-

Posts

416 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by charlie libby

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

you know you are welcome anytime Andrew. just started a new car, and a new thread. got to do under glass this weekend. where is Francis / are you still out there? -

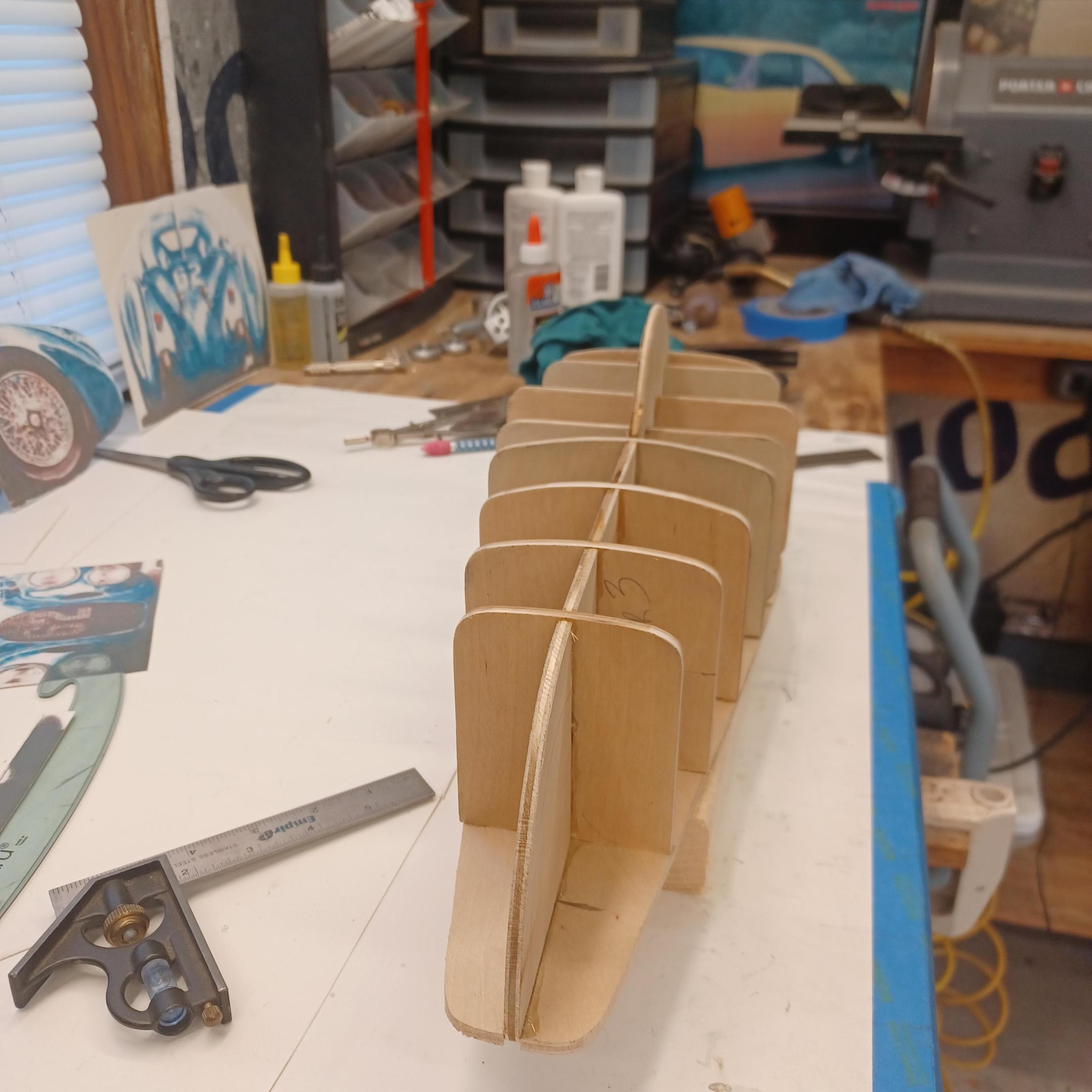

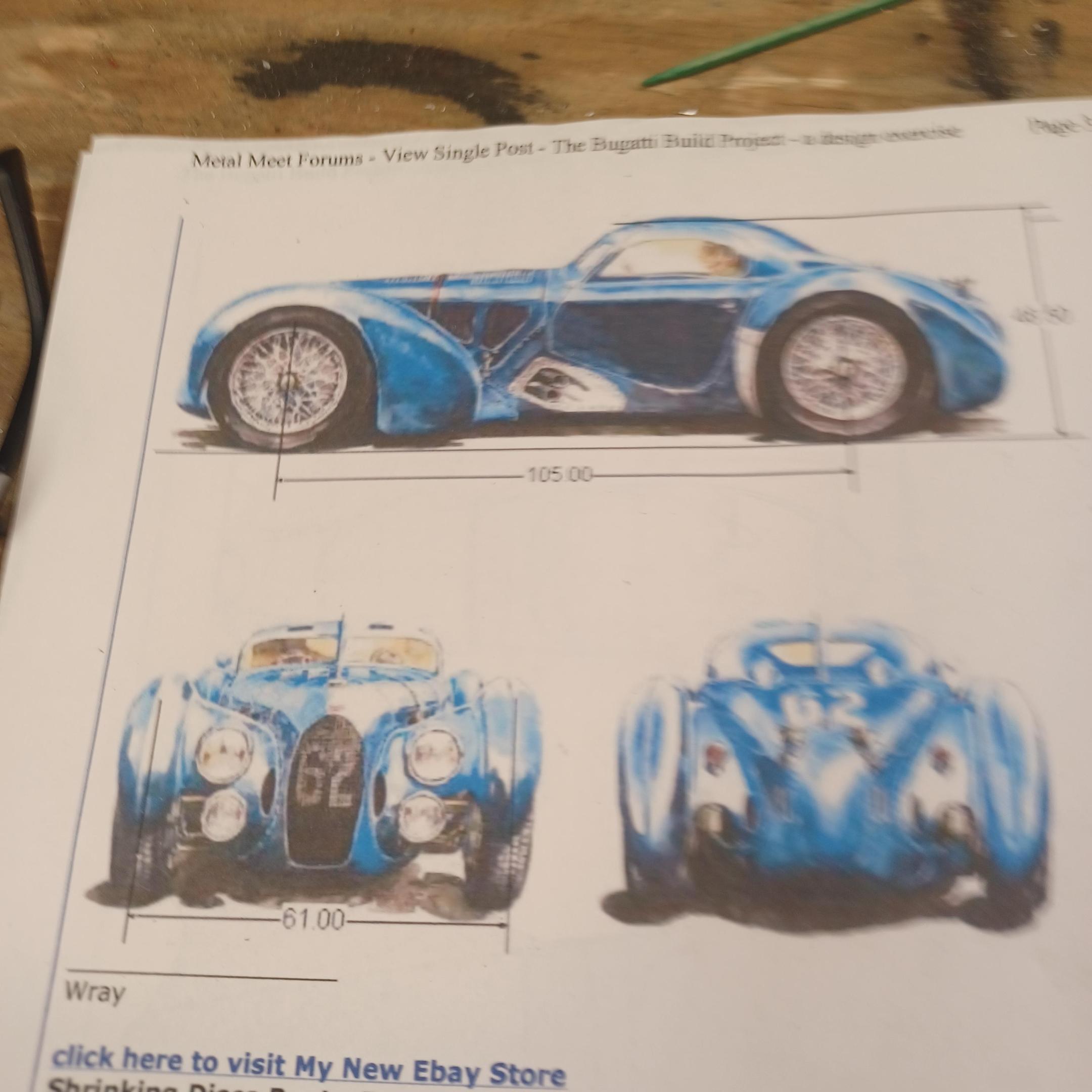

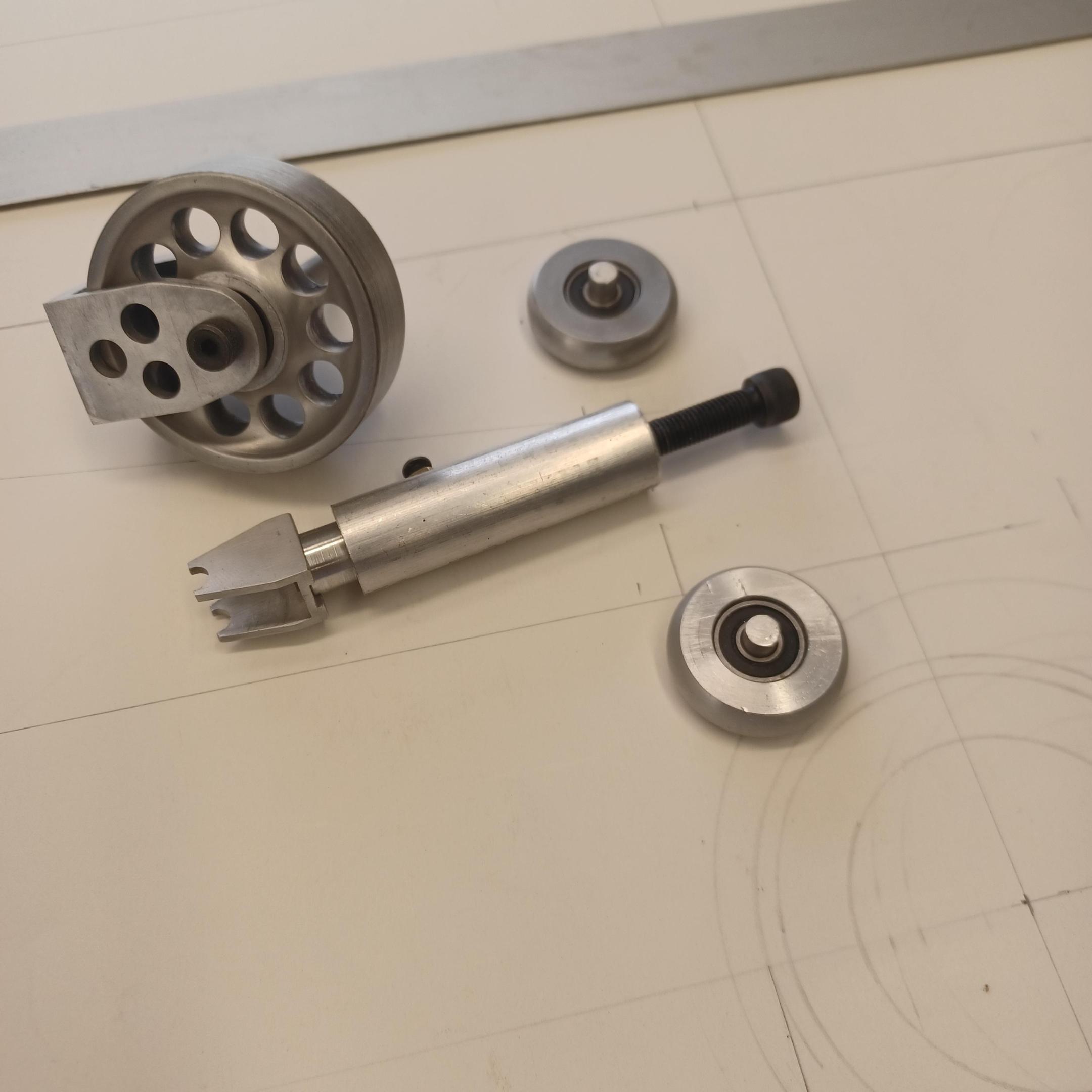

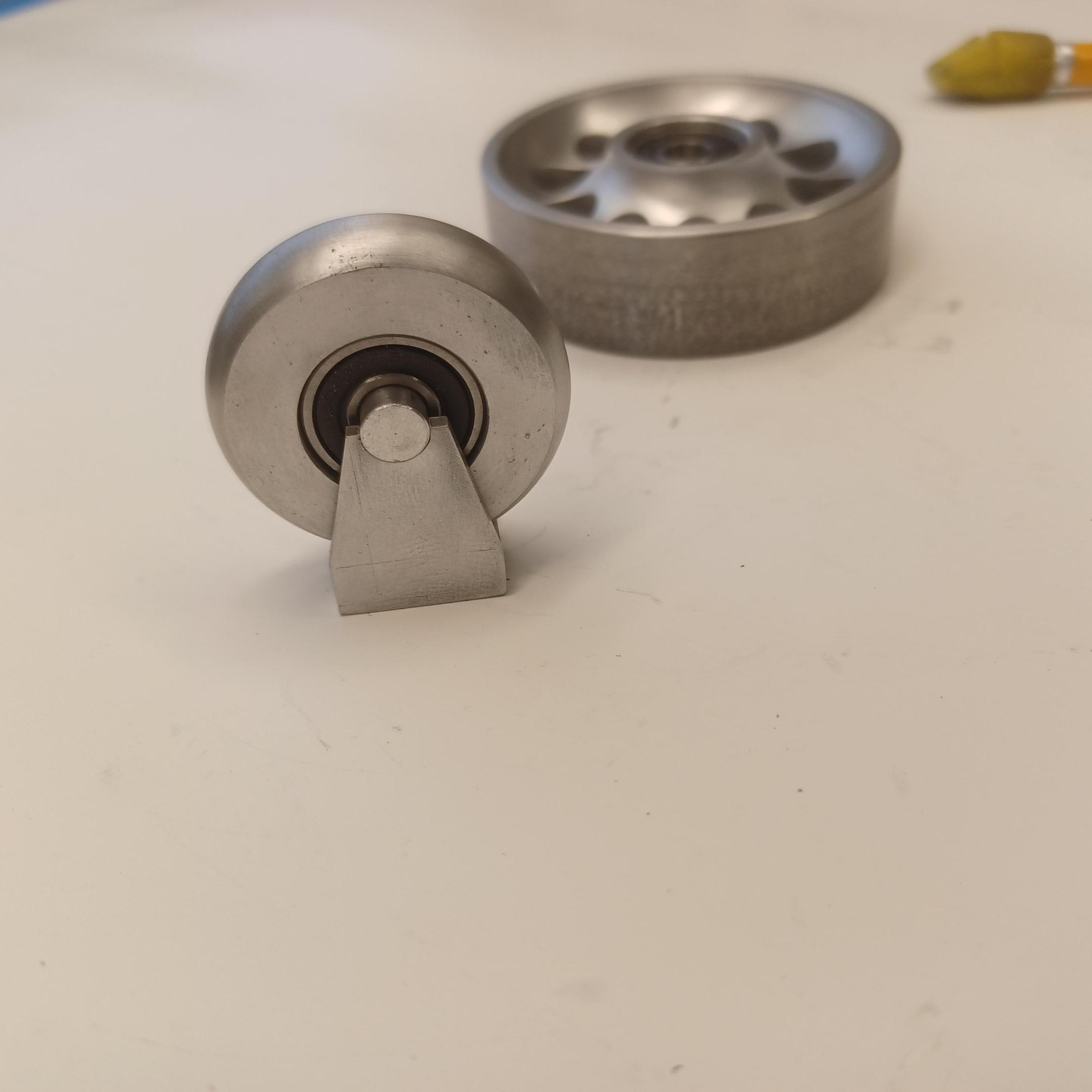

just getting started on this project. i believe its going to be a long build. i am building an English wheel to help with the metal forming, i hope it works. i just got the metal today to build the frame for it, I'll get started on the it tomorrow. i had pictures of the car blown up to the correct 1/8 scale dimensions and am building a body buck from those. i have a few pictures of what i have done so far. i built this car body in full size a few years ago and sold it unfinished. last i heard it is in a hotrod shop in Detroit being finished. i can only find a couple of pictures right now.thanks for looking.

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Thanks claude,i hope you enjoyed it.i am going to start the buck for the new body tomorrow.hi andrew, i should have the material for the frame foe the wheel tomorrow.looking forward to trying it out. It might take a little experimenting to get the wheels right.you should stop by and try it when its up and wheeling.thank you -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

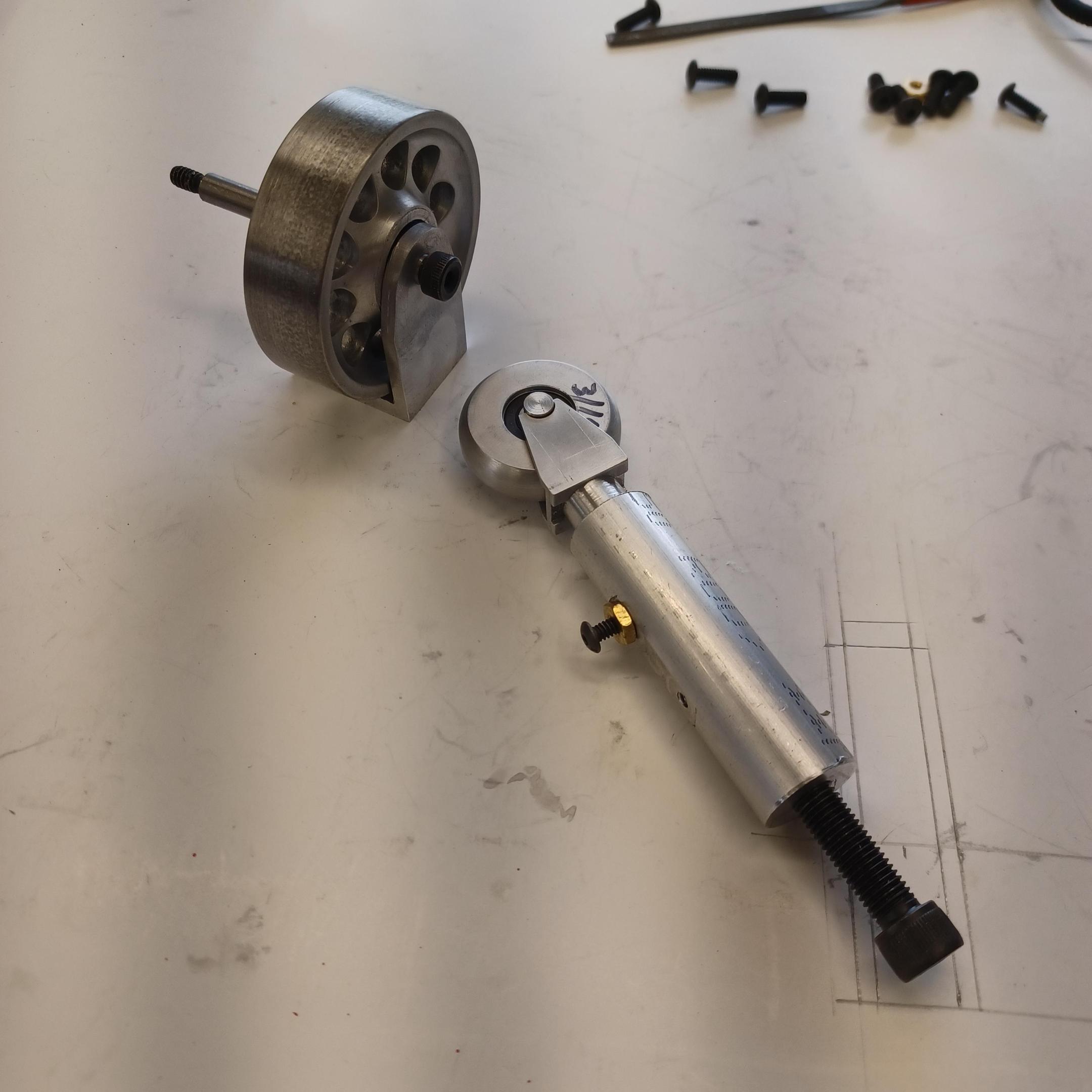

i think the 32 is finished .got the windshield formed and installed . i think it looks pretty good .got started on the english wheel. need to order material for the frame now that i have decided what it will be made from. ill get pictures on under glass this week i hope. the english wheel is the beginning of my next project. -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Be out of town that weekend. -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

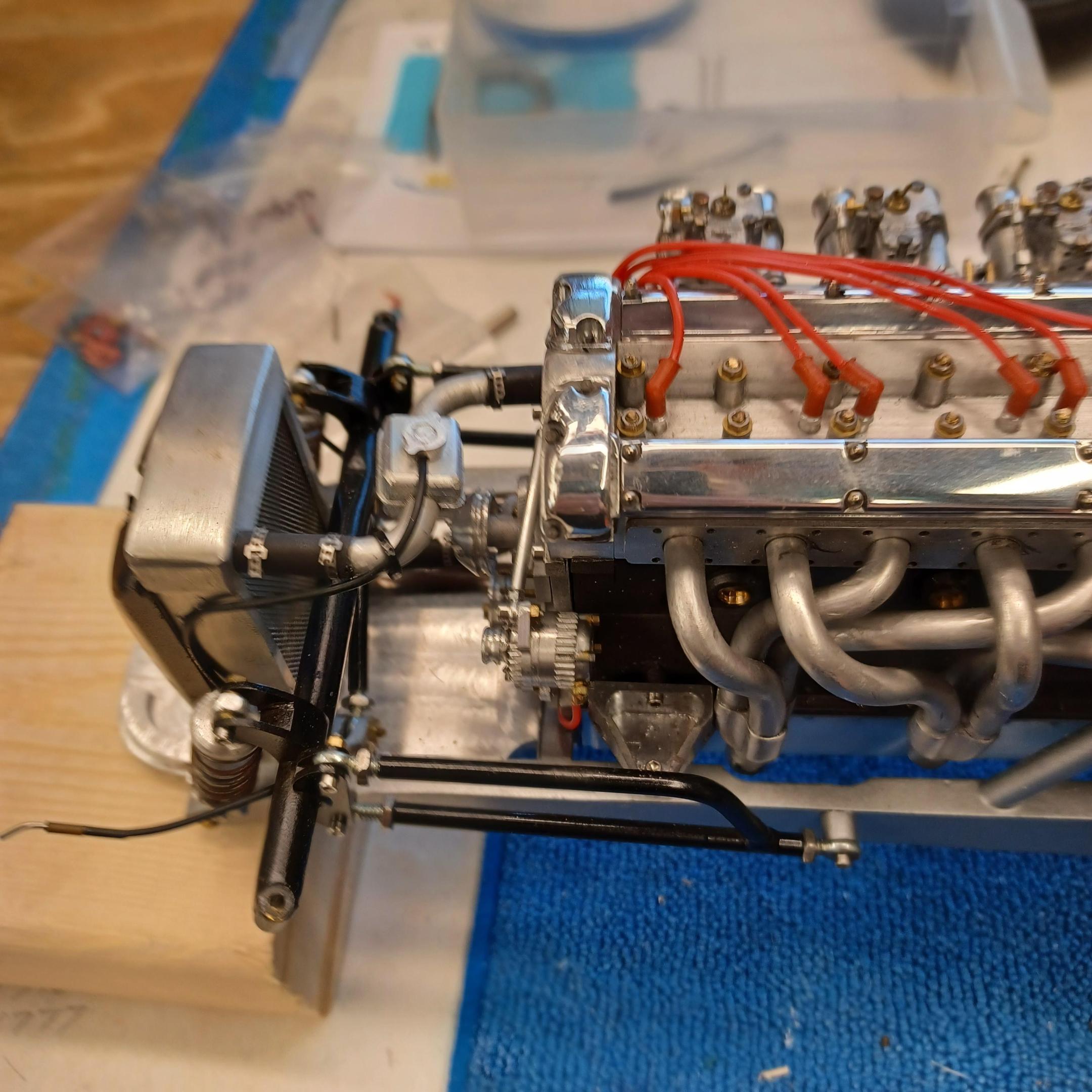

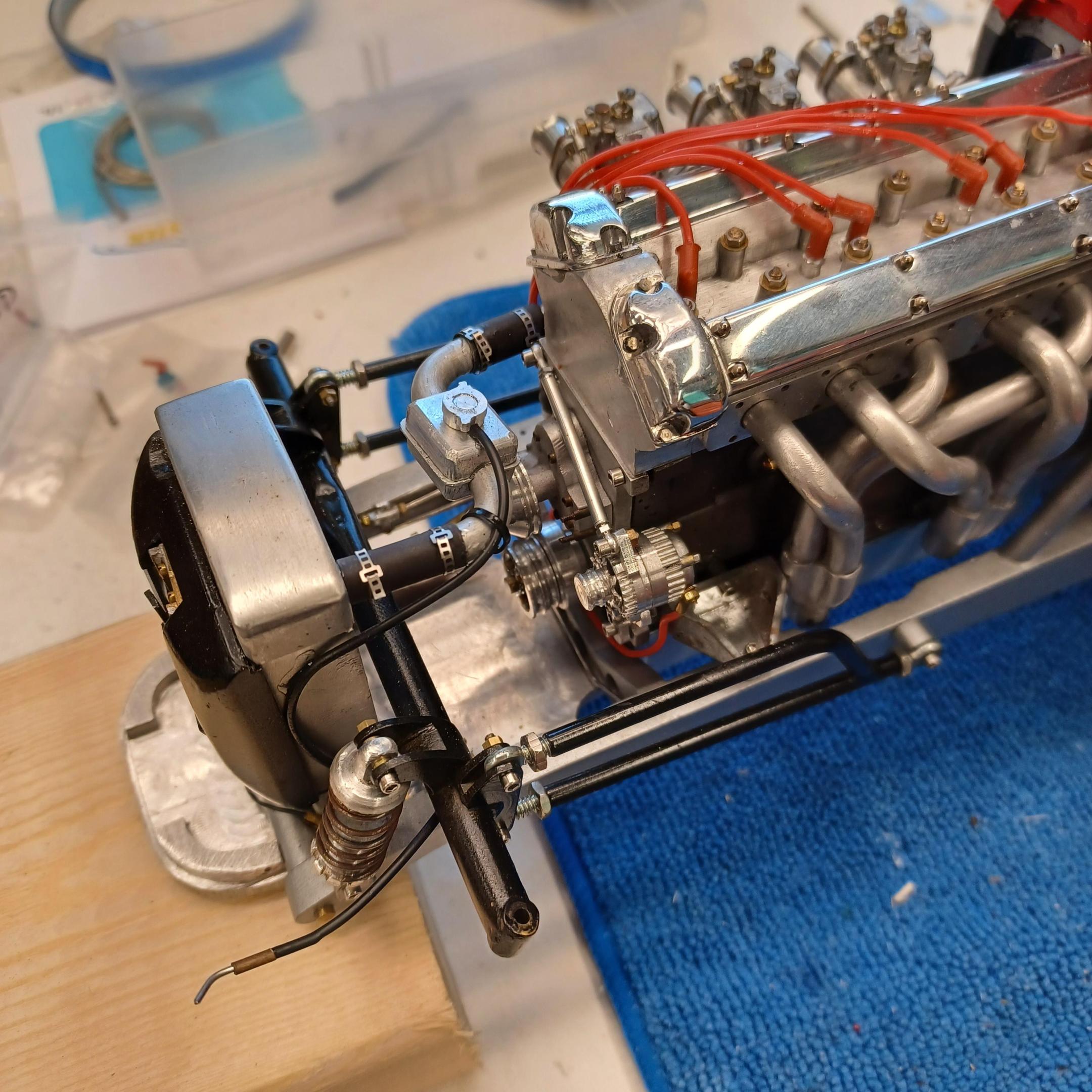

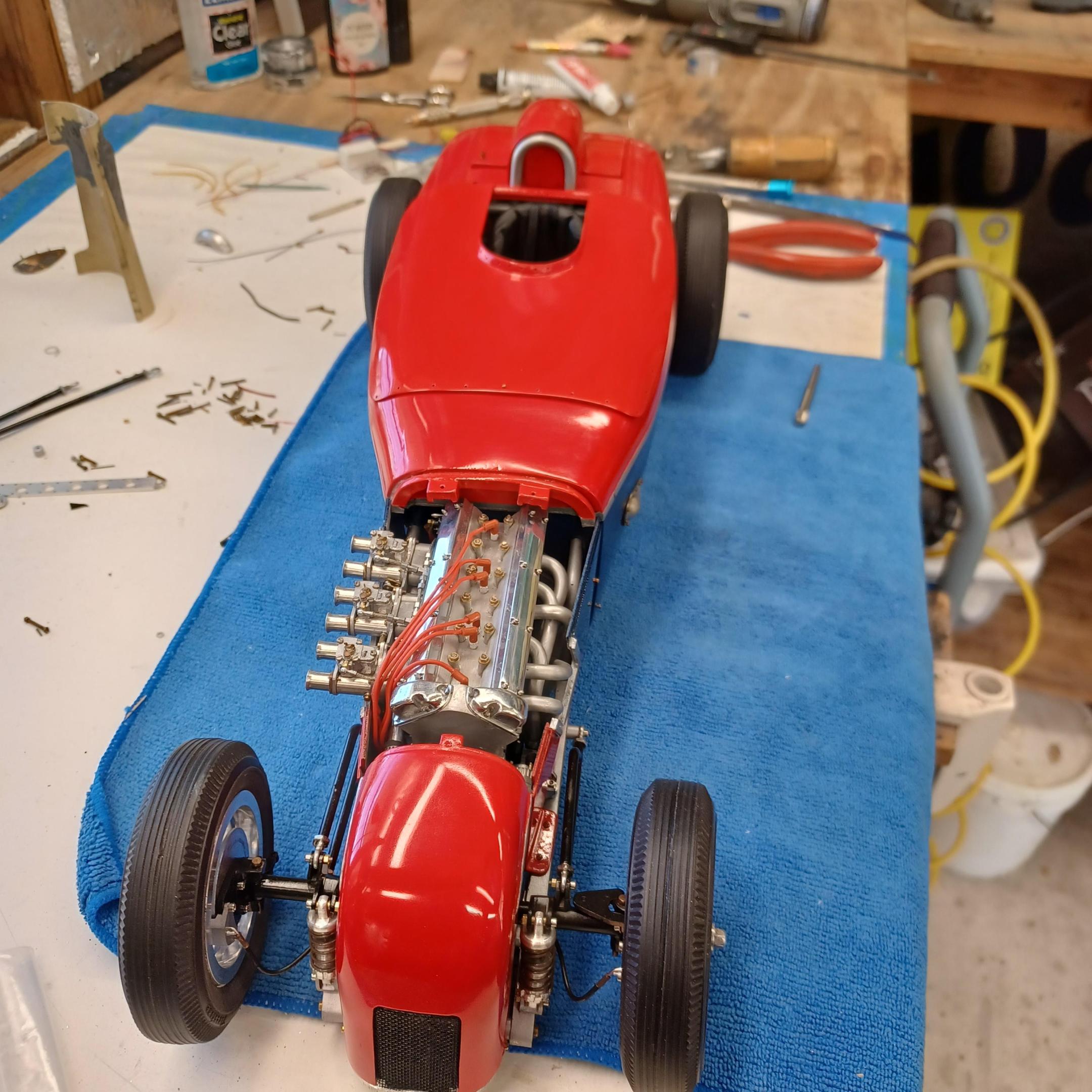

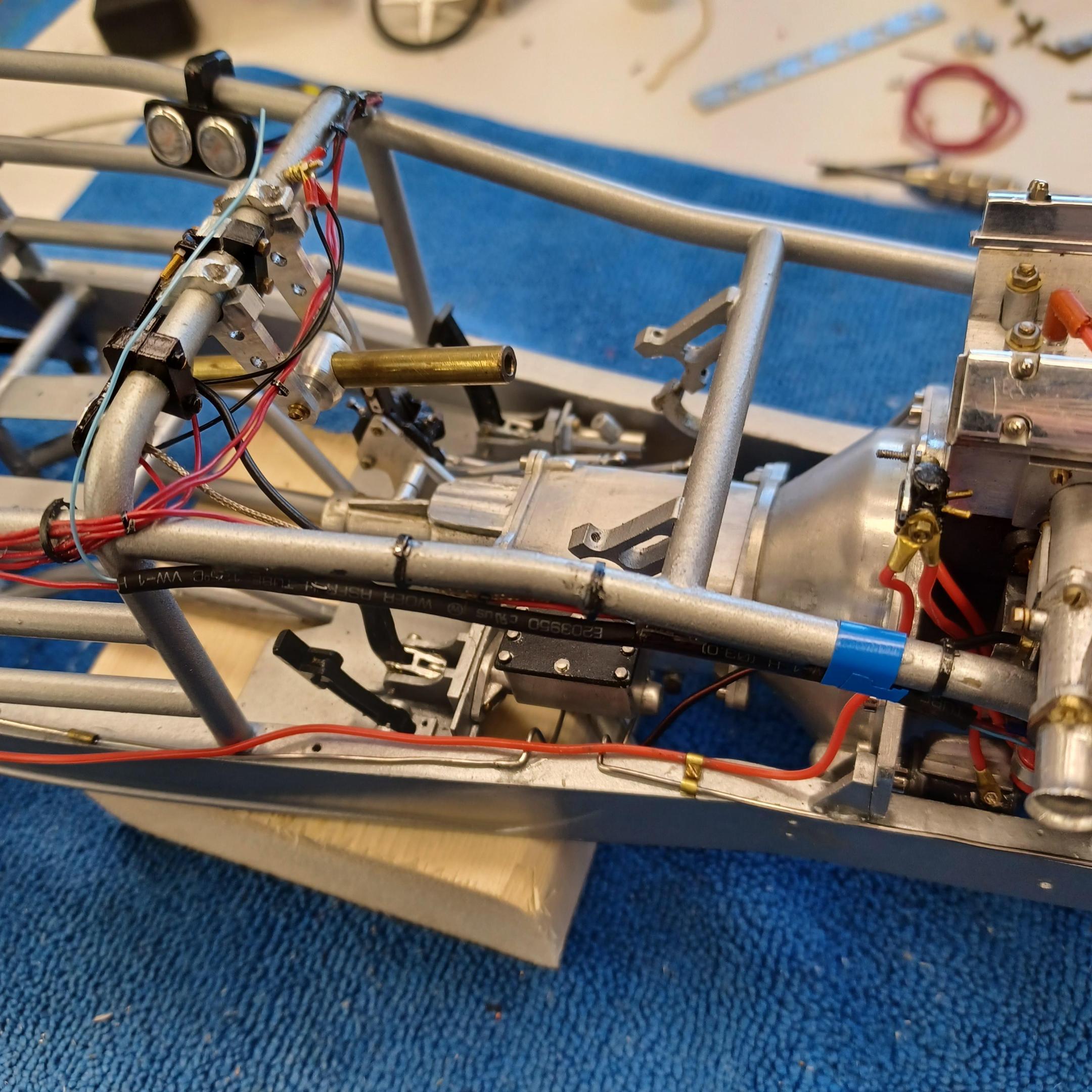

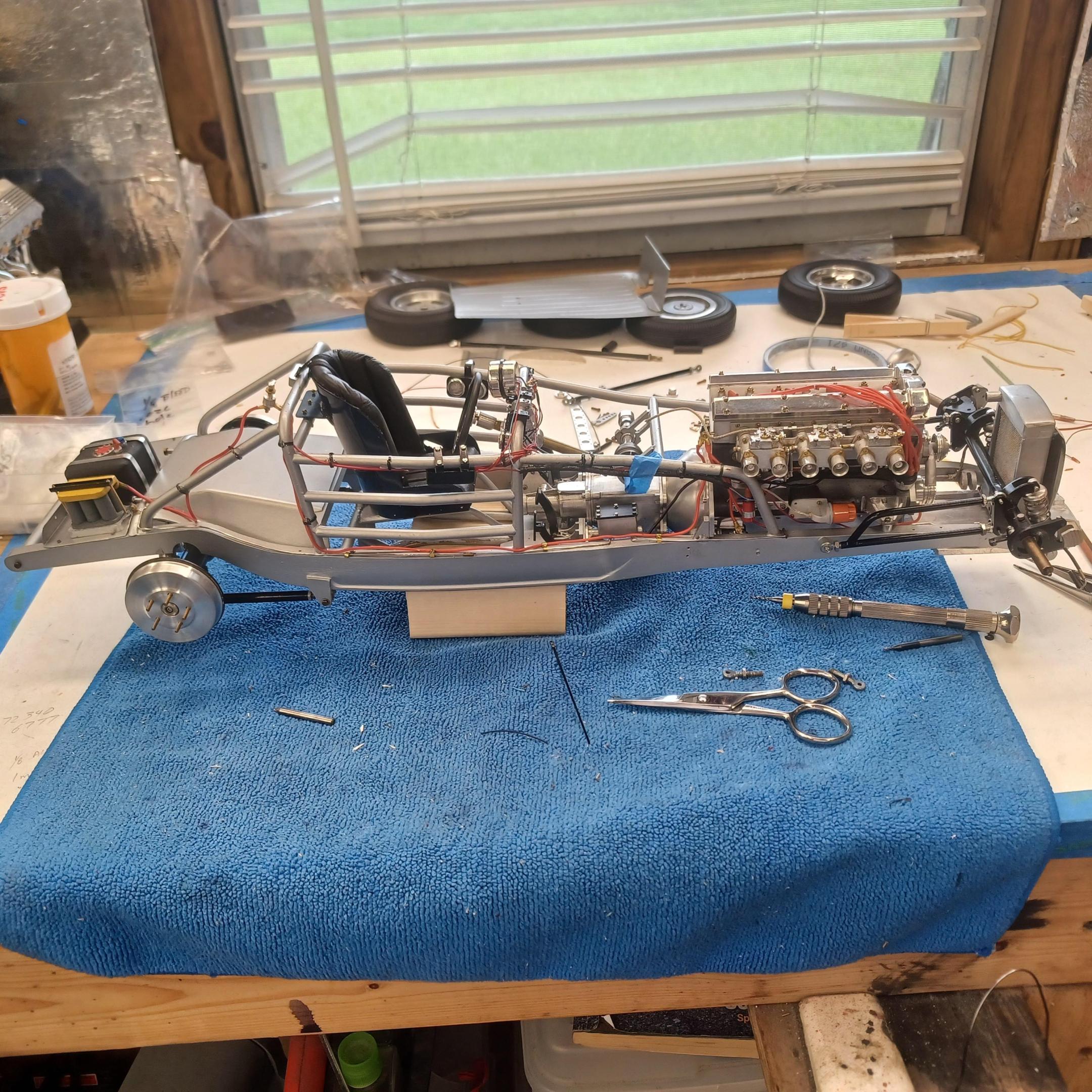

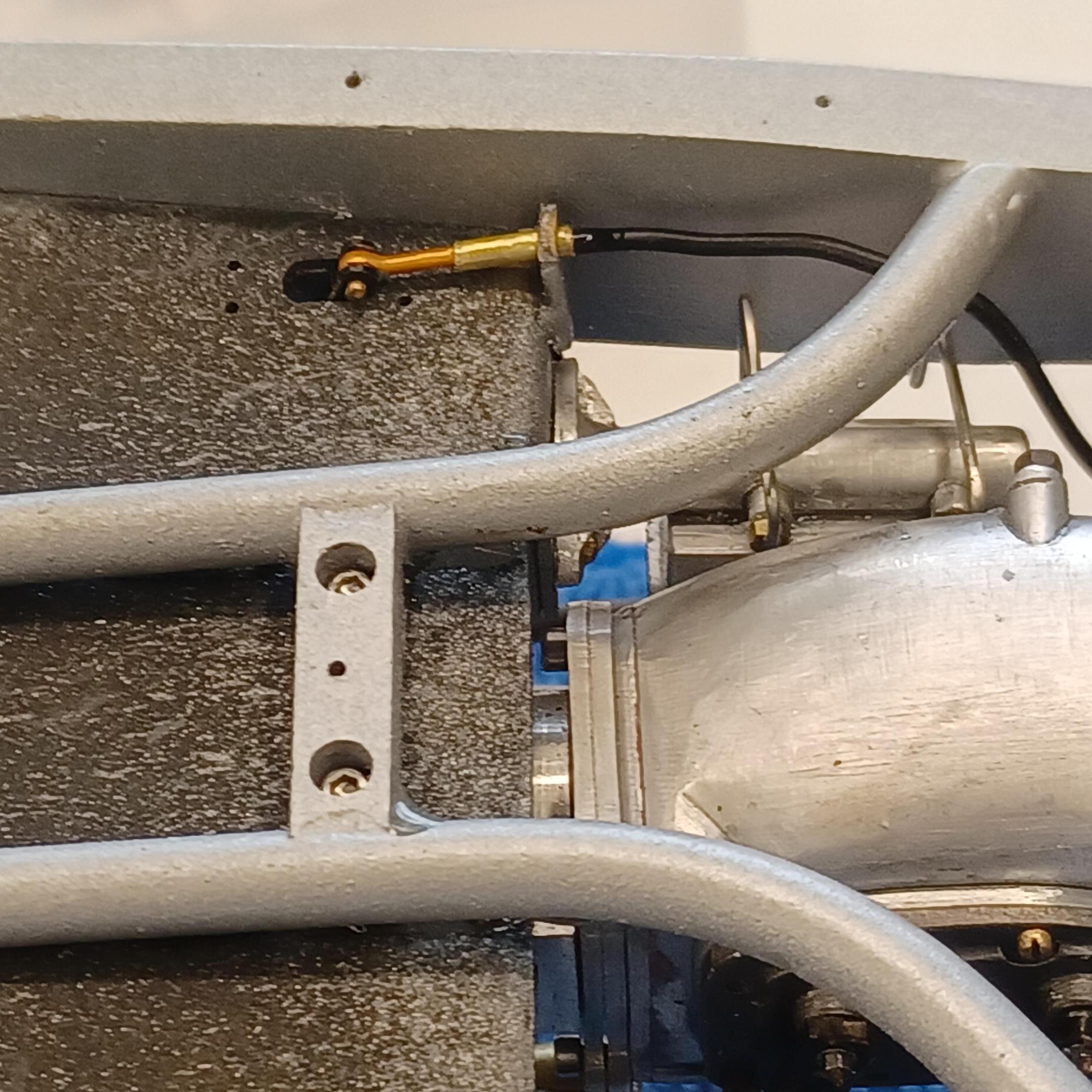

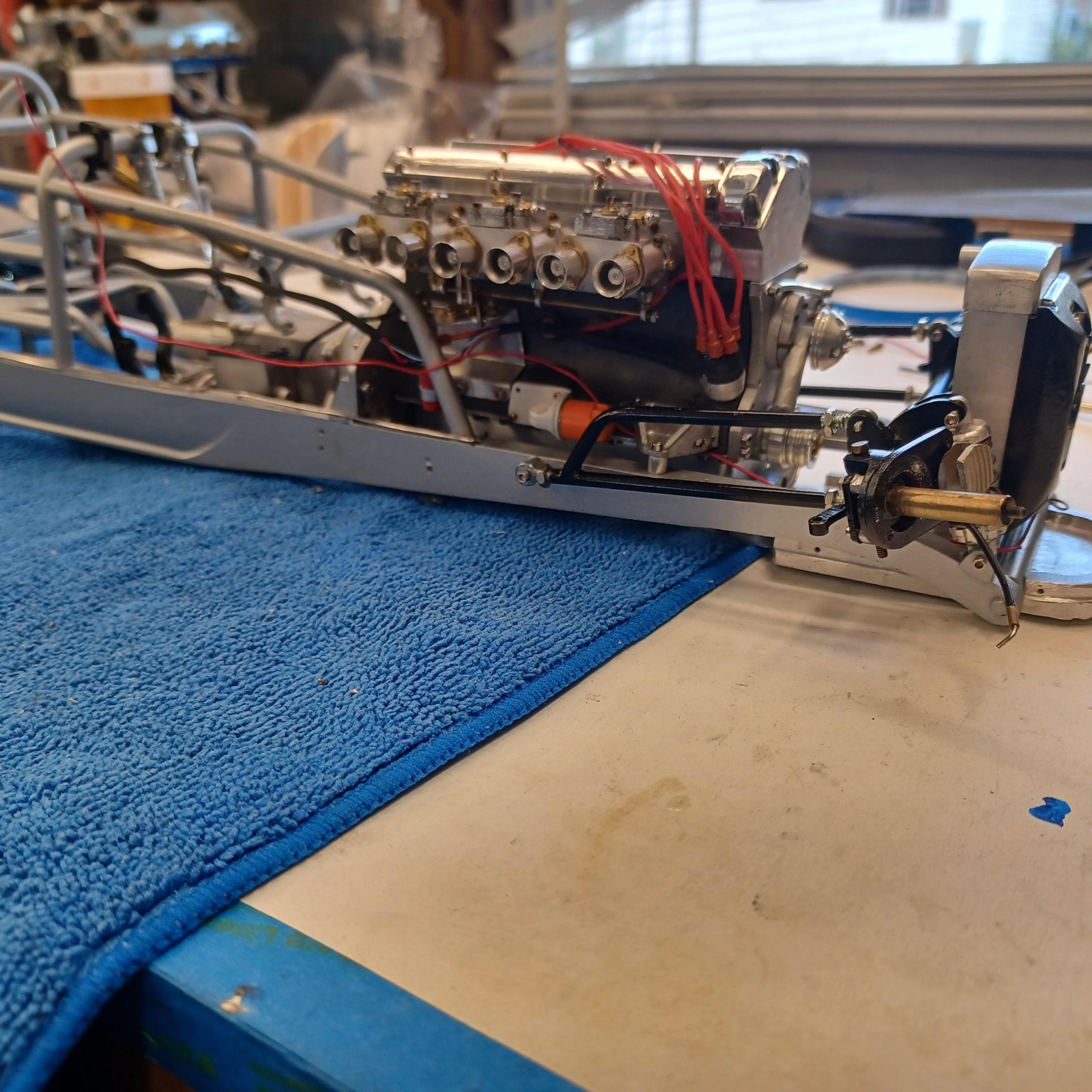

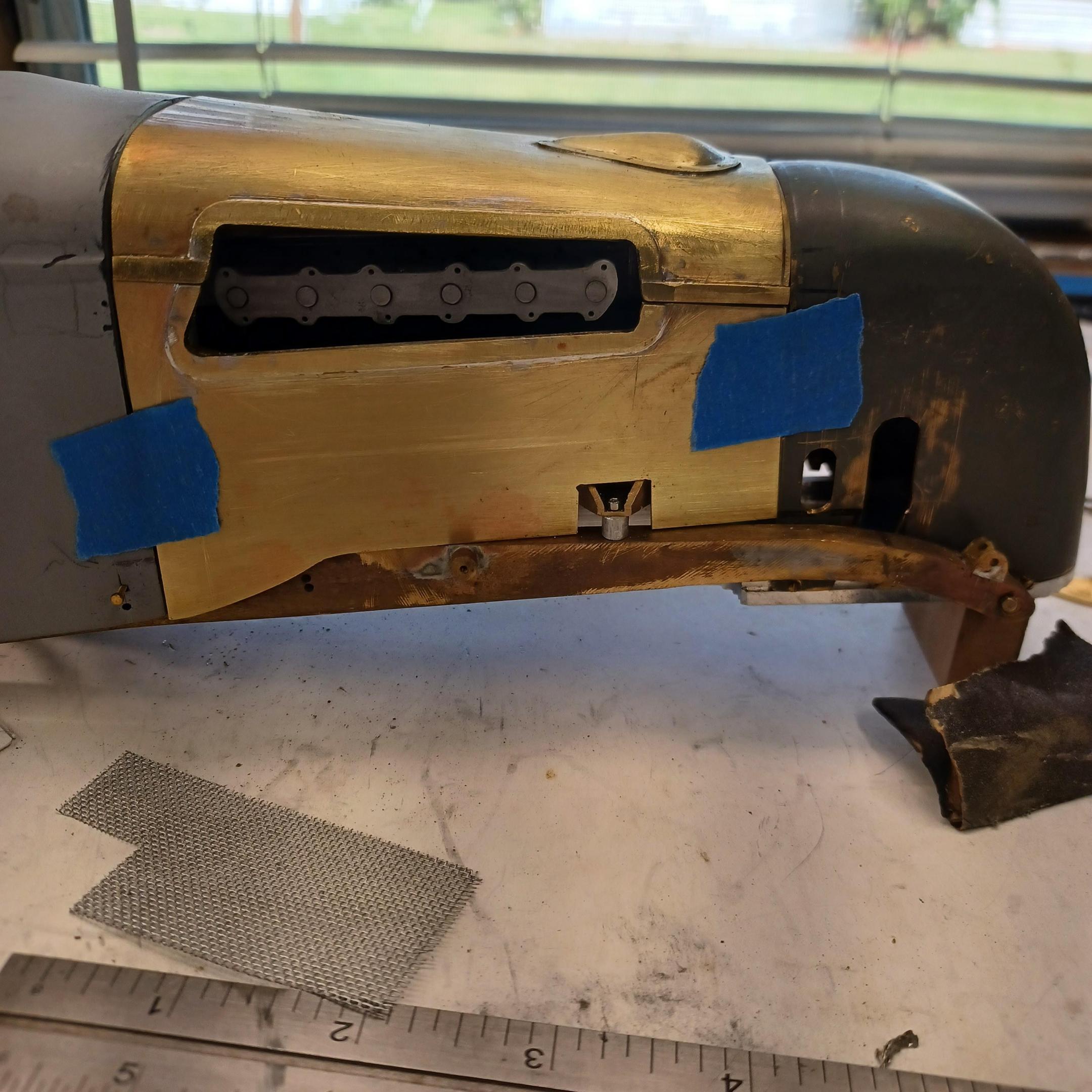

andrew they changed the date and location for the nnl show,but you probably know. thank you claude and donato for looking and your comments. continued assembly. got almost all the wiring done,finished the radiator hoses. put the entire body on mostly to make sure it all fit right. i found a major problem with hood. i am in the process of fixing that,it will take awhile. fuel lines and fuel filter are in. clutch line and reservoir are on. i haven't finished sanding and polishing the main body maybe tomorrow or sat. getting close but the hood will hold me up for a few weeks. then the english wheel,still drawing and thinking.thank you all -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

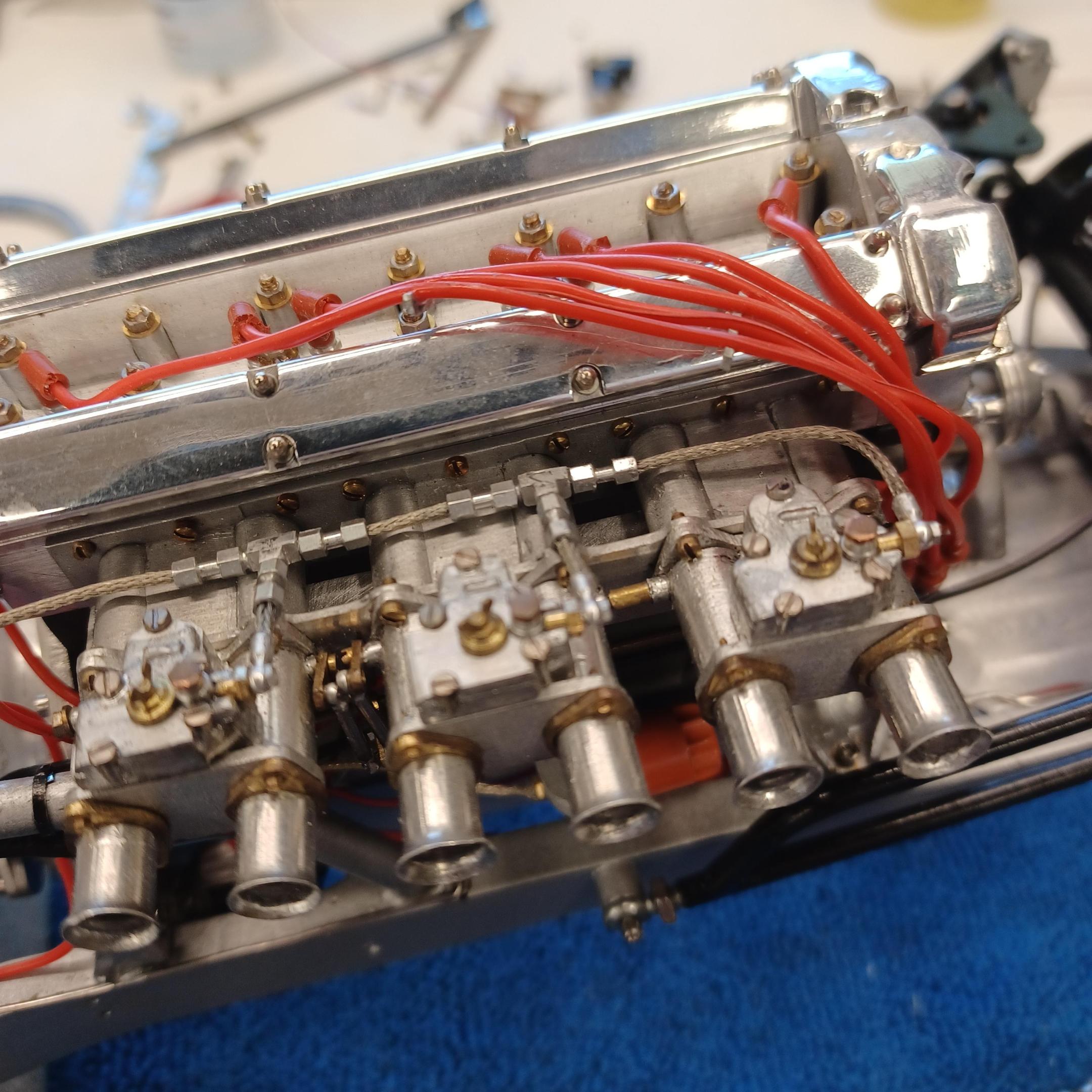

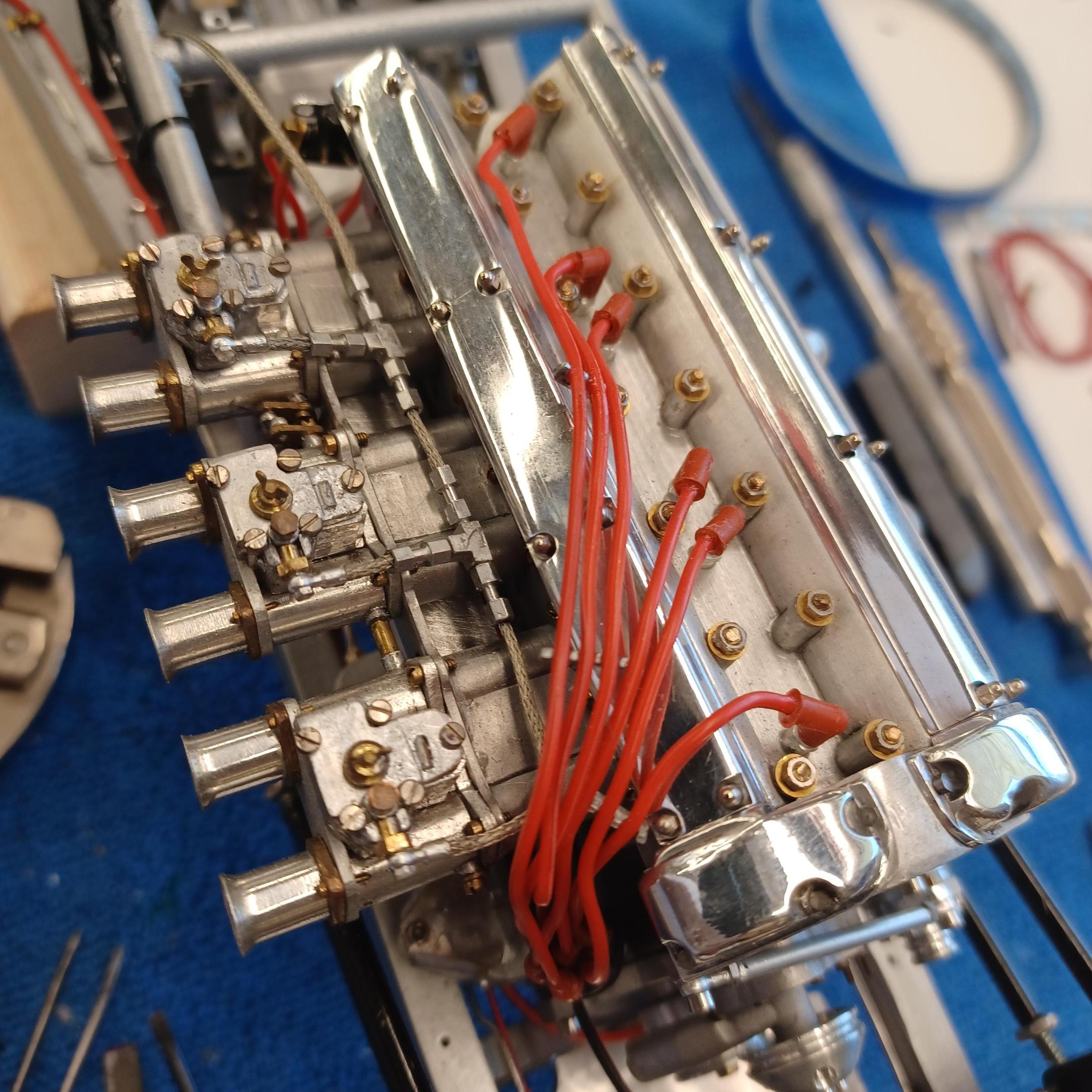

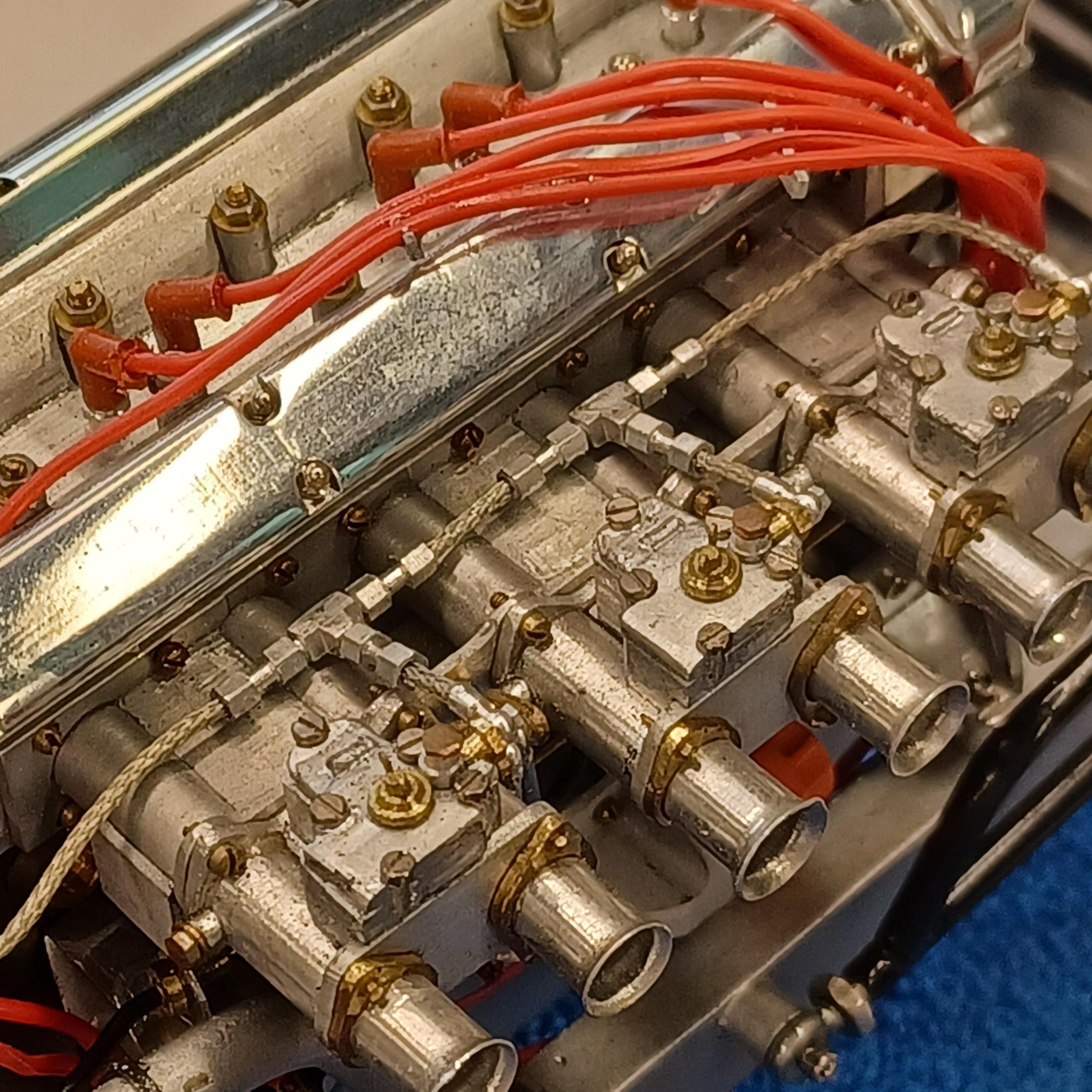

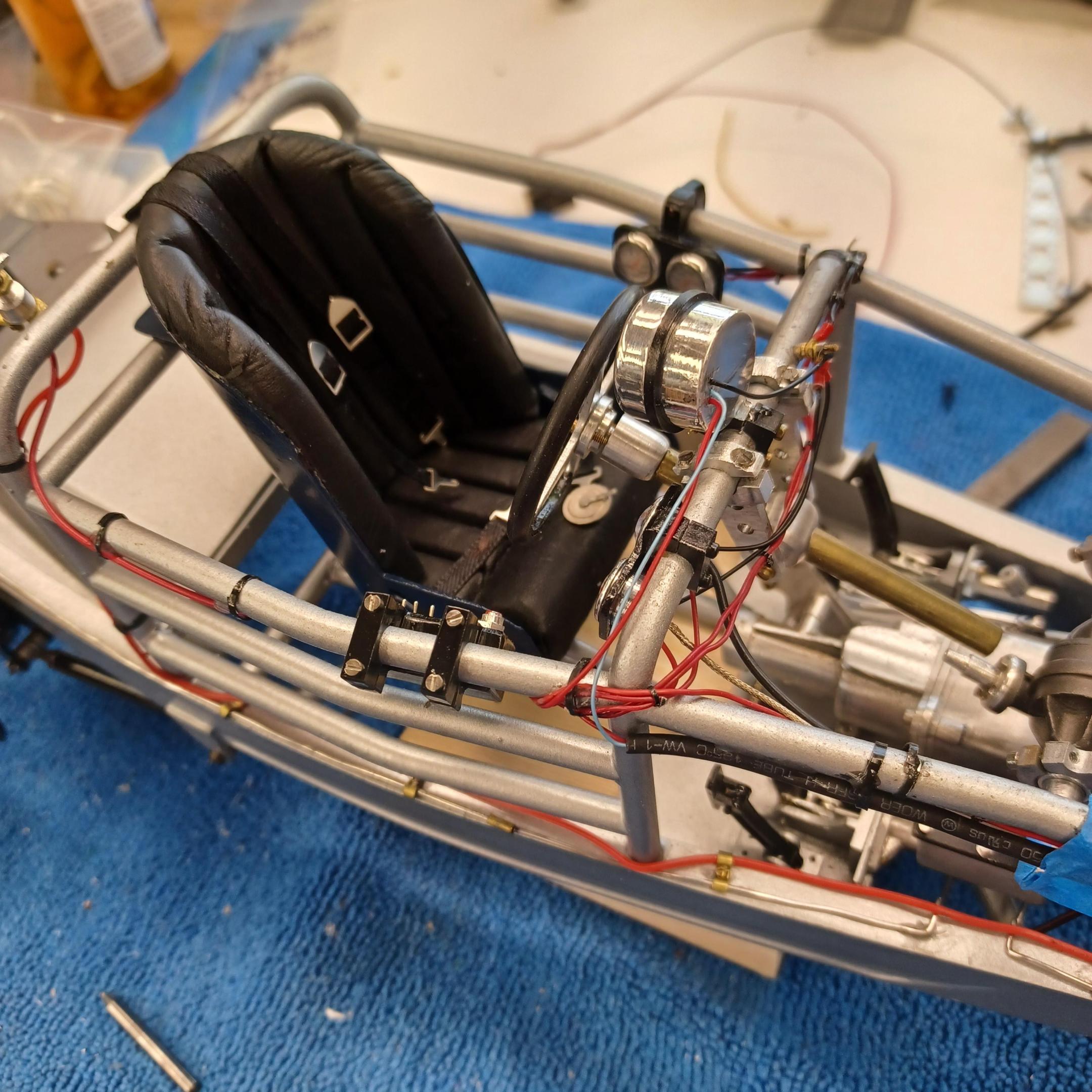

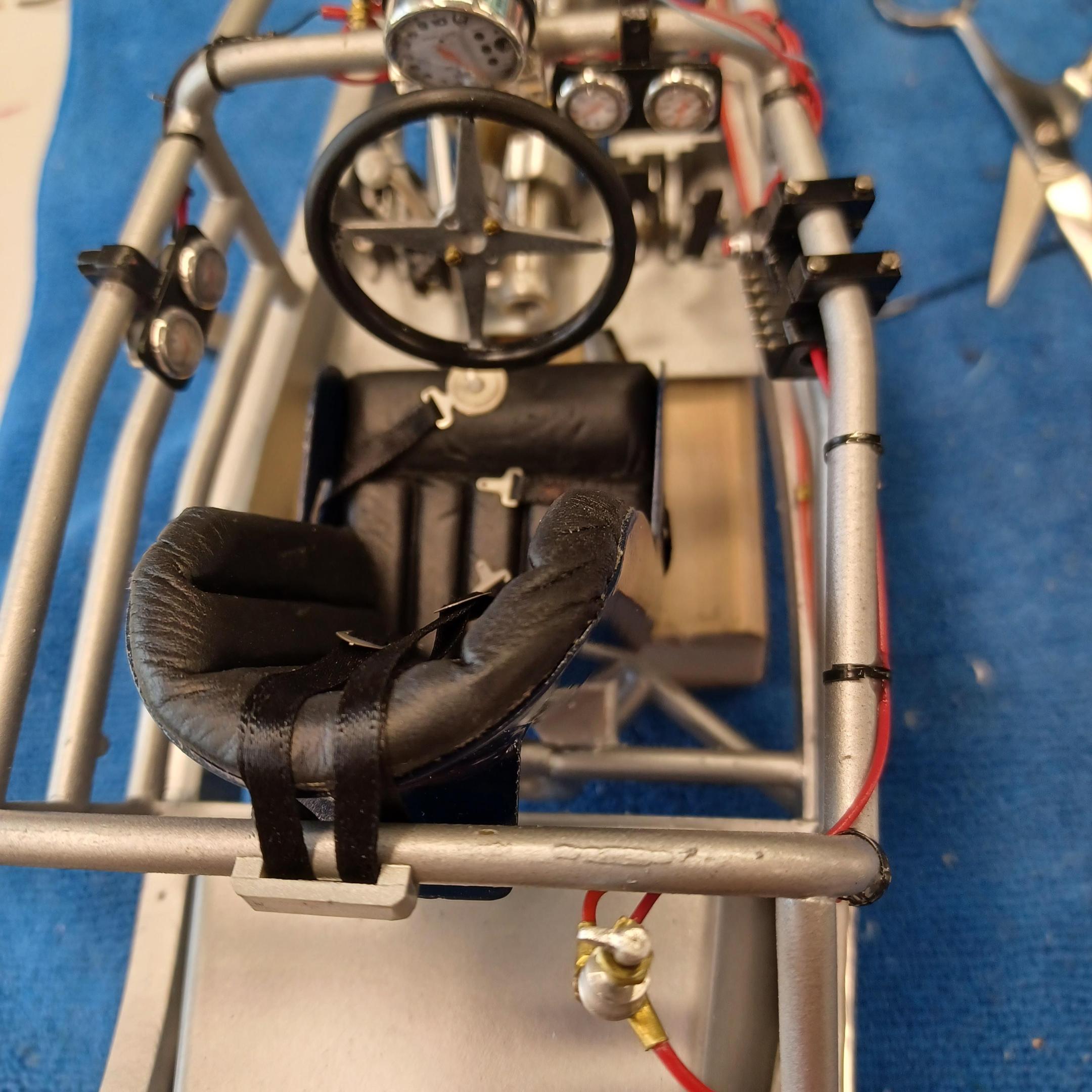

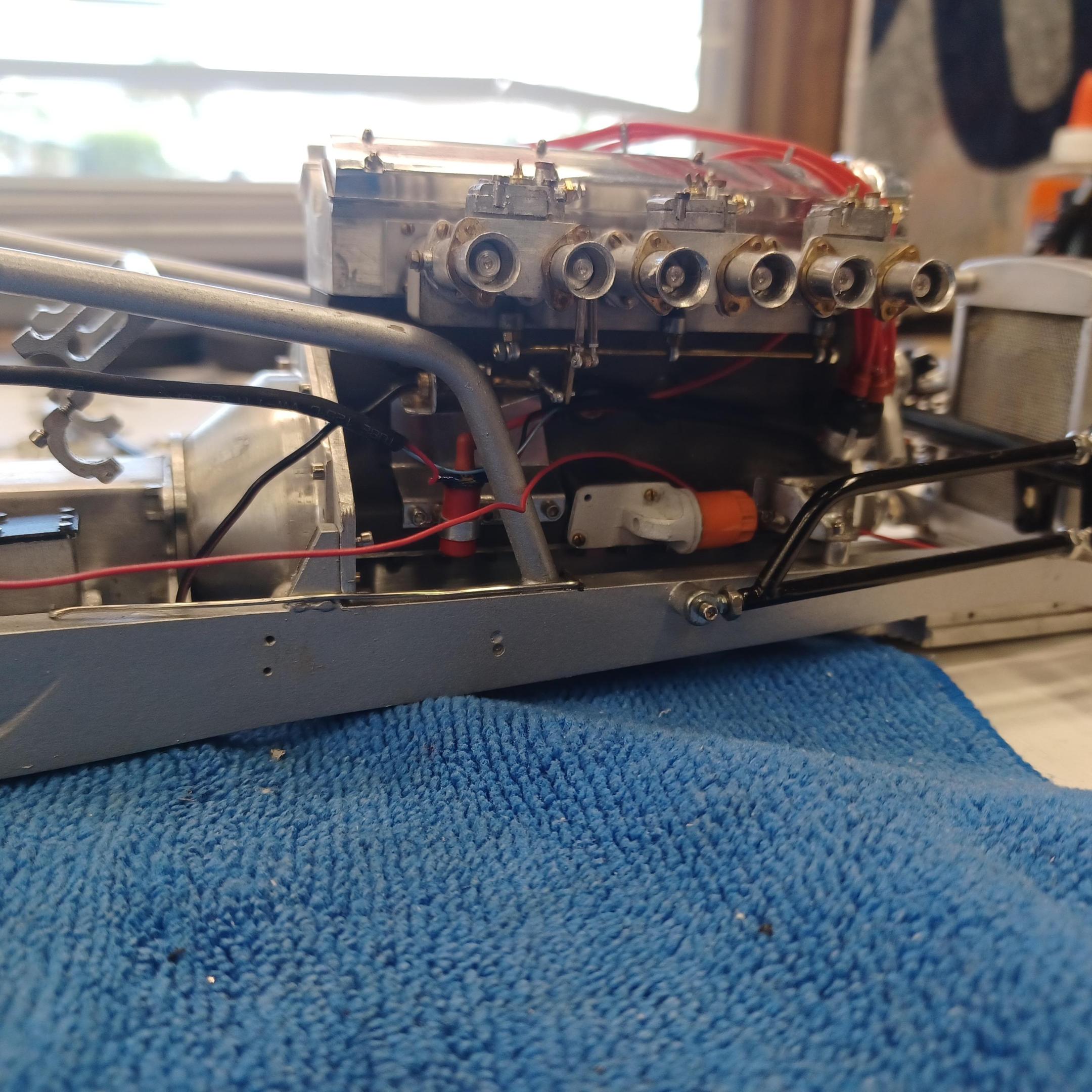

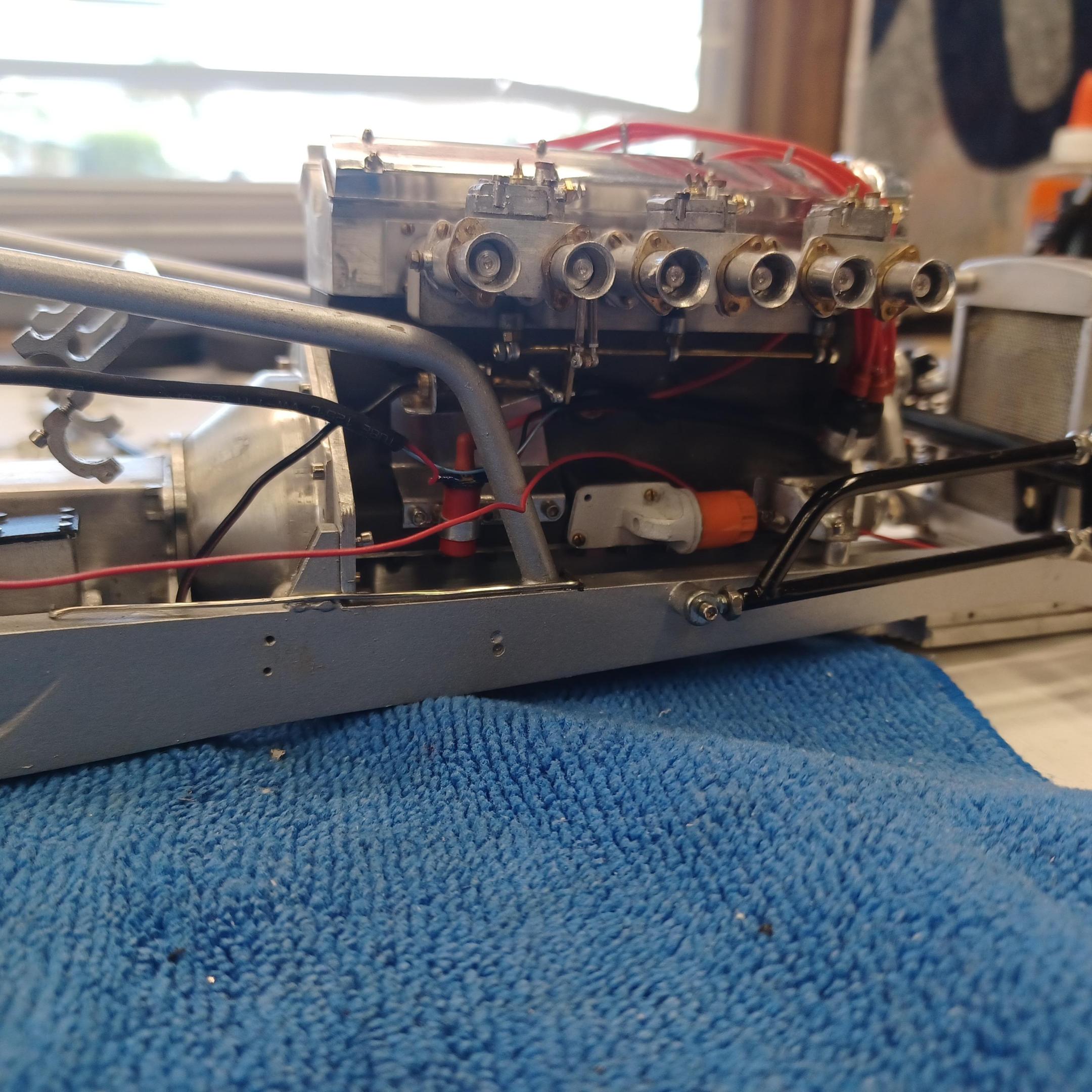

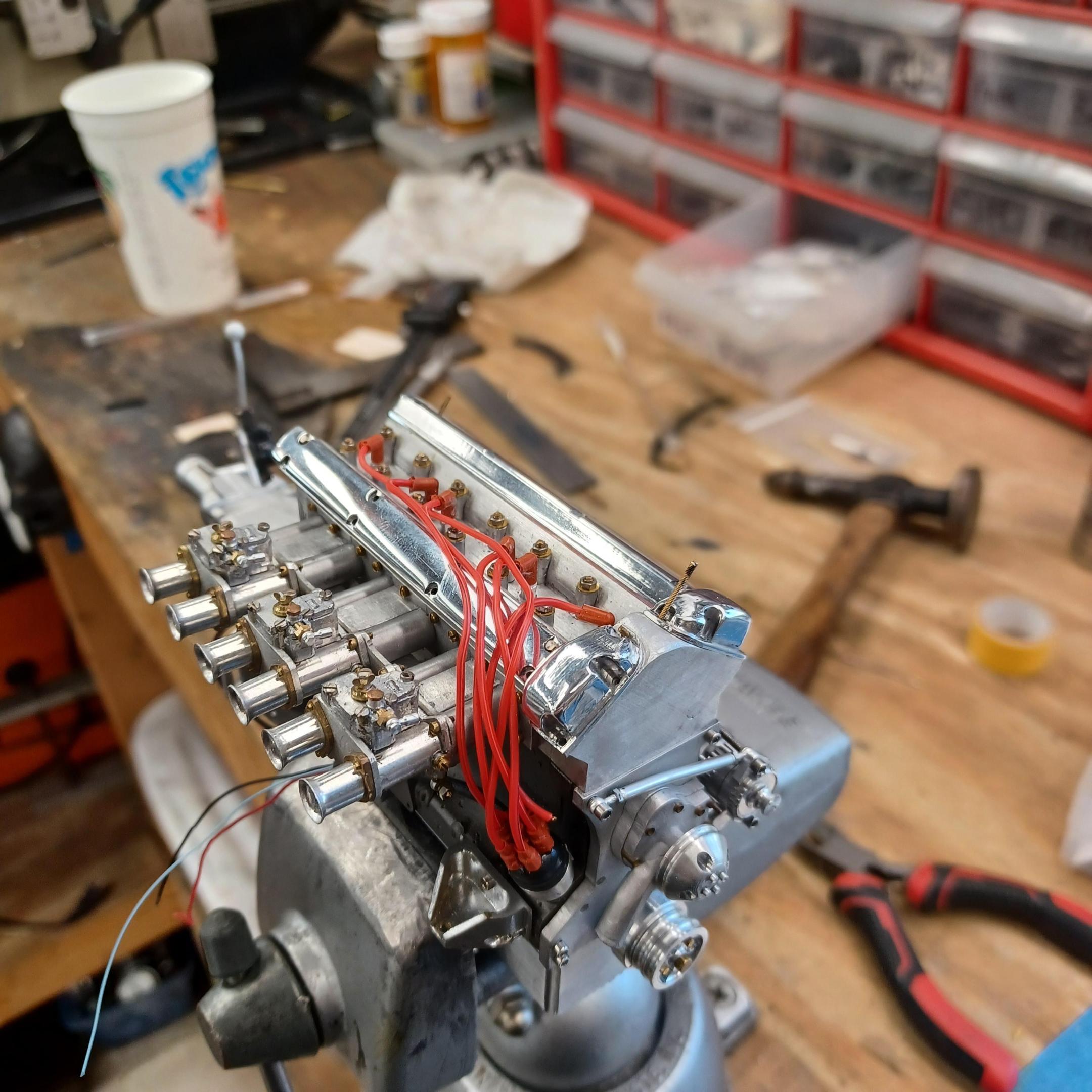

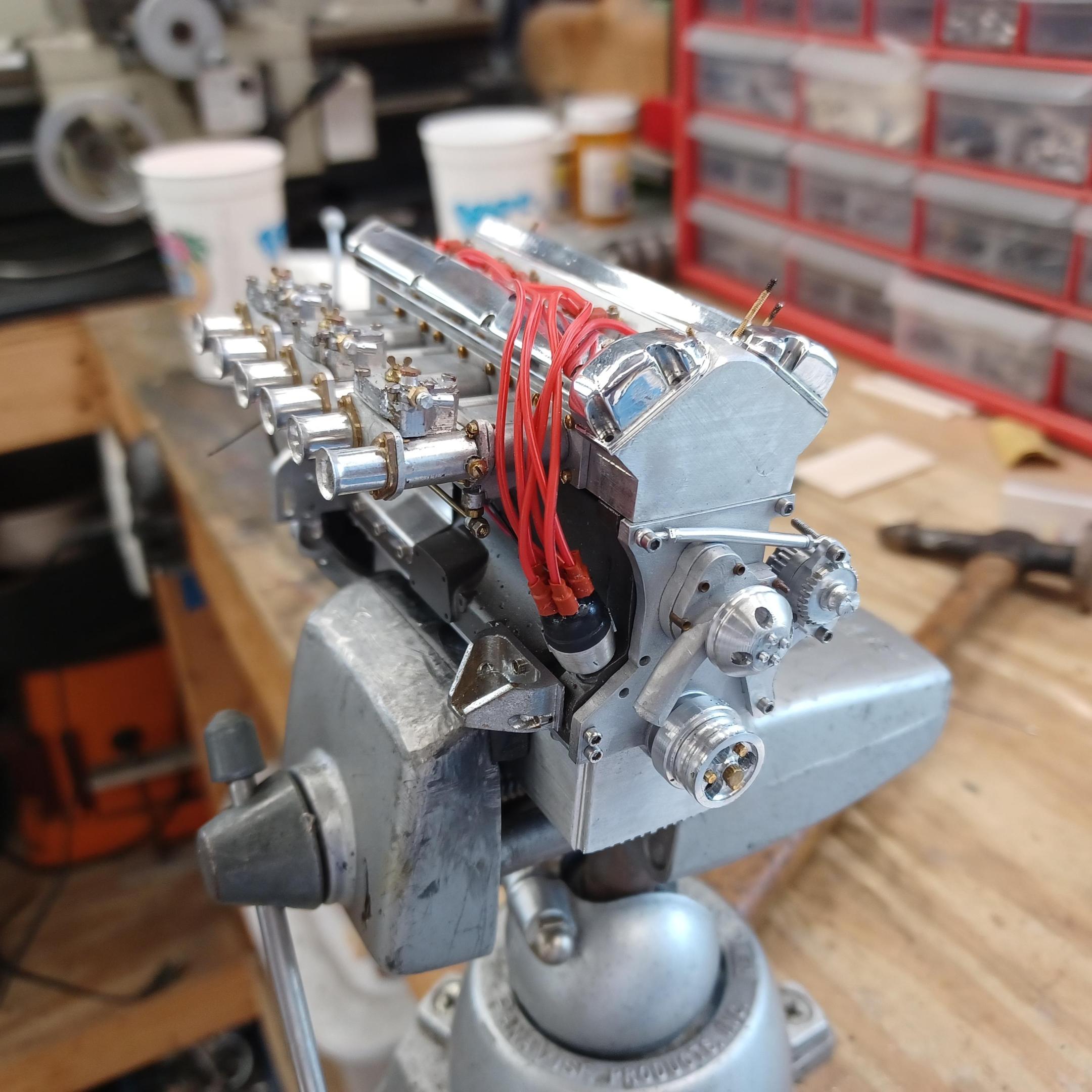

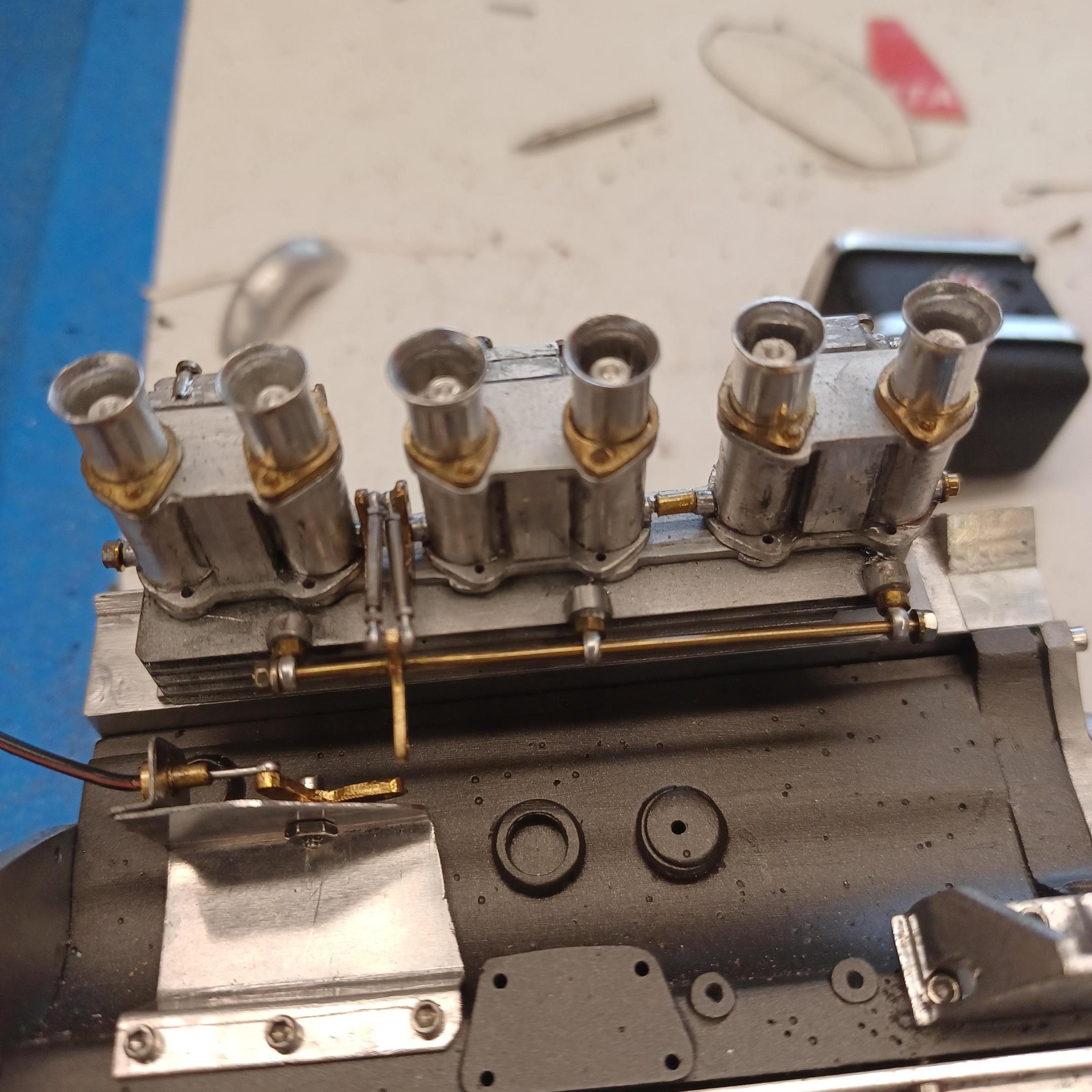

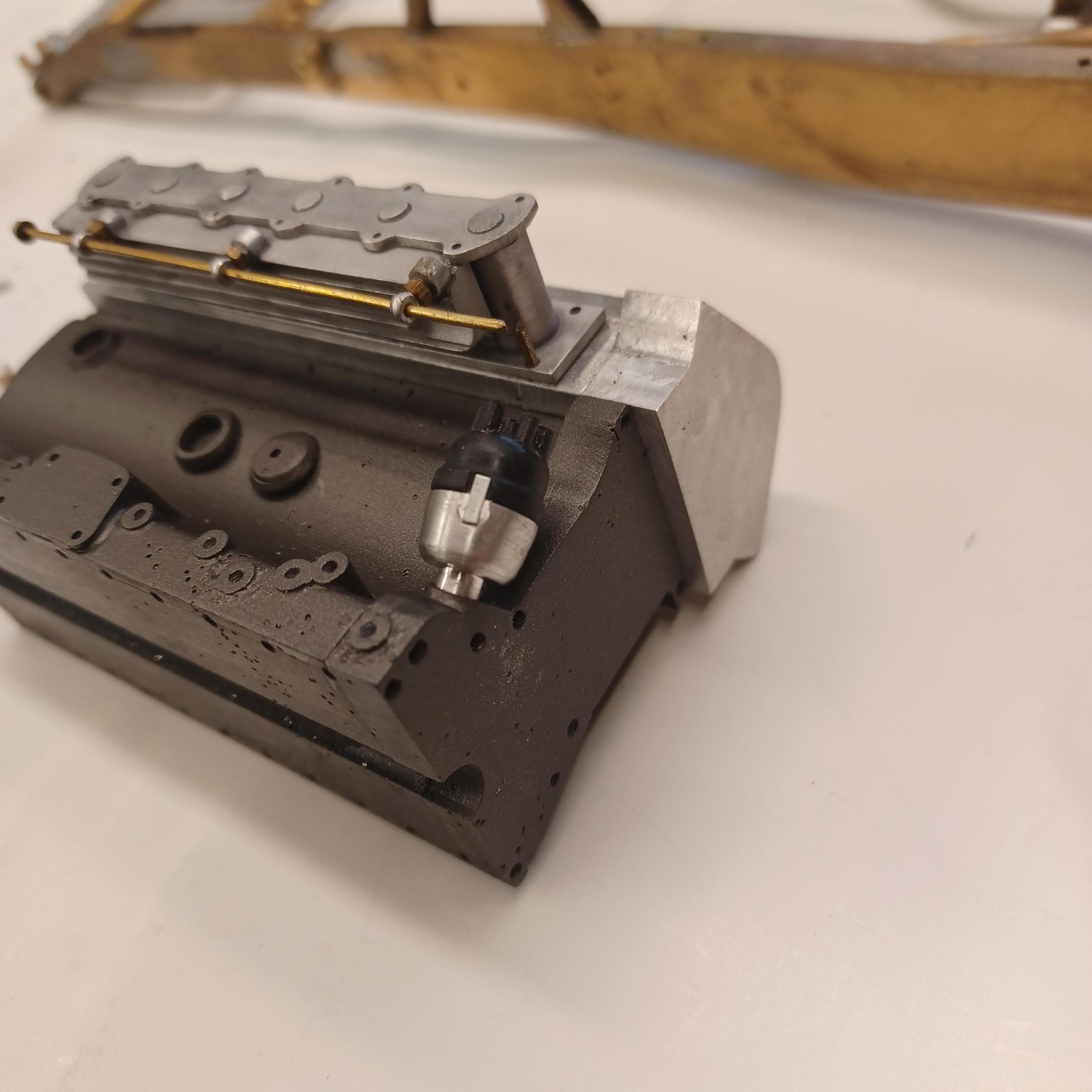

assembly continues. machined the fittings for the fuel line at the carburetor. got most of the wiring run. the wire ties are a time consuming effort. i finished the seat and upholstery. i think the leather came out pretty nice .i have to install the eletric fuel pump and the fuel line going forward to the webers. not alot left to do . maybe have the body on by the end of next week. turned 69 last Friday and my birthday present might eat up some of my time. that truck is a blast to play with. andrew i am looking at your info and i hope maybe to make one of those shows. -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

thank you andrew -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

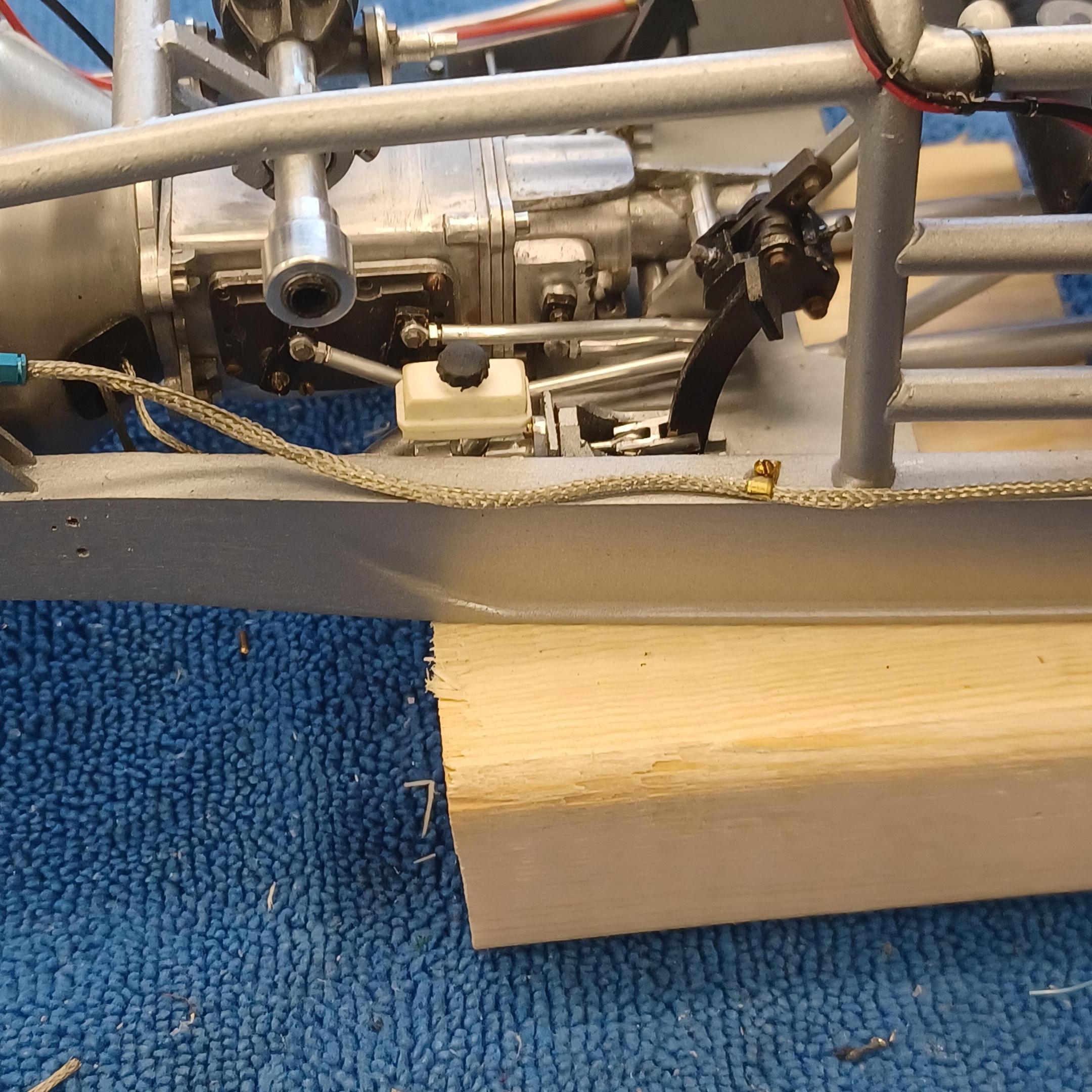

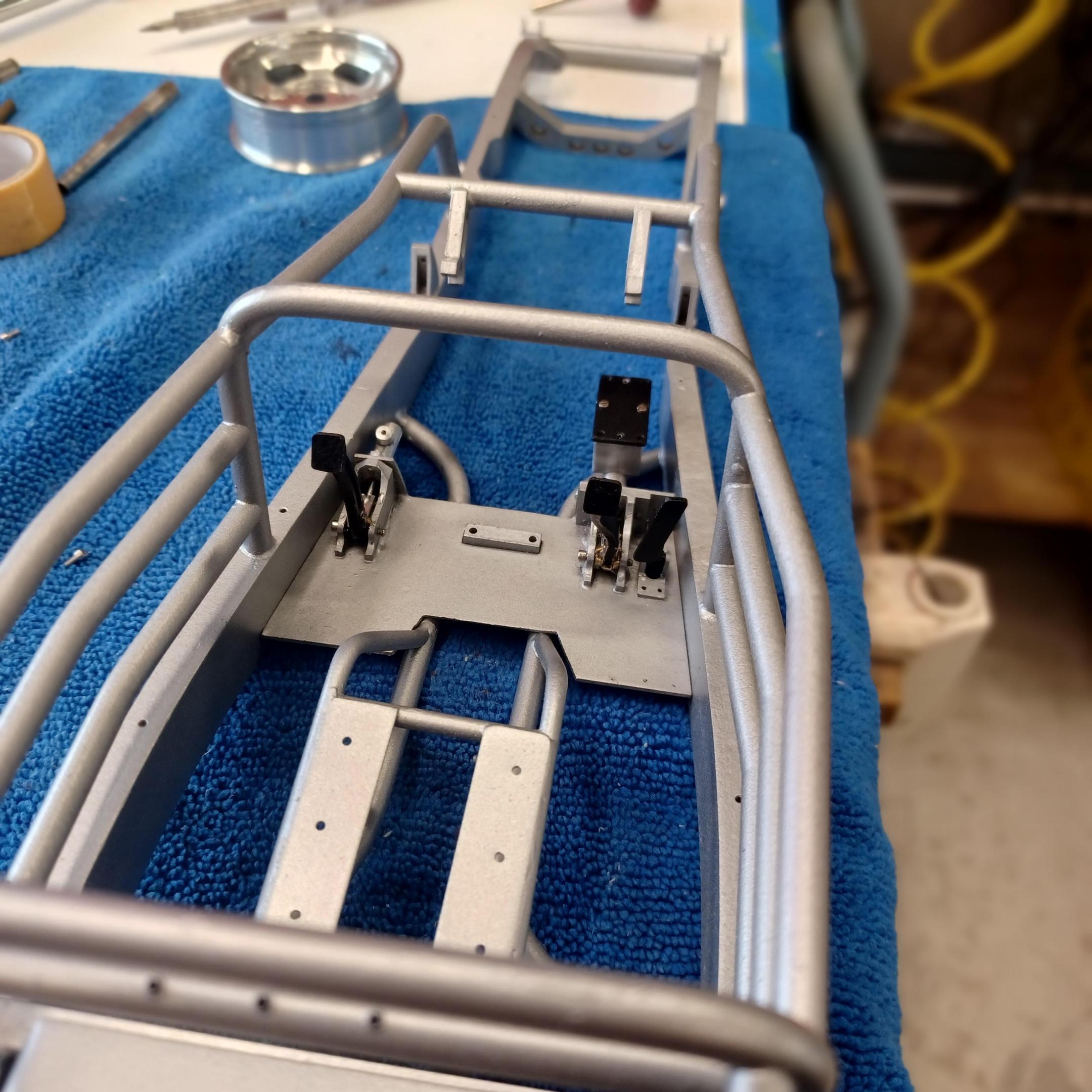

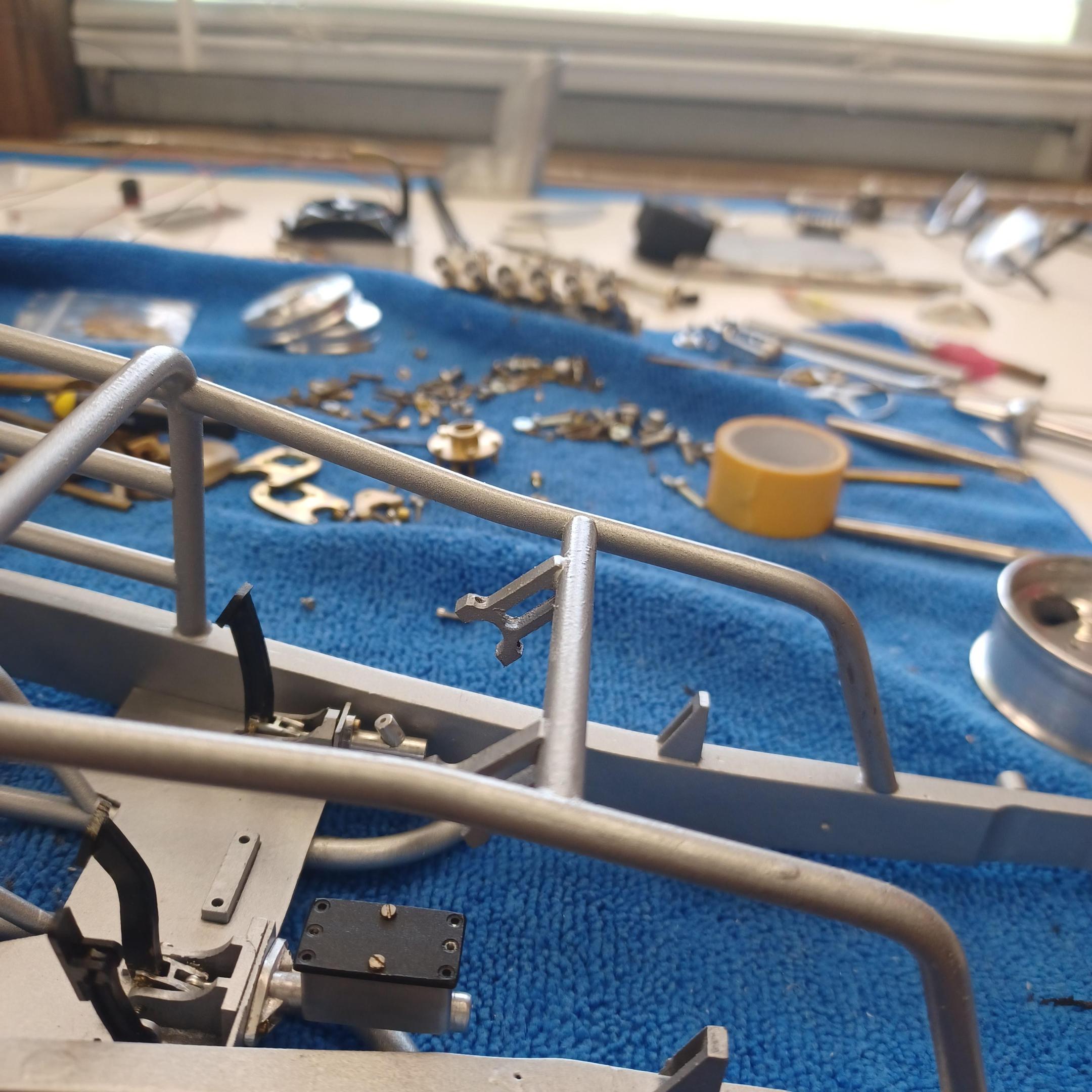

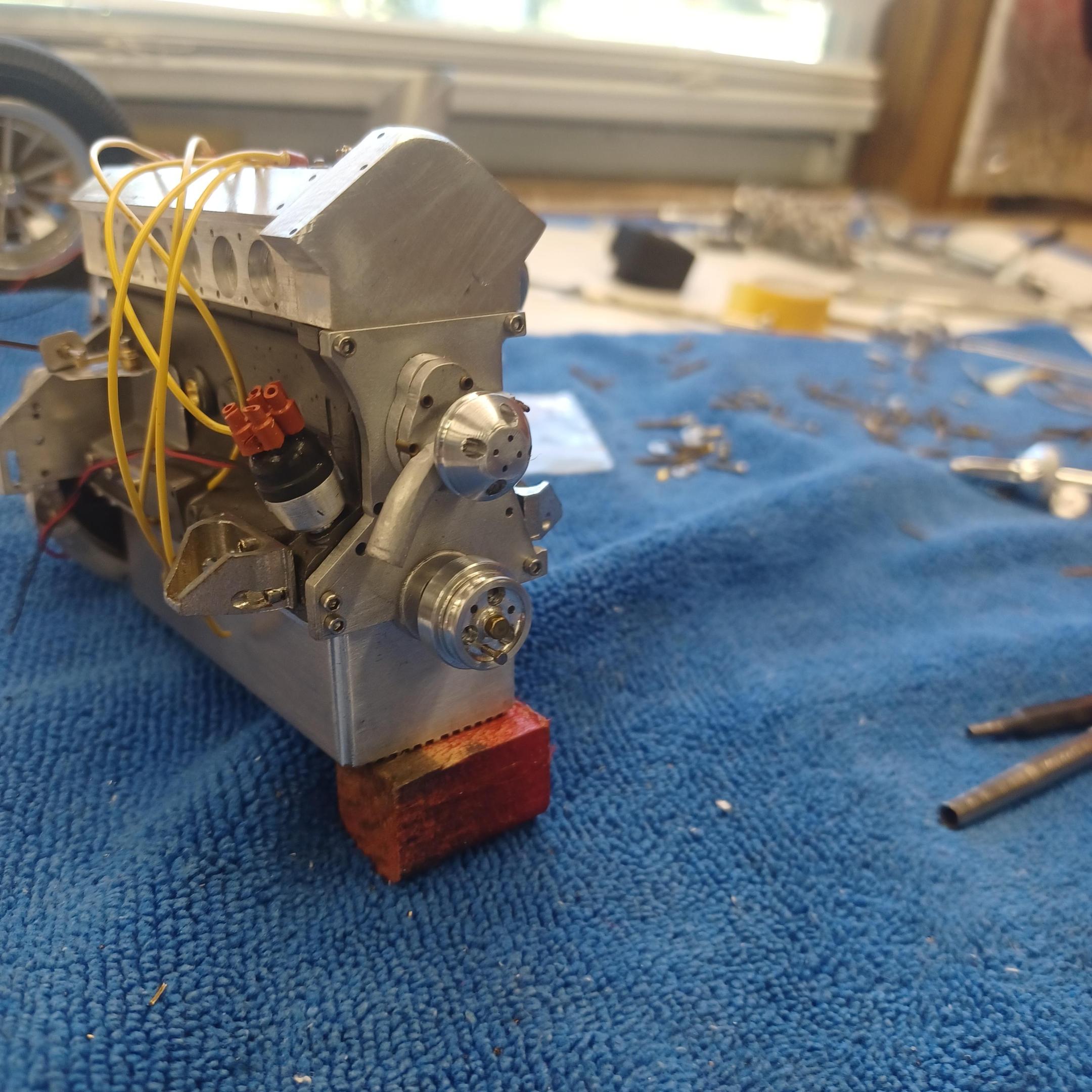

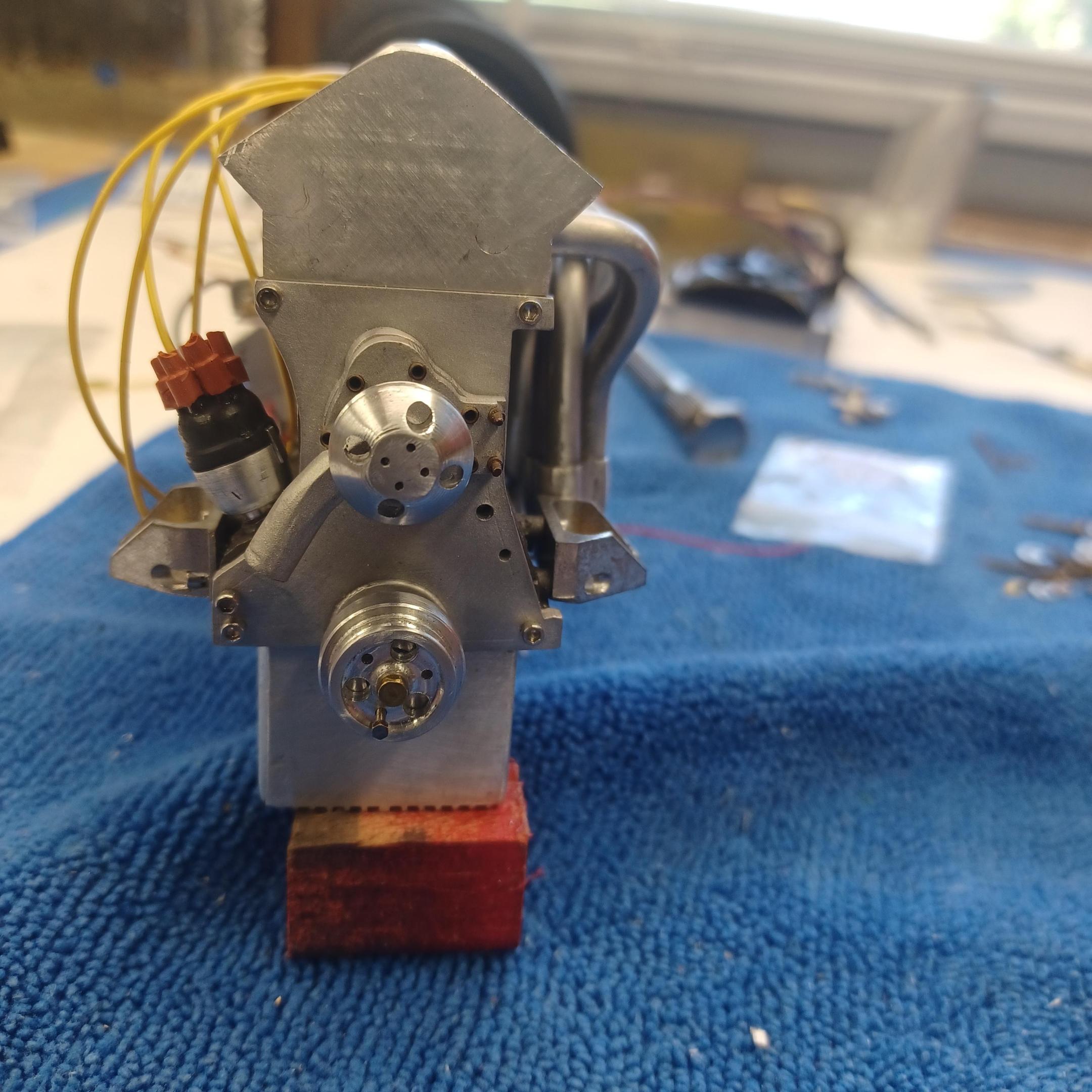

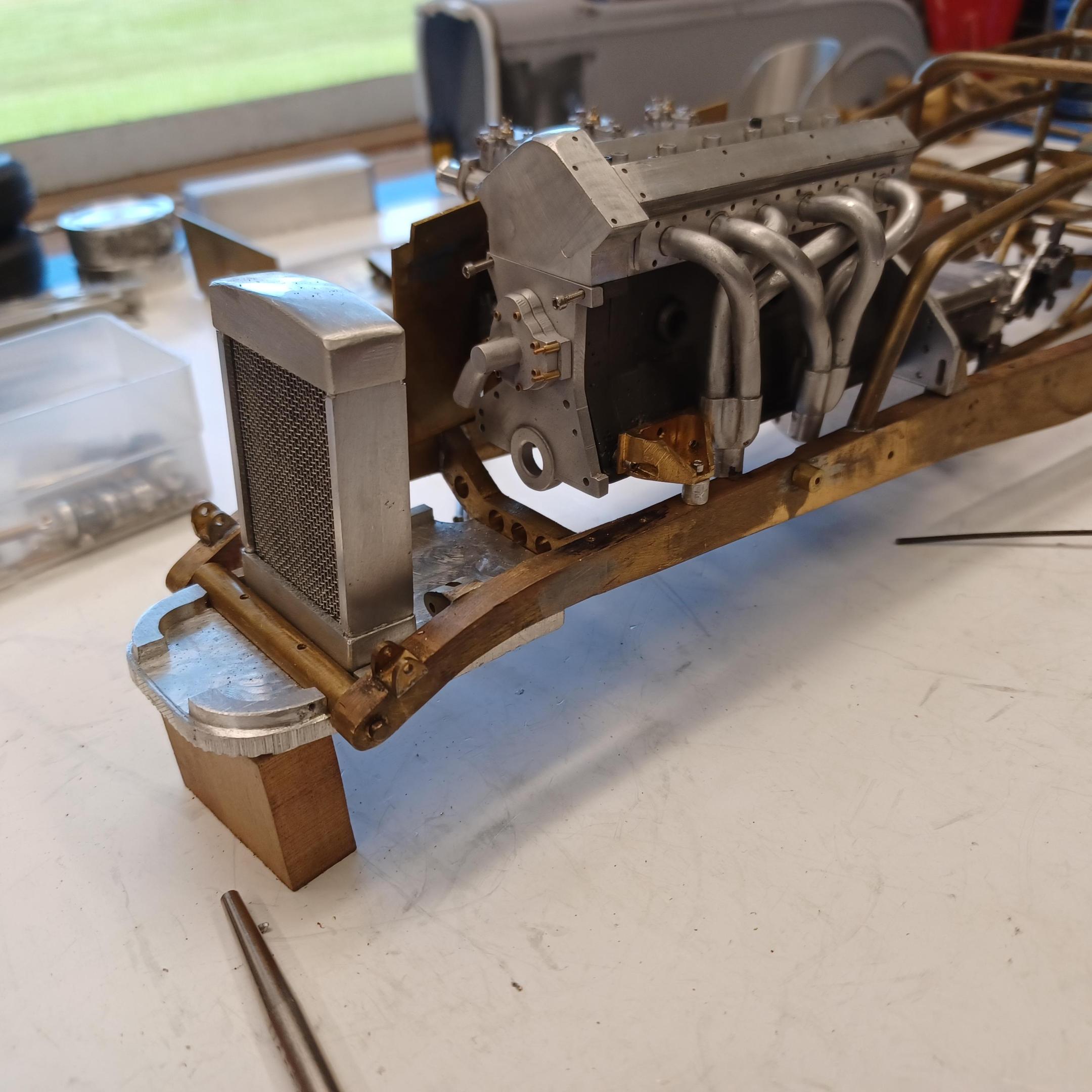

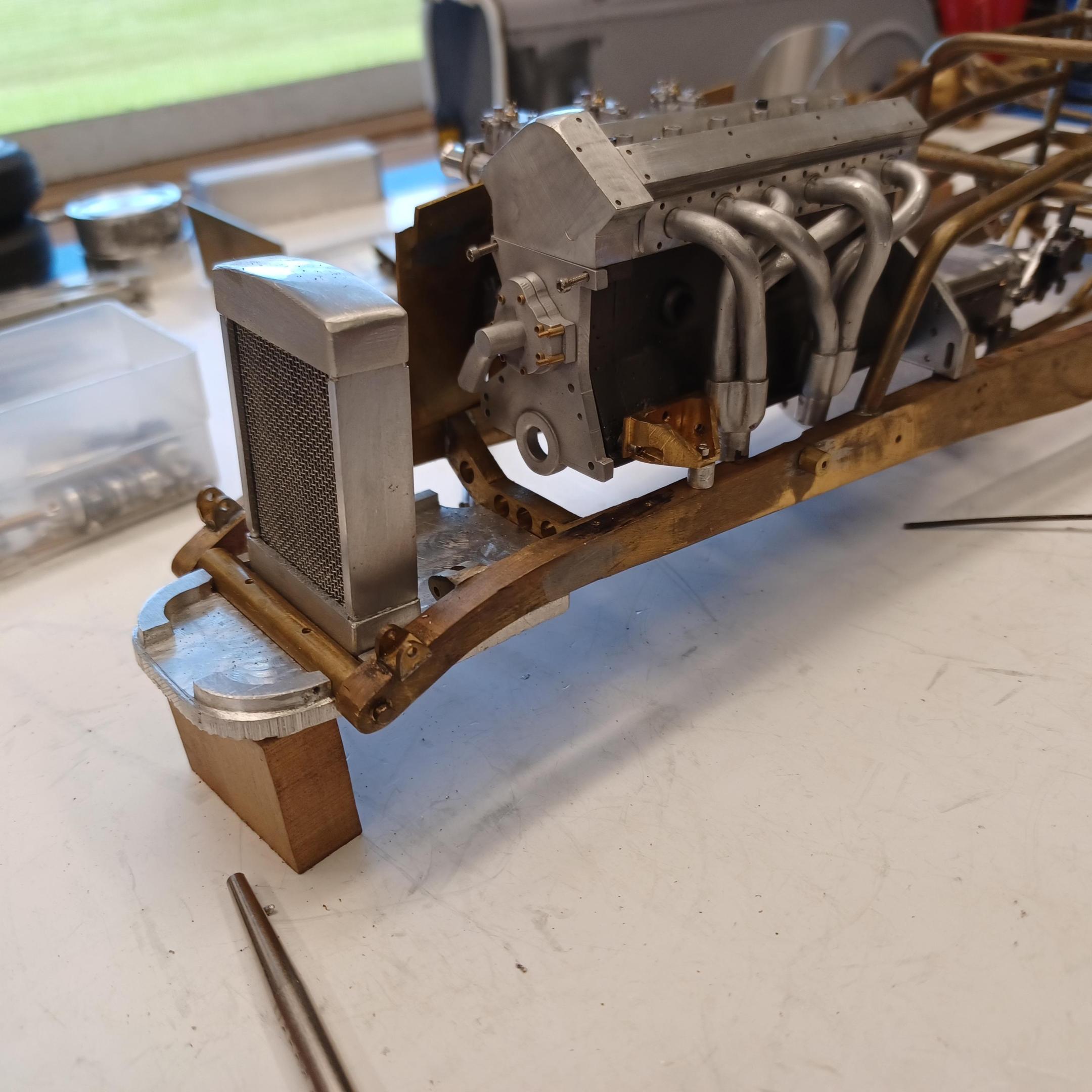

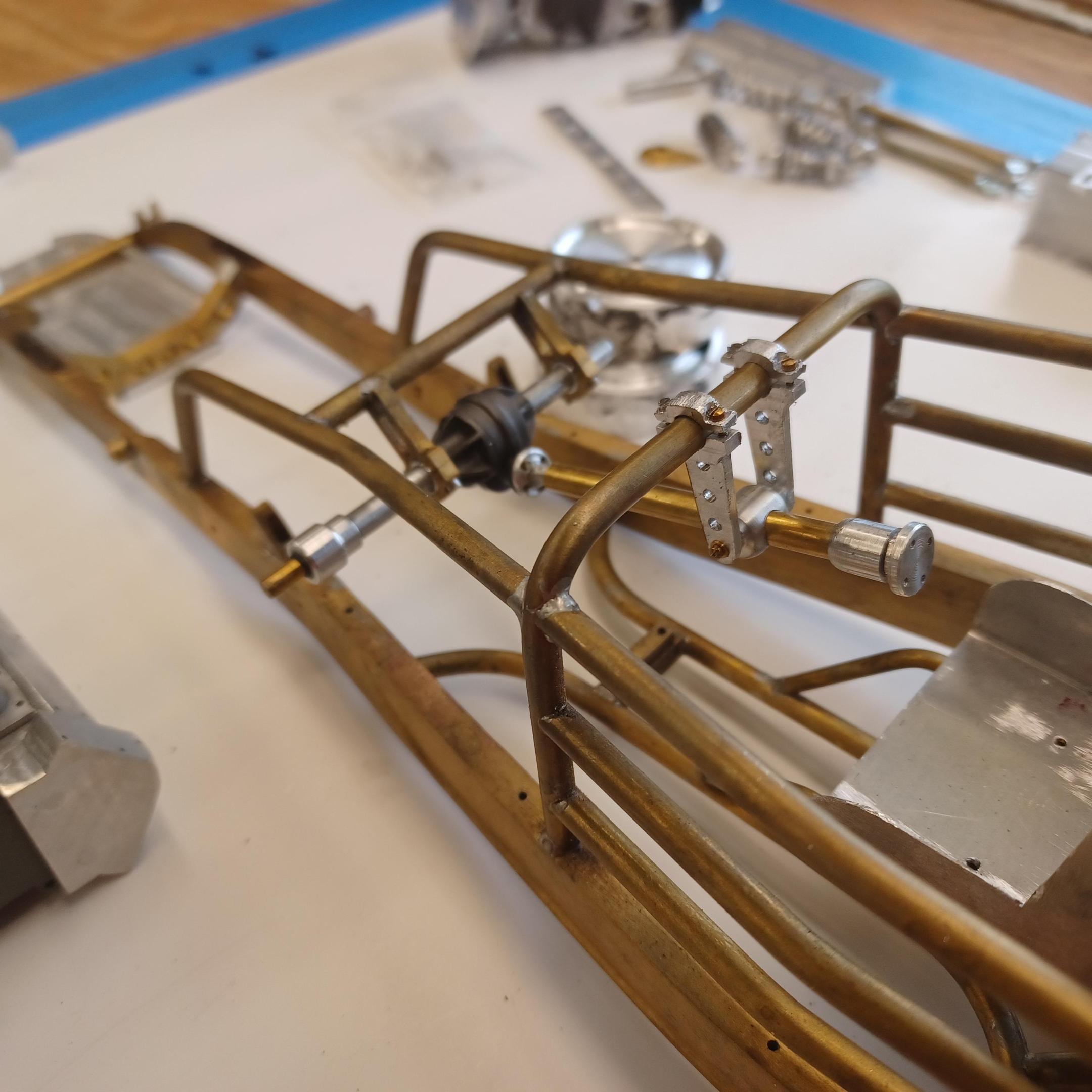

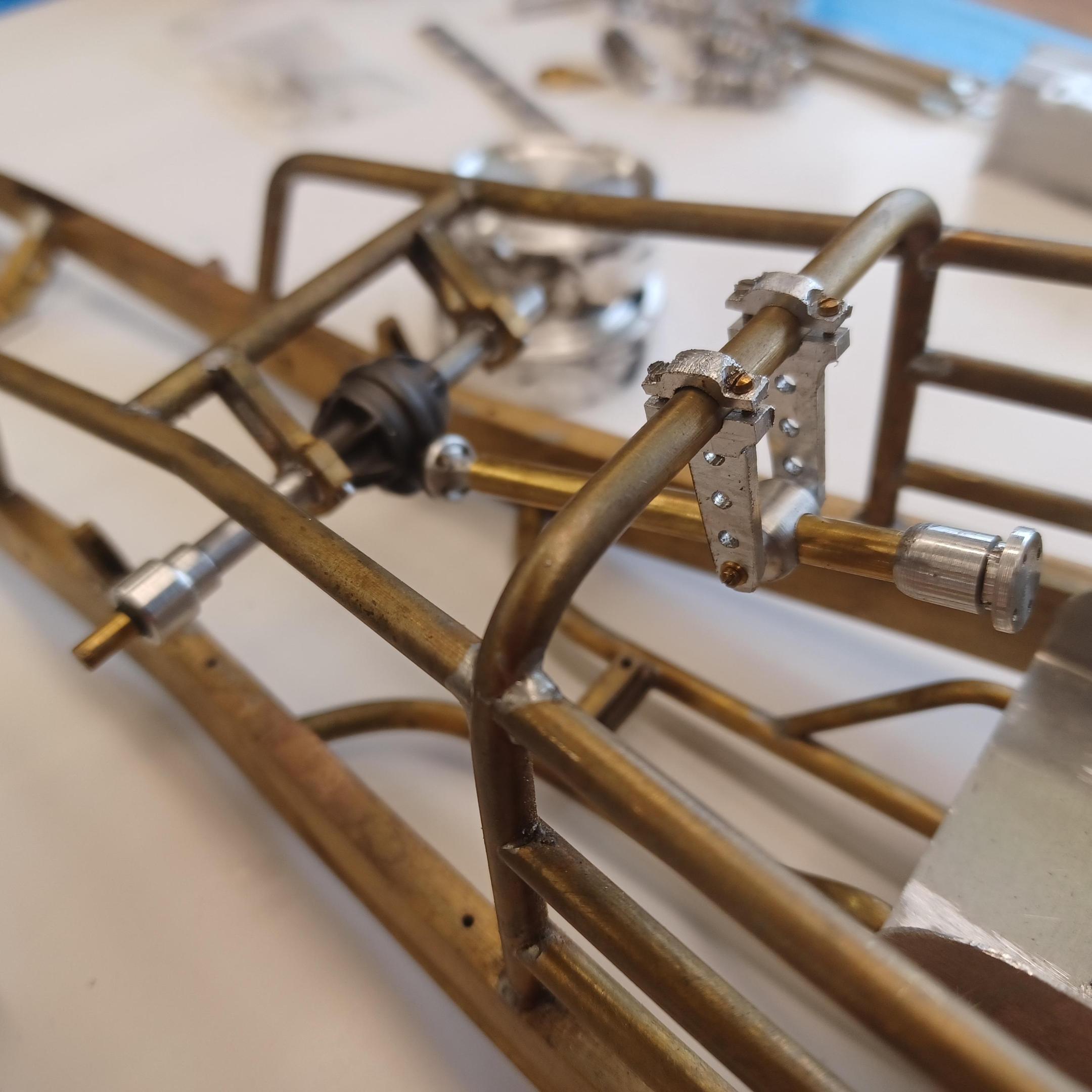

assembly is going well. making detail parts as i go along . made the starter solenoid , got the throttle cable hooked up to the peedal. remade the oil filter amount. the other one hit the frame. radiator and battery mounted.working on the wiring and fuel lines. got fuel line material on order. i am still sanding and polishing the body and body parts, they are looking pretty good. i would like to go to a few shows this year for the first time. any suggestions would help. i have not been to any model car shows. thanks -

Shelby Cobra Daytona

charlie libby replied to 2whl's topic in WIP: Other Racing: Road Racing, Land Speed Racers

WOW.awesome kit and awesome work. One of my favorite cars.your work is great.you are for sure doing it justice. -

Hi andrew wait to see when your done ding your thing on this beauty. Love the body shape on the 166

- 565 replies

-

- quarterman

- fisher

-

(and 1 more)

Tagged with:

-

Thats awesome.great work.

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

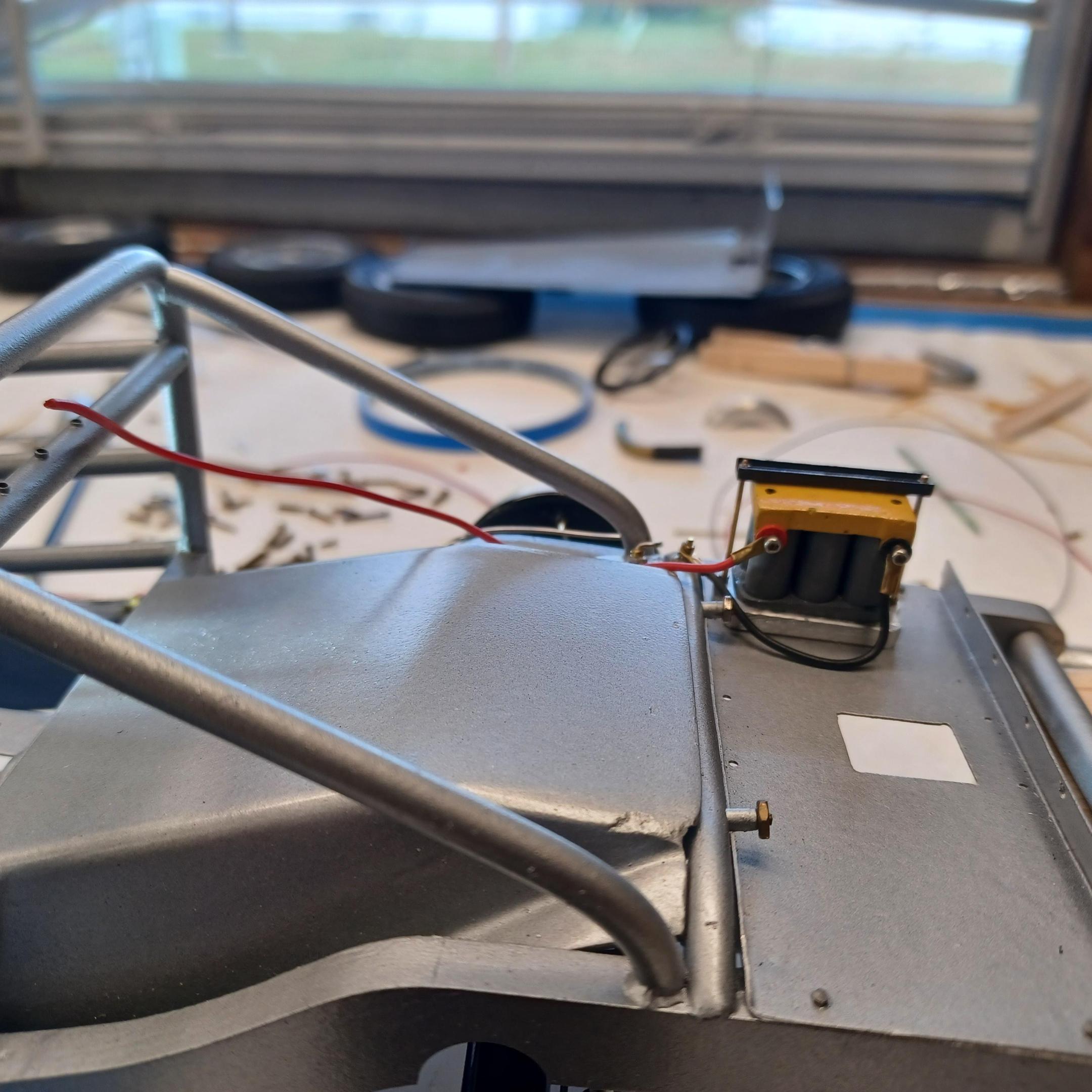

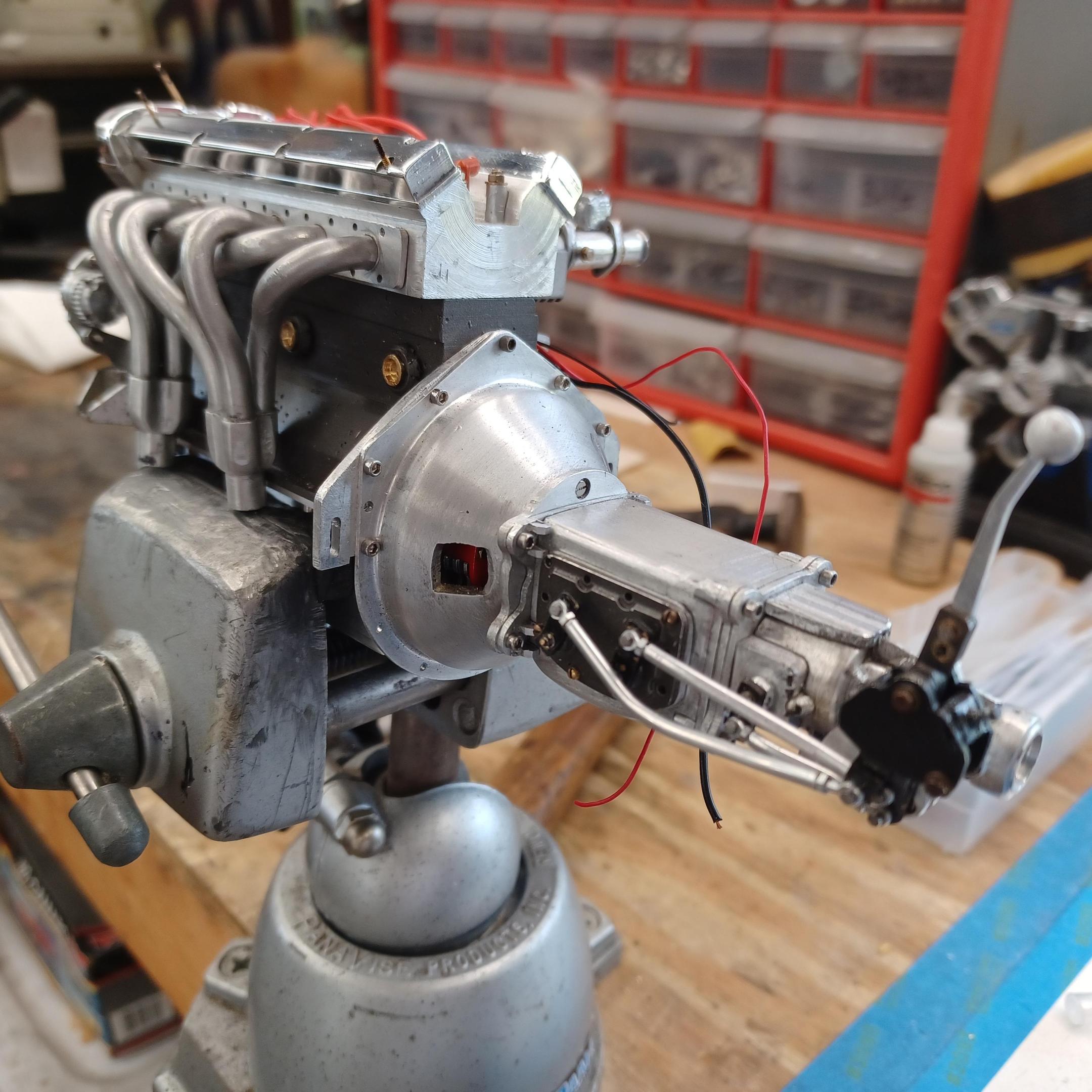

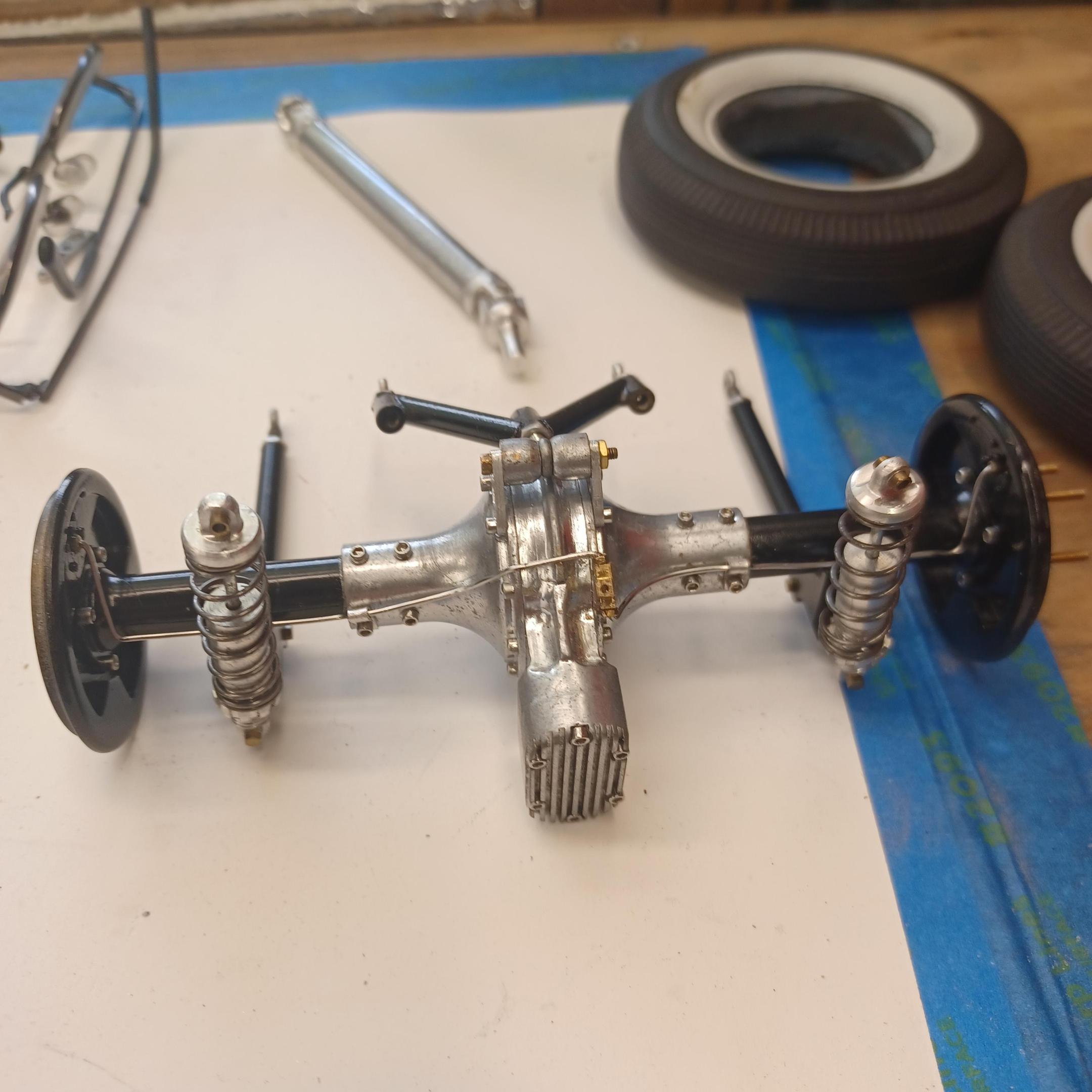

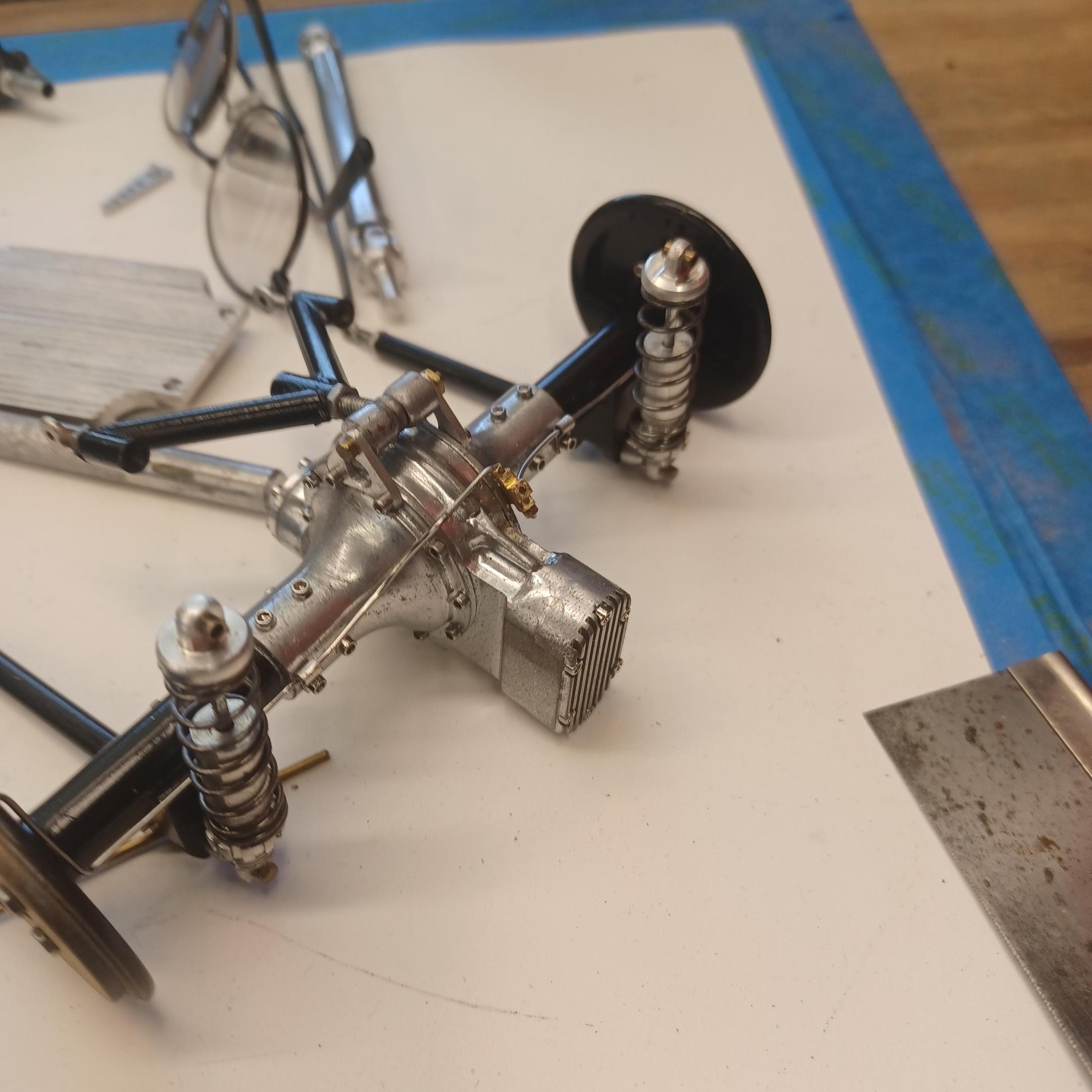

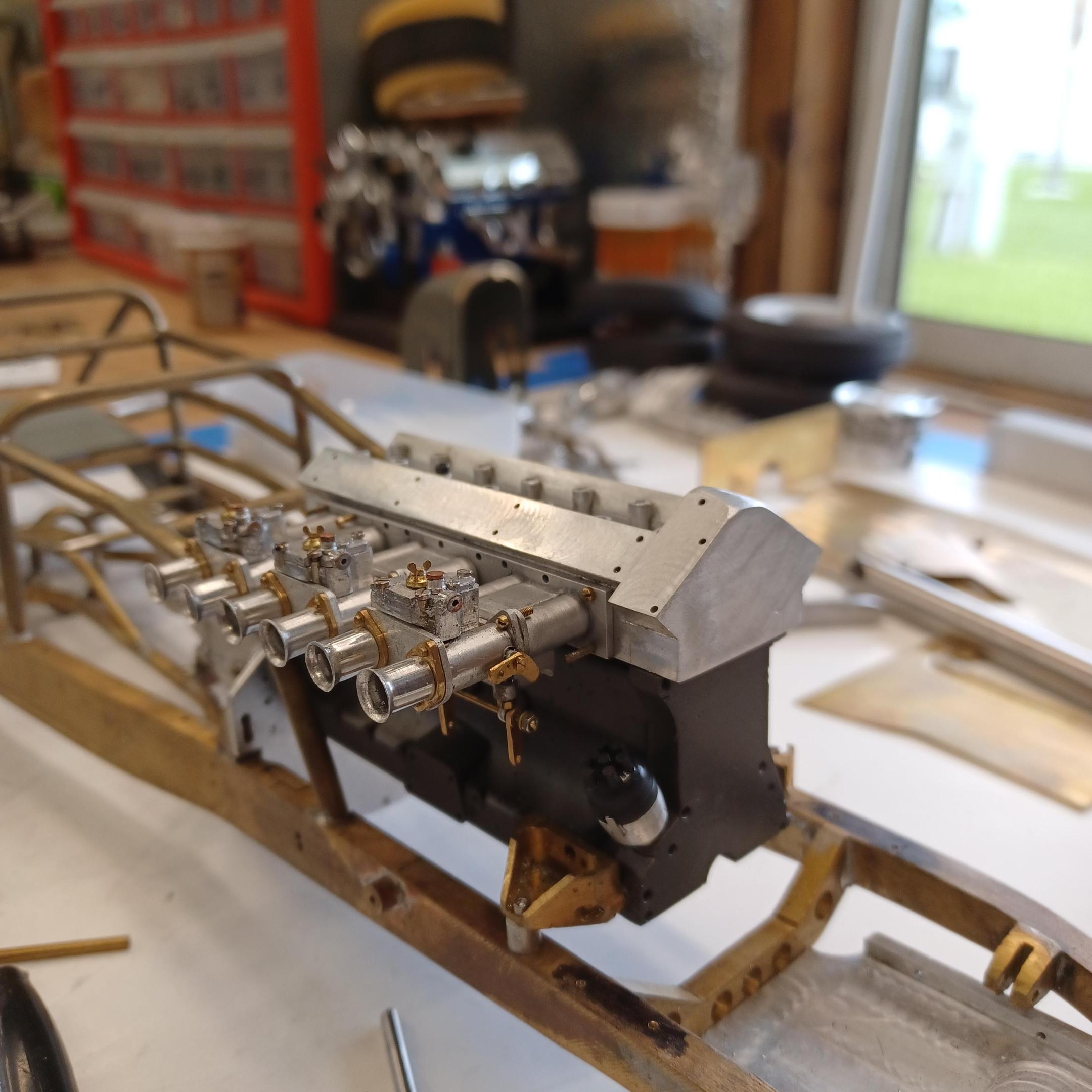

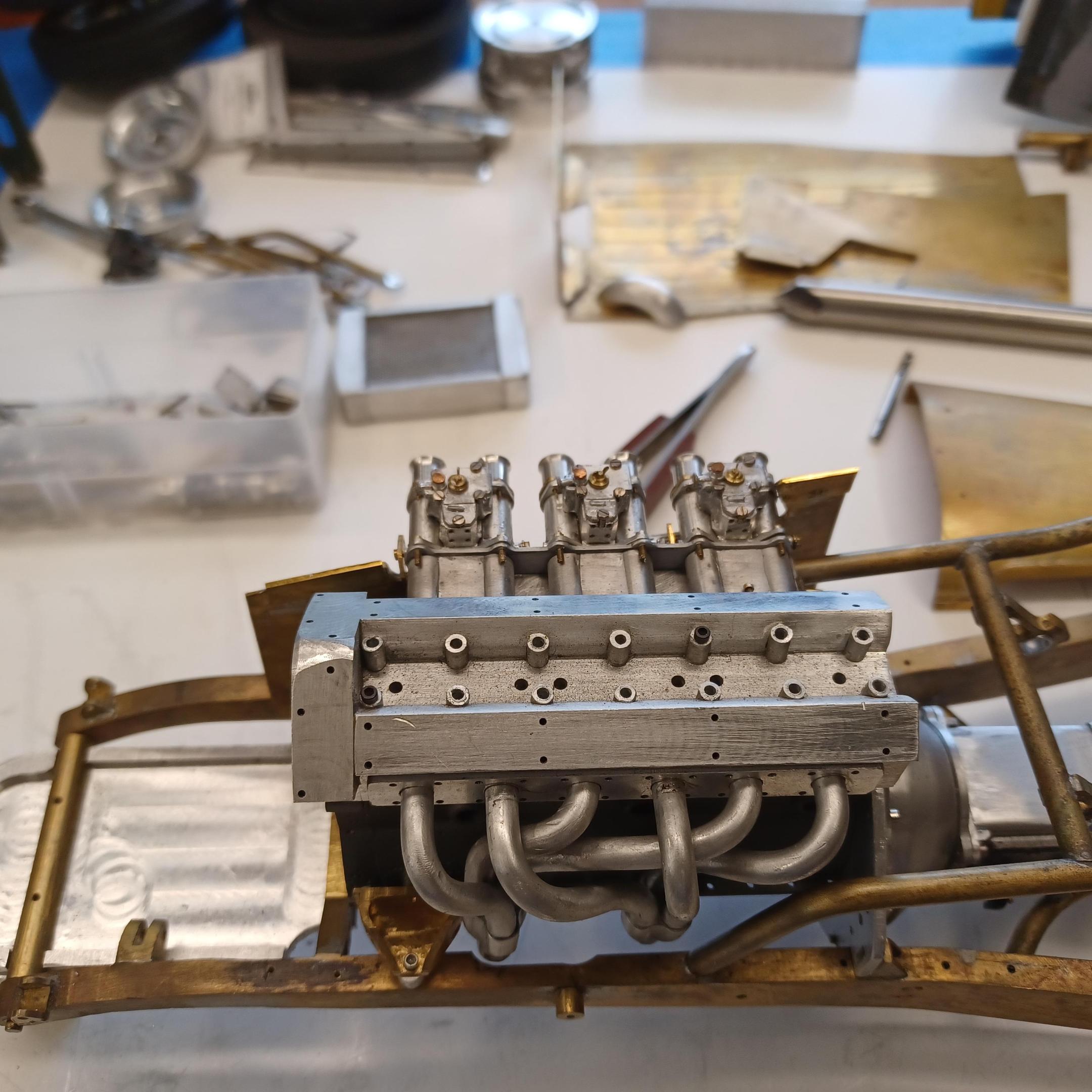

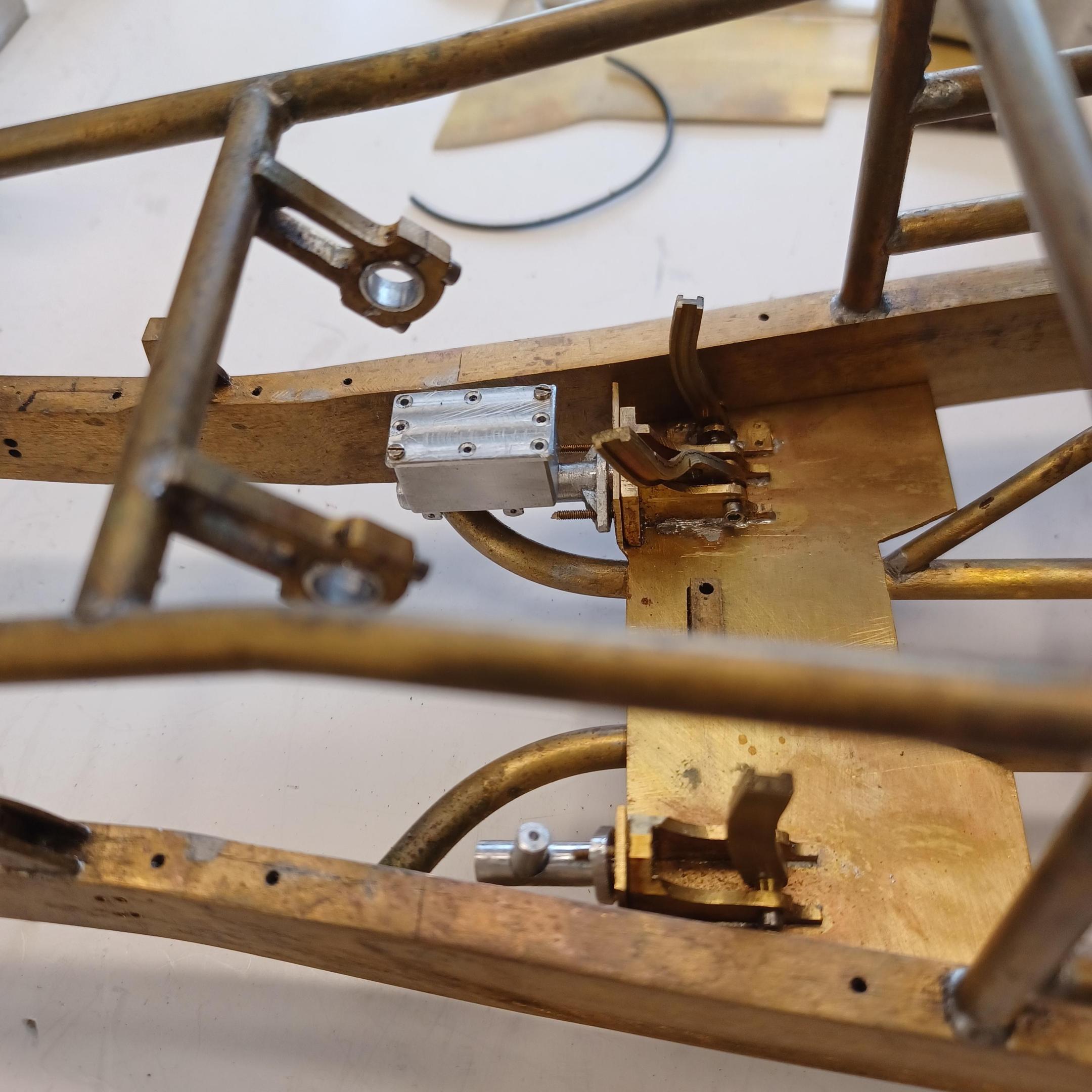

hi everybody.hello andrew hope all is well way down south. i bob nice to hear from you. i have been dealing with details and stuff i forgot to make. i am in the final stages. i took a few pictures to share. assembly is going well.got an alternator done just started on gauges. have most of the brake lines done. i have been designing or drawing pictures i guess of the englishwheel i am going to build. looking forward to seeing how it works. sould be interesting. pictures of the finished chassis soon i hope -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

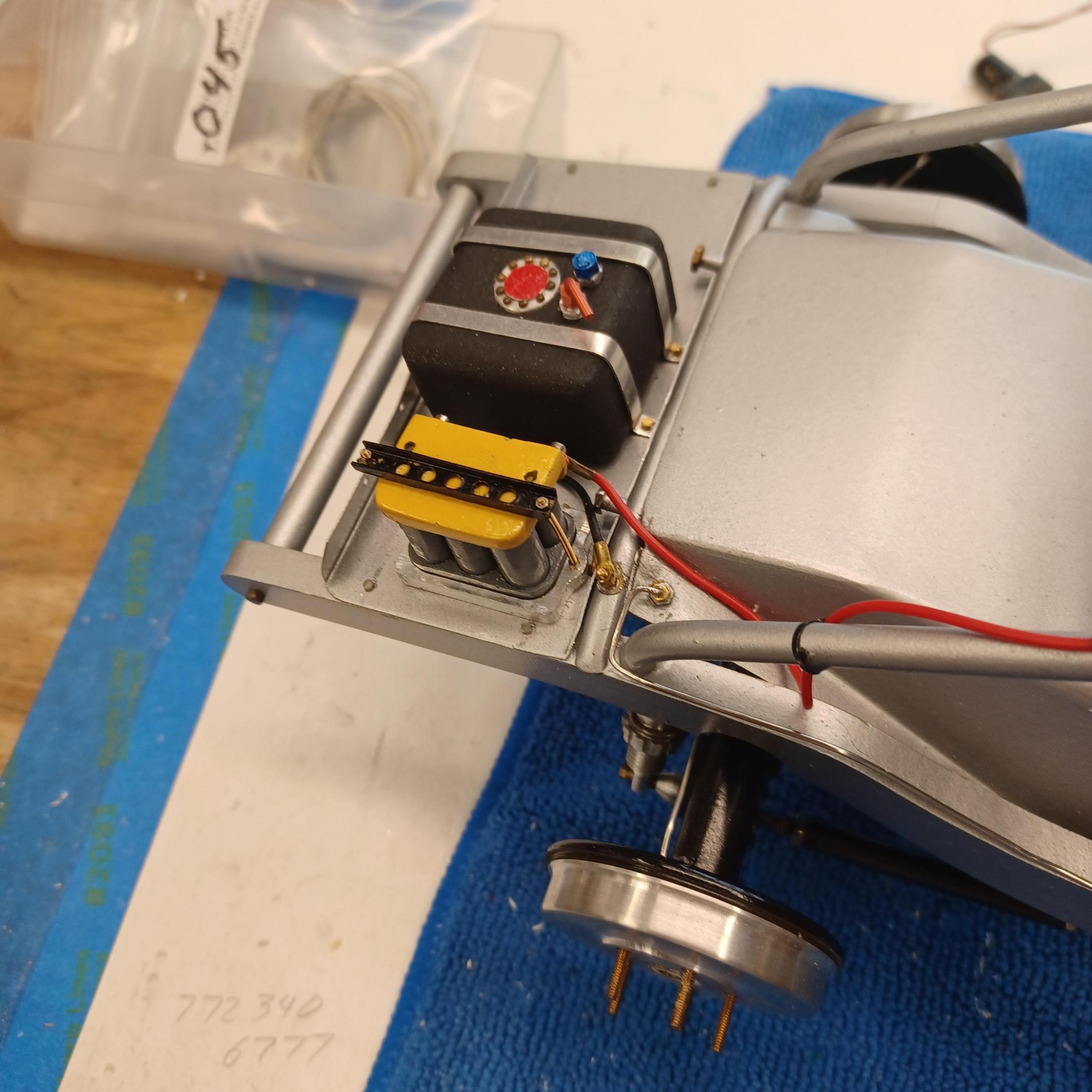

got a little sanding and buffing done . did some rivets as well.working on carbs and fuel lines.anyboby got a good place to buy smaller braided hose , like .045 and .060? would appreciate the help. thank you -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

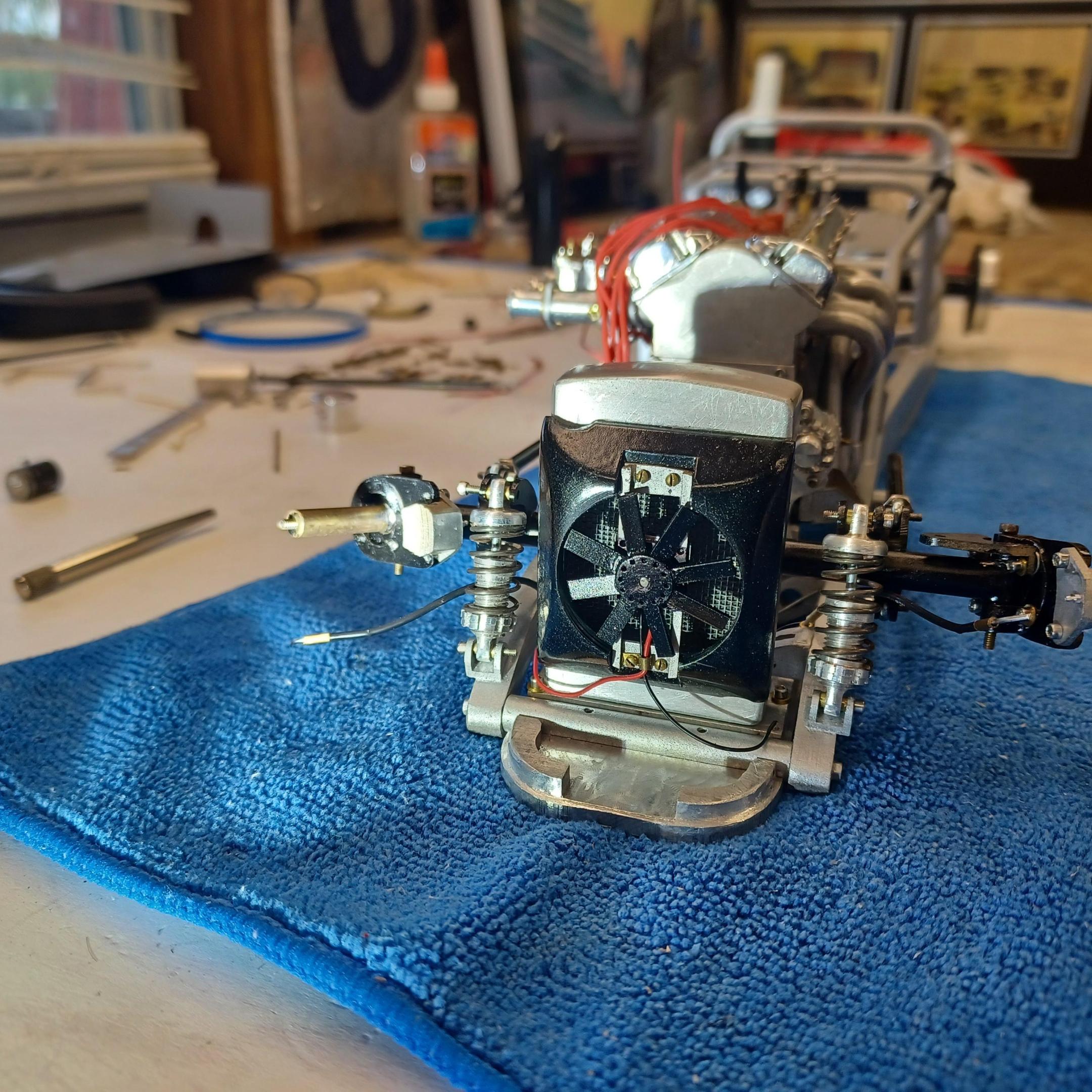

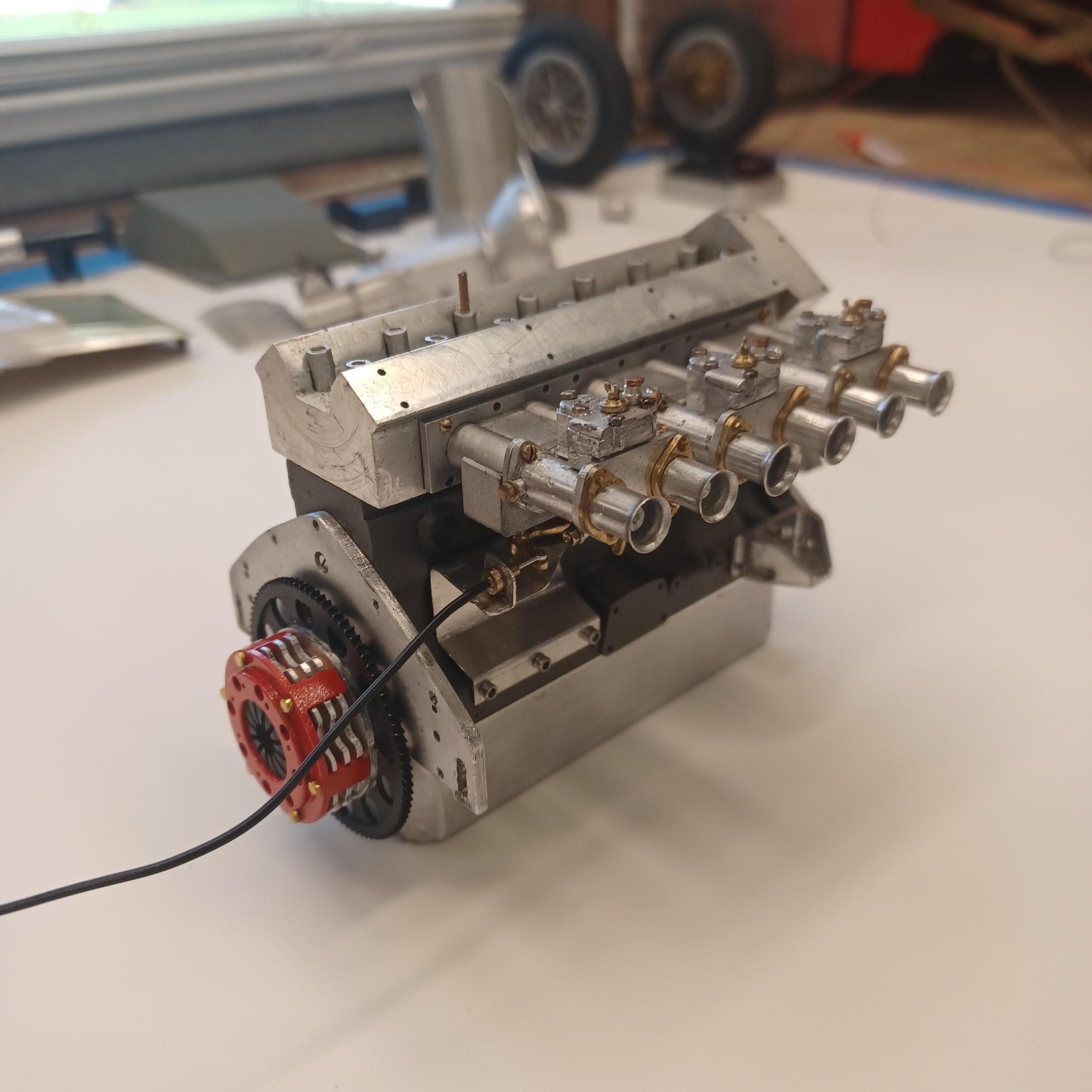

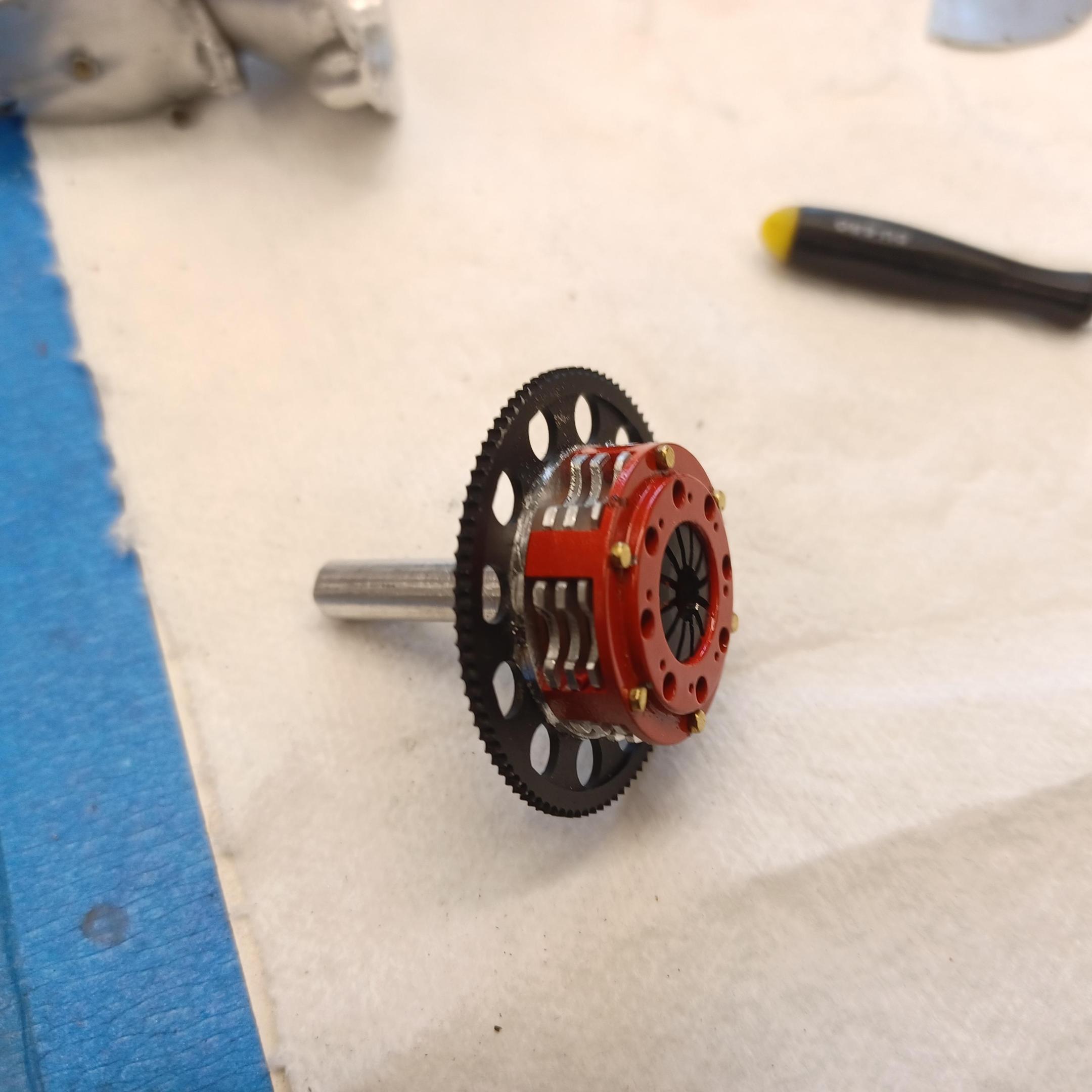

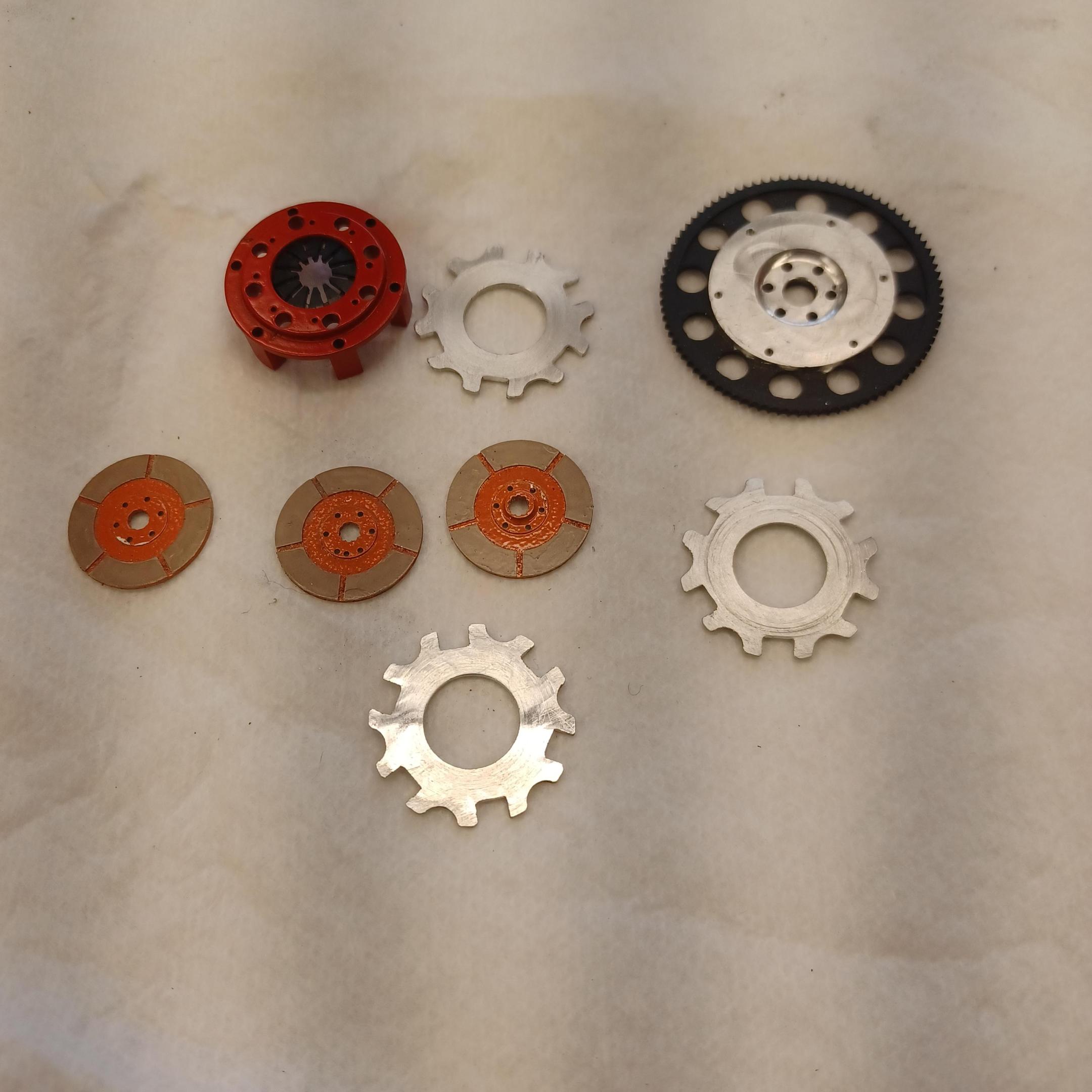

no air just sweat. ok till about 2:00 . hi bryan thanks for your comments. working on final parts and assembly ,got brakelines on the rear. got the pedals installed. made pullies and balancer for the engine. i have been sanding and polishing the paint. the main body is sanded to 12,00 and is ready polishing. waiting for real screws and fake allen bolts. -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

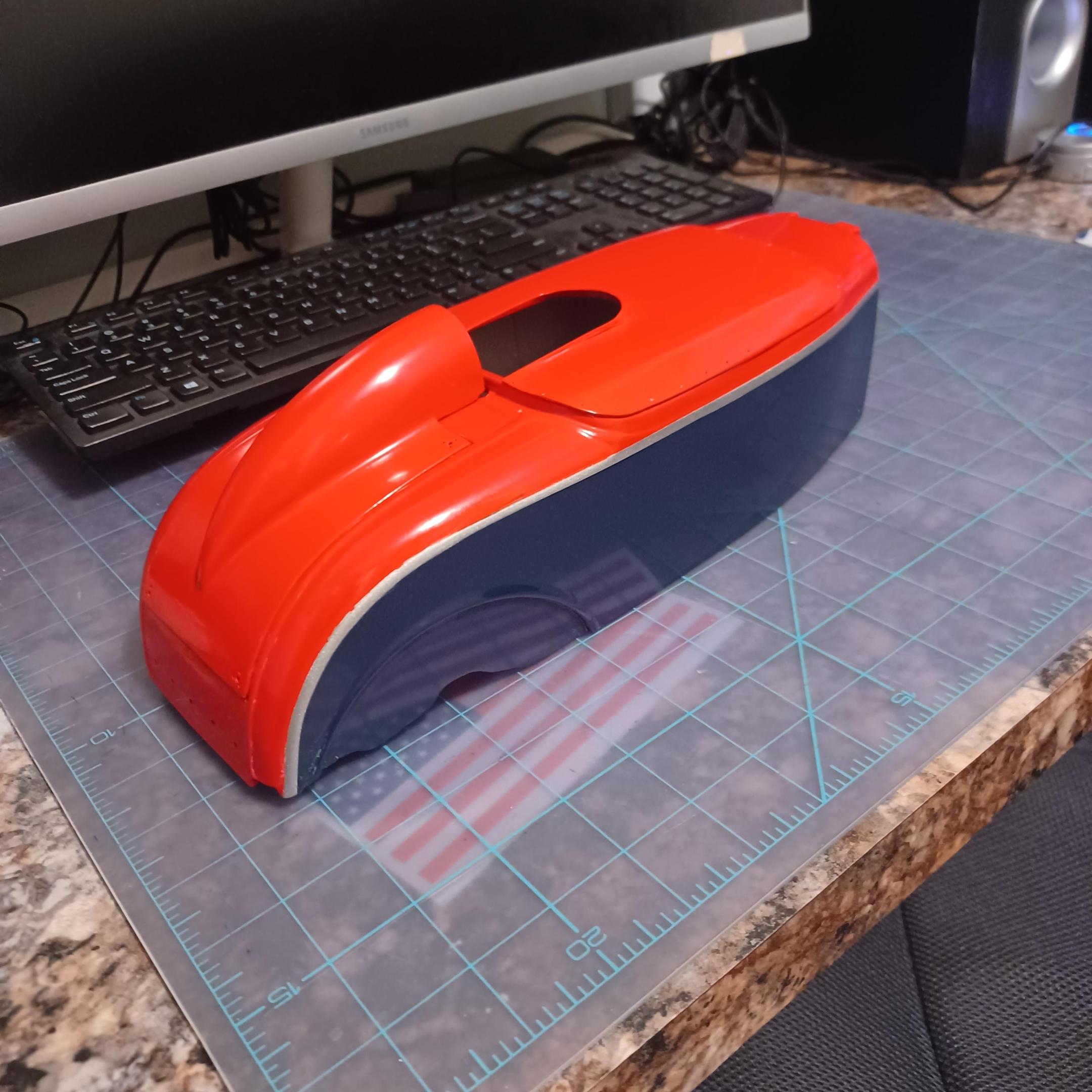

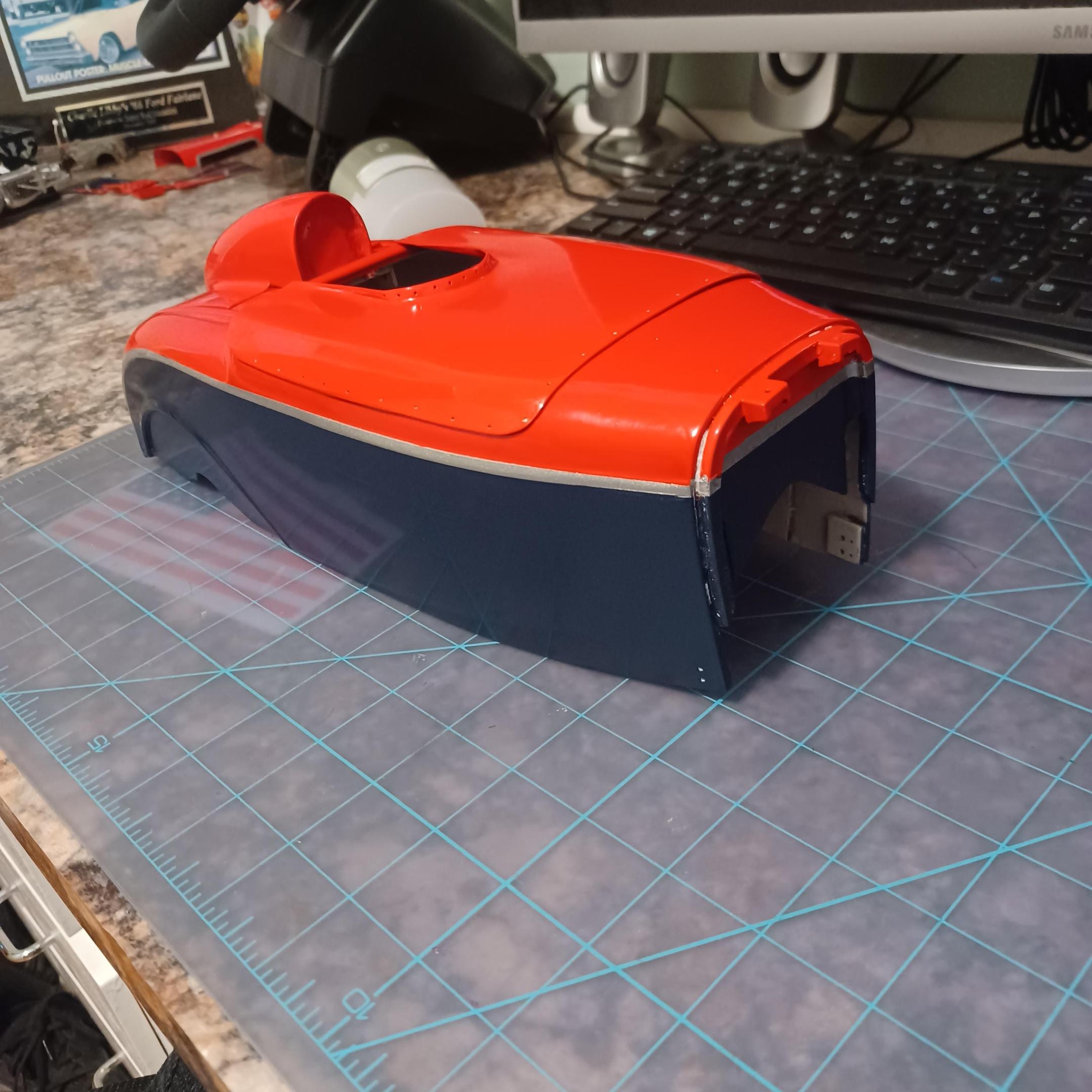

hi andrew nice to hear from. hey noel ,i think you will like my next project. i am trying to design a small english wheel mostly for finish work after hammering a shape. i want to build a body the same as the 1 to 1 car that i did . francis so happy to hear from you, glad all is well.here are a few more pictures of paint and i am in the process of doing finish work and finding things i forgot or missed. the paint looks pretty good after sanding and polishing the clear coat. i have striped the nose to refinish because the sides were not looking as good as the rest of the parts. i have painted the frame argent silver but i have not taken pictures. -

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

glad to see an update francis i was start to worry about you. looks really nice -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

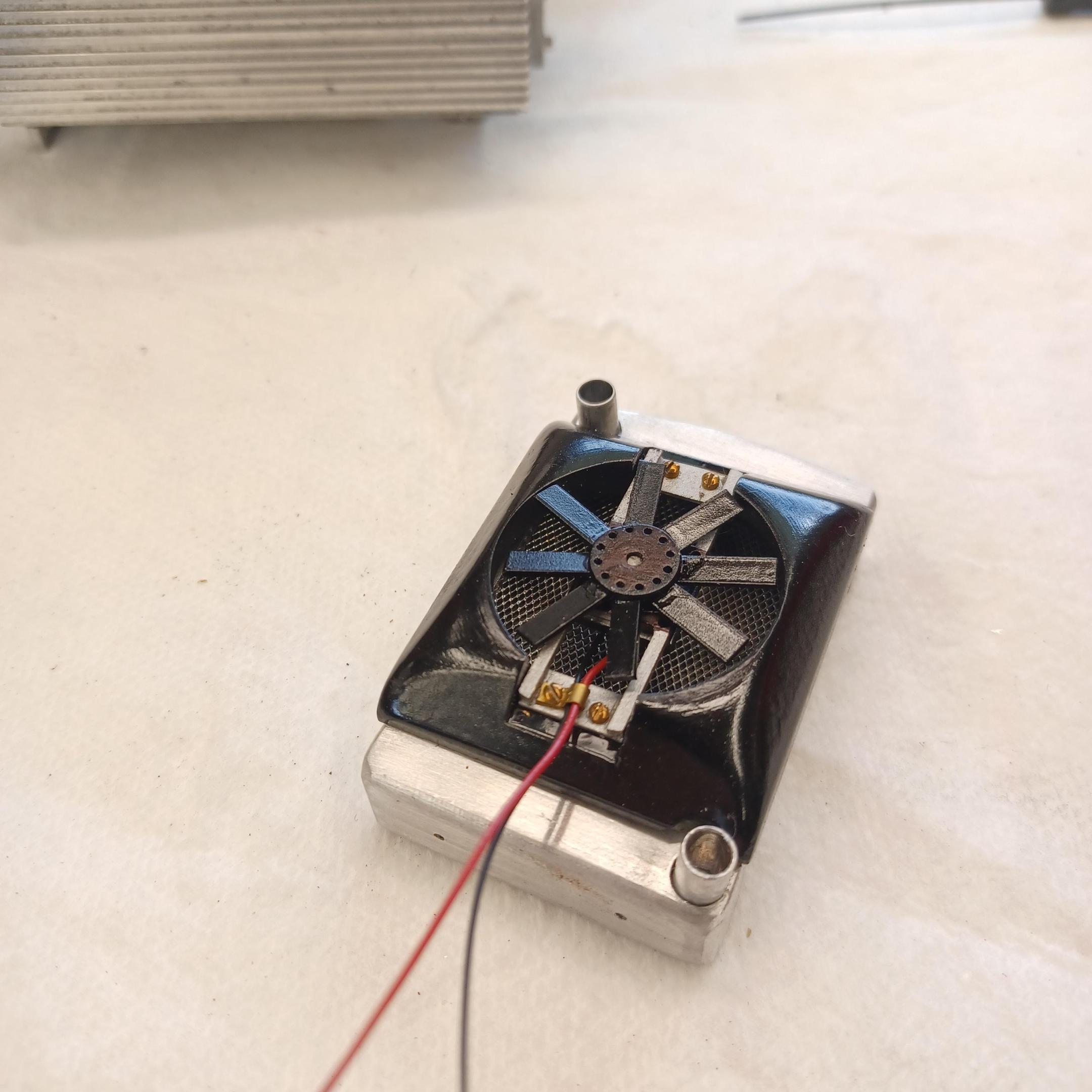

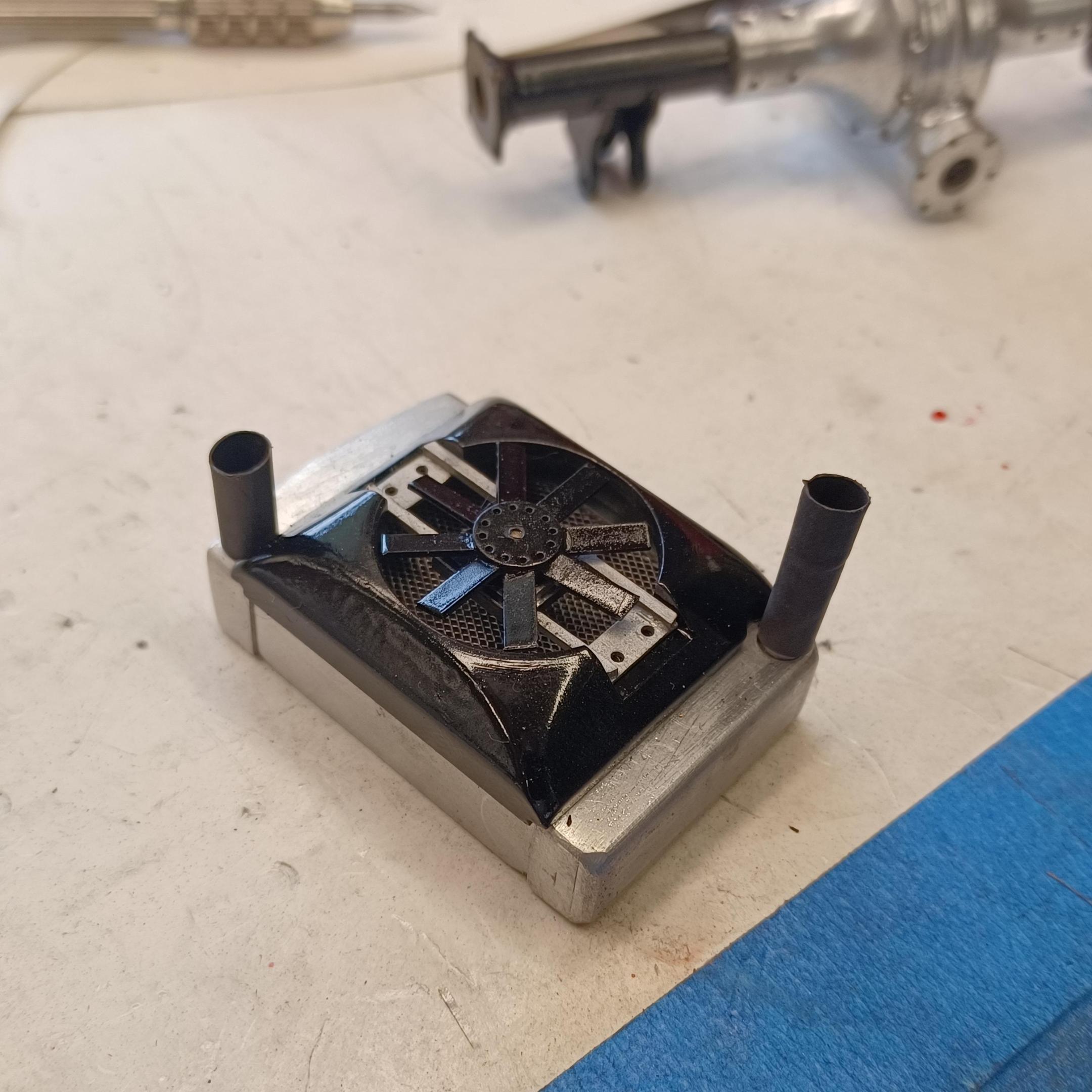

got a little behind on updates.working alot on the hydreds of details,also on the paint. the top above the body line is as you can see bright red,a silver stripe at the body line and dark navy blue below the line.i am waiting for the red to make sure the tape wont affect it.later this week will be 7 days,that should be enough. made the drive shaft and electric radiator fan and shroud. i think the red came out well,a little wet sanding after all the colors are on and 3 coats of clear. i have the carb linkage all most done thanks to RB motions hiem joints. thanks for looking and thank you for your nice comments. -

Awesome work.very nice.

-

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

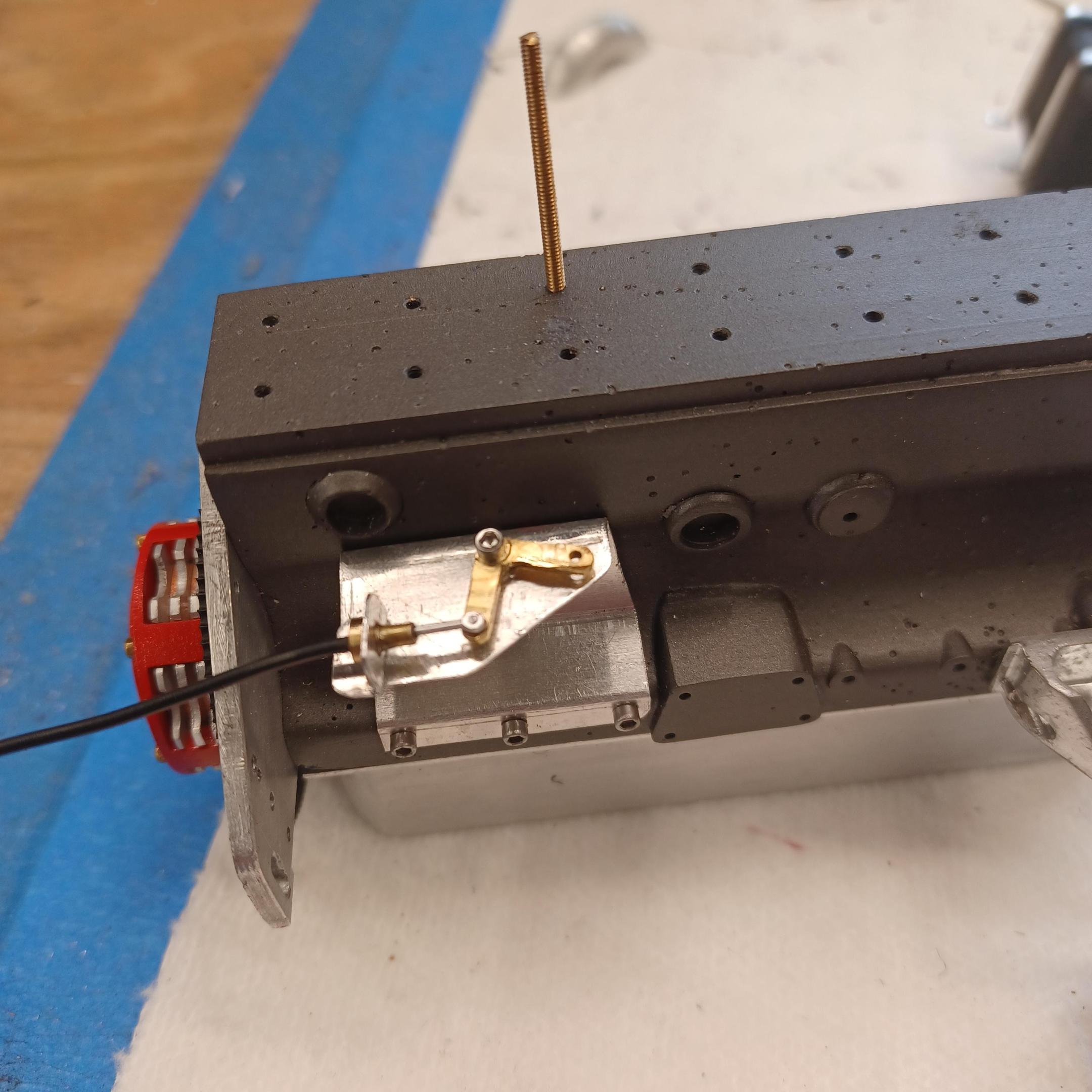

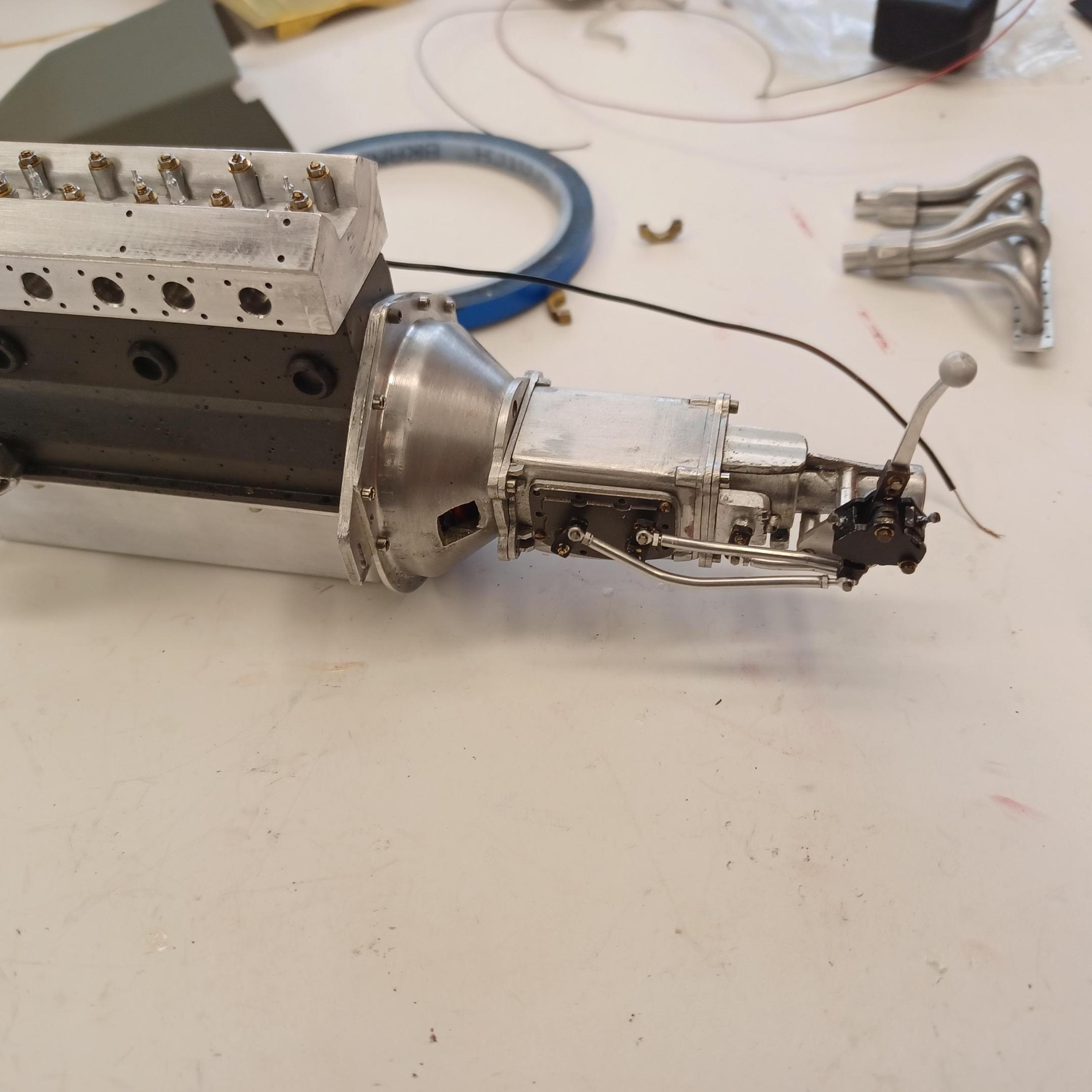

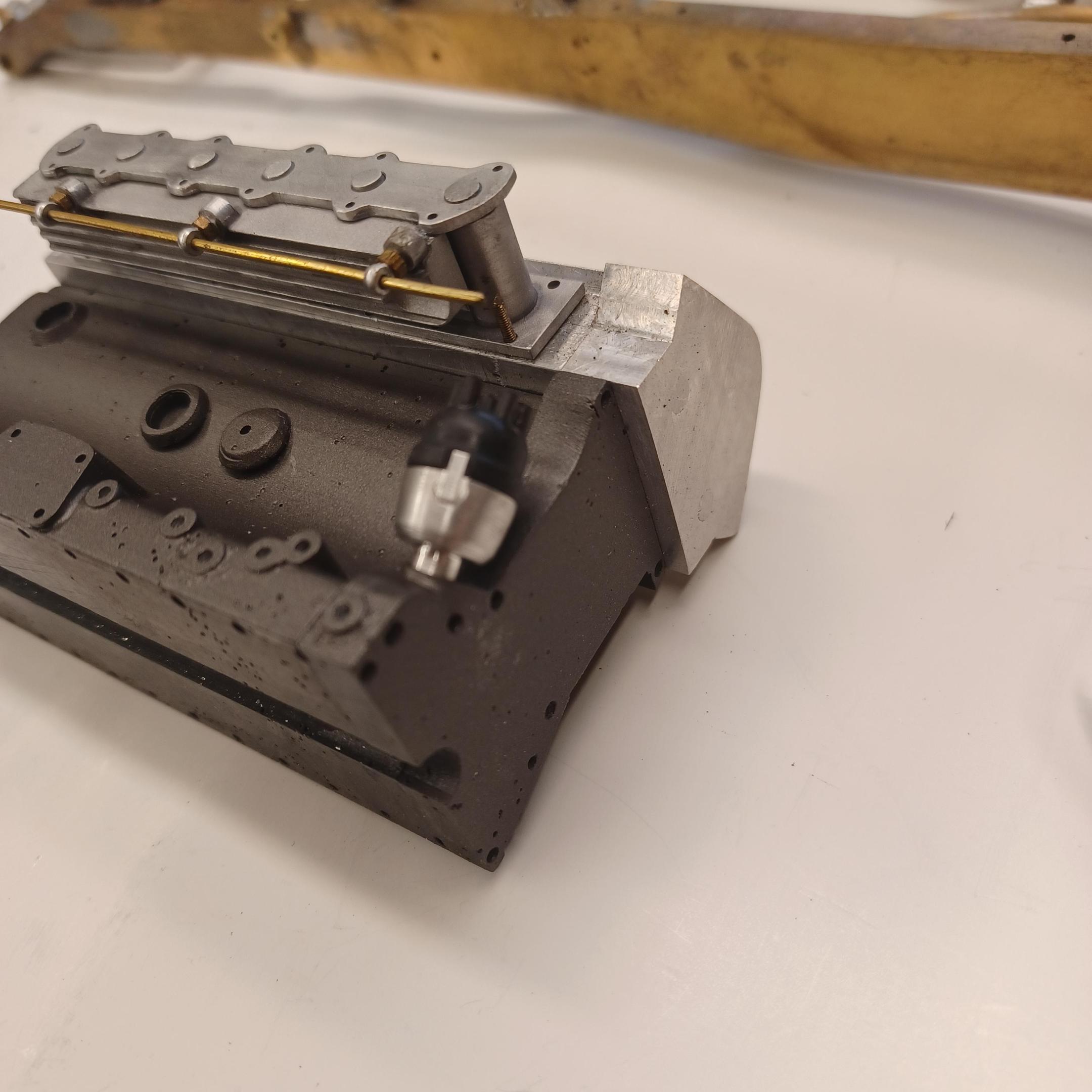

first time attaching the carbs to the manifold all the holes lined up . working on the radiator and water pump. got a good start on the brake clutch and gas pedal. i have to order some rod ends from RB to finish the carb linkage. i am almost ready to start the final finish of each part check the fit and paint or anodize them. i guess i do it different . i make my parts make sure they fit and then finish them for paint. might be backwards .but it works for me. more later,charlie -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

finishing the adjustable steering column support . just need to wire the distributor. getting started on the carb linkage on the bottom side to help with my new hood configuration. hi francis here is a picture of a diesel powered hot rod i built a few years ago for a customer in charleston ,sc. has a turbo 4 cyl diesel from a bread delivery truck. still cant find the hood pictures .one drive is new to me and am having some technical problems. found them -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

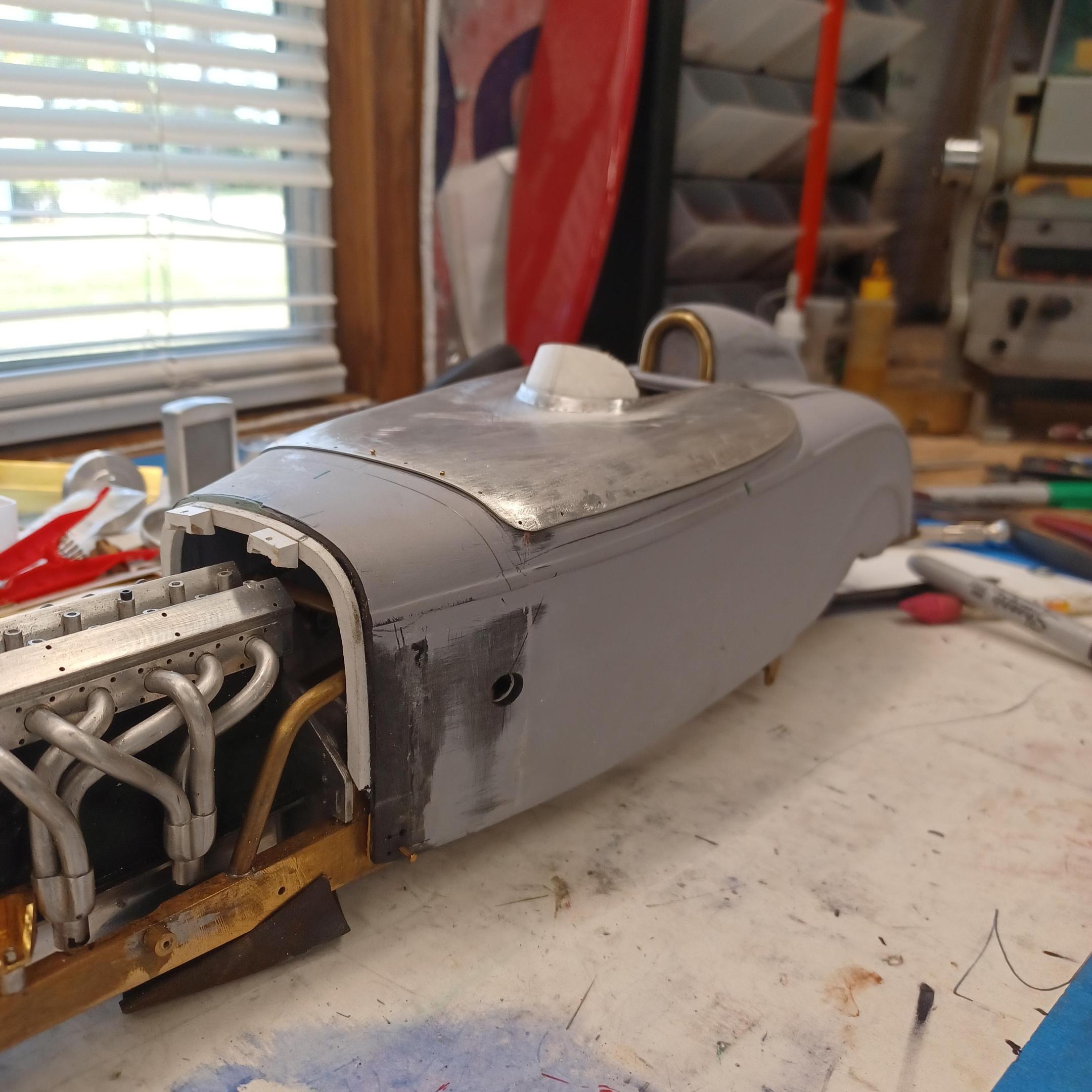

decided to build a new hood an d hood sides but the pictures don't come up. this is the aluminum top and soon to be windshield. i like the new hood and sides better . as soon as i can i will get the pictures up -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

You know where i live. Call me -

1932 ford saltlake car

charlie libby replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

-

’72 Dodge Demon Drag Racer 1/25 scale

charlie libby replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

impressed as always. such nice clean work. i love the doors and hinges. if i send you my address can you send me a big box of your patience. obviously you have tons of it.