-

Posts

418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by charlie libby

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

-

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

impressed as always. such nice clean work. i love the doors and hinges. if i send you my address can you send me a big box of your patience. obviously you have tons of it. -

NICE WORK andrew !looks incredible ! your machining capabilities are moving upward on every part. beautiful !

- 406 replies

-

- harry miller

- indy

-

(and 1 more)

Tagged with:

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

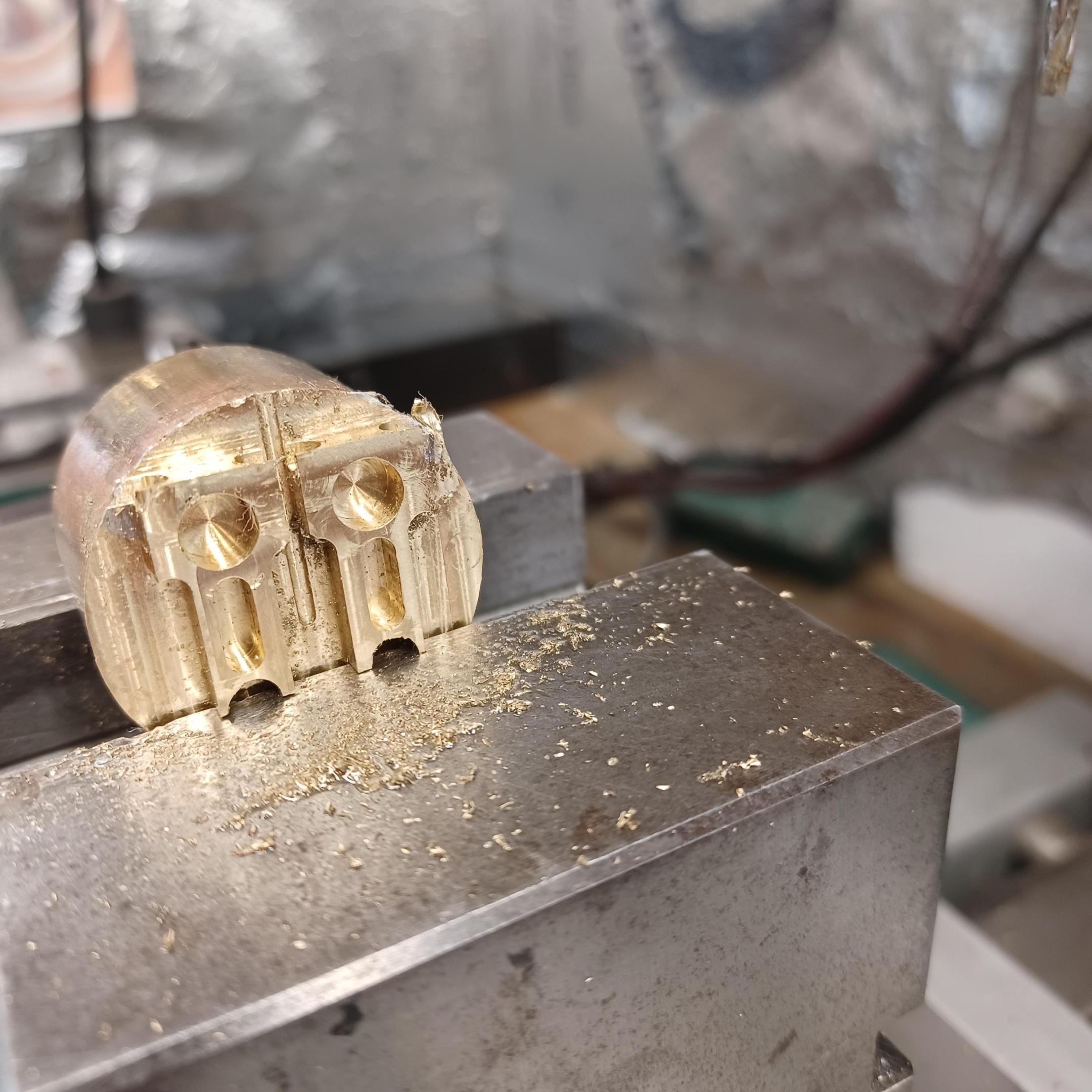

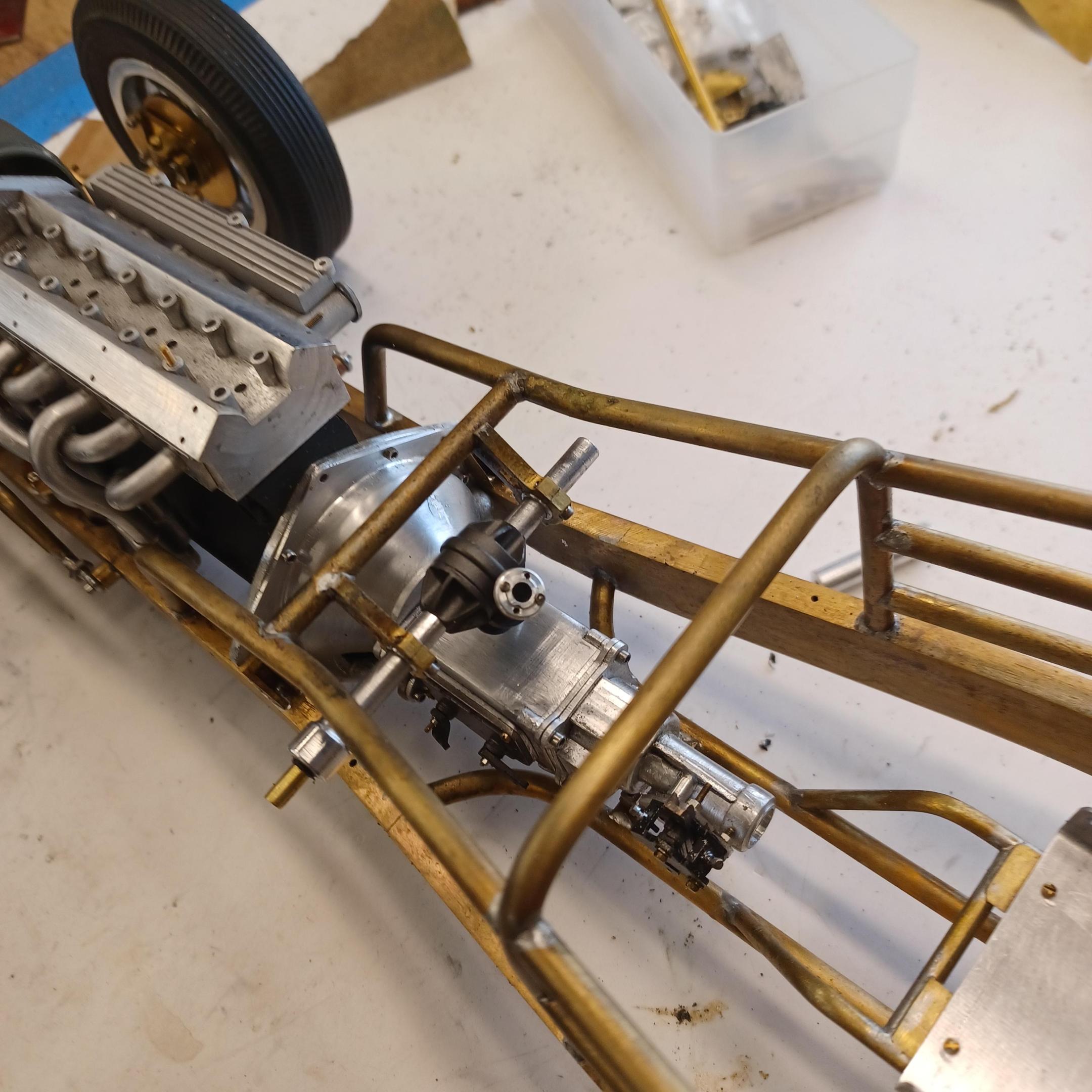

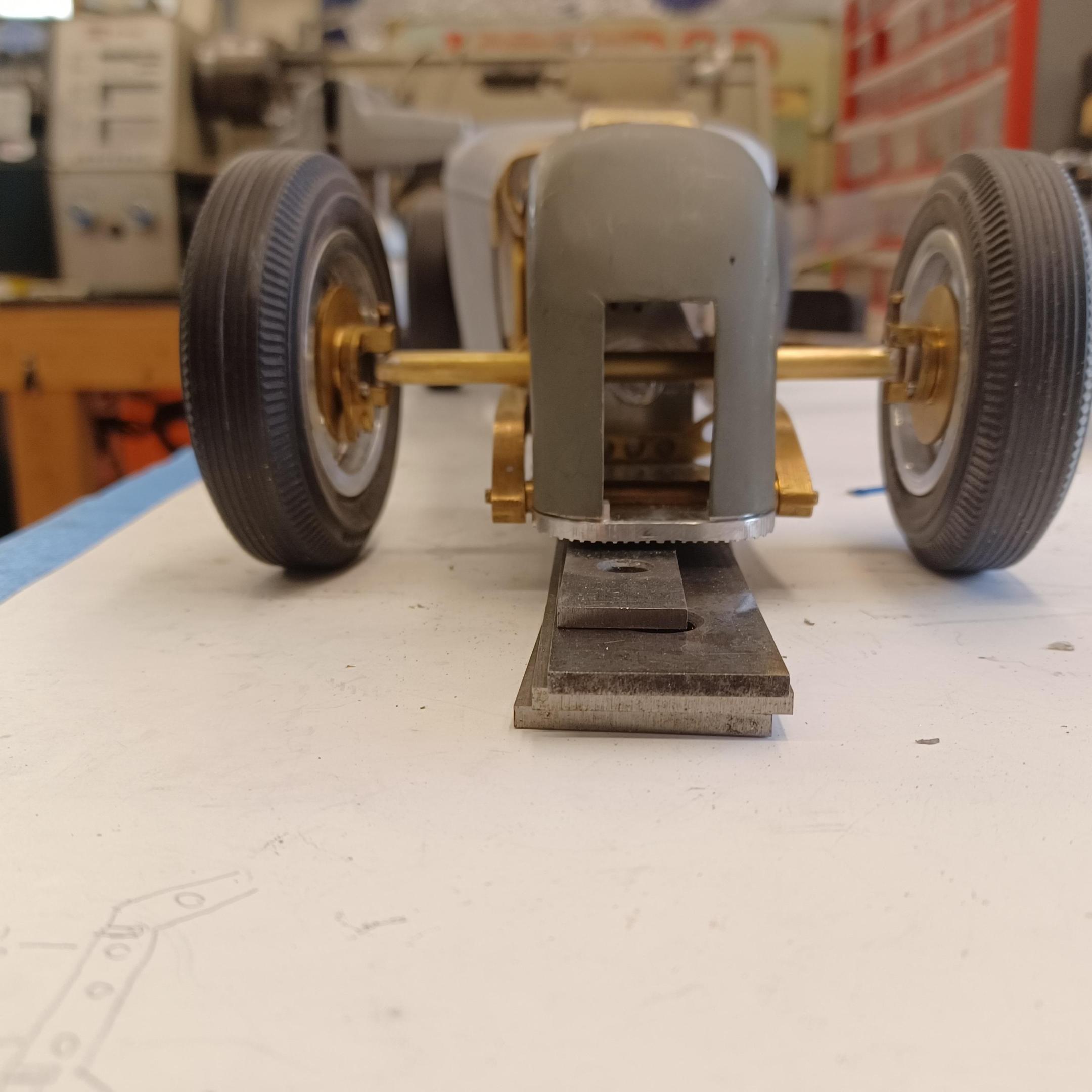

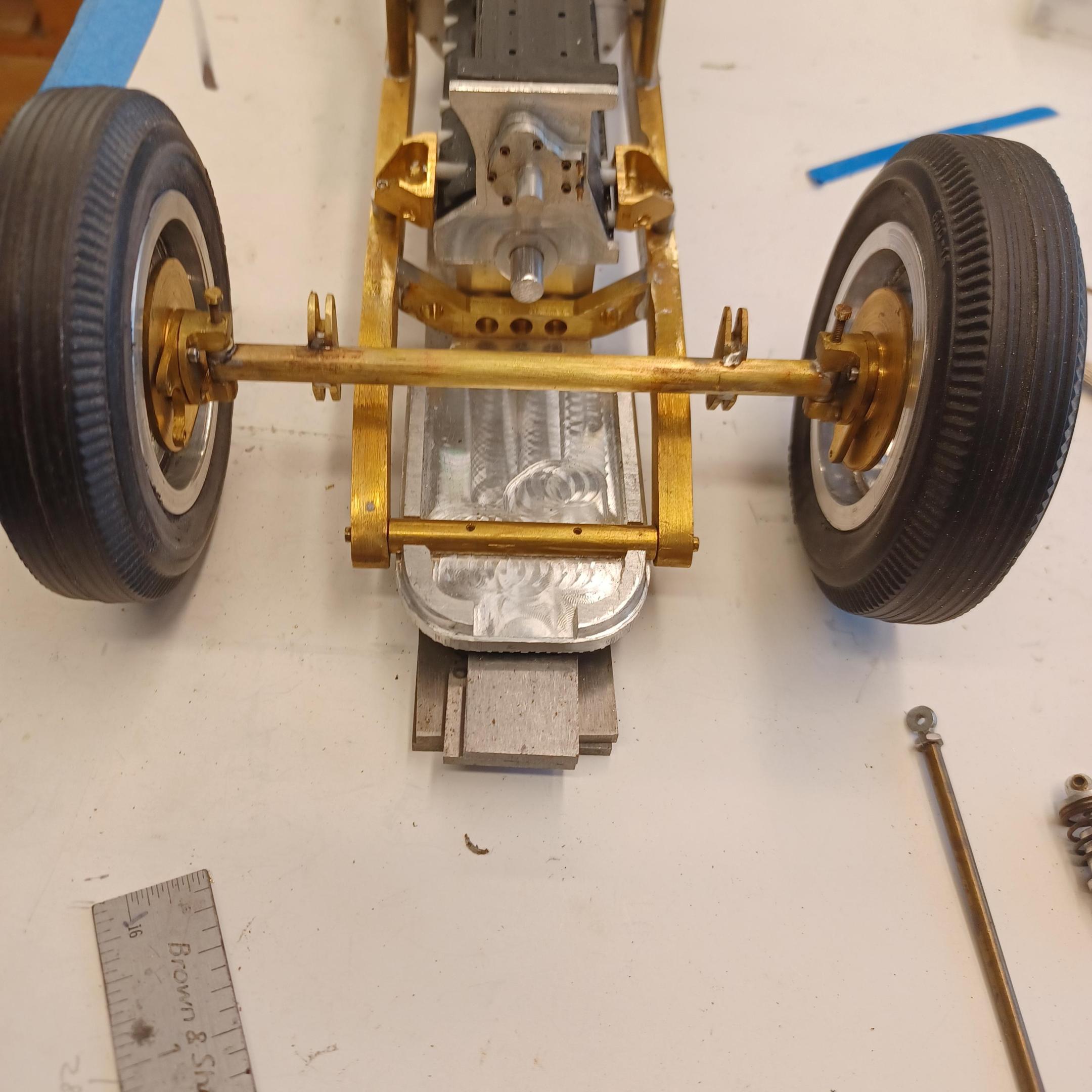

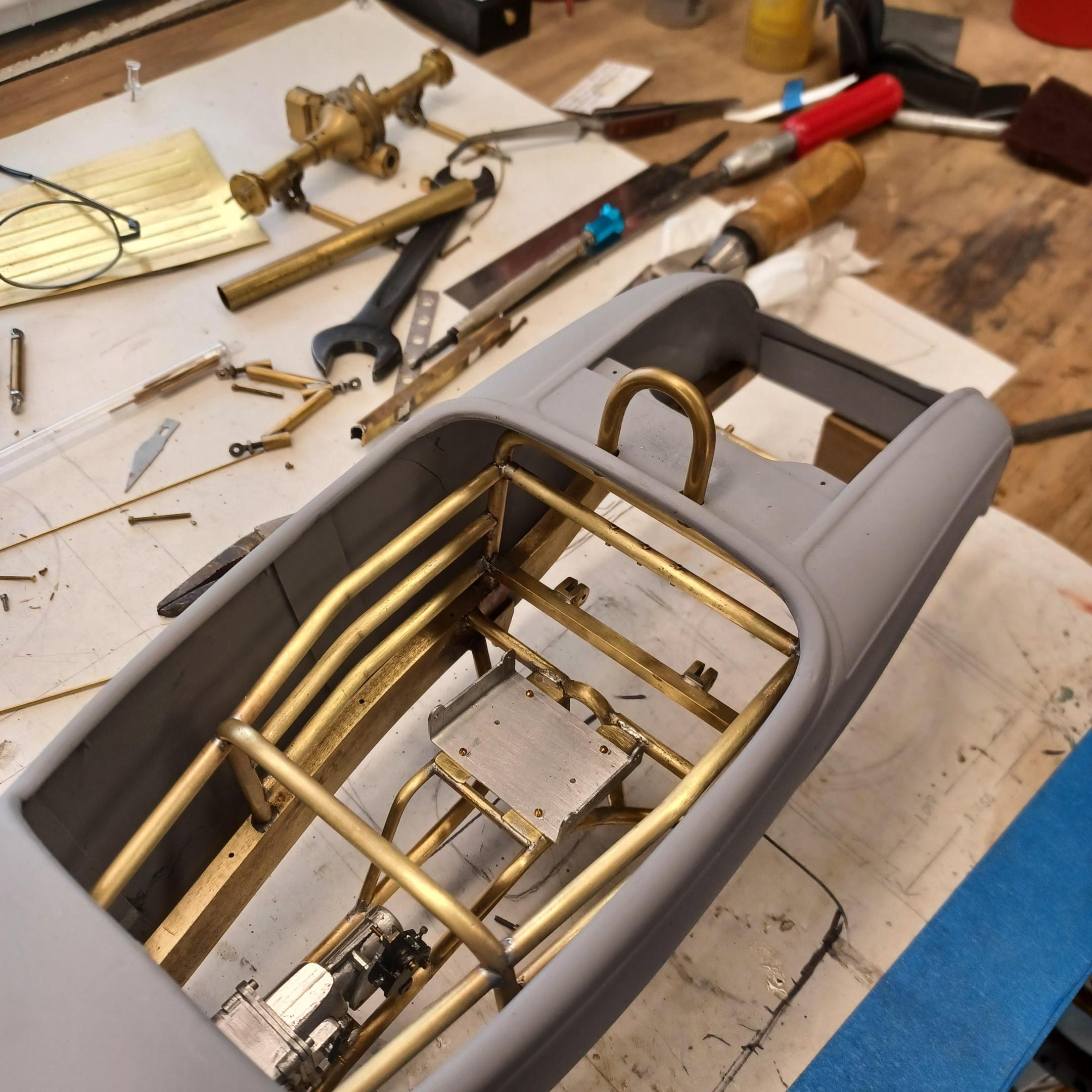

first time back. i have still been working on my project. i think i have my computer back to normal. we will find out, if i can include pictures. it worked ! ok, this is the center steer box. i have used it on several 1 to 1 cars. very common in sprint cars. the 2 brass pcs. are the mounts for it. just got started on the radiator. i have been working on the rear floor pans. not quite done yet.glad this is working again. i know nothing about computers. if they don't do what they are suppose to do i am lost -

Hi andrew,wow looking amazing.very close to the finish line. Very well done.your machine work is awesome.

- 406 replies

-

- harry miller

- indy

-

(and 1 more)

Tagged with:

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Sorry i have not been here lately. Having computer problems and i dont know anything about computers. Trying to find some help. -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

After a little more practice i might try some thicker parts like engine or suspension parts -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Hi andrew, it calls for about 580 i guess thats less than silver solder -

i know how that is ,i am from maine. your project is really looking incredable. always a pleasure to look at

-

condolences tim .i lost my mom the week before her 90 birthday last year, its hard. getting back in the shop will help.

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

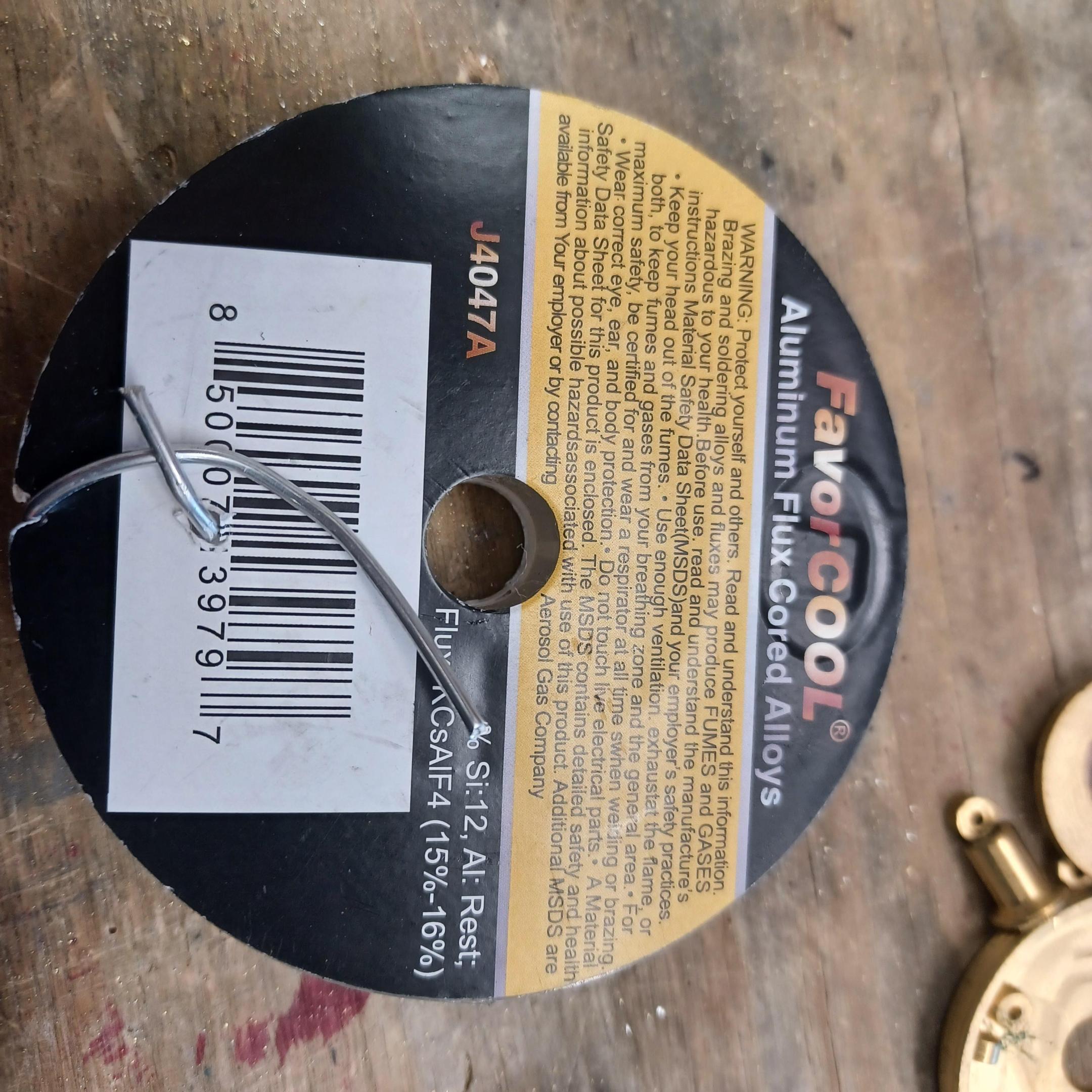

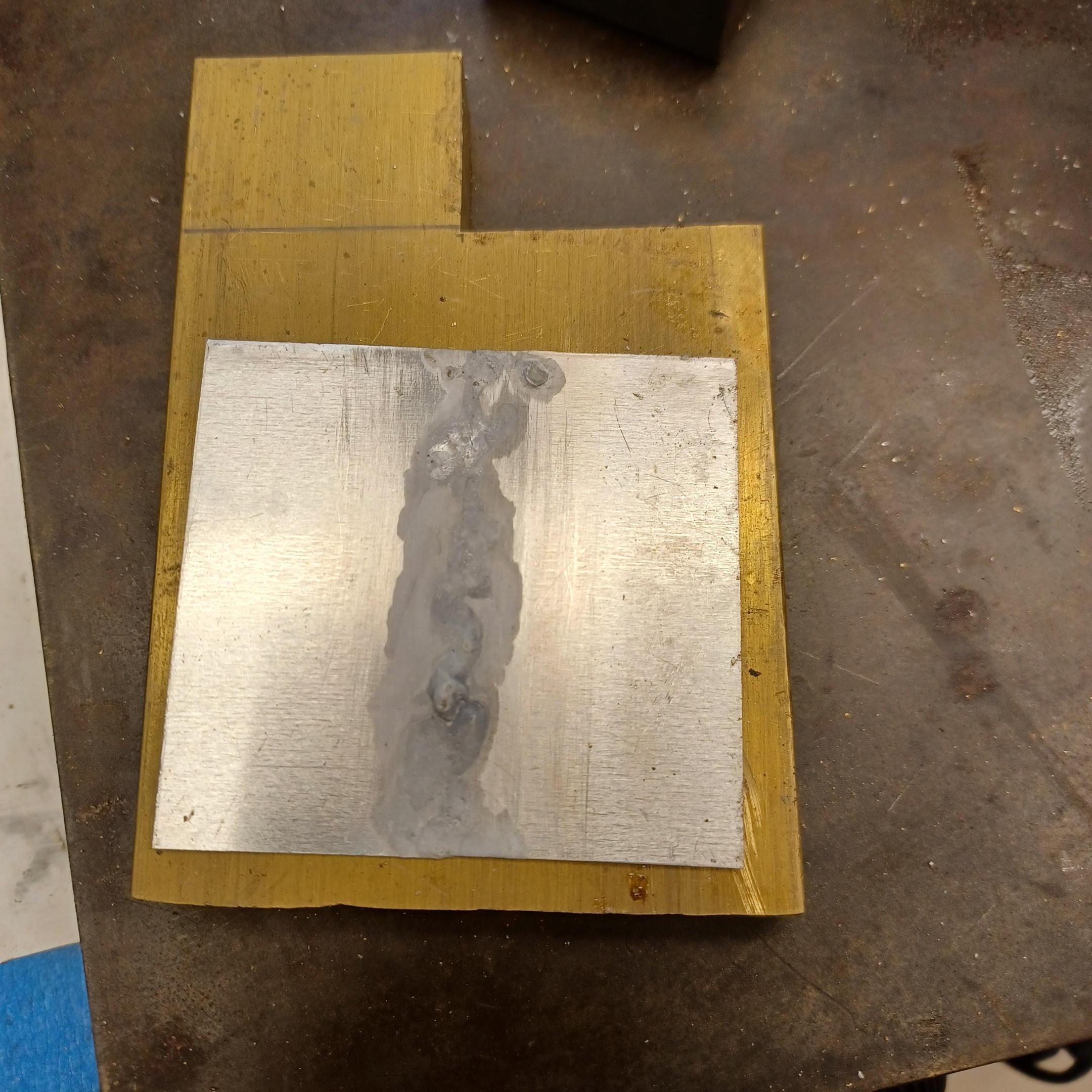

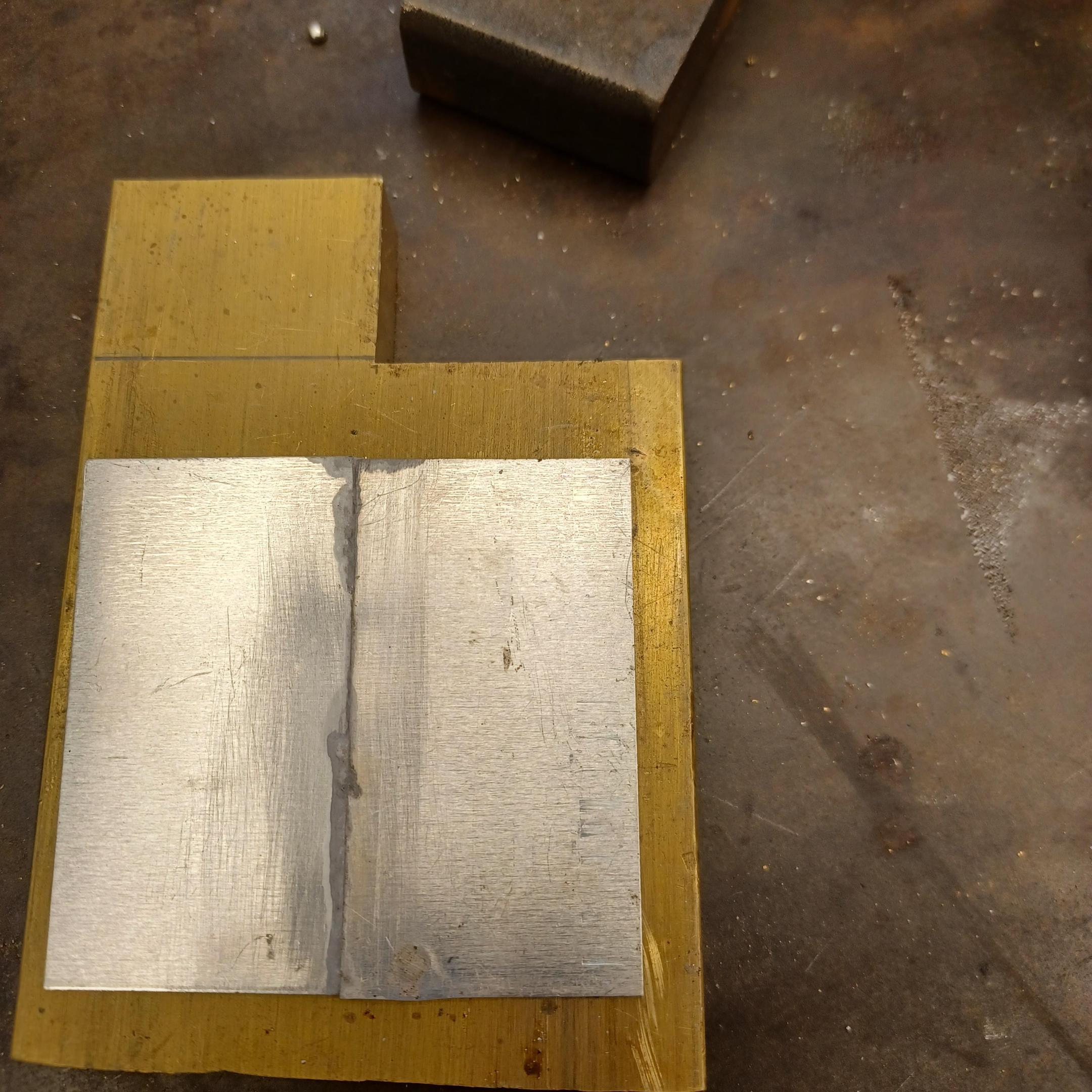

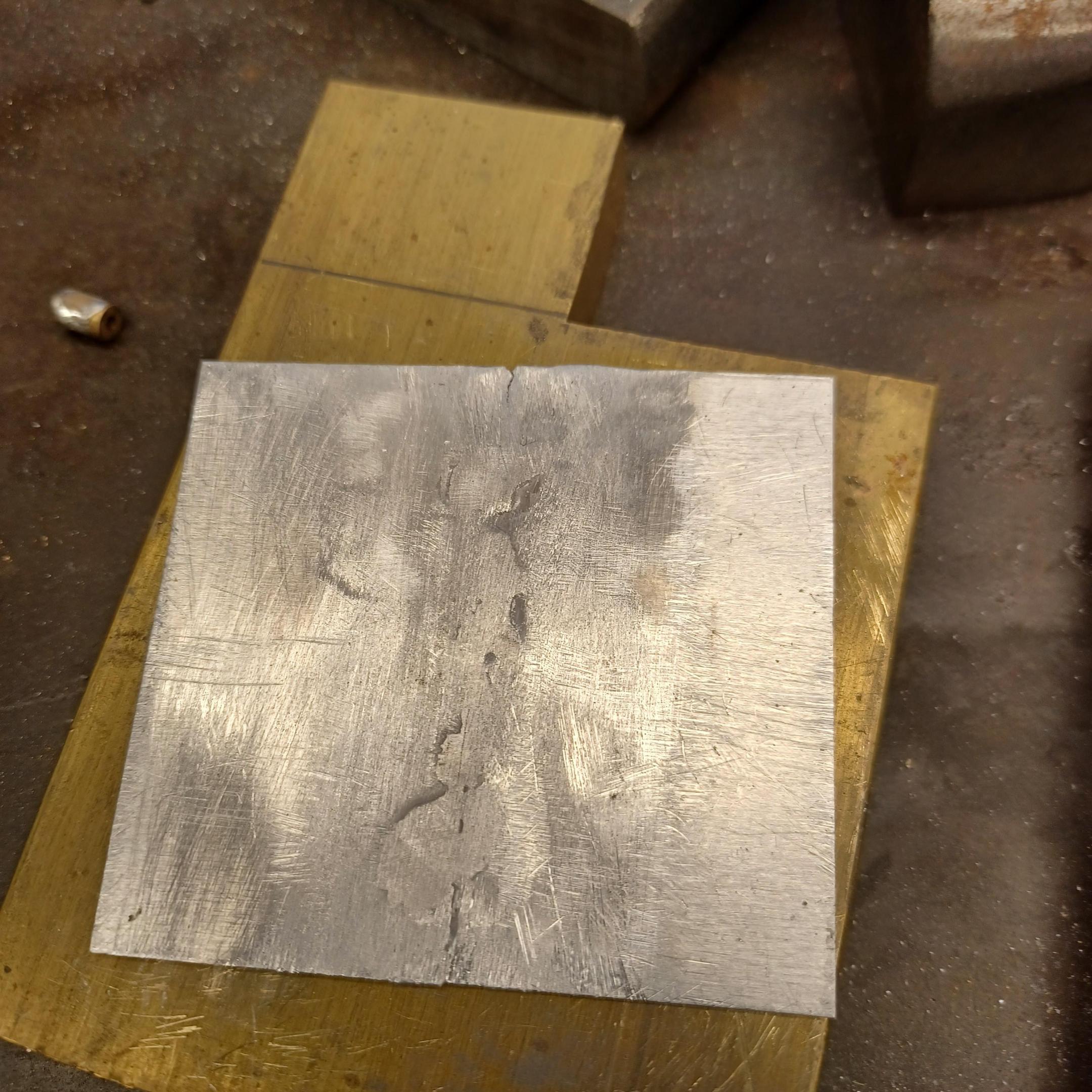

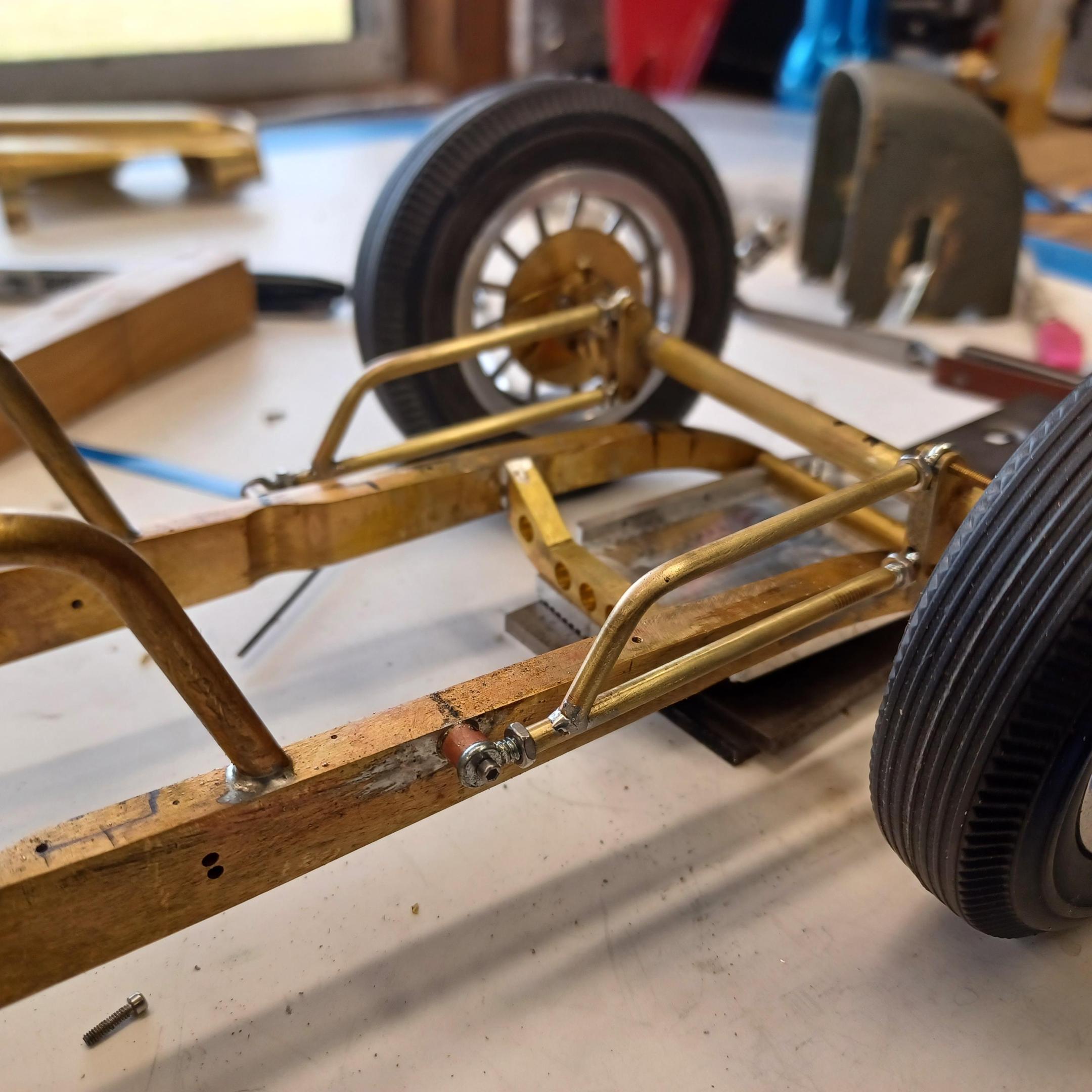

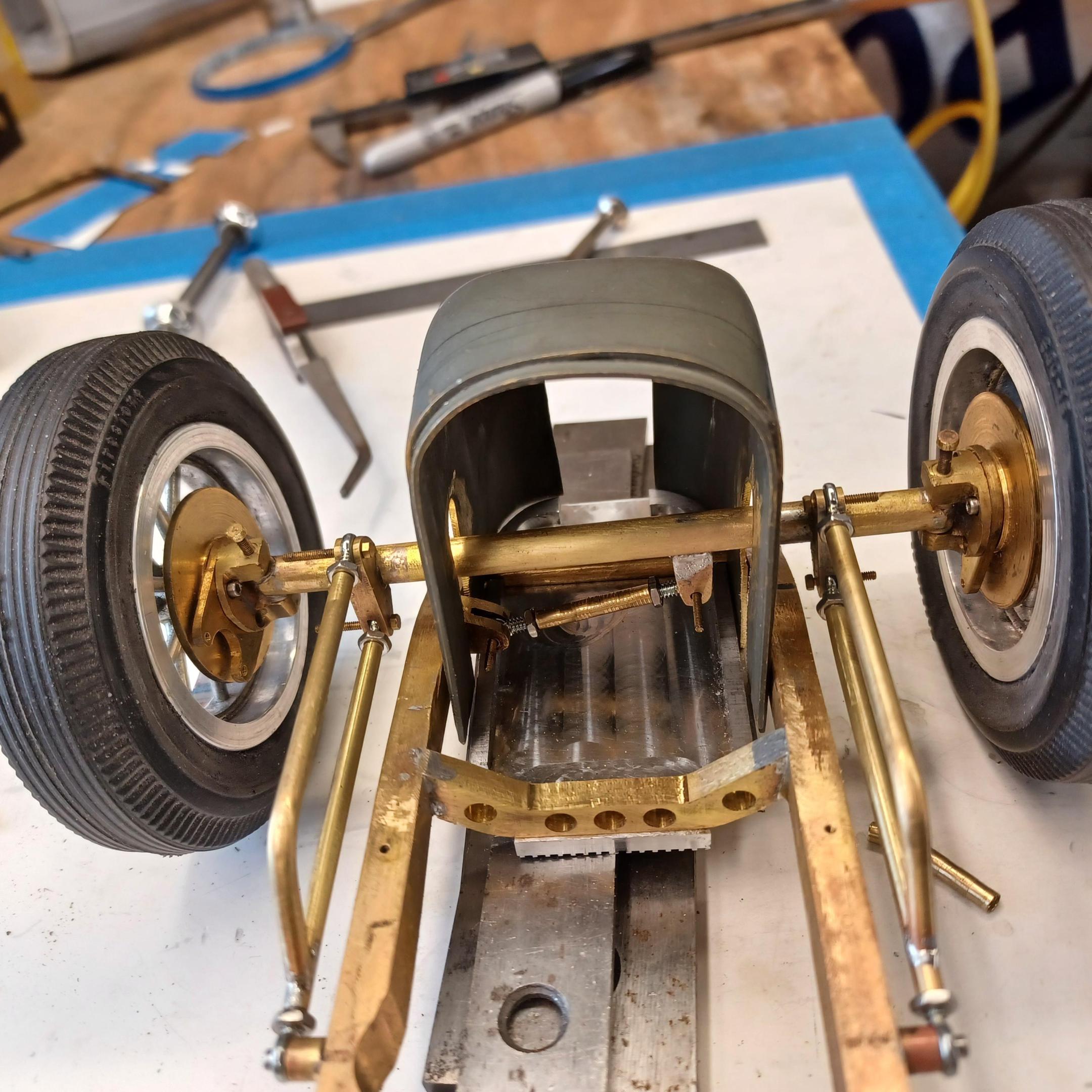

hi bob ,great to hear from you. tim ,not polite to laugh at other peoples work. just kiddin. nice to hear from you how are you doing. any progress on your neck ? this getting old thing is tough. daniel, i have finally got the aluminum solder and tried it on .025 aluminum.that is what i want to use to do an aluminum body. i am very happy with th results.it solder very nice. it is realy strong. i filed and hammered the solder to the .o25 ,same as the material and it was just as strong as the the base metal.as you can see i bent and rolled the material on the solder and it was as strong and as flexable as the the rest of it.great stuff . cant wait to finish the 32 and start on some practice body parts. i have spent many hours tig welding and gas welding aluminum . i think when you solder this you should be sure not to cool the material after solder in any way. dont even let air from a fan blow on it. if you let it cool on its own it will anneal the material and it will be softer and more flexible. i hope this will help you .i rolled the piece and then flattened it out with no problem. also i have been working on the front suspension, its coming along well. hope i have enough room for a radiator. -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

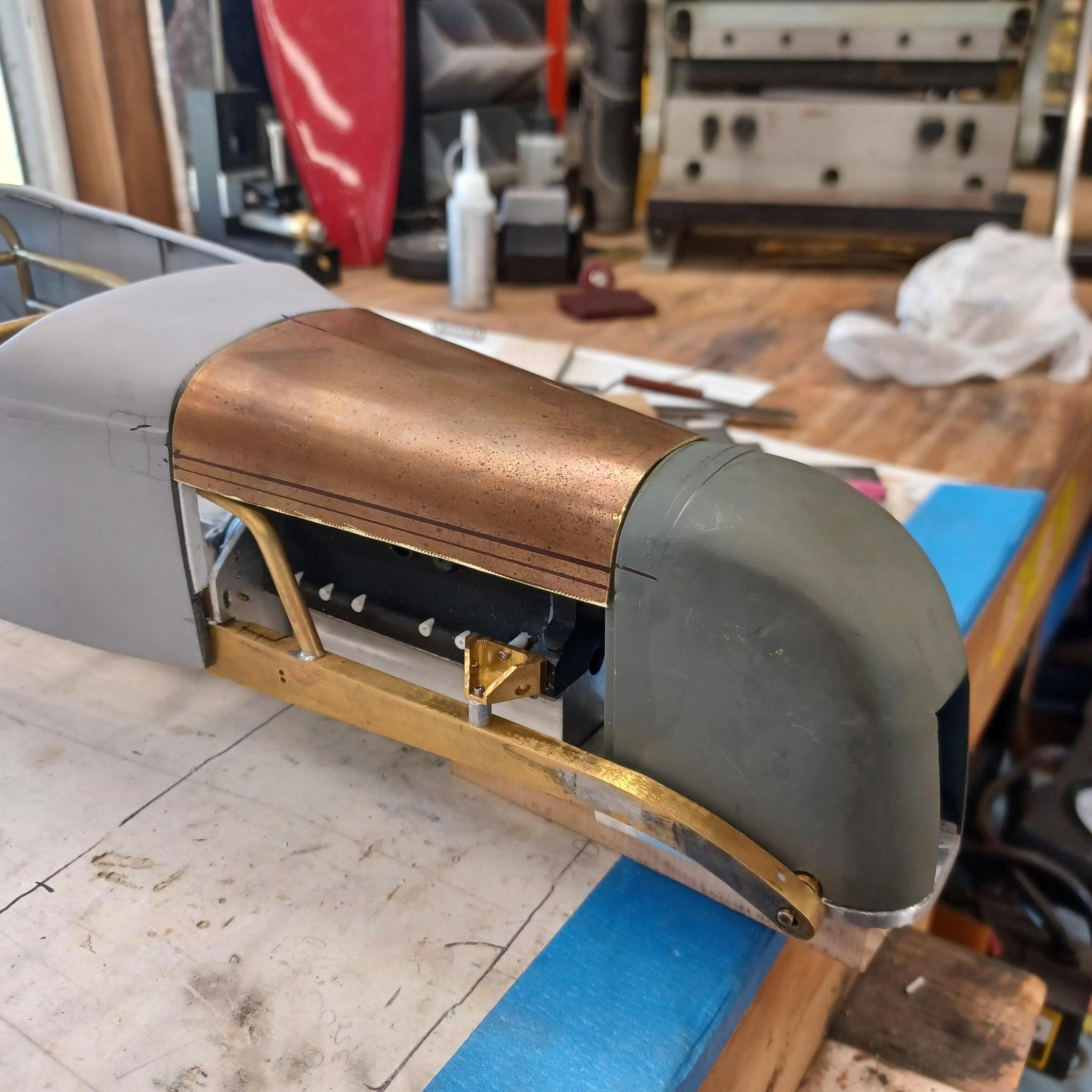

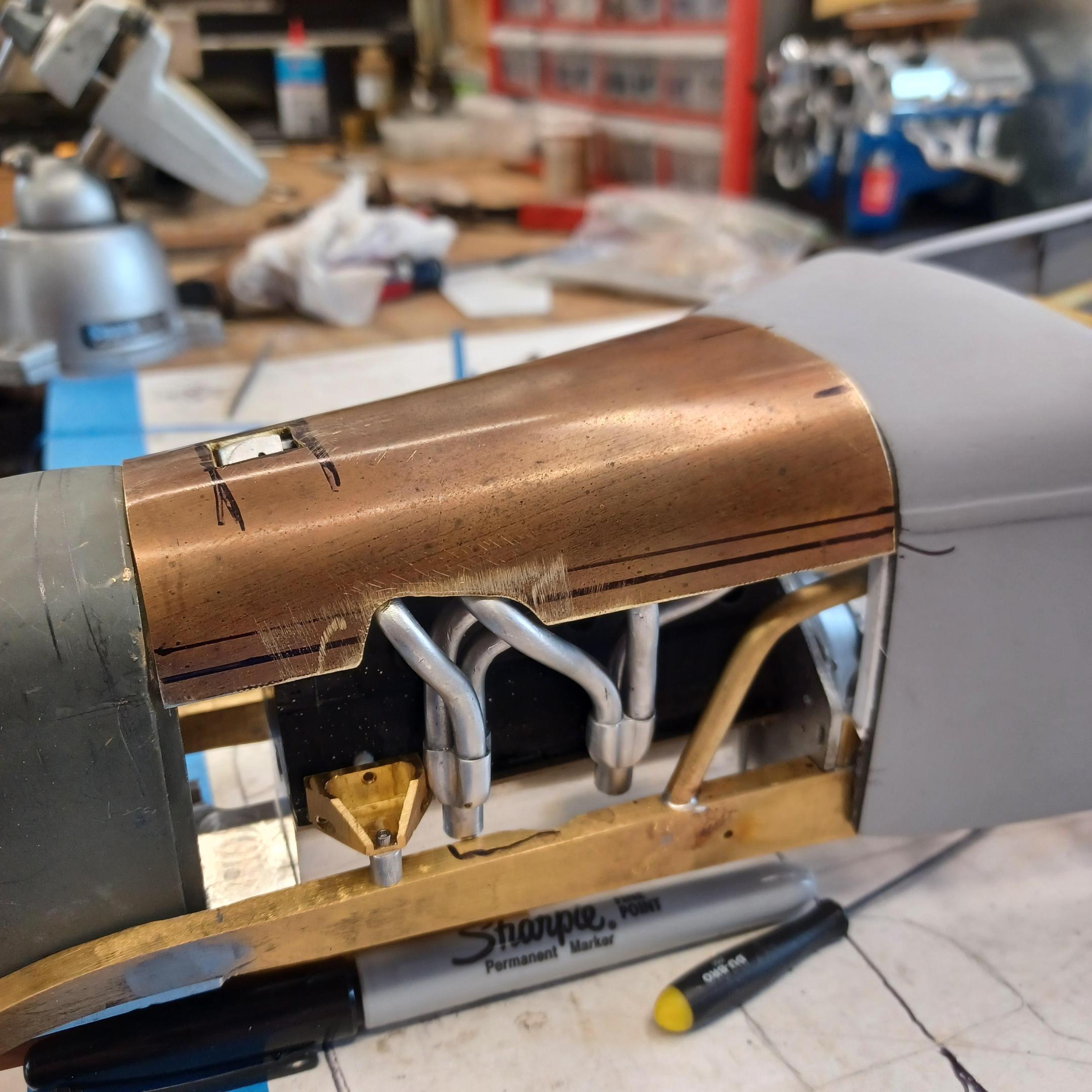

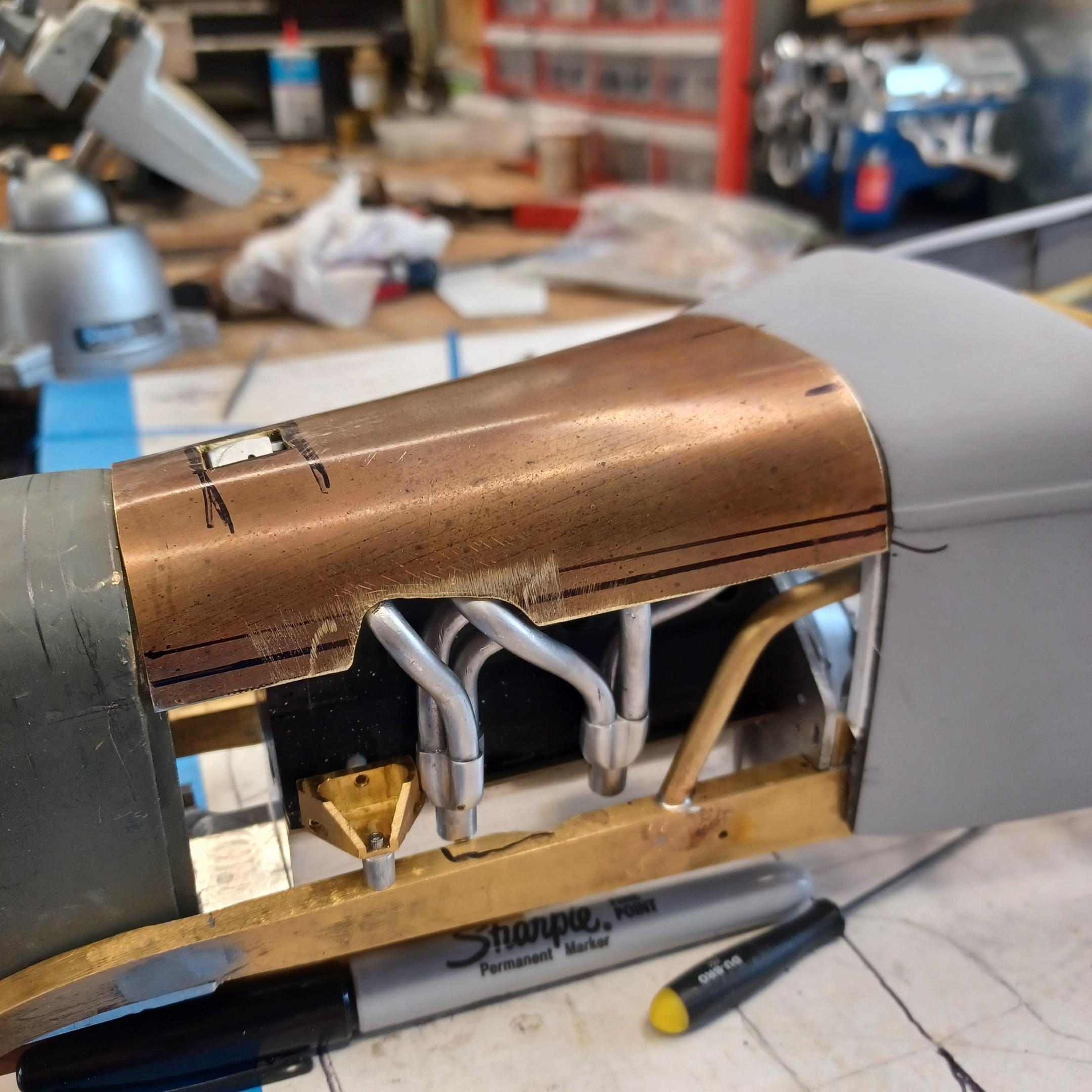

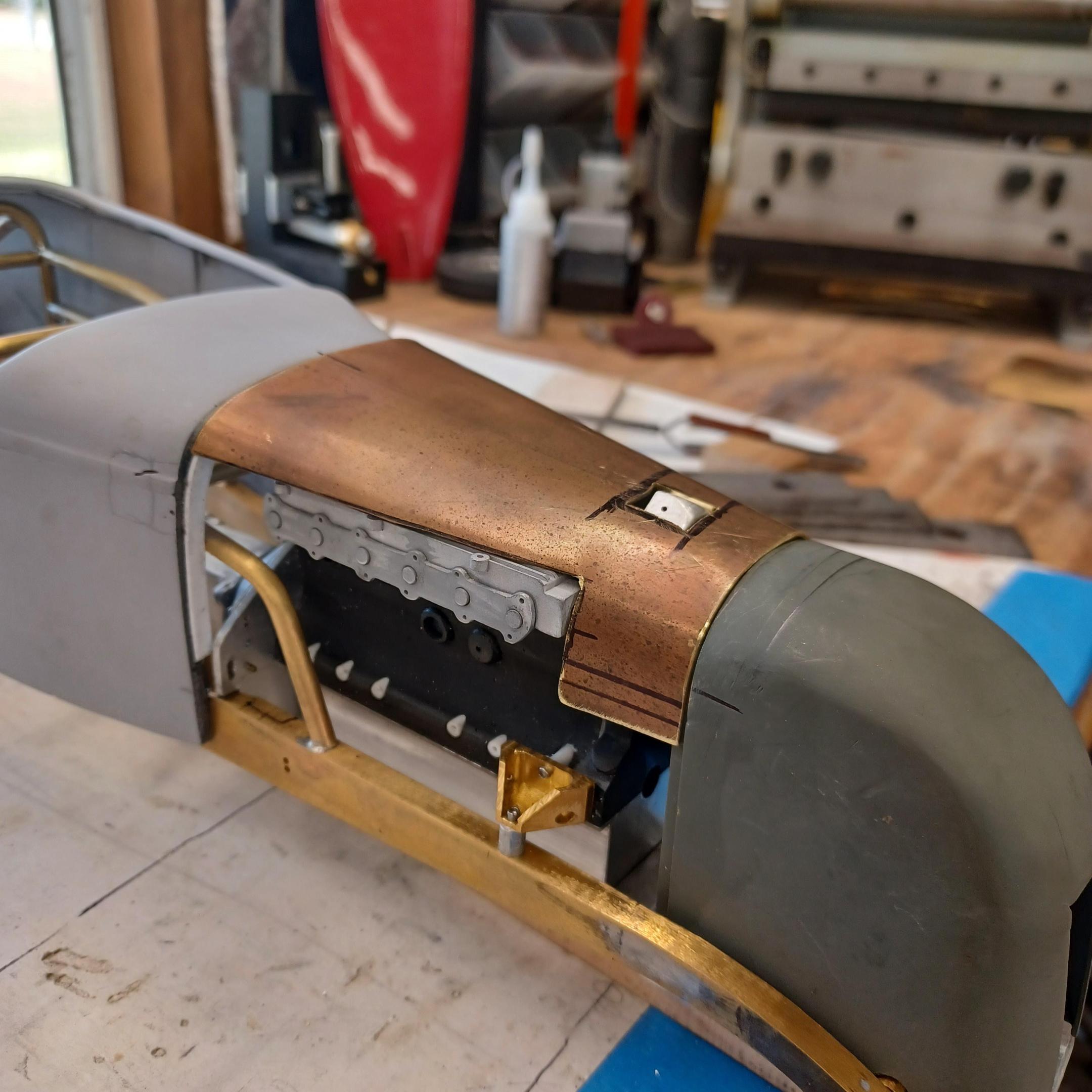

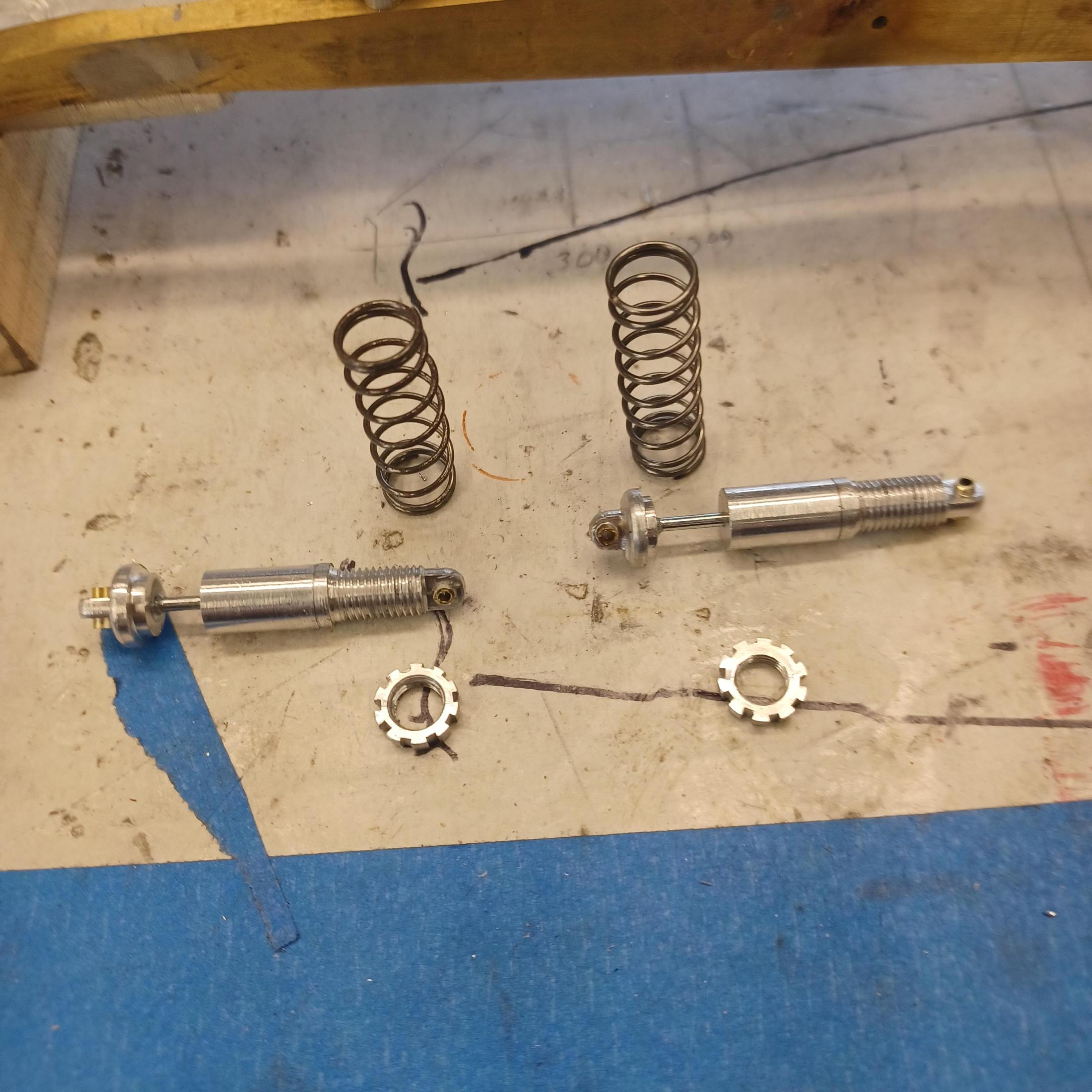

nice to here from you ian i have been following your current build . hello jim thanks for looking and commenting. pictures of the shocks almost finished,a little detail and anodizing. continuing on the hood. so many engine parts in the way. but its getting closer. leaving the weber out there in the open.this is more work than a 1 to 1 car. -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

hi francisnice to hear from you ,cant wait till you start machining aswell. always fun to see. andrew i think maybe a window on the bottom of the bell housing. dave , you tube for the anodizing, great source. thanks for your kind comments bill. rattlecan dan, i ordered some soldering wire for aluminum and should be making an attemt next week . i will post pictures nomatter how bad they look. started and finished the rear shocks. they are better i think than the last ones. felt like playing with sheet metal today so i started on the hood. not sure what the final hood will look like just going with the flow. alot of things in the way. happy st. patricks day -

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Looking great francis.i have never cut open doors. Cant wait to see your hinges. -

Looking good andrew.all u lack is finishing up

- 406 replies

-

- harry miller

- indy

-

(and 1 more)

Tagged with:

-

Looking good andrew. Glad to see another update.

- 406 replies

-

- harry miller

- indy

-

(and 1 more)

Tagged with:

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

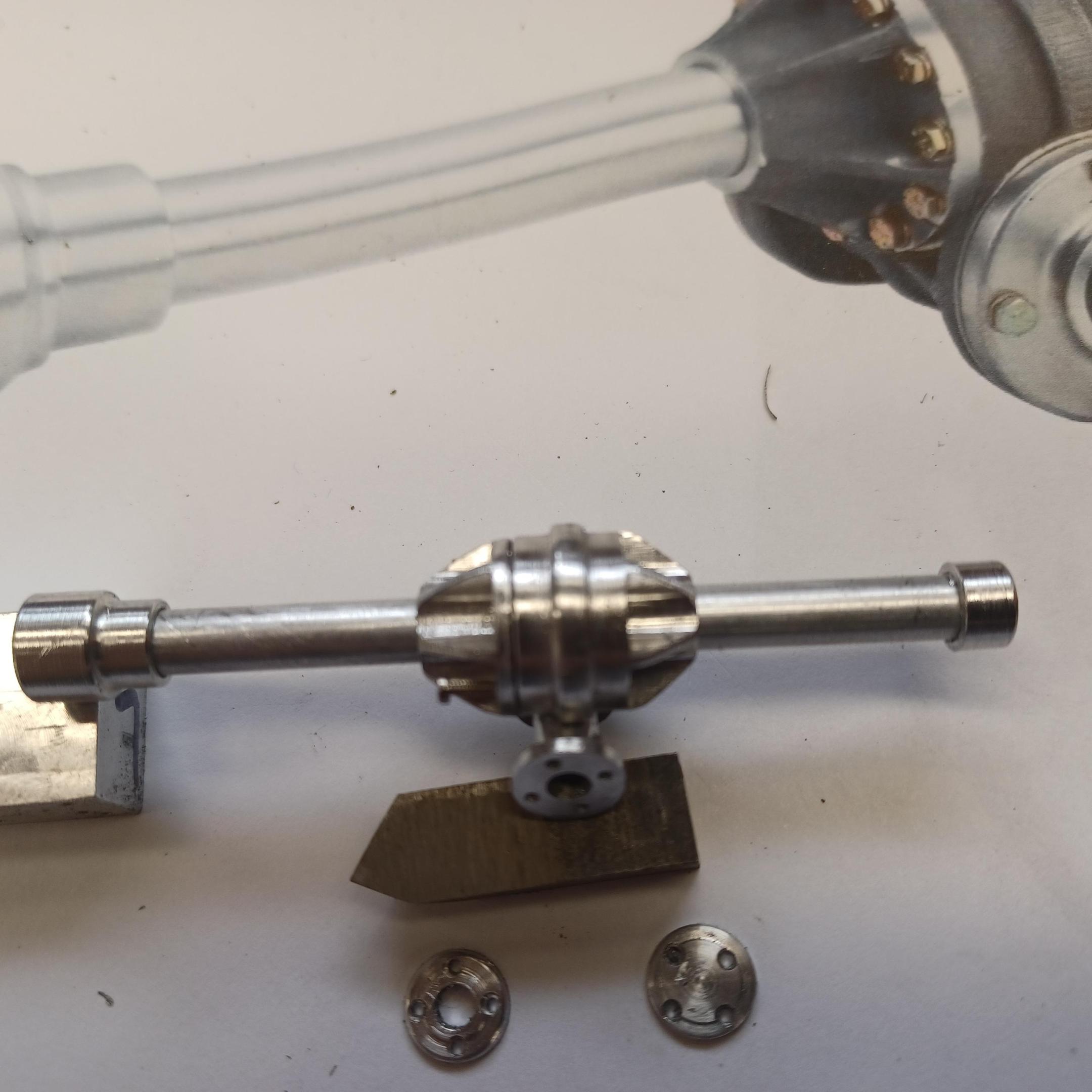

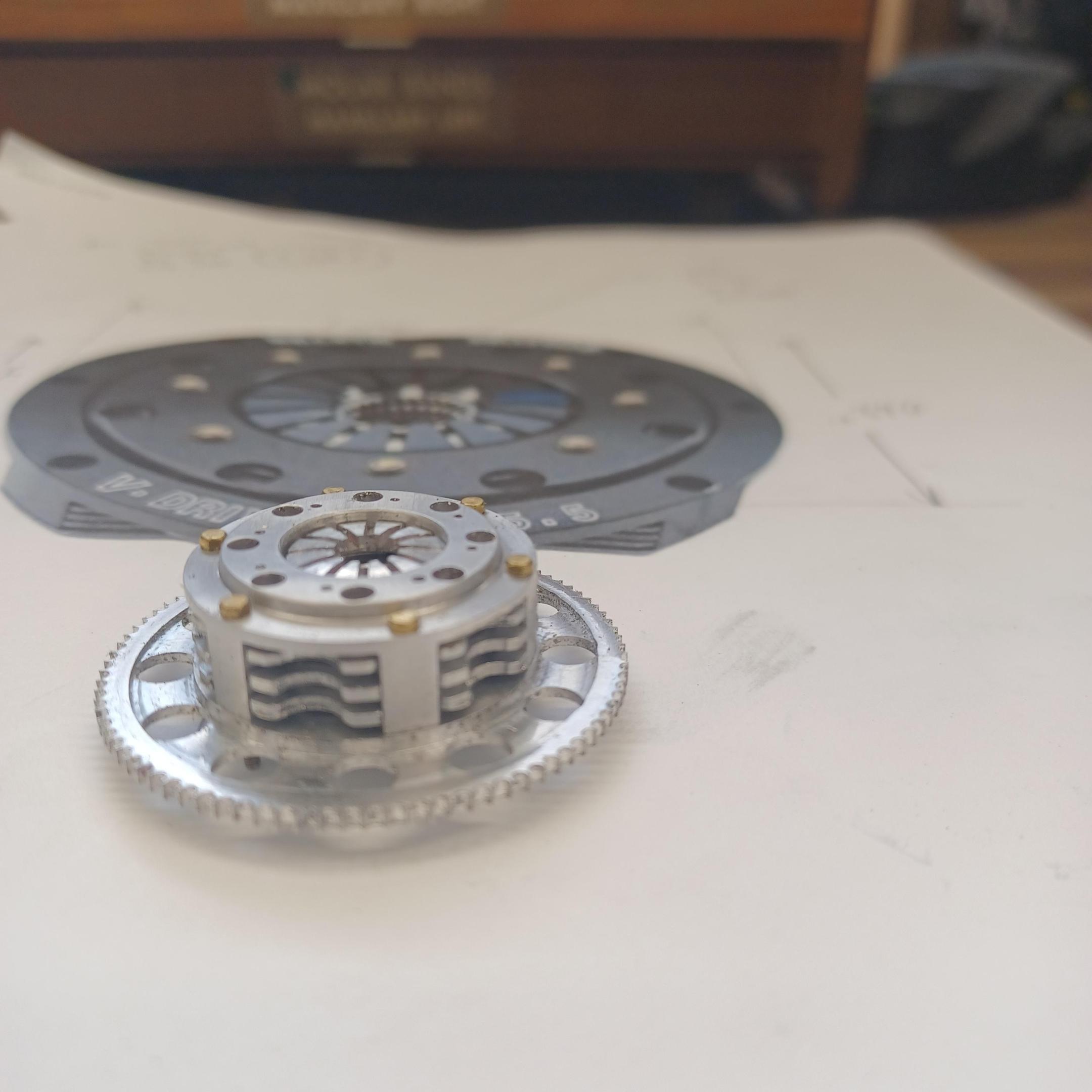

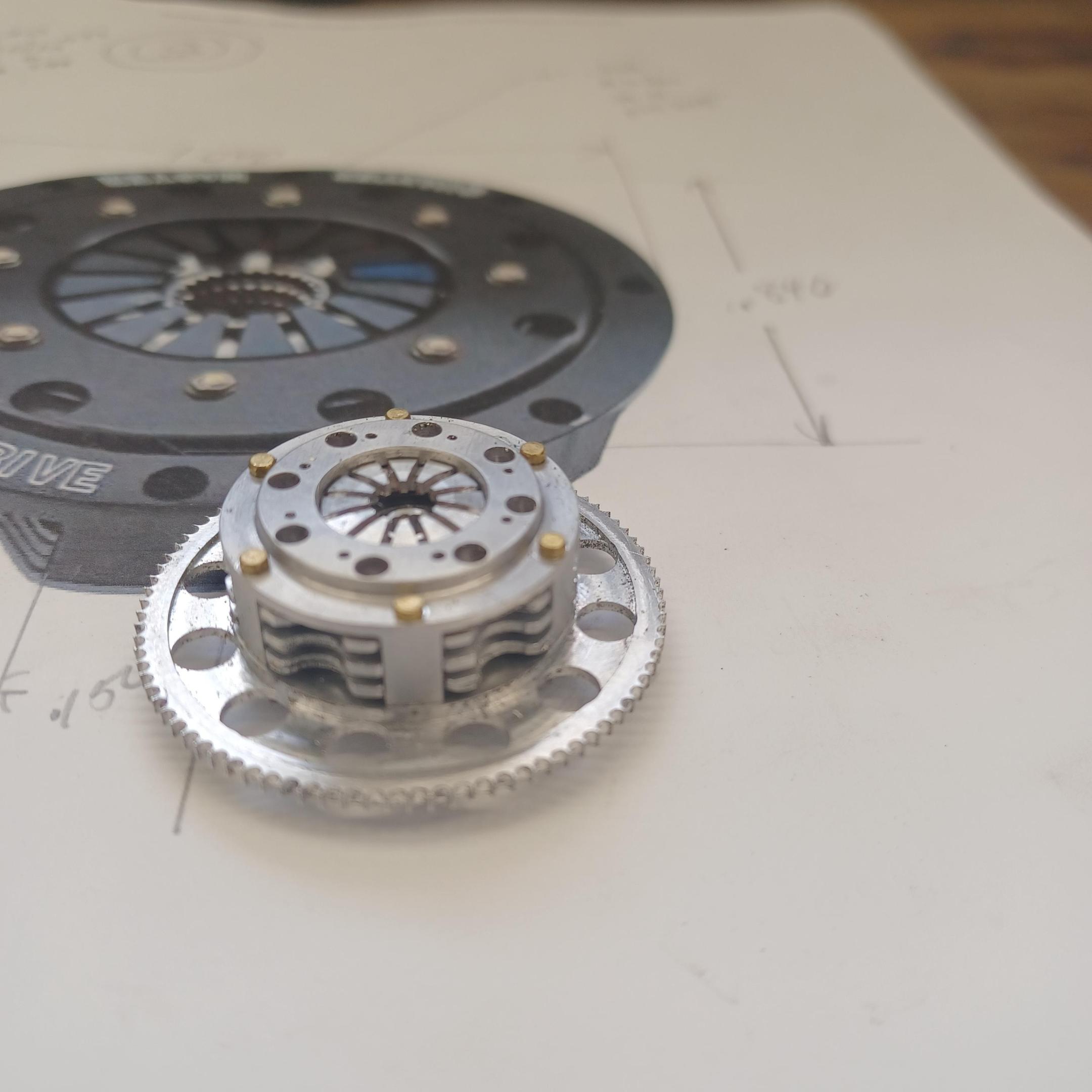

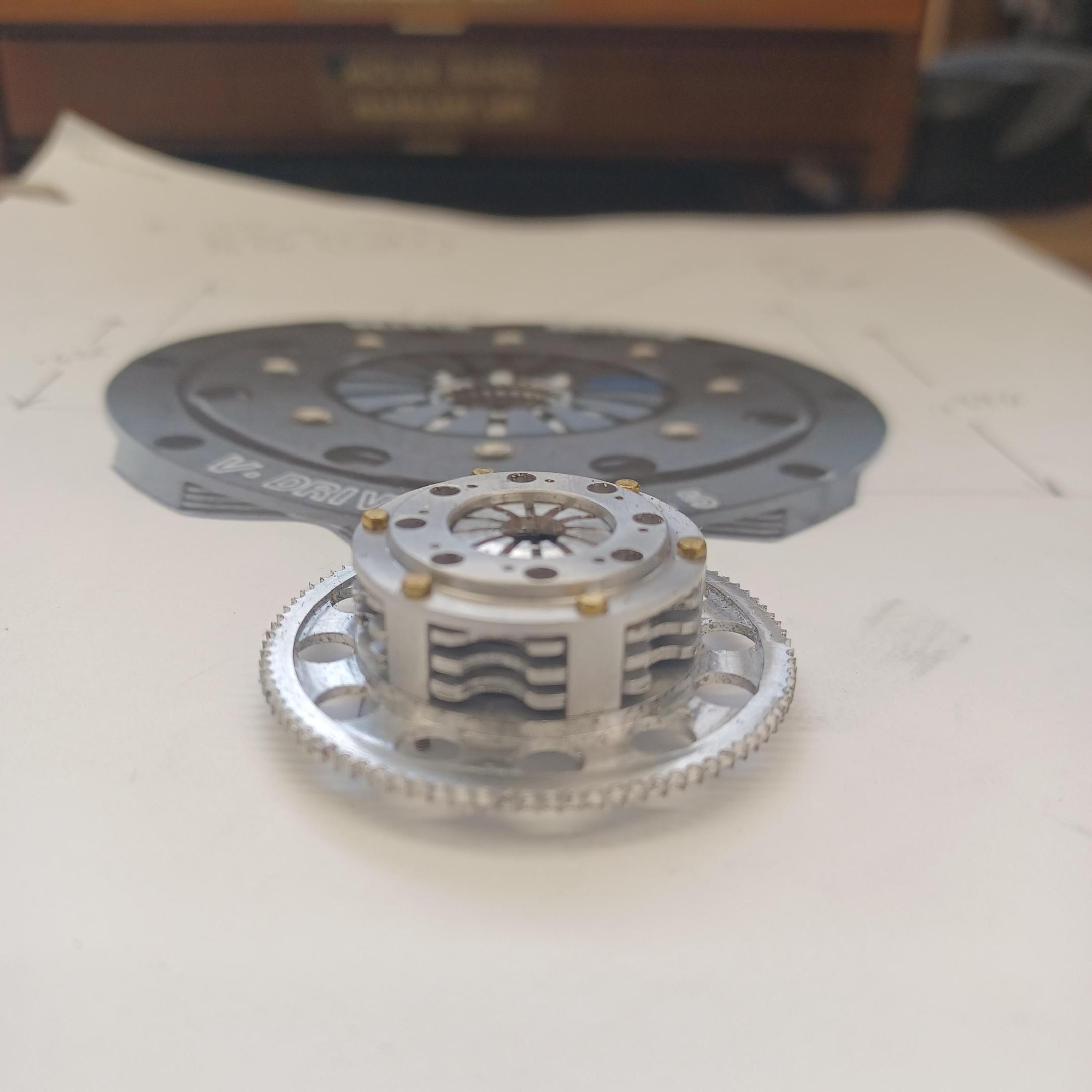

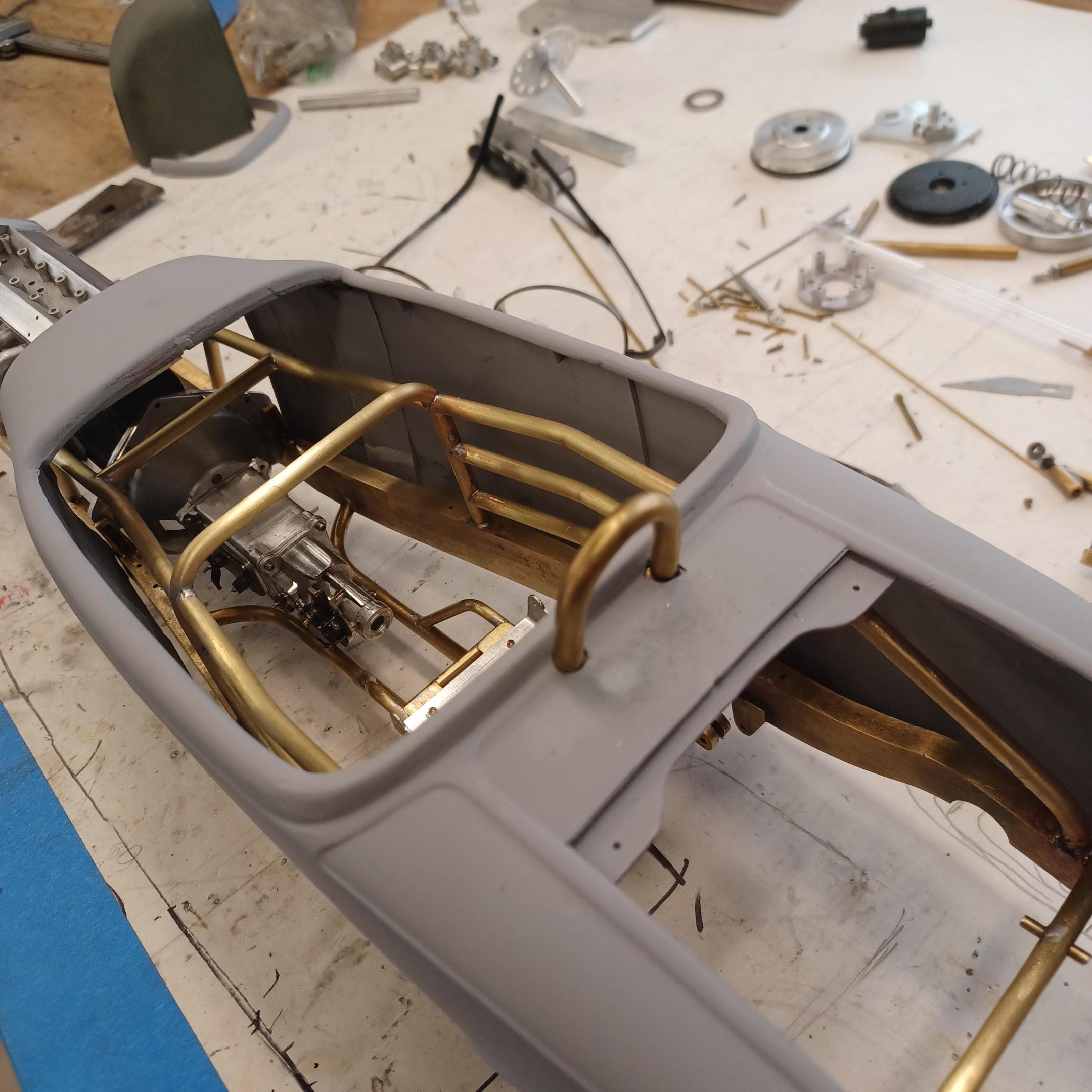

i haave been busy making the rollcage and seat mount. i will make an aluminum seat . i have the flywheel and clutch finished but not anodized yet. i am pretty happy with the triple disk clutch. when i take it apart clutch to anodize and paint i will take a picture of all the parts . rear coilovers next to finish the rearend. i think the driveshaft after that. i haven't started on the front suspension but i think i know what i want. -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

You might check and find out if the flashing has any type of coating on it,that will cause a major problem.i am going to try the flux cored wire on ks metals aluminum. I will let you know when i do it.soon i hope.thanks for your info.charlie -

Your project is looking awesome .keep up the great work.

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Thanks for the pictures andrew -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Hi adam thanks for your comment and for looking.have any of you tried brazing aluminmum.i want to build an aluminum bodie and would like to solder it. -

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Hi francis , very nice as always. Did you wrap the wheel tubs around something the correct diameter while the glue set? -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Hi francis,i enjoy hearing from you. Thanks for your comments and praise. I think it is coming along.i am have never been totaly happy with my work so it keeps me trying to learn and do a better job. -

WOW,the car is very cool, but the paint looks amazing.