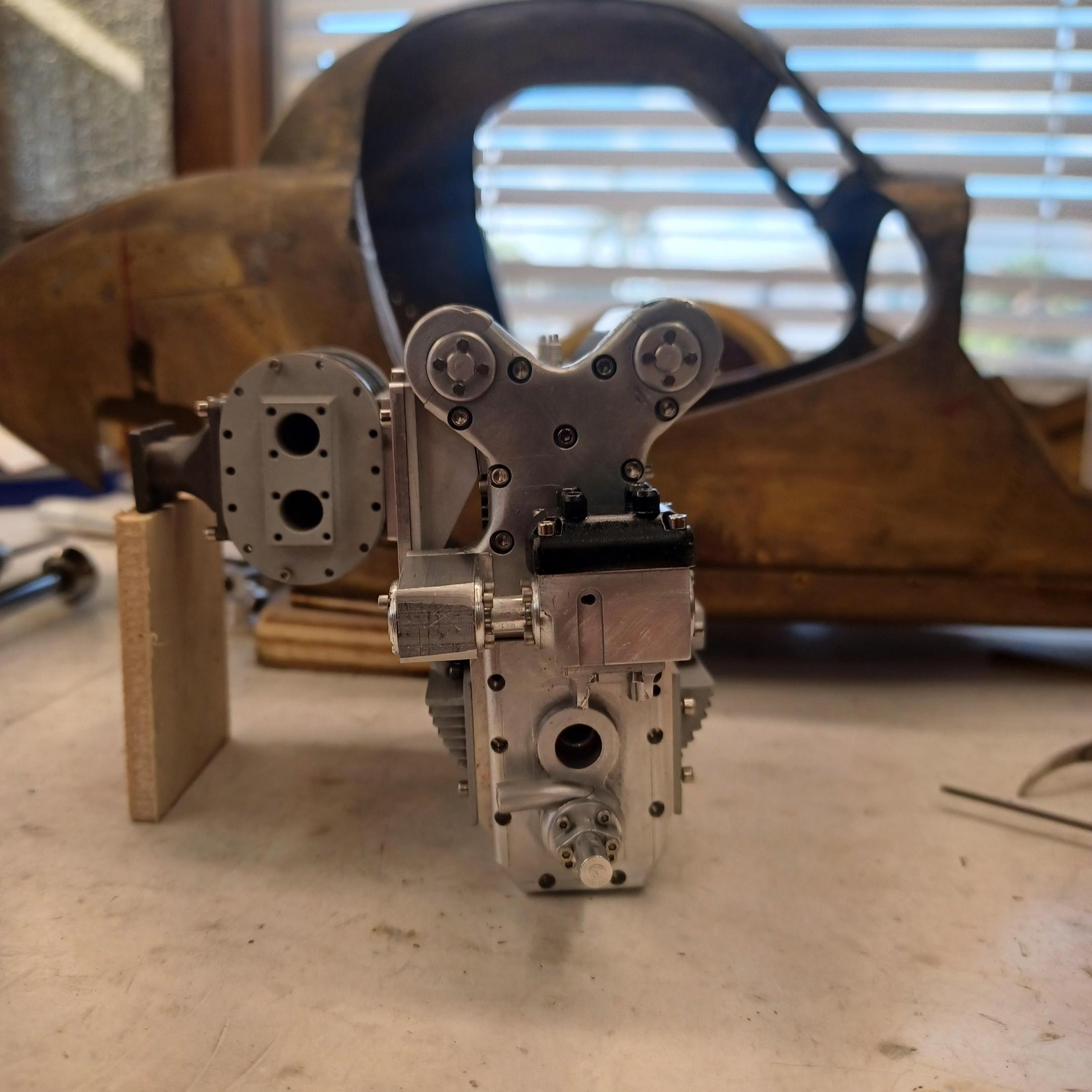

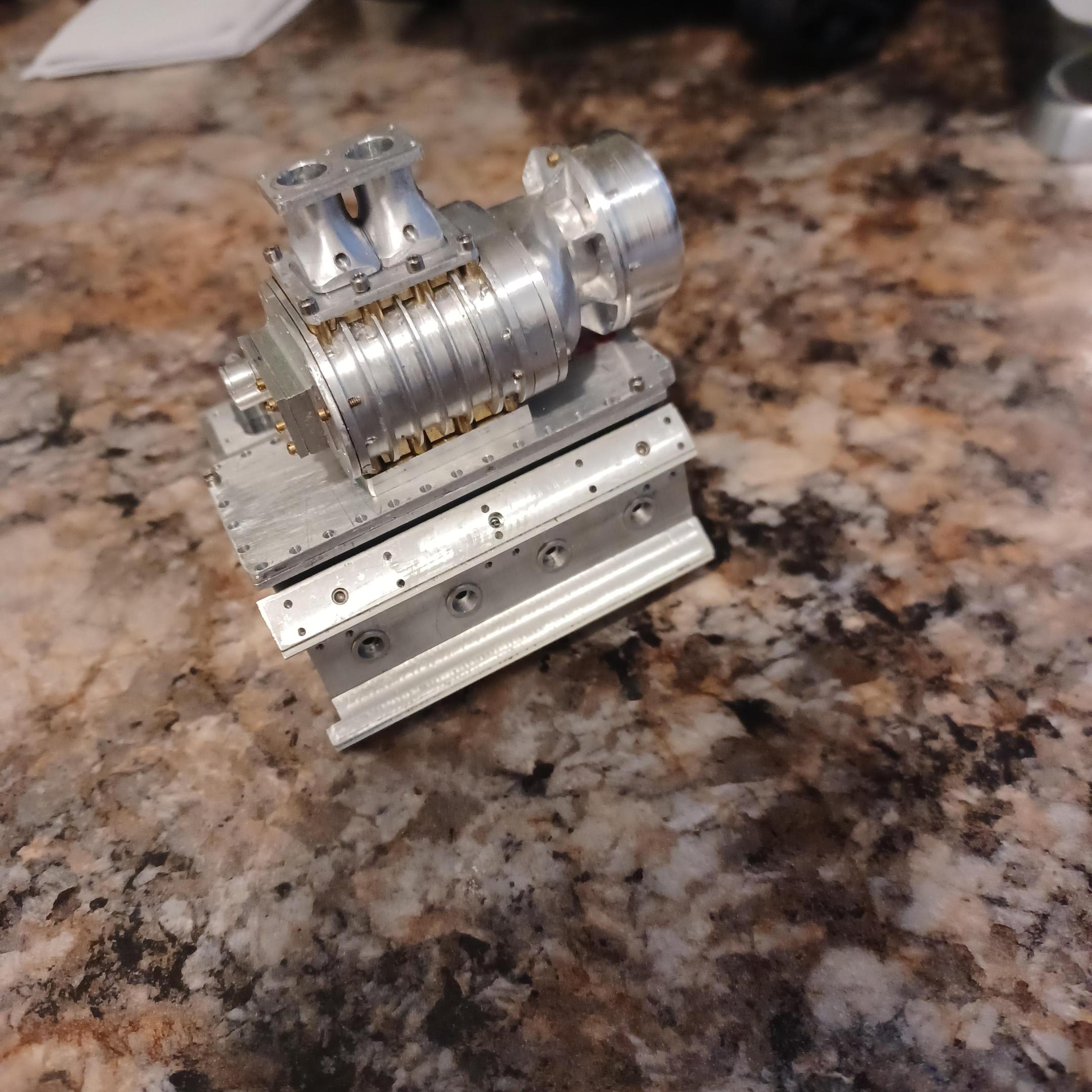

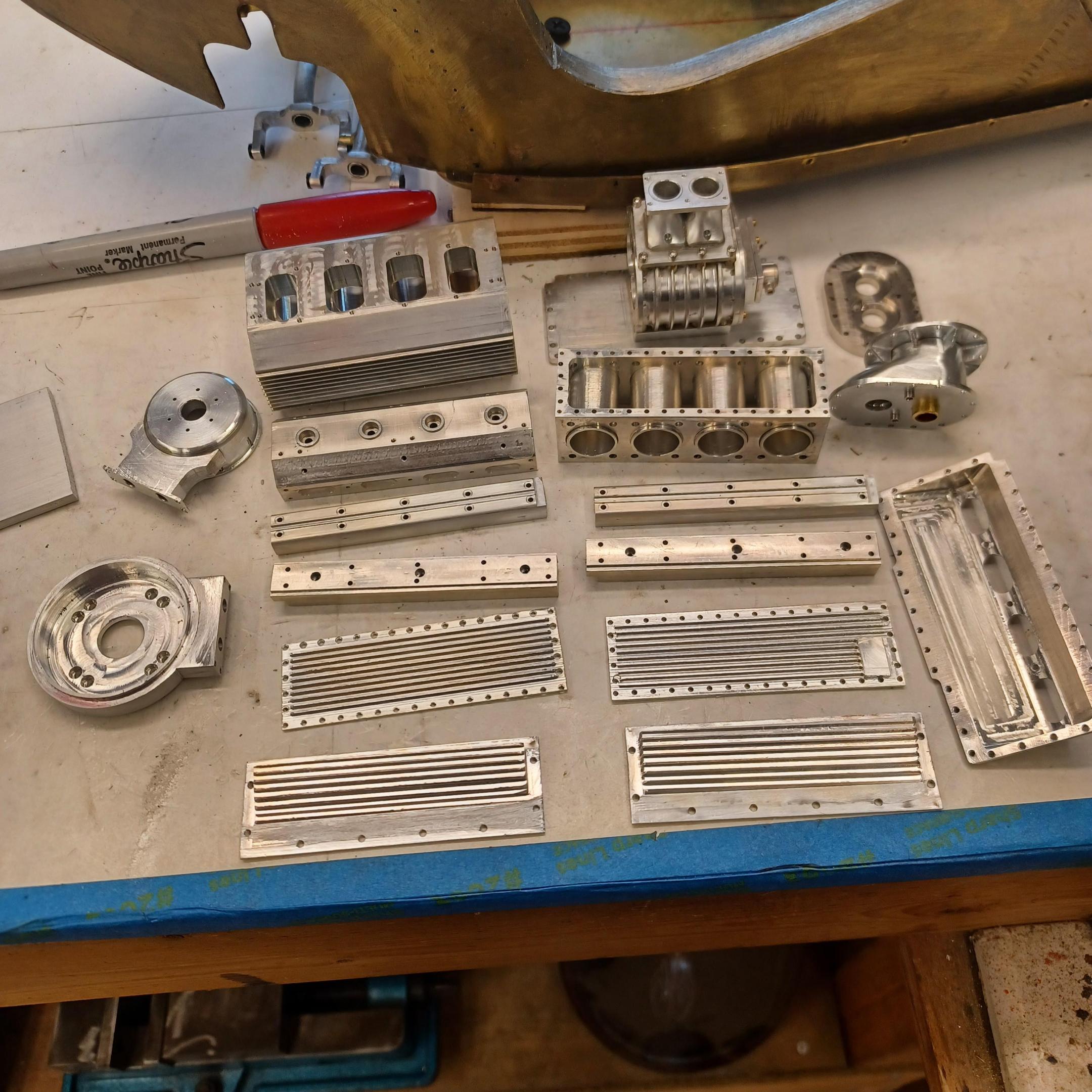

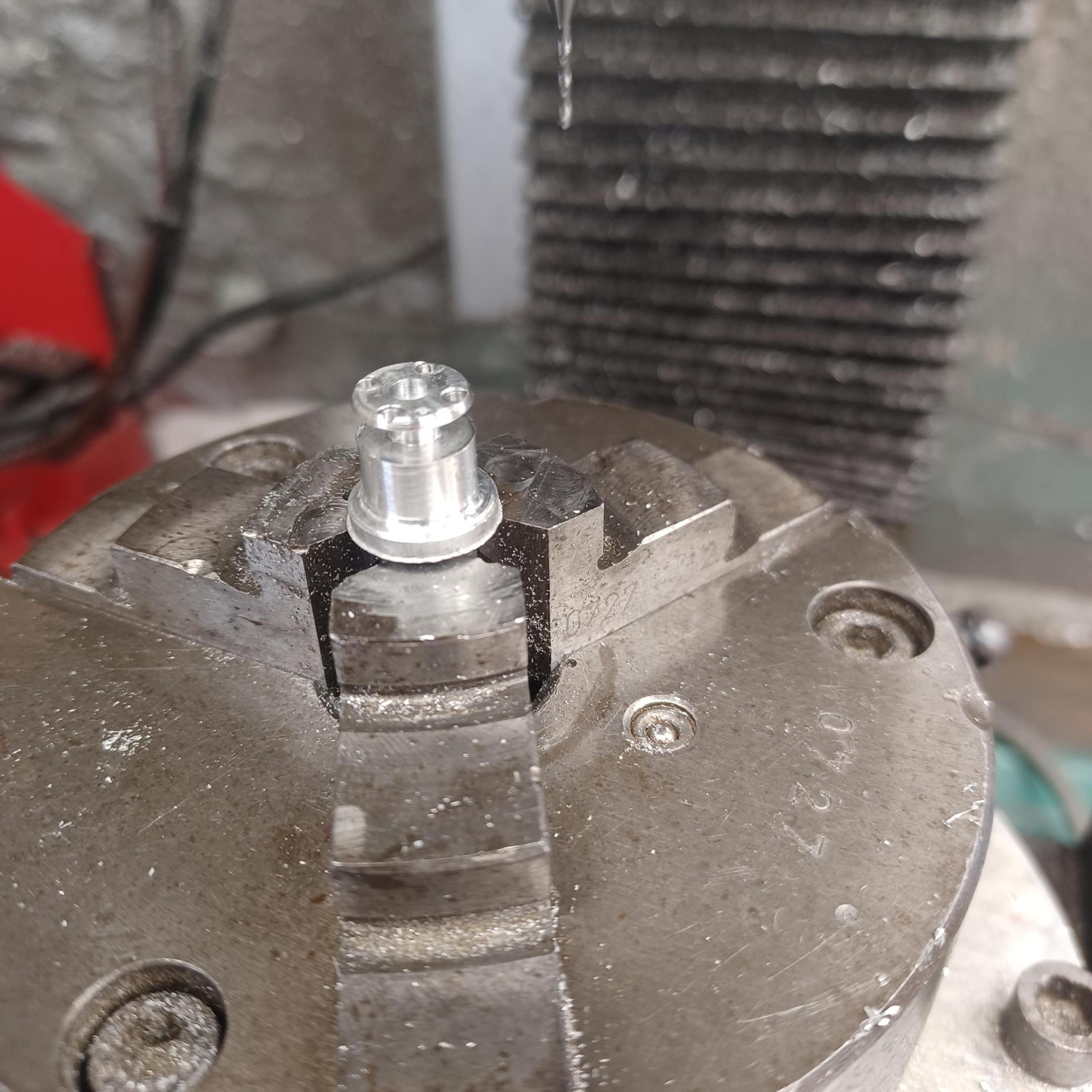

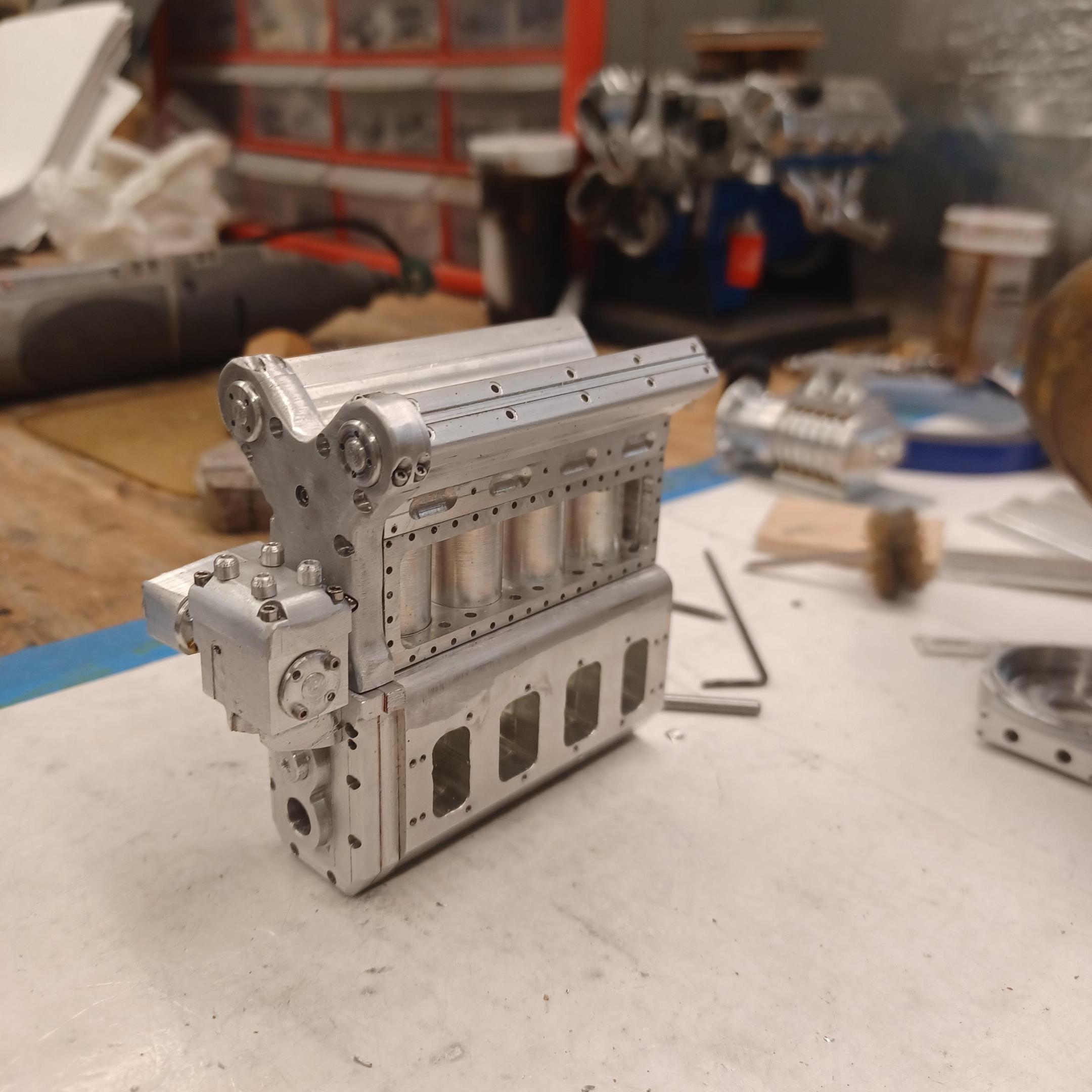

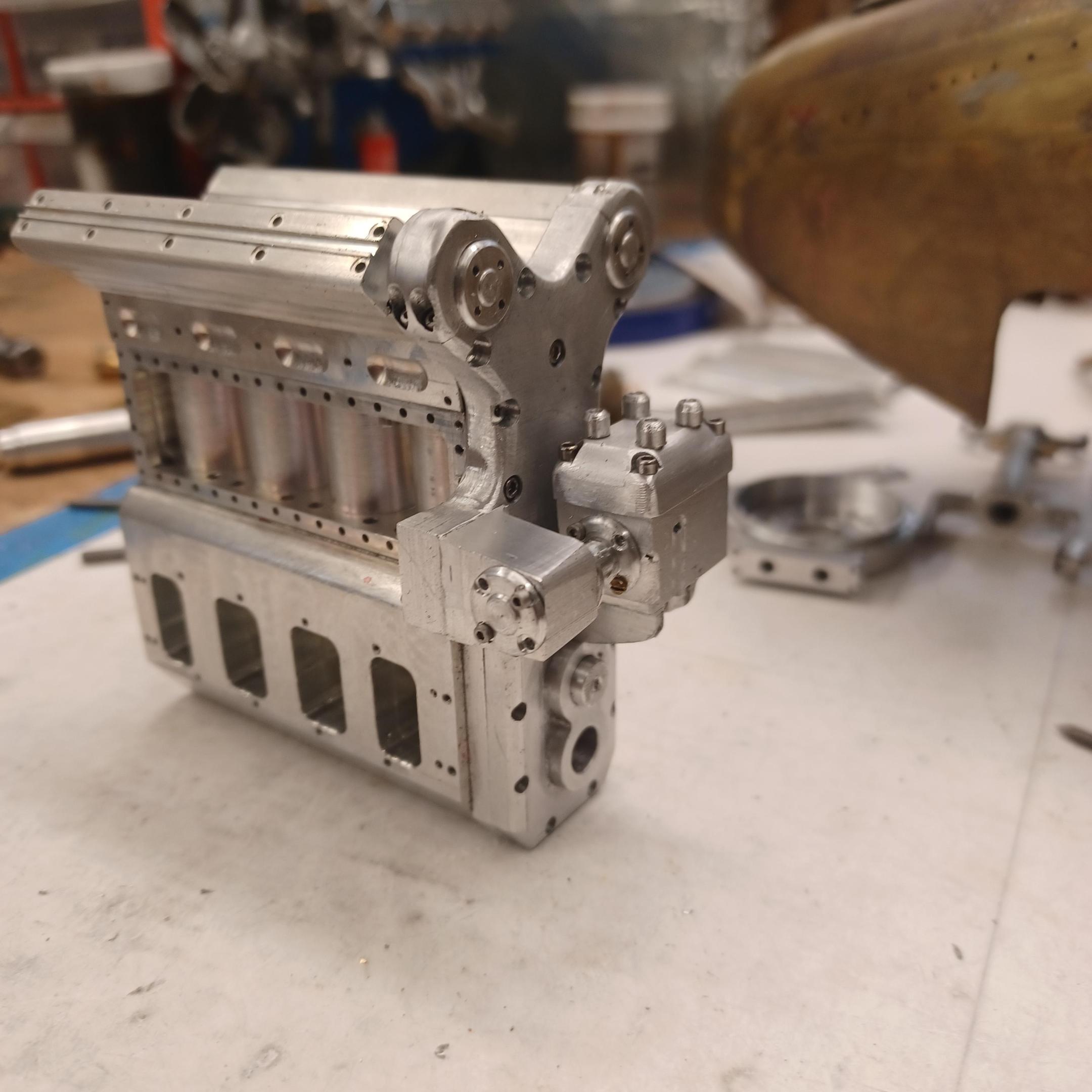

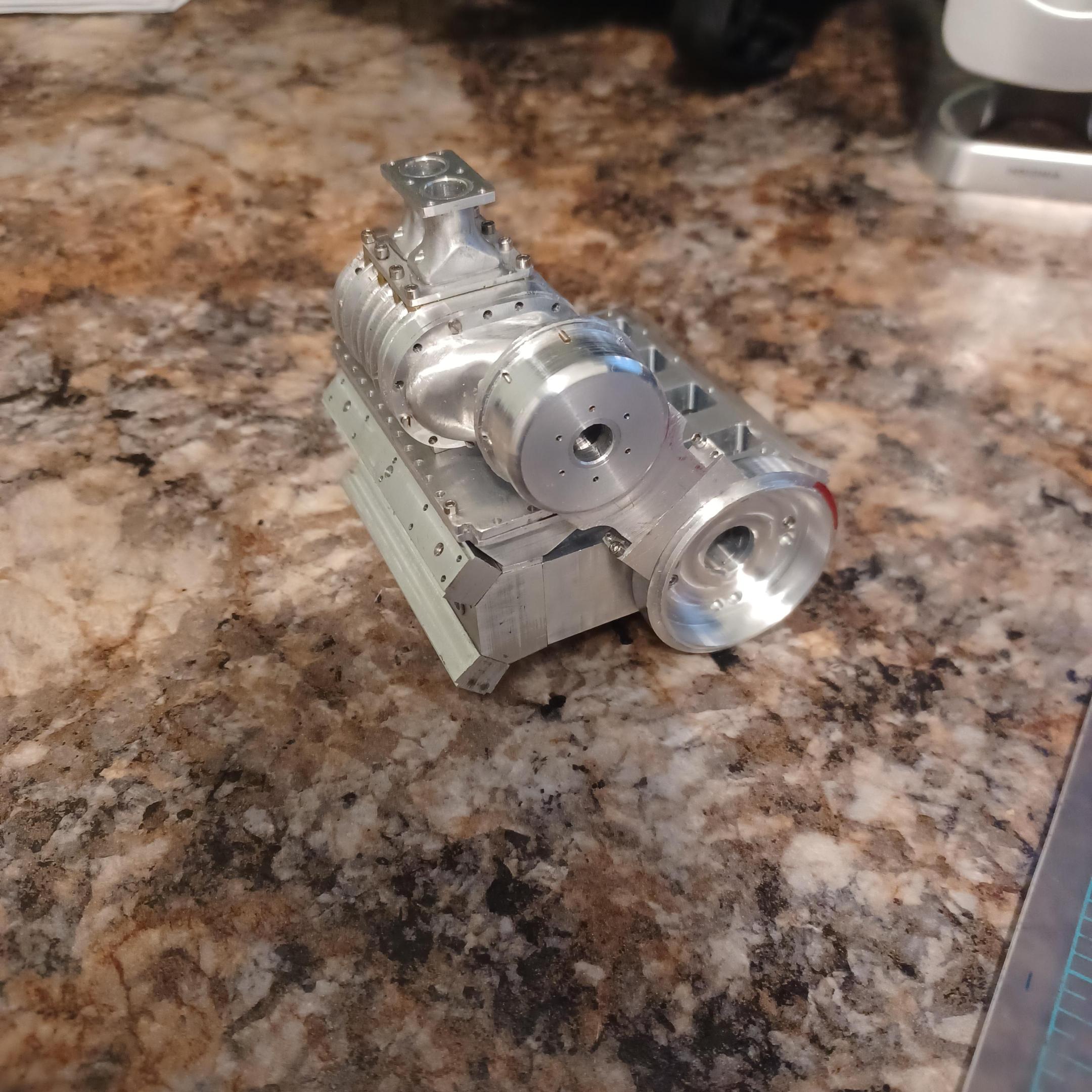

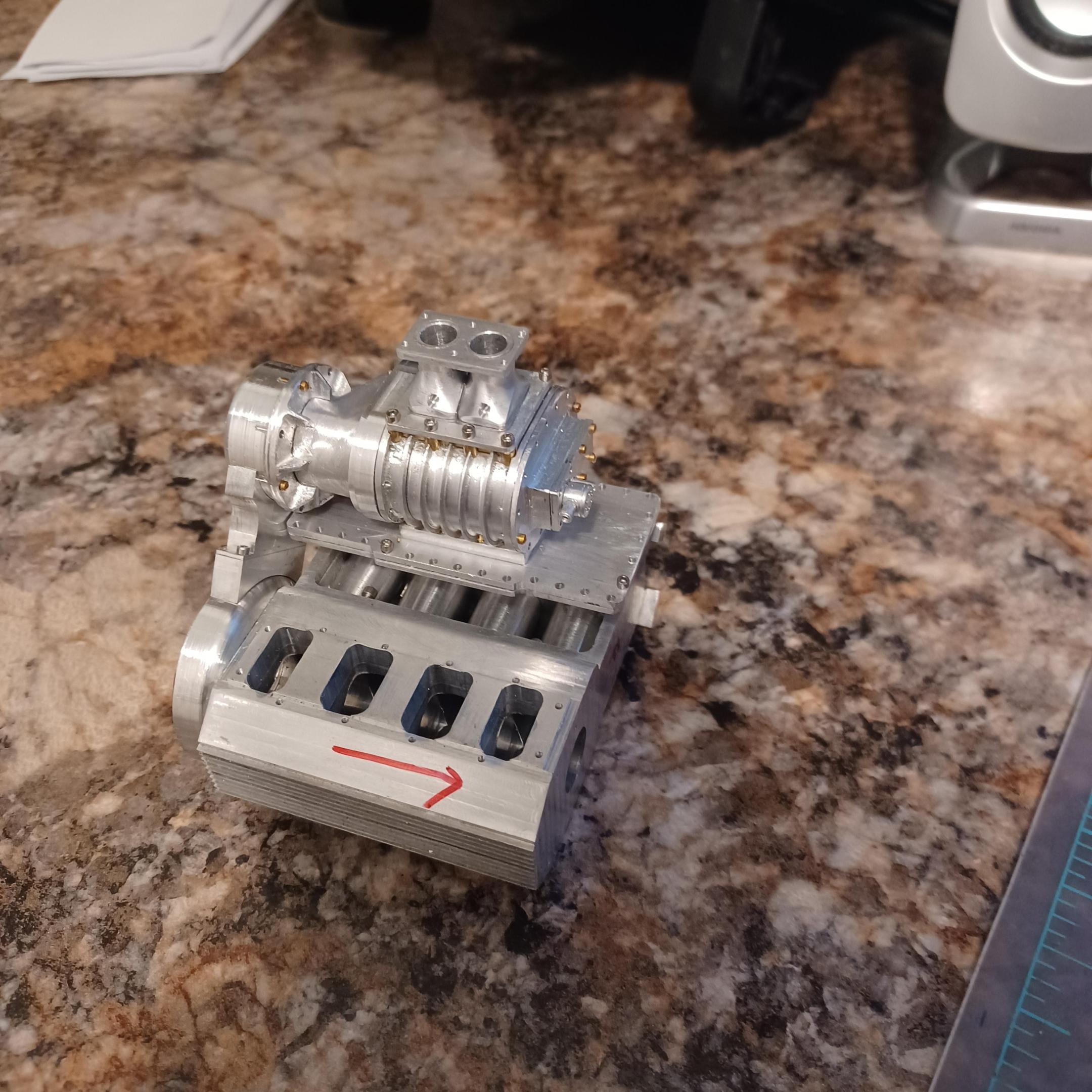

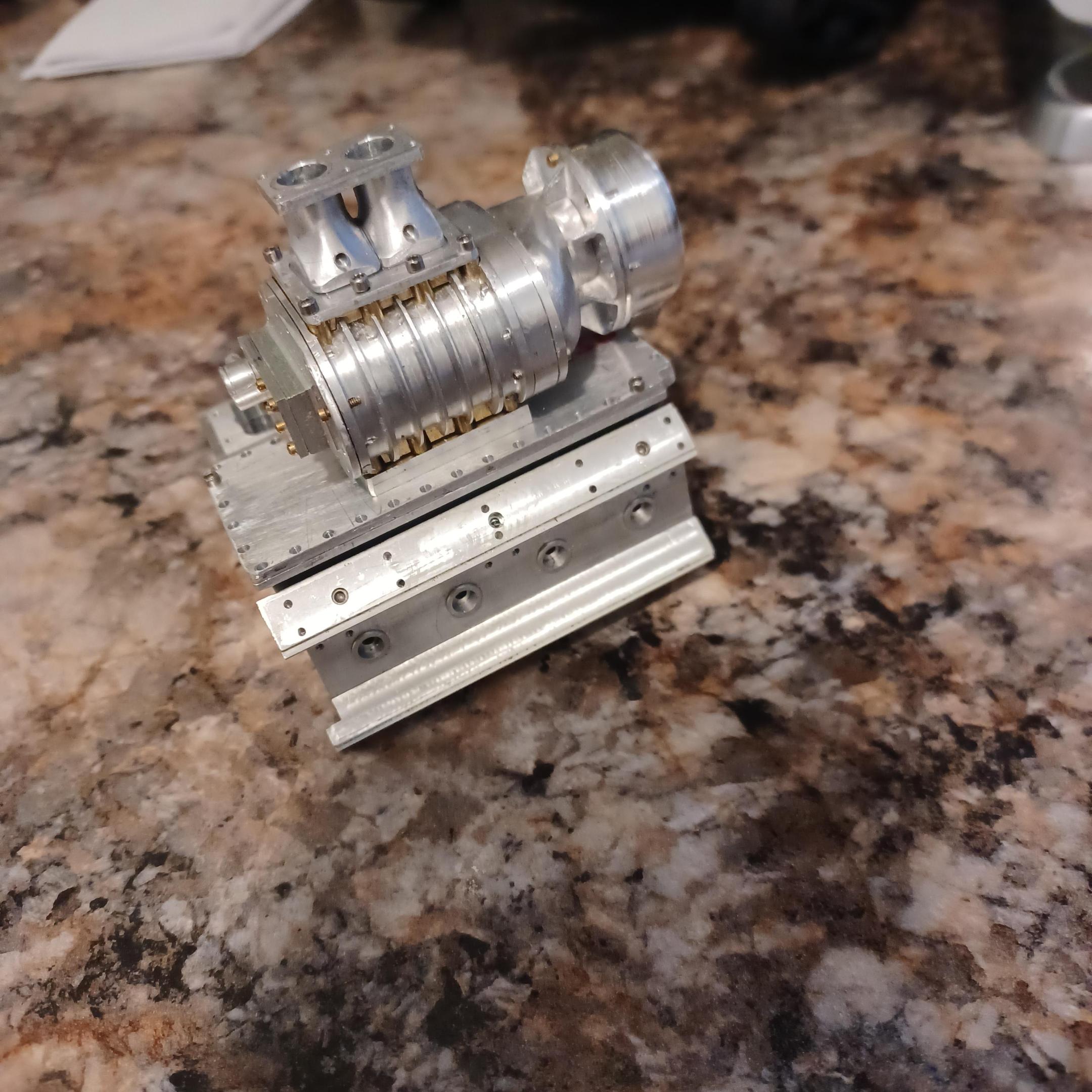

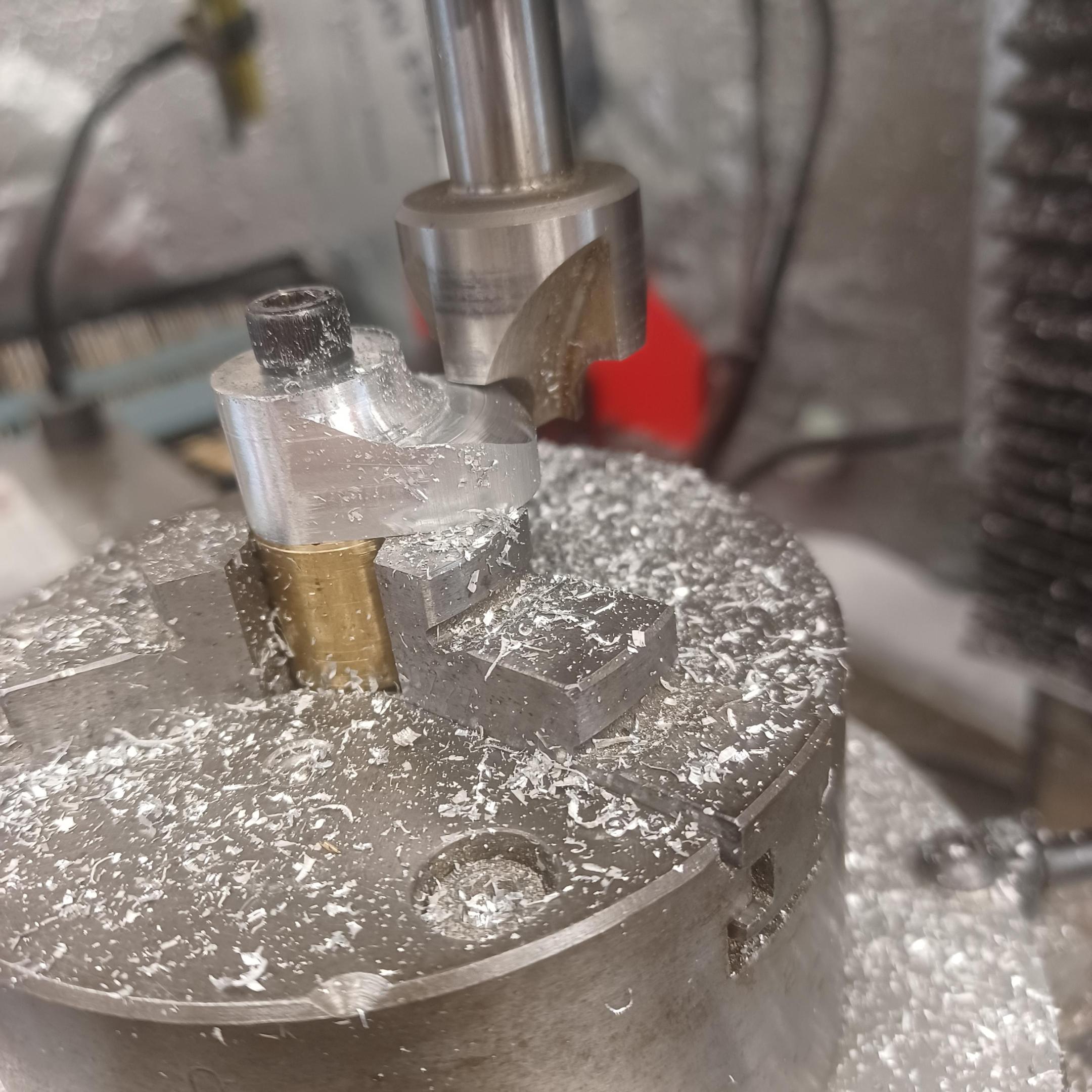

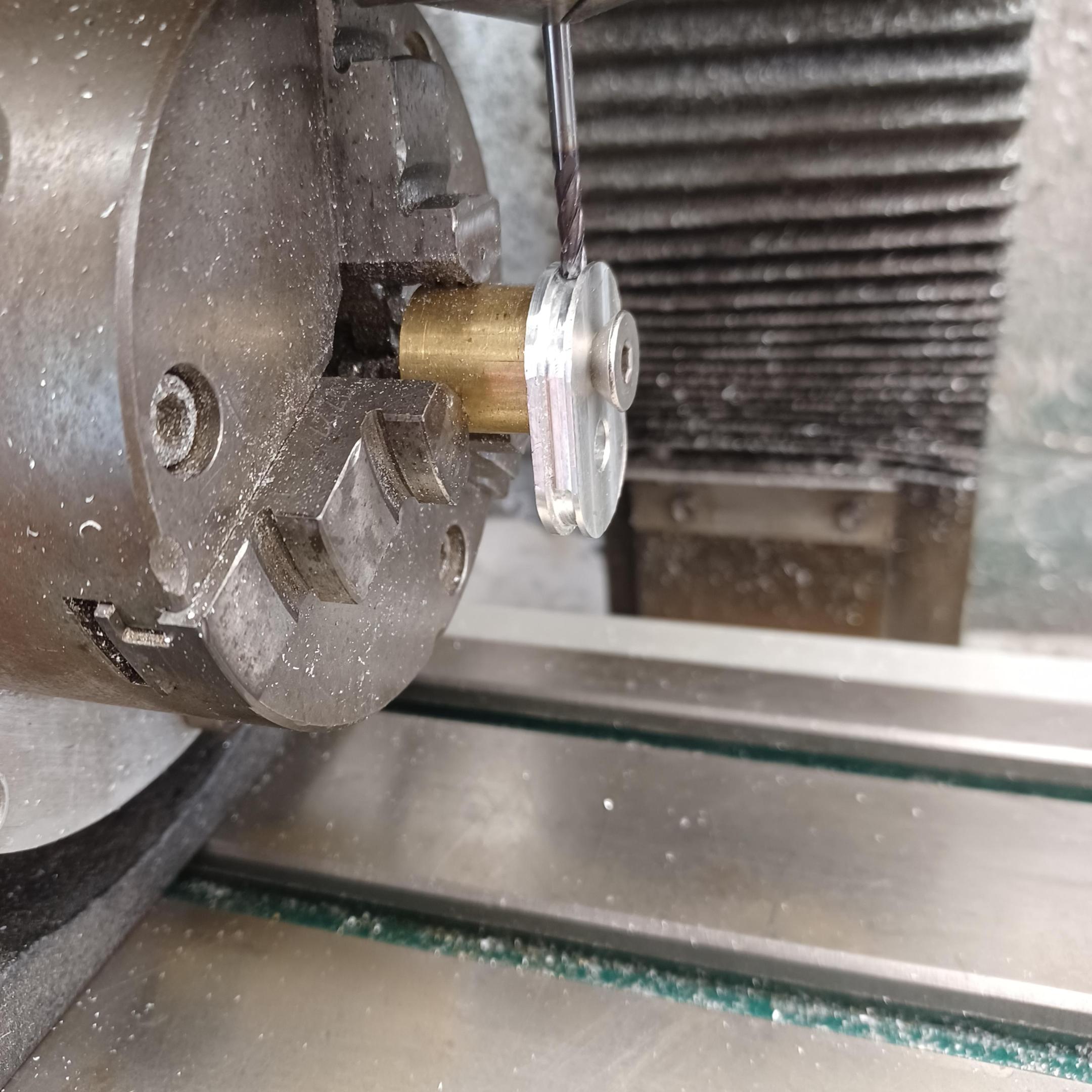

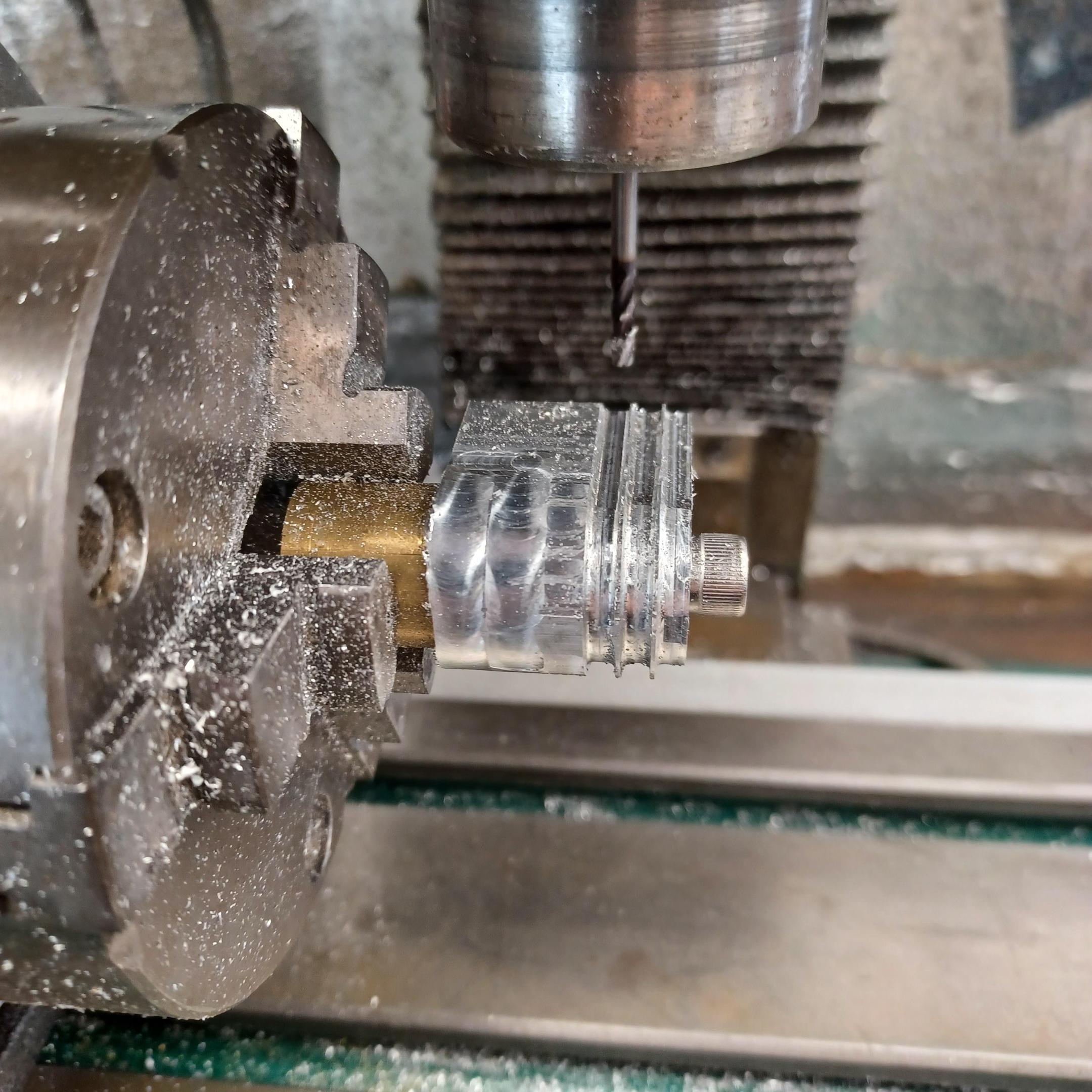

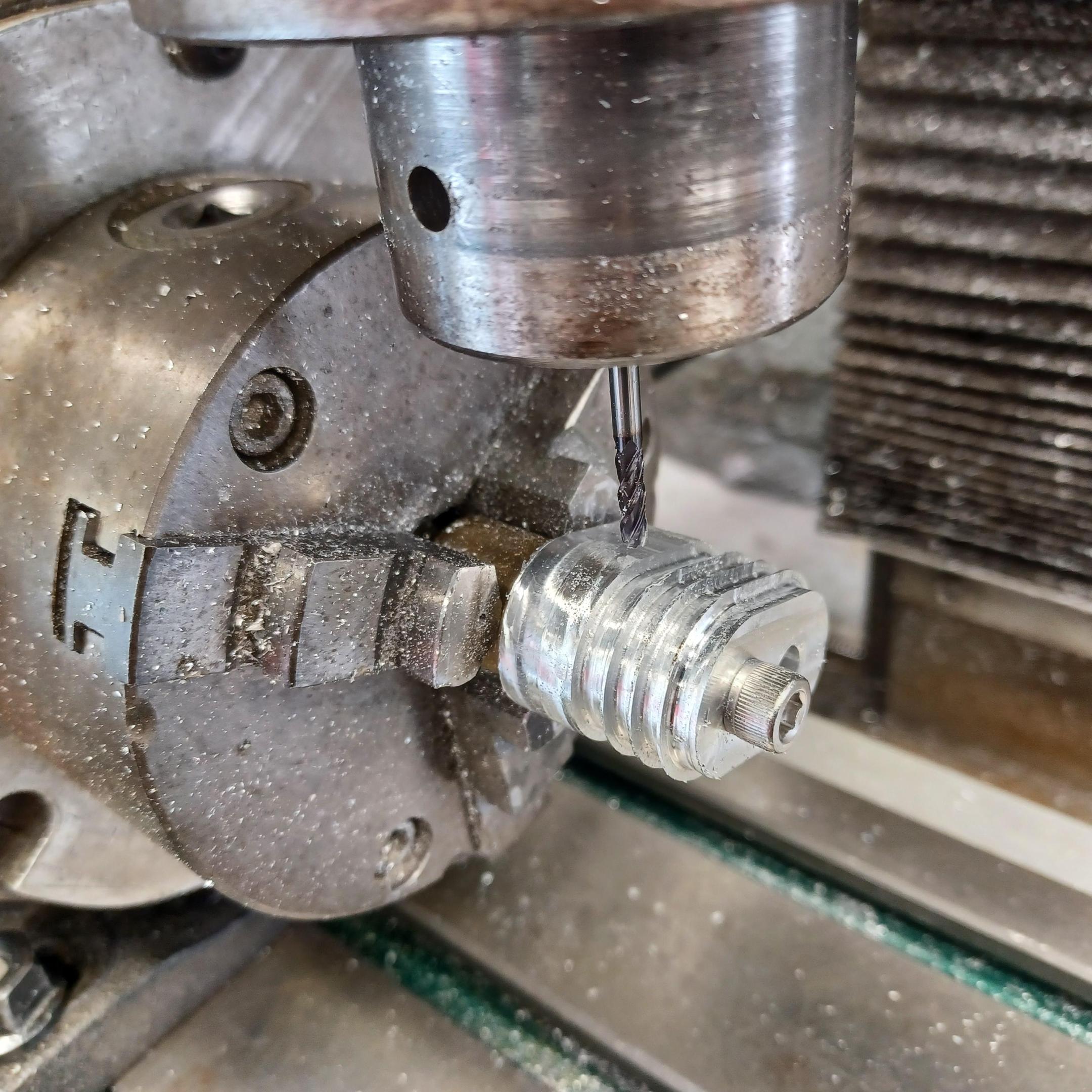

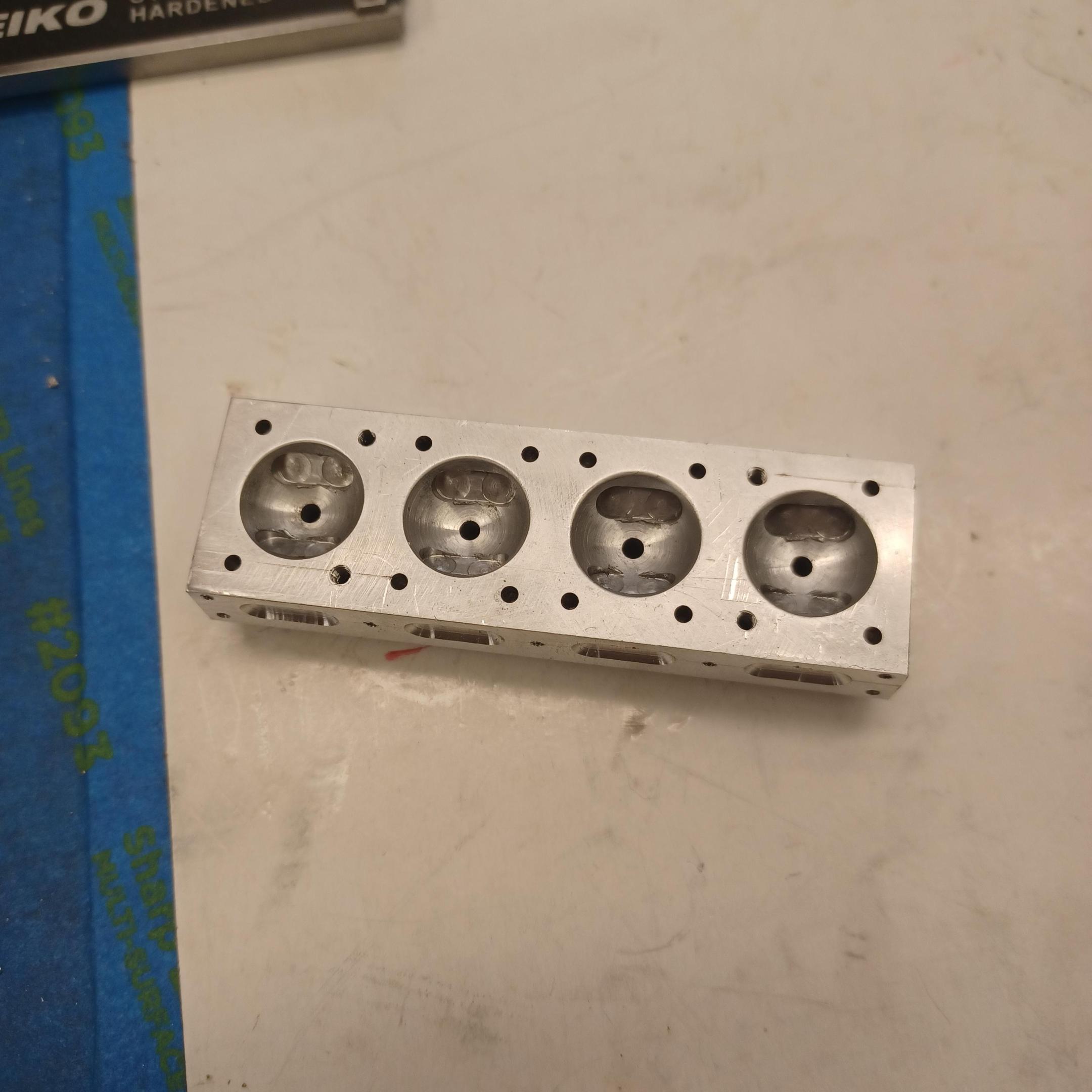

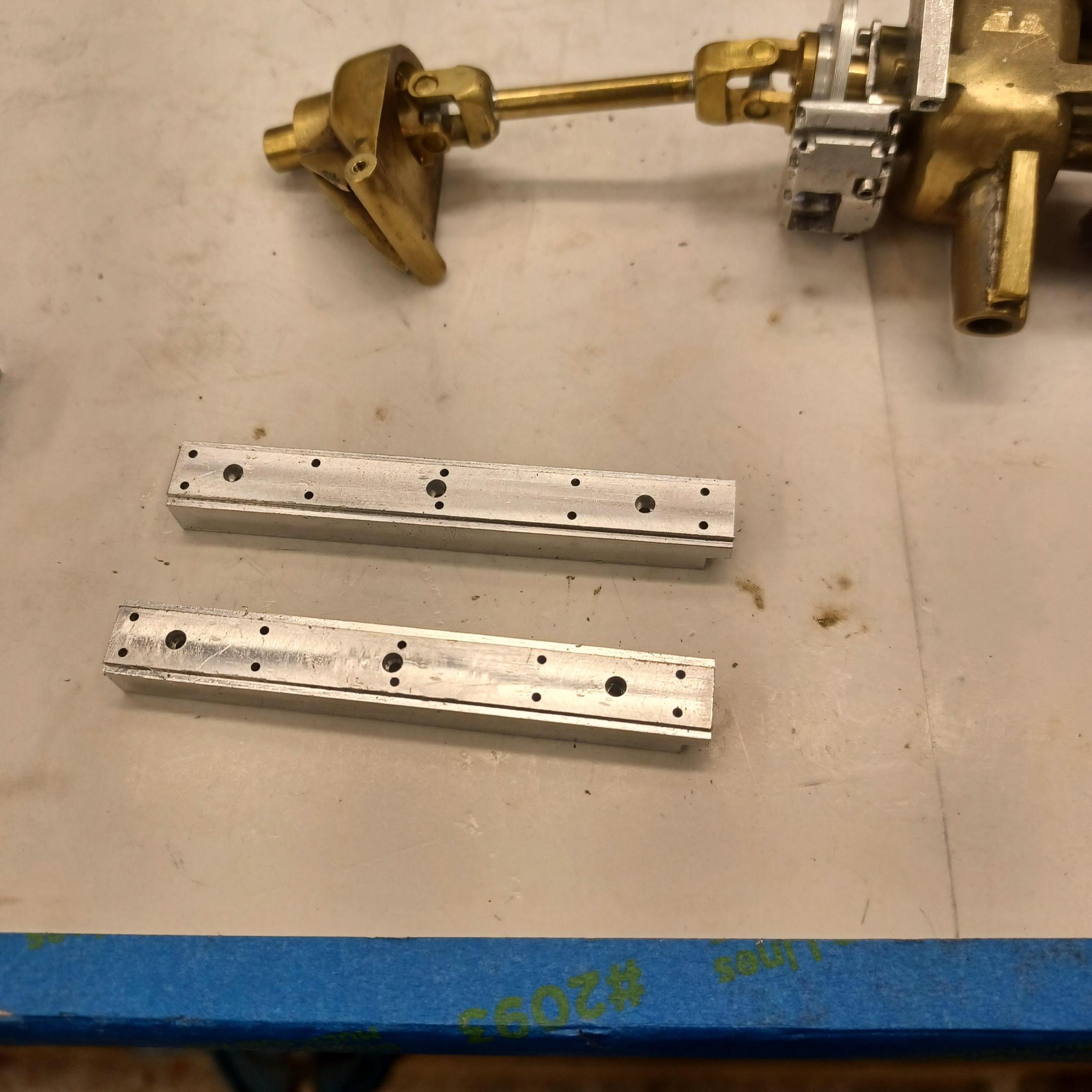

got most of the blower and blower drive parts made. still got some filing and sanding to do. i can't believe all these parts fit together and bolt to each other. some details left but i like it so far. take it apart now and make all the side covers and breathers. bellhousing and transmission after the covers. i think i will have to mount the engine at an angle with the blower to the top like they did in the indy cars. if i mount it straight up and down the injector will have to stick out of the side panel with some kind of scoop or cover. this is alot bigger than the last one i did. heres a few pictures . all the parts had a pair of holes drilled and reamed to .250 so i could align all the pieces to each other with 2 pieces of .250 brass tubing. i also used them on my rotary table with a small brass fixture to drill and tap all the holes . i didnt count but there is alot of holes. used the same little fixture to radius all the parts. you may notice the blower is on the opposite side of the engine than the picture of the original. these engines were ambidextrous ,just switch the cams from one side to the other. enjoy the pictures . thank you for looking. -

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

thats a really ingenious way to do the u joint. i have to agree with moparman how can you be so accurate .can i use your method? -

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

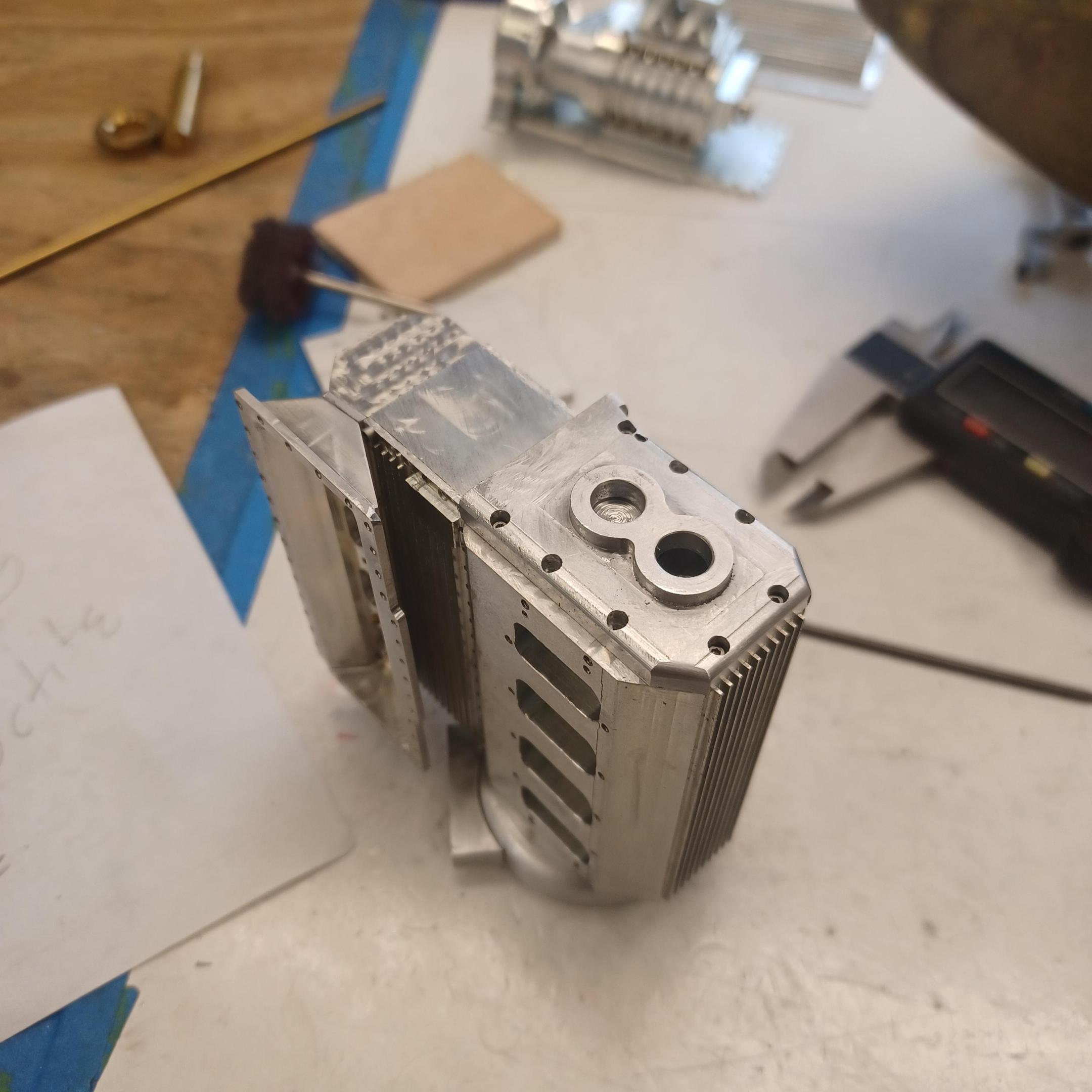

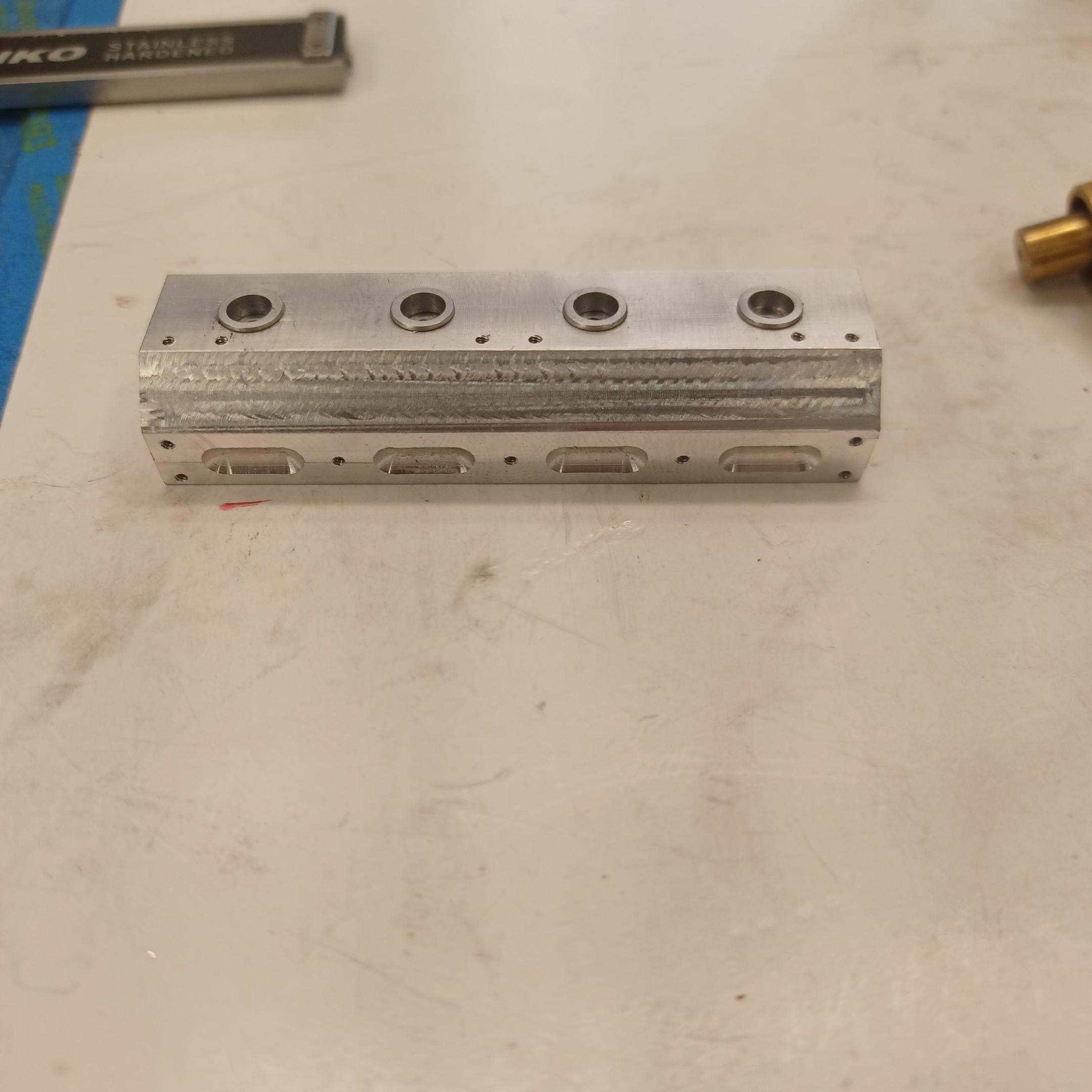

the supercharger is coming together. i got the manifold 3/4 done and the blower is starting to look like the picture. got a long way to go but it will look good. connecting the blower to the bell housing will be a project in itself. i want to get the so engine and transmission done so i can finish the frame, the floor and the firewall. hope the next update mill have the blower mounted to the engine -

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

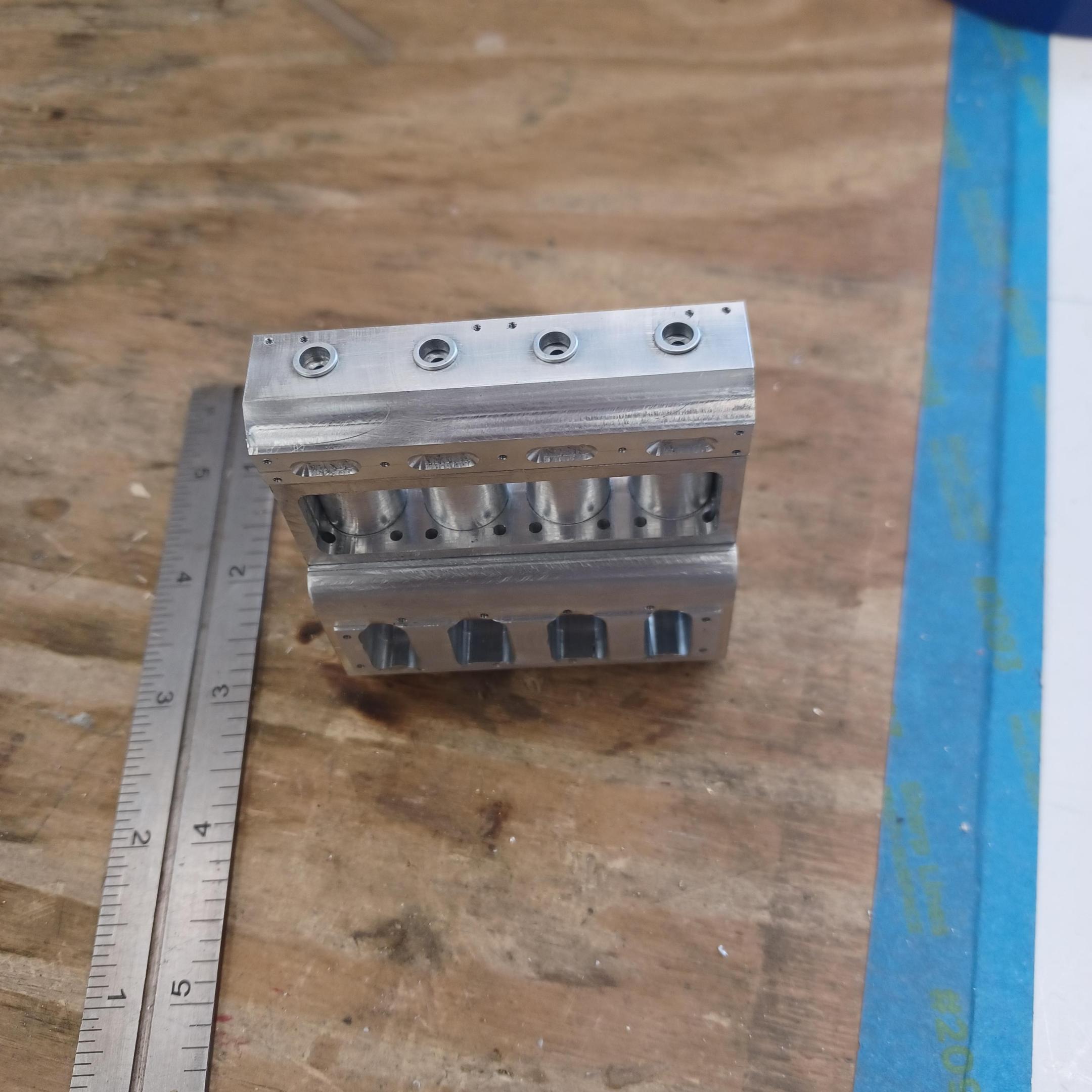

working on the blower today . i wanted to make it with as few pieces as possible. 3 pcs for the main section. next are the end plates. -

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

super nice francis -

When i worked for jack roush in nascar i was lucky enough to get to his museum in lavonia. Very cool place.

-

T41 Bugatti sport coupe

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers