-

Posts

416 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by charlie libby

-

wow, love this car.you must have a million hours in it.so much great detail.cant wait to see it finished

- 599 replies

-

- open wheel

- jim clark

-

(and 1 more)

Tagged with:

-

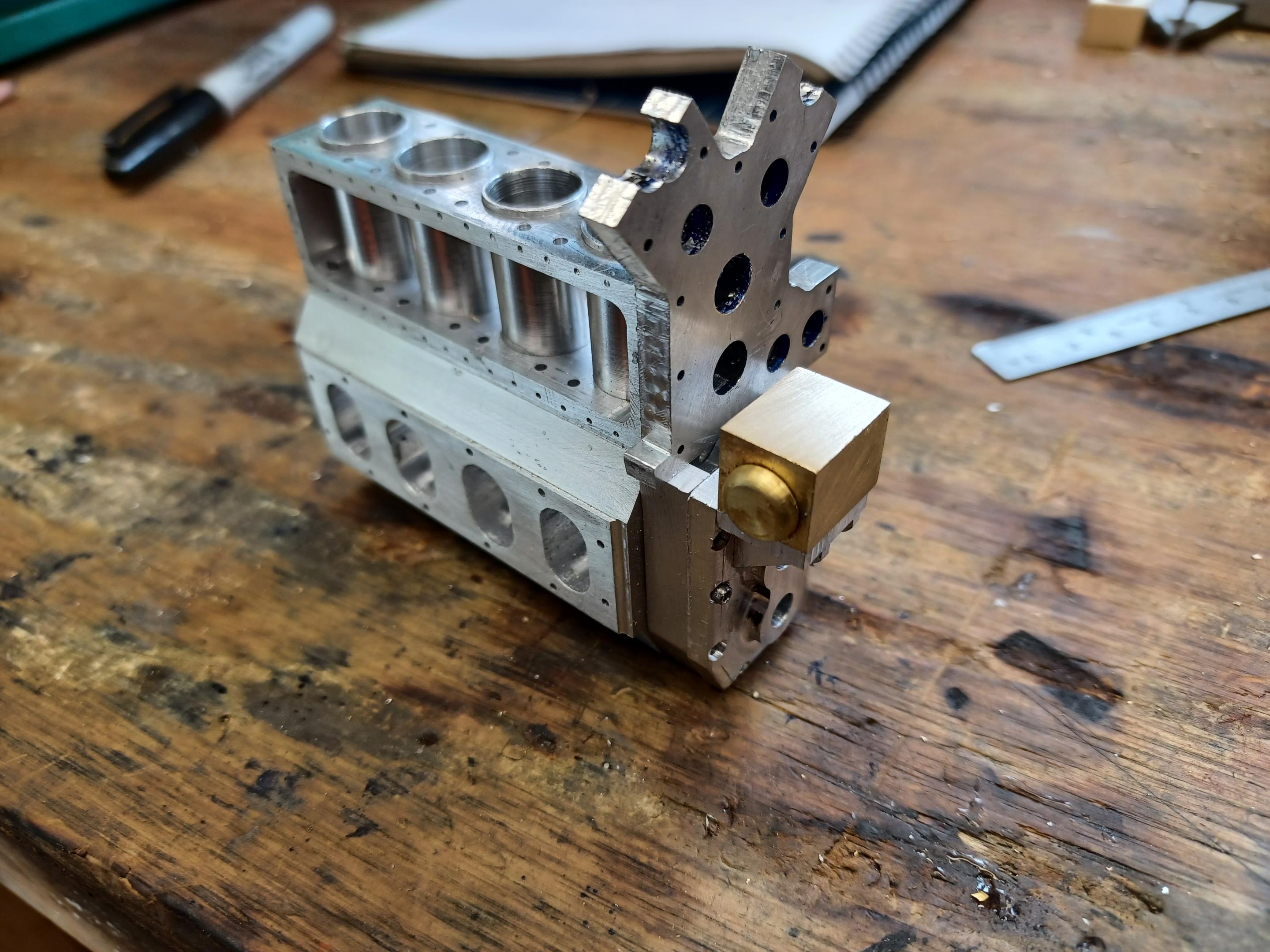

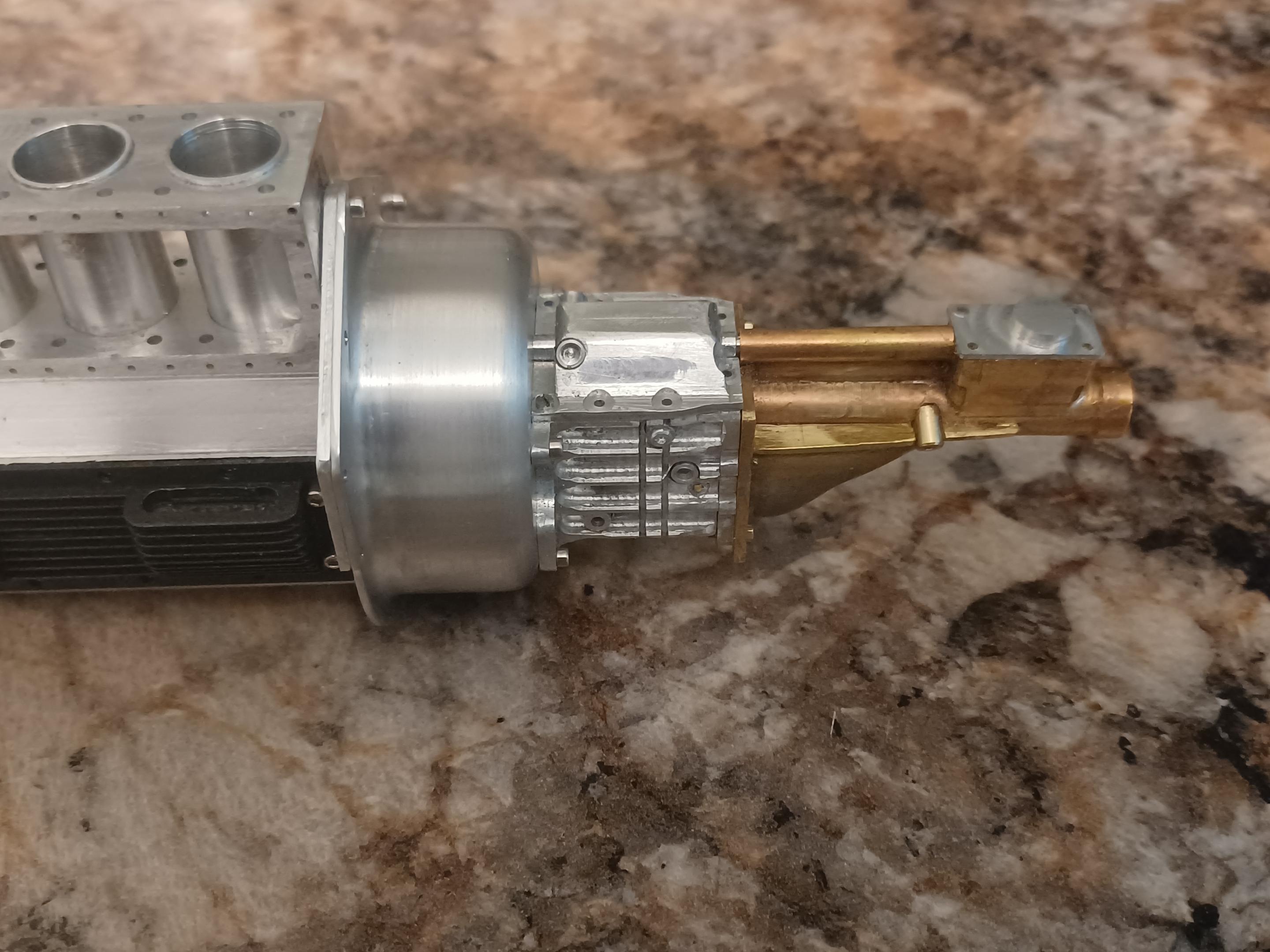

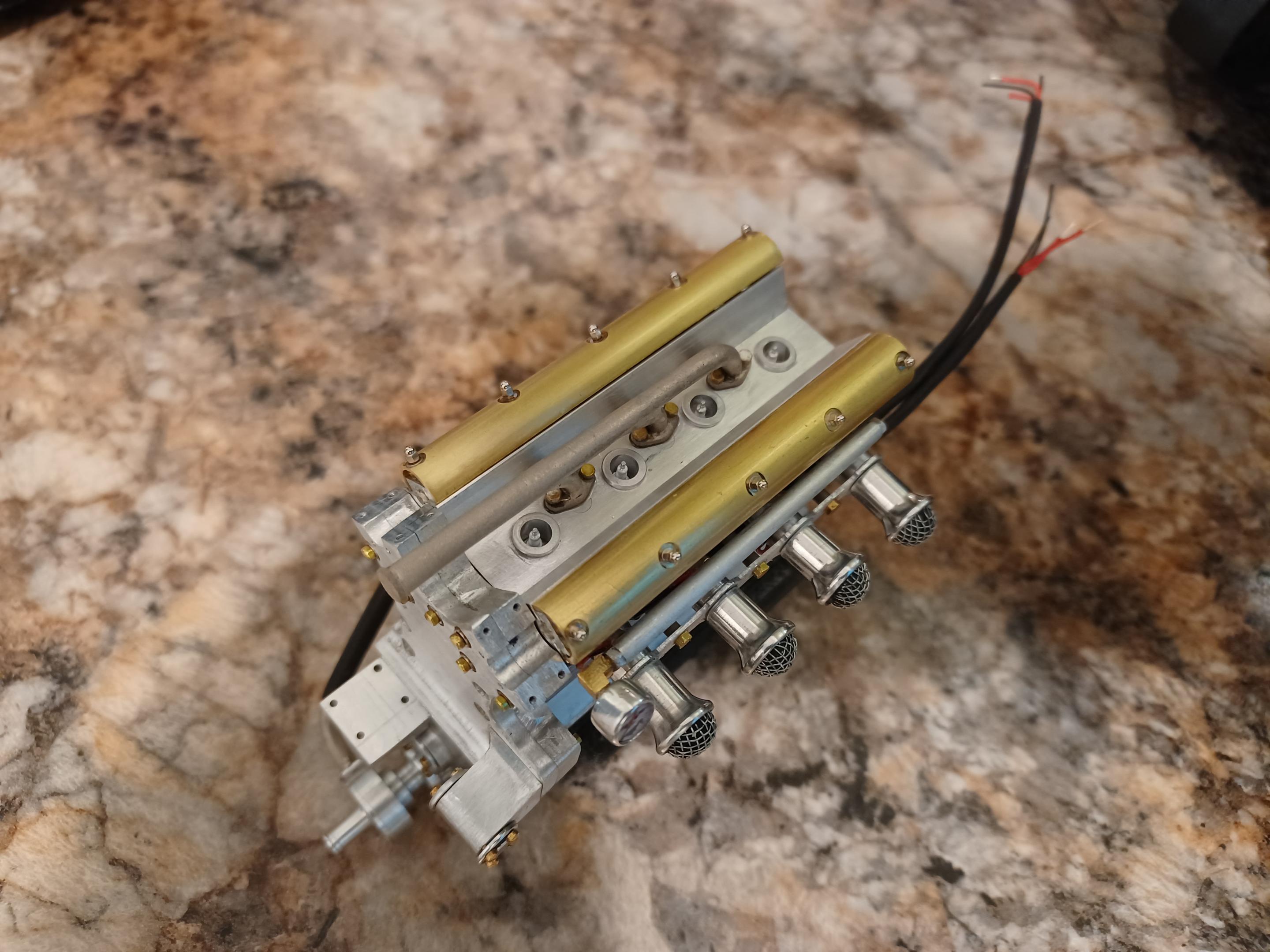

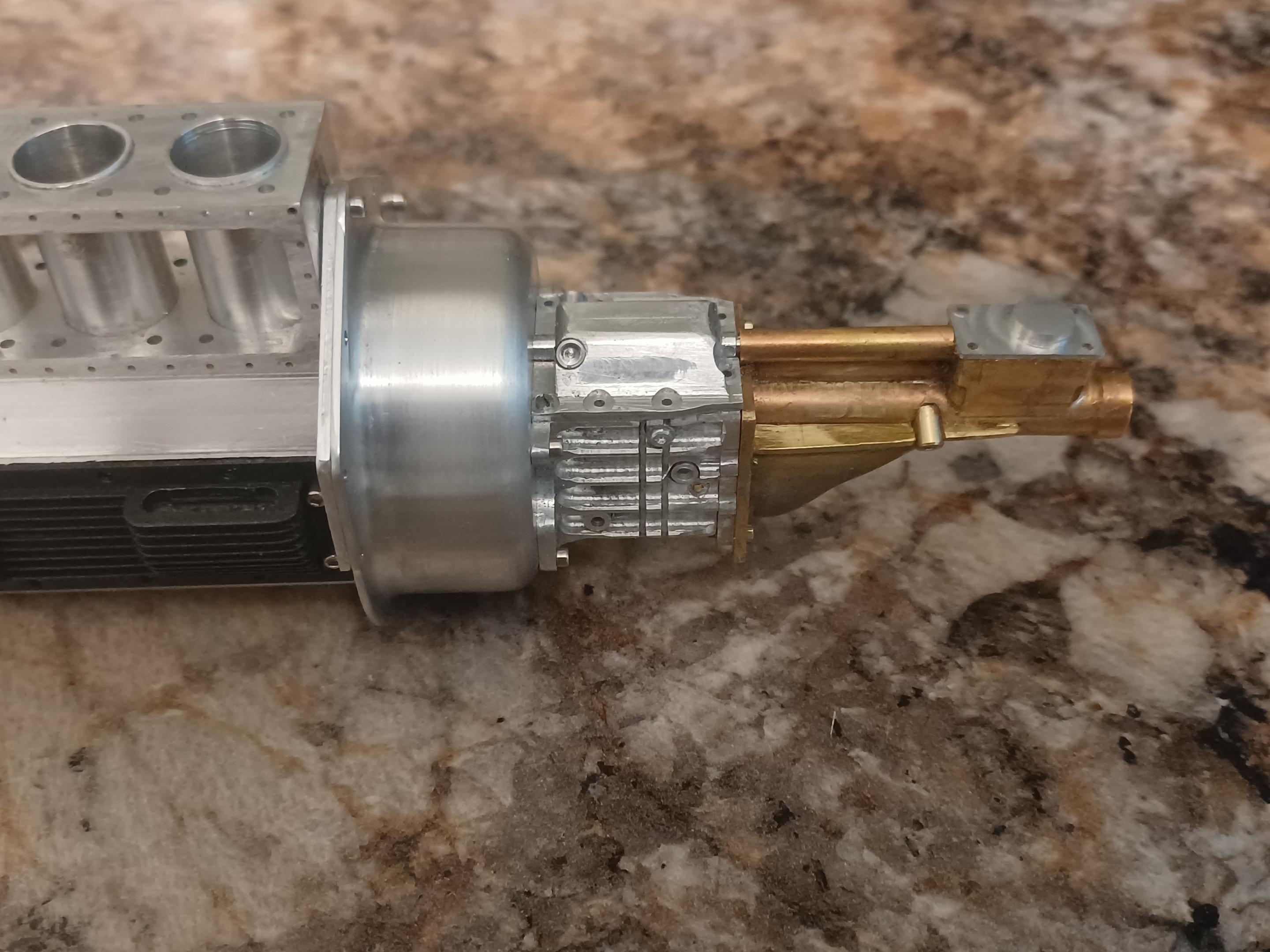

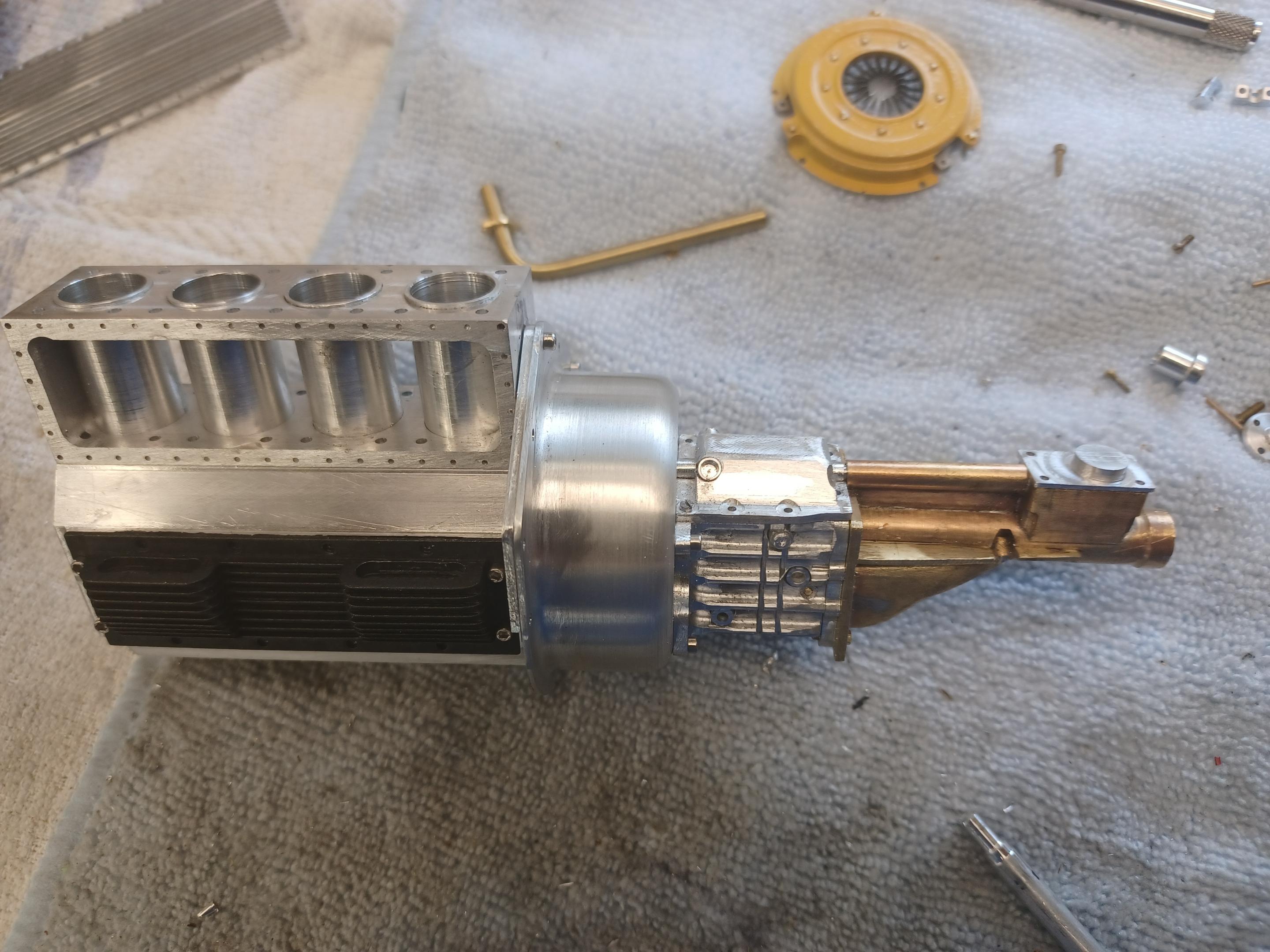

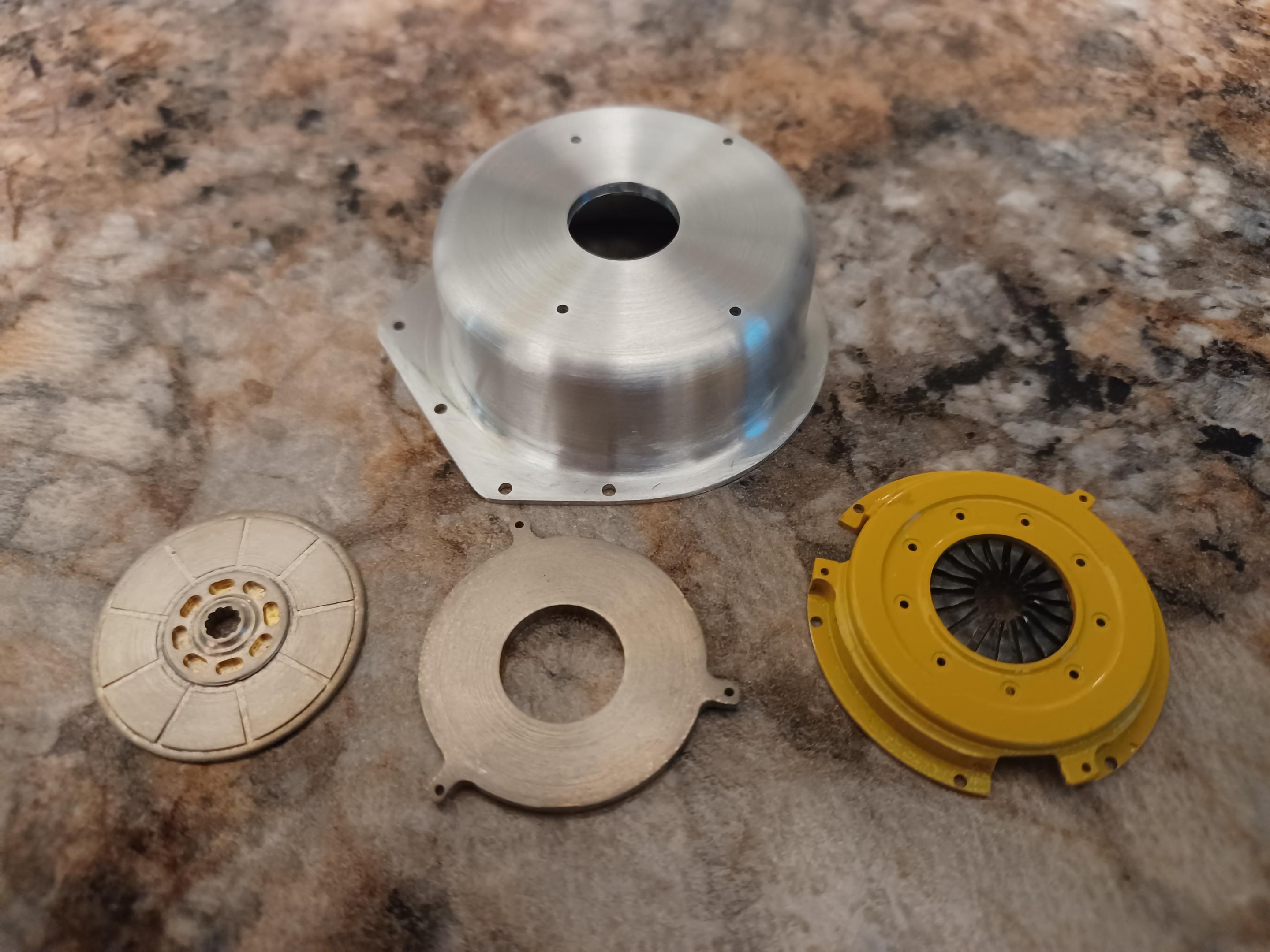

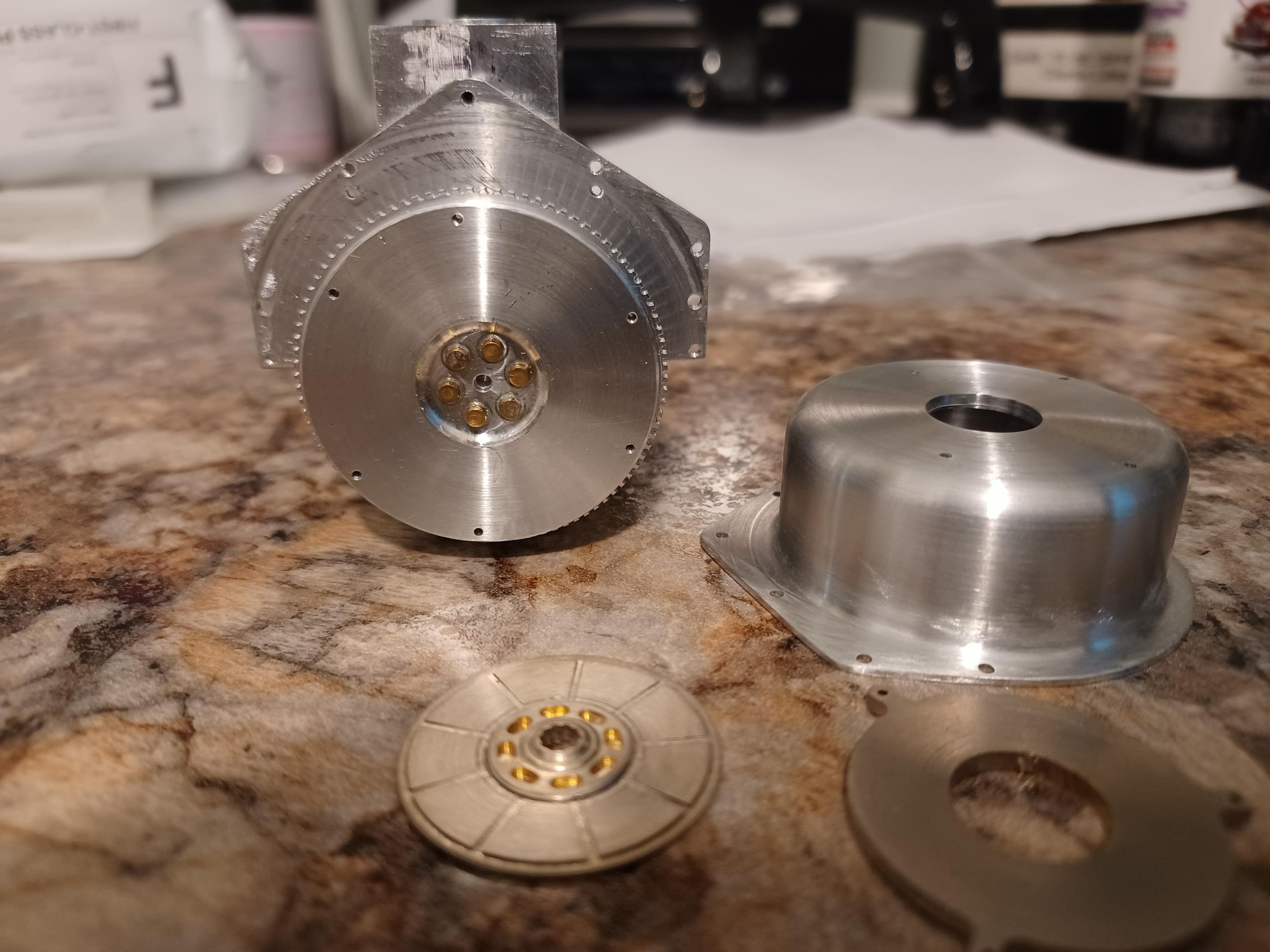

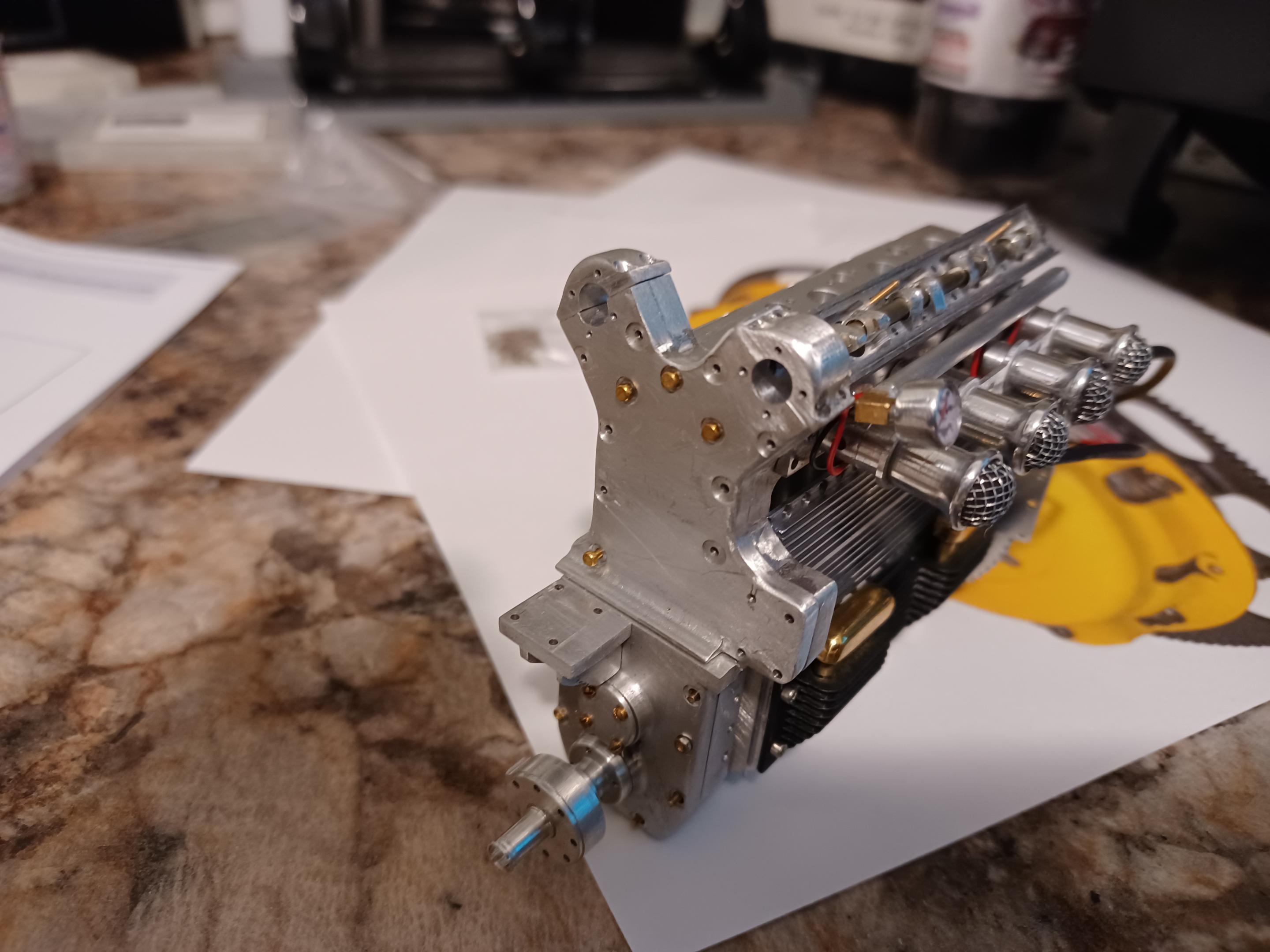

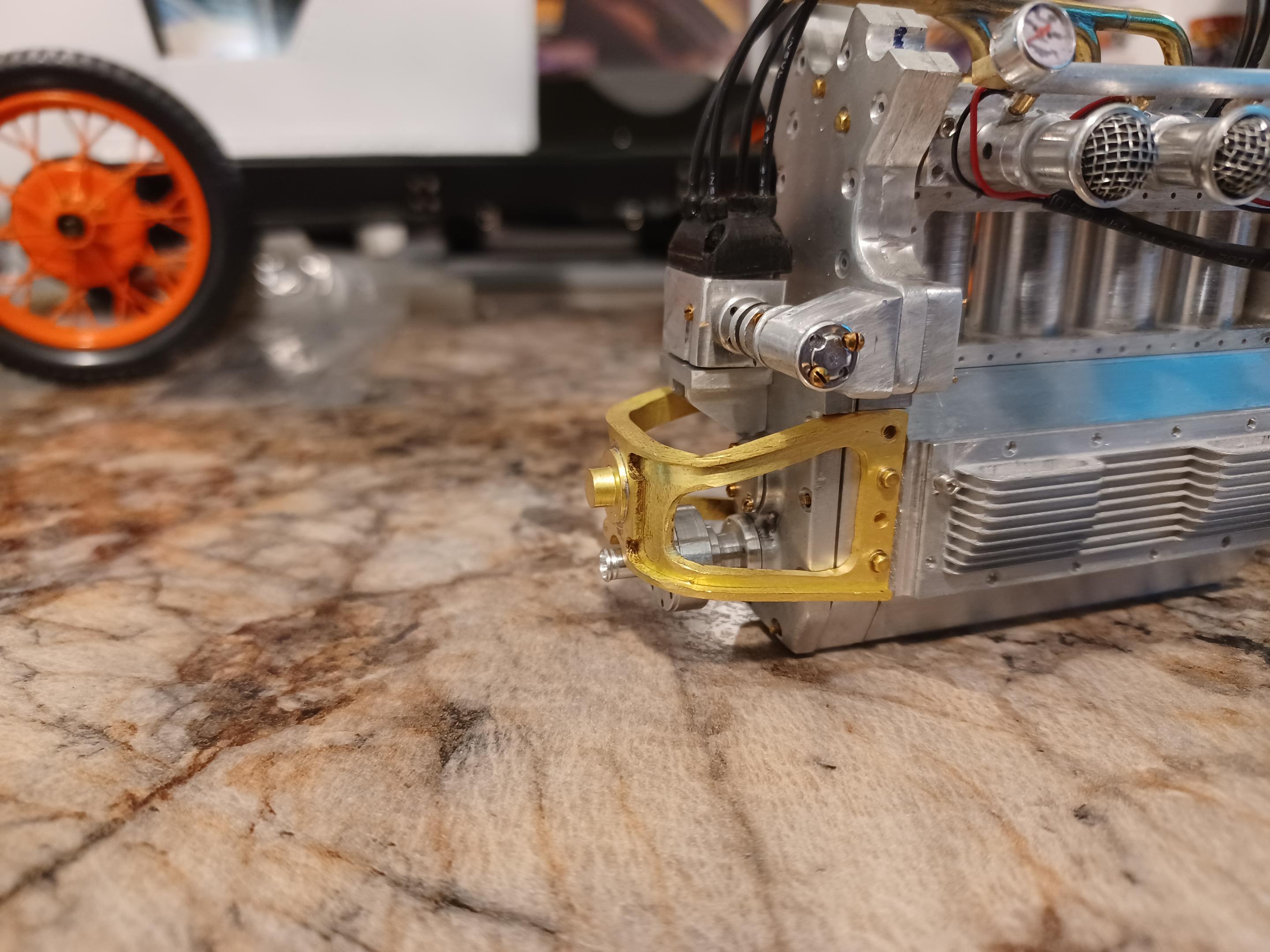

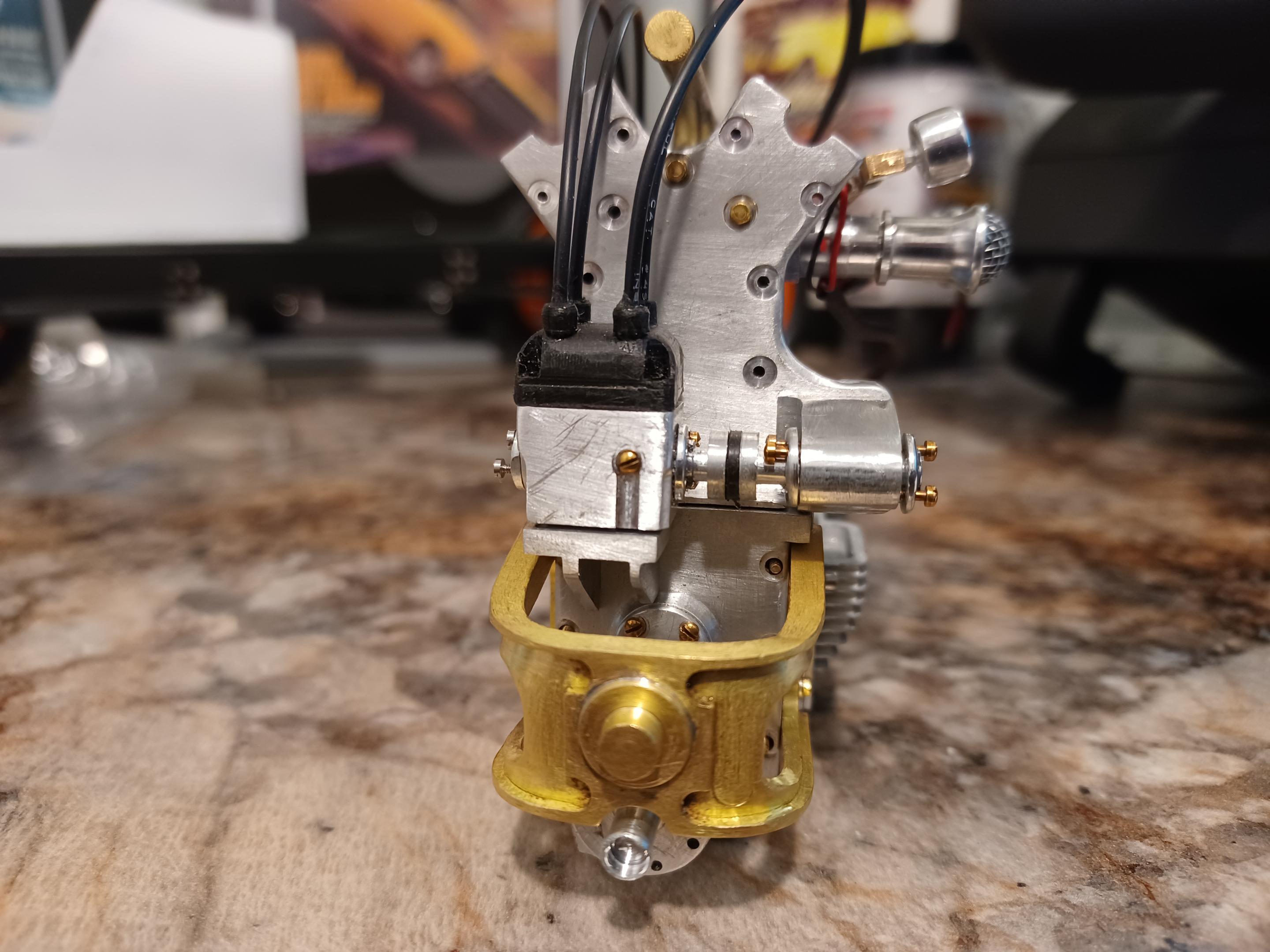

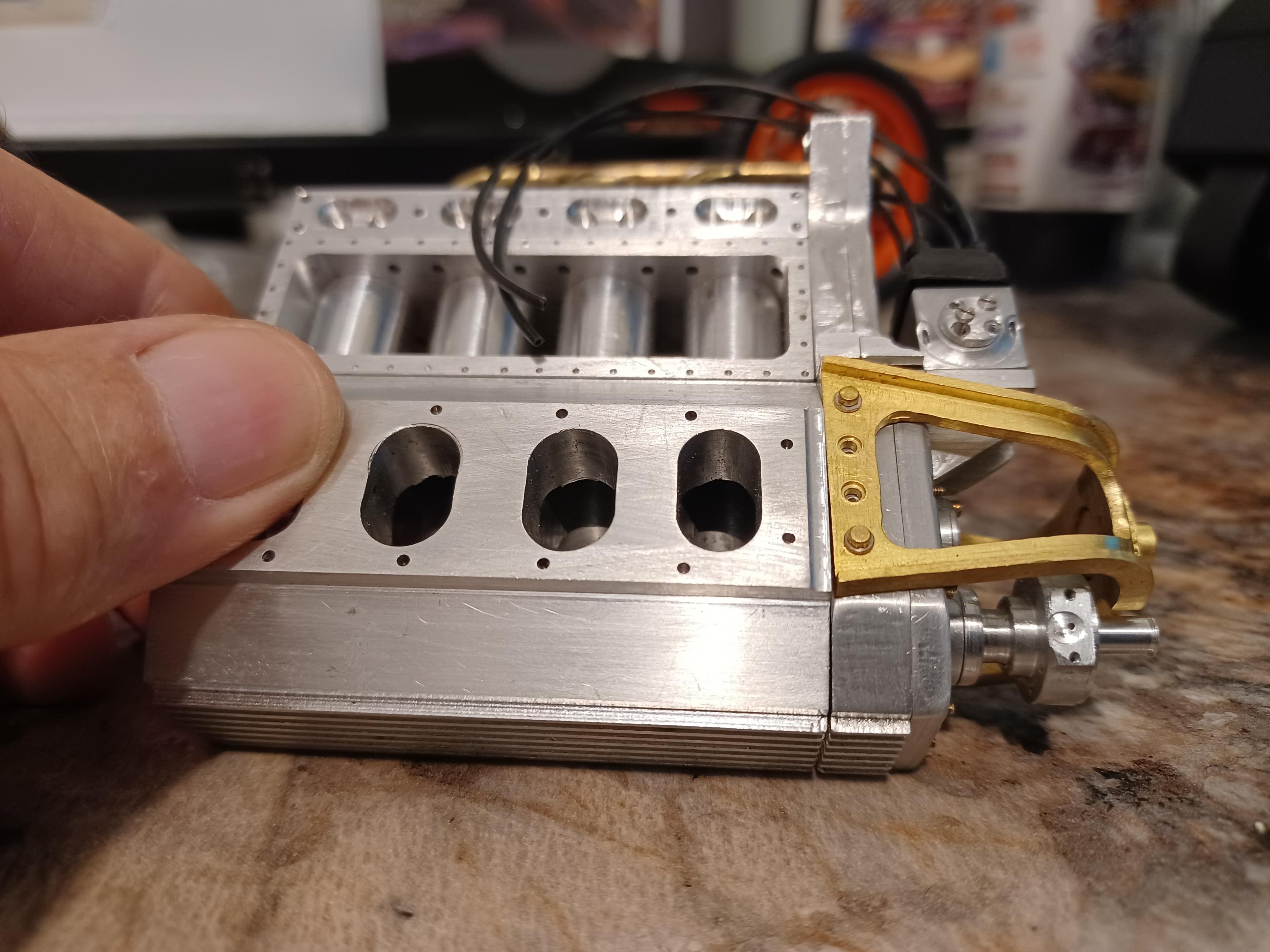

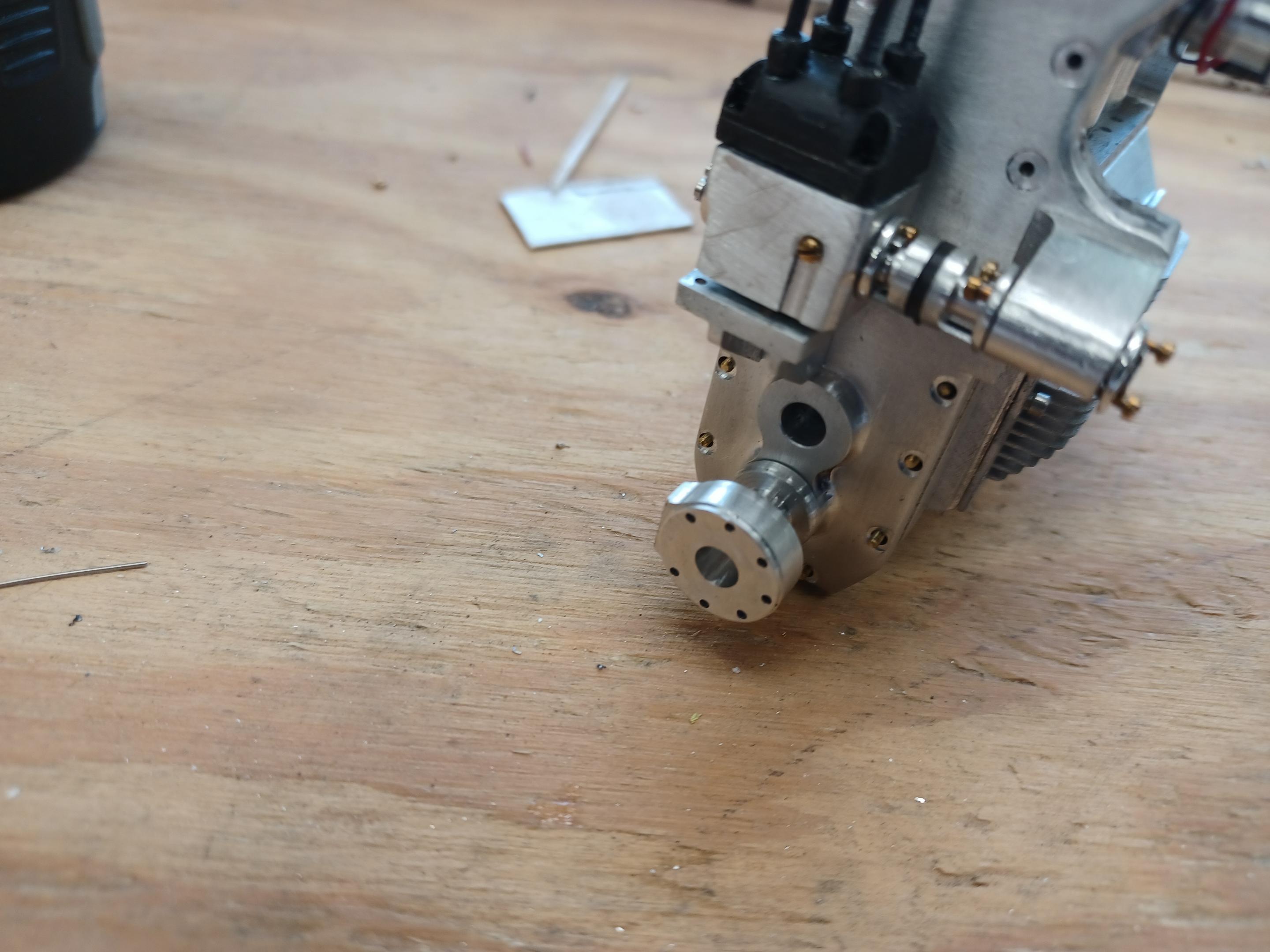

got the clutch finished and most of the bell housing .have to locate and machine for the starter and make the starter. transmission is coming along. had to ues brass for the back half so i could solder all the pieces. not quite done. maybe 2 more days. when the tans is done i will final finish all the parts and assemble it all to make sure it all fits together.

-

it lloks better everytime i seeit very intersting project to watch.keep up the great work.

-

PACERS, Fuel Altered, 1:16 brass, 1965

charlie libby replied to Mike Williams's topic in WIP: Drag Racing Models

wow its looks better everytime i go thru your pictures. its going to be a stunning model for sure . you should be very proud of your. ill keep coming back. -

hi tim, glad your surgery went well,anytime they operate on your eyes can be a very scary thing. now i think your parts will be even better and thats scary for all of us. glad your ok,charlie

-

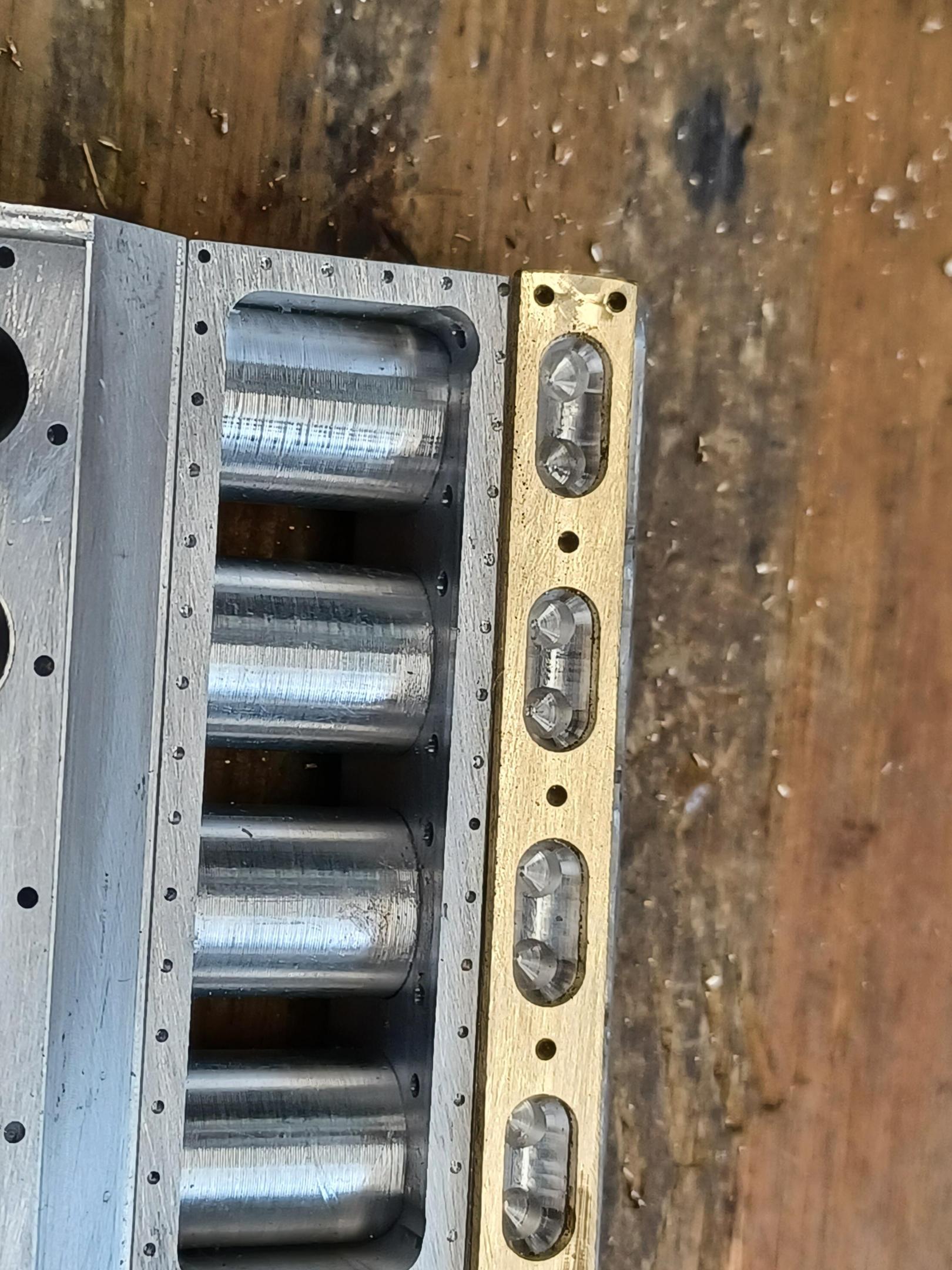

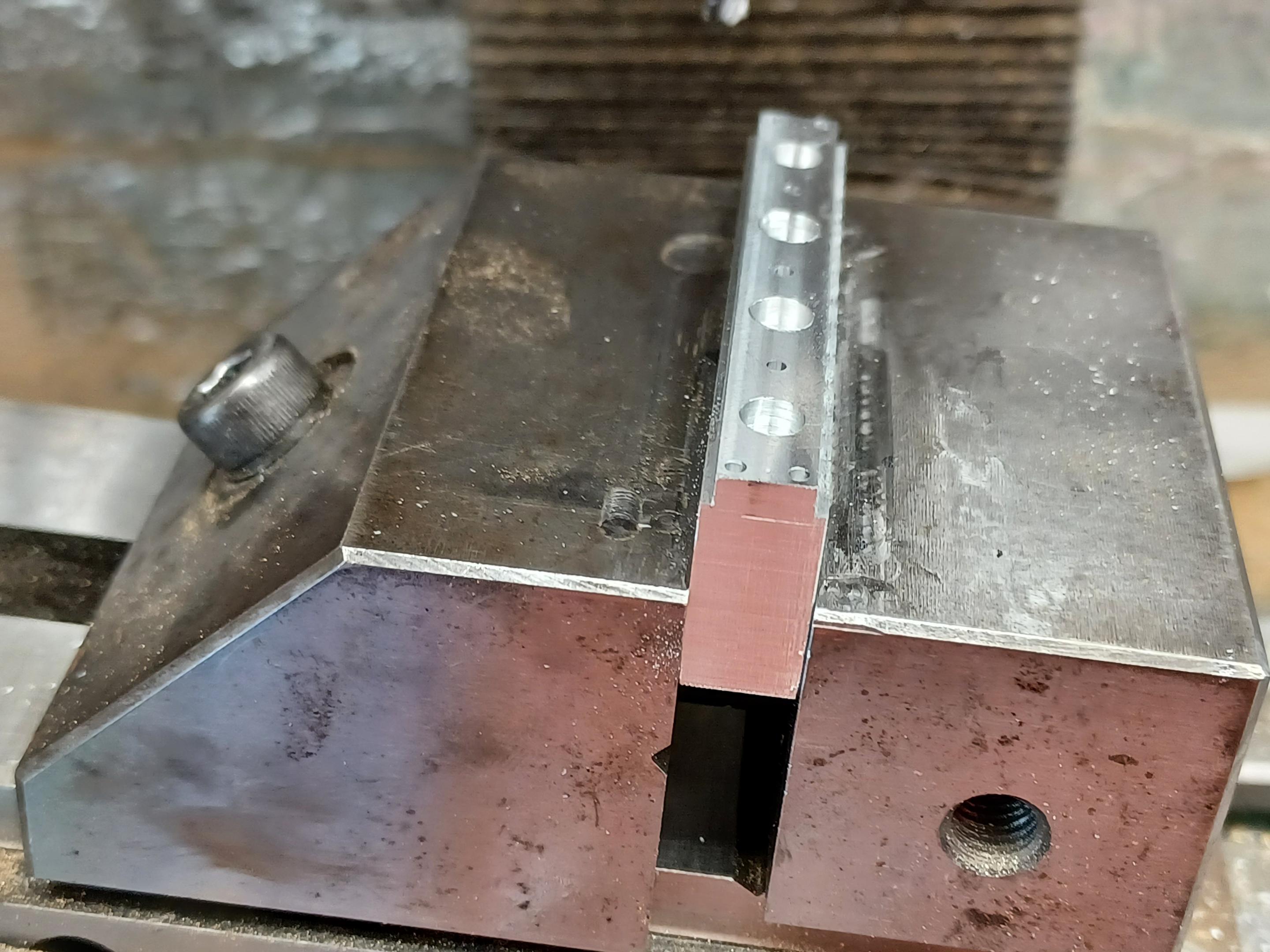

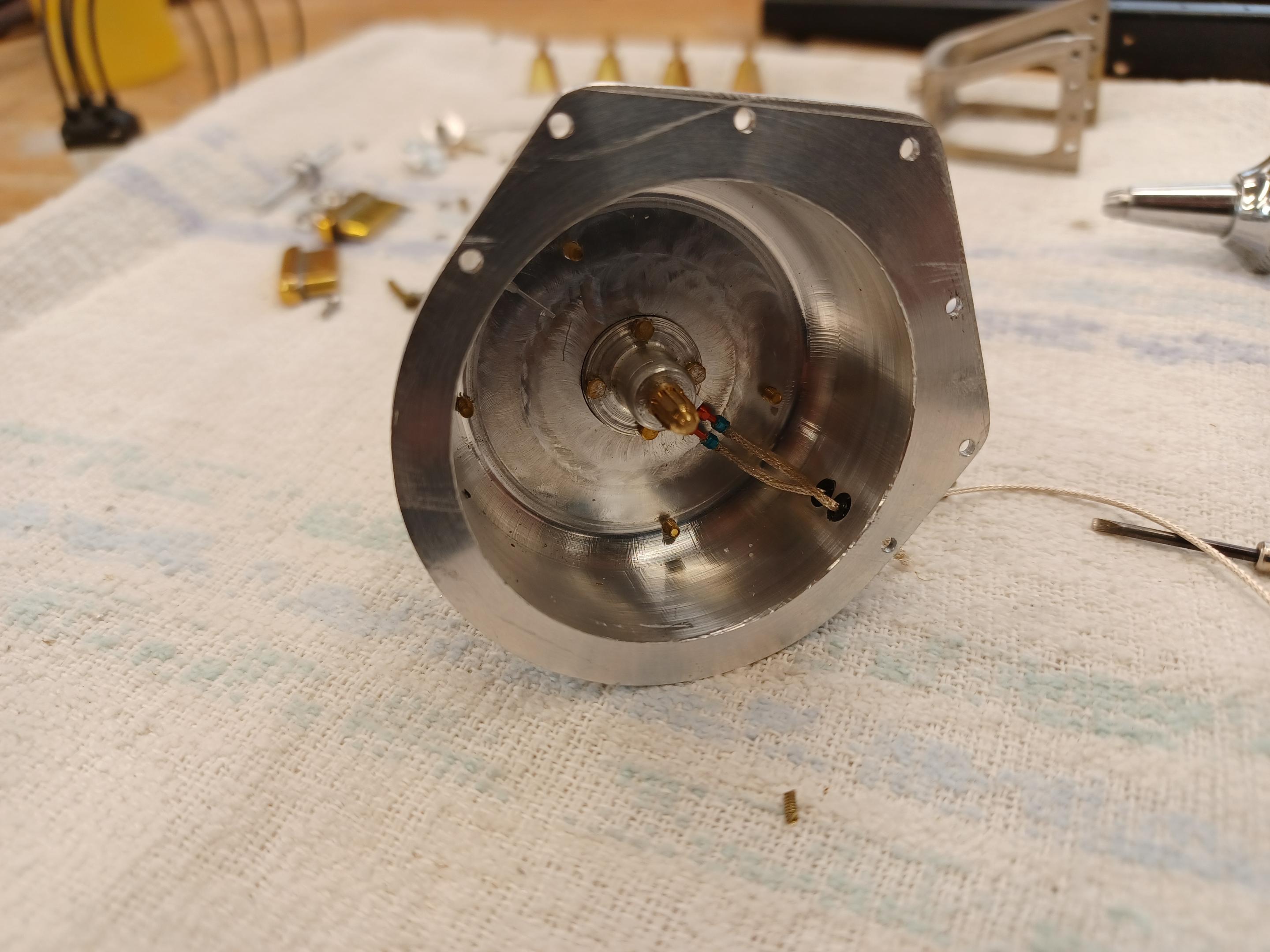

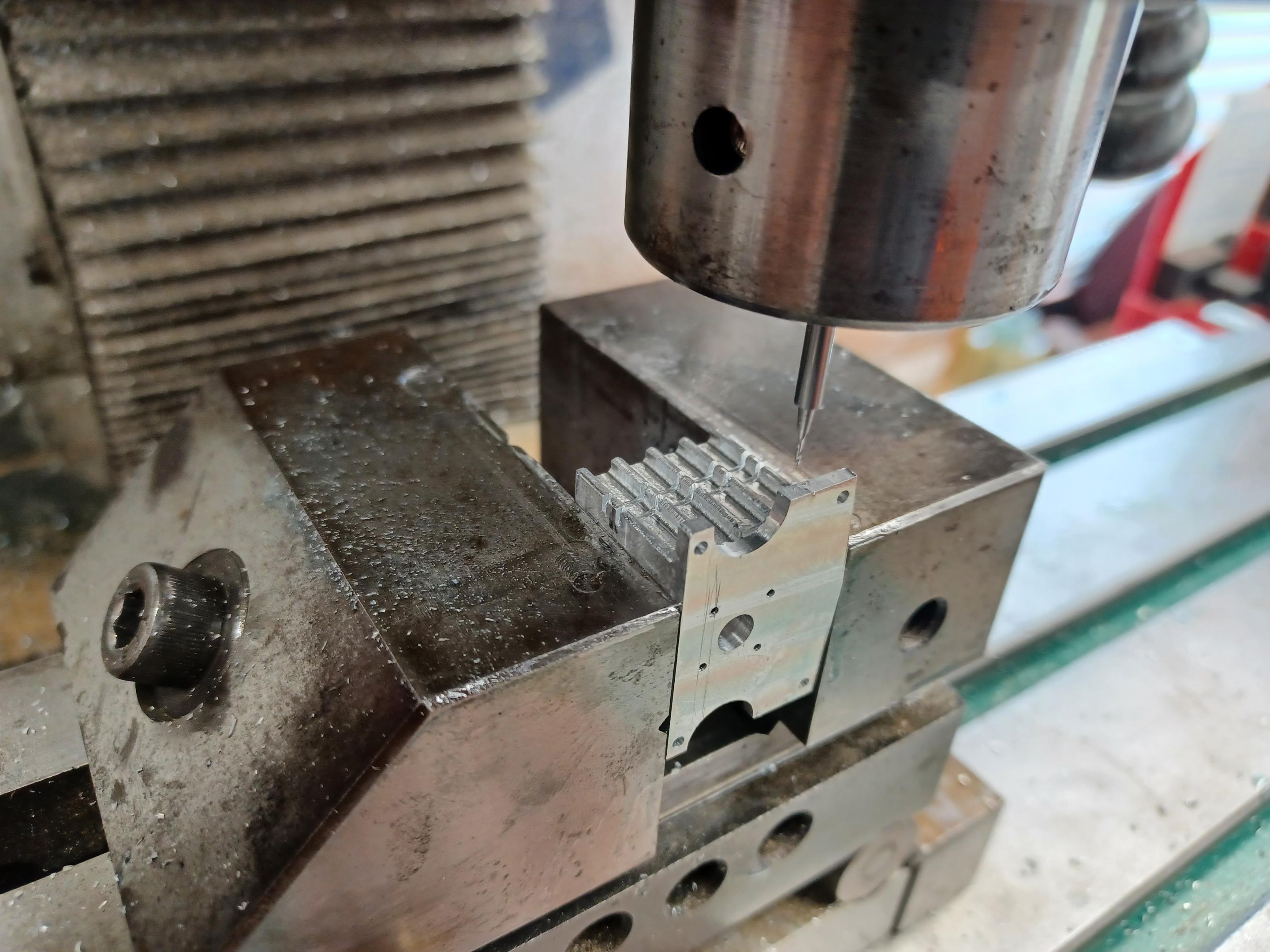

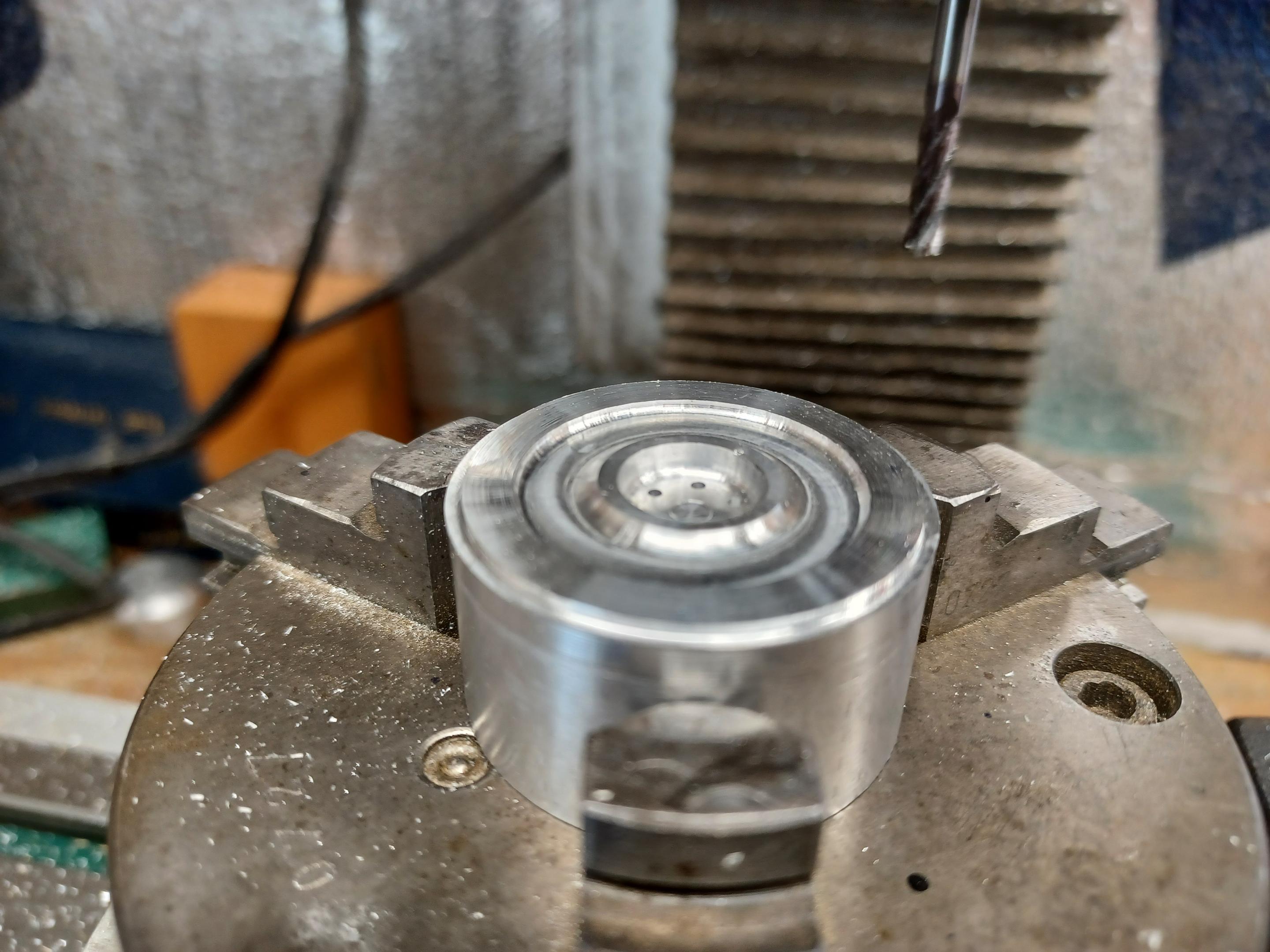

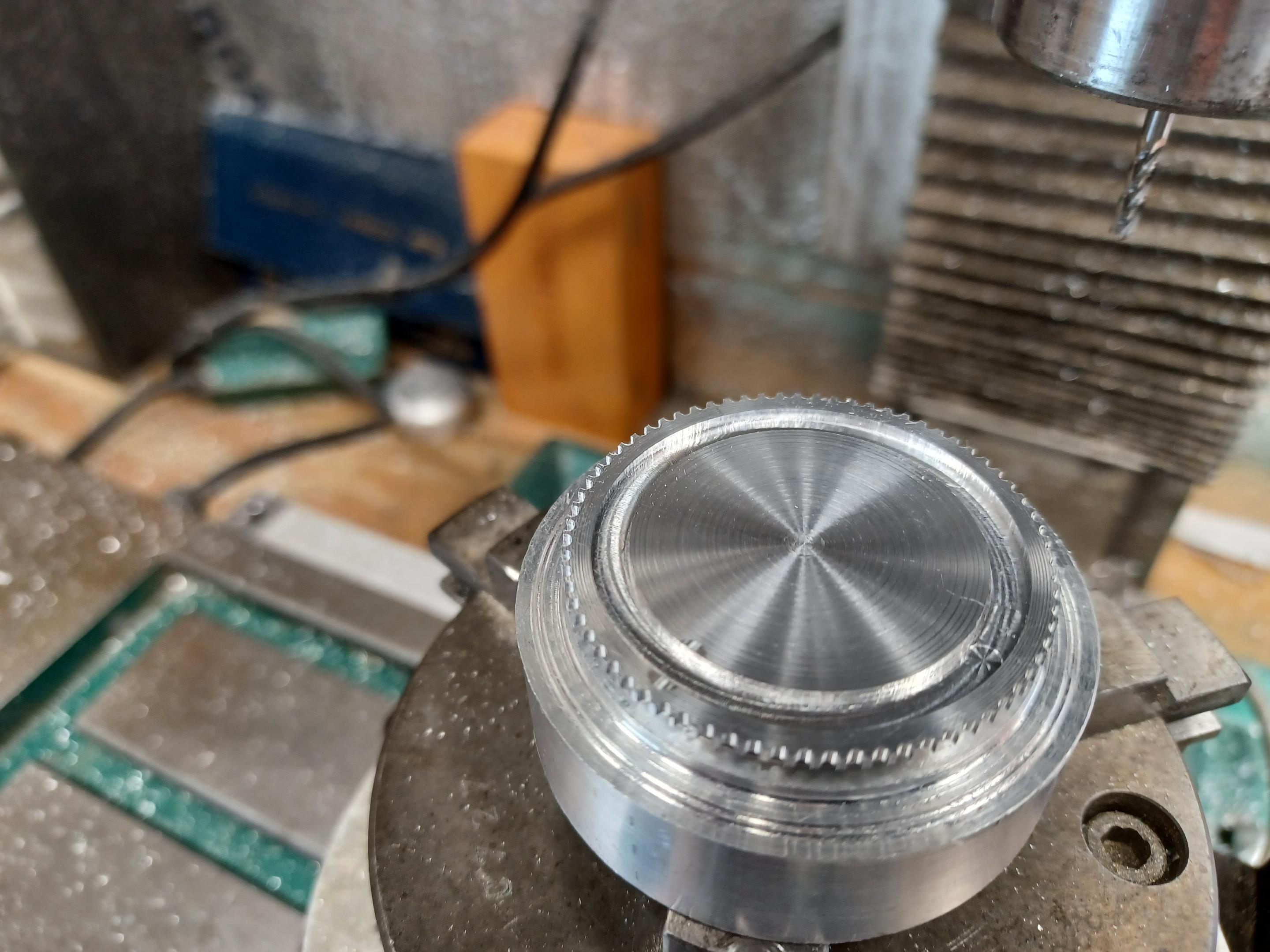

got a good start on the clutch hope to finish it tomorrow. ordered all the stuff to attempt anodizing. should be an interesting science experiment. here is also a picture of the bending fixture for the front motor mount to get the width correct.. still have the actual plate and the attachment arms left for the clutch. the fingers in the center will rivet on like a real one through the 9 holes on top.

-

thank you all for your comments and for taking time to look.i am glad you all liked it.on to new projects

-

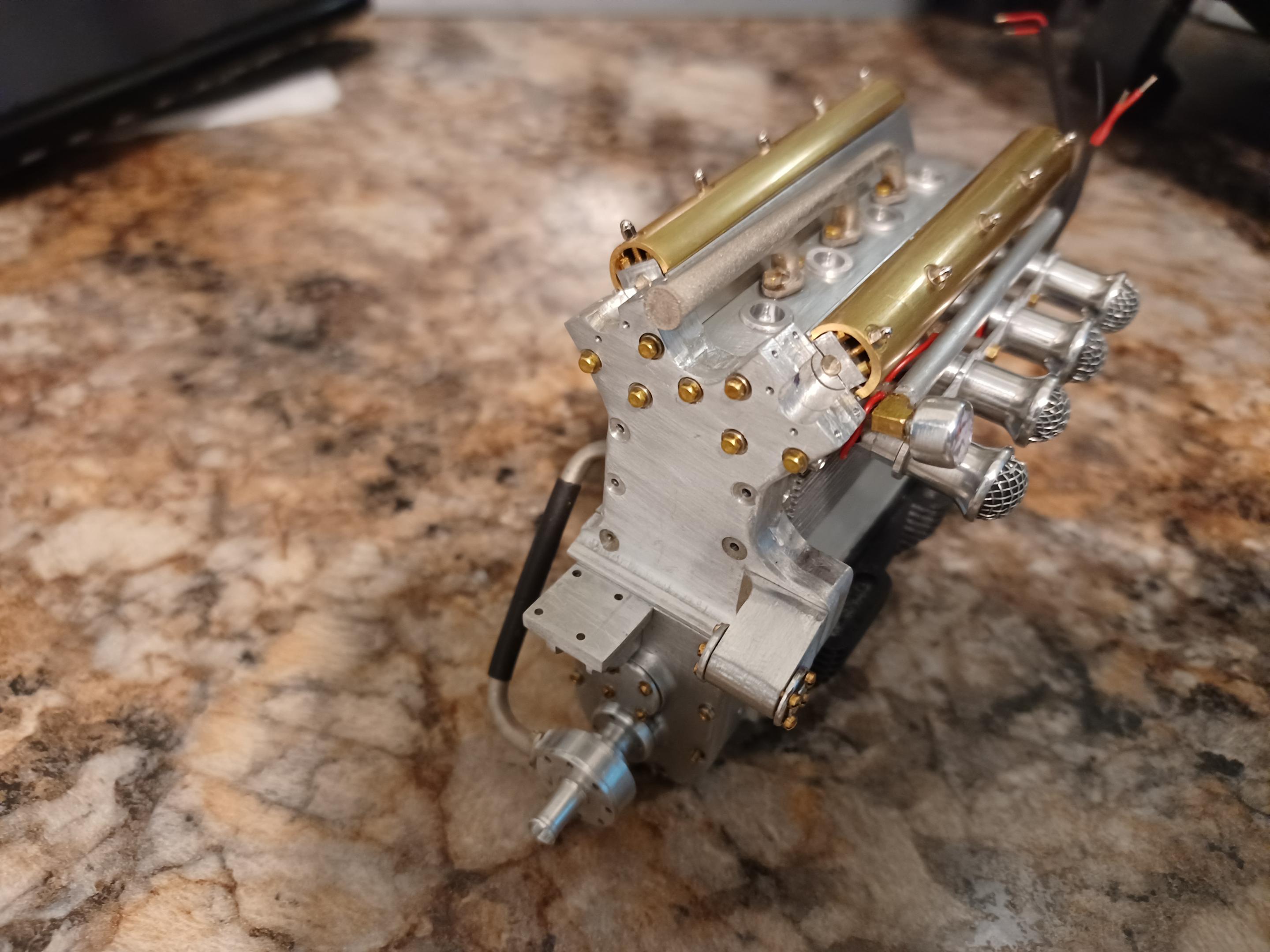

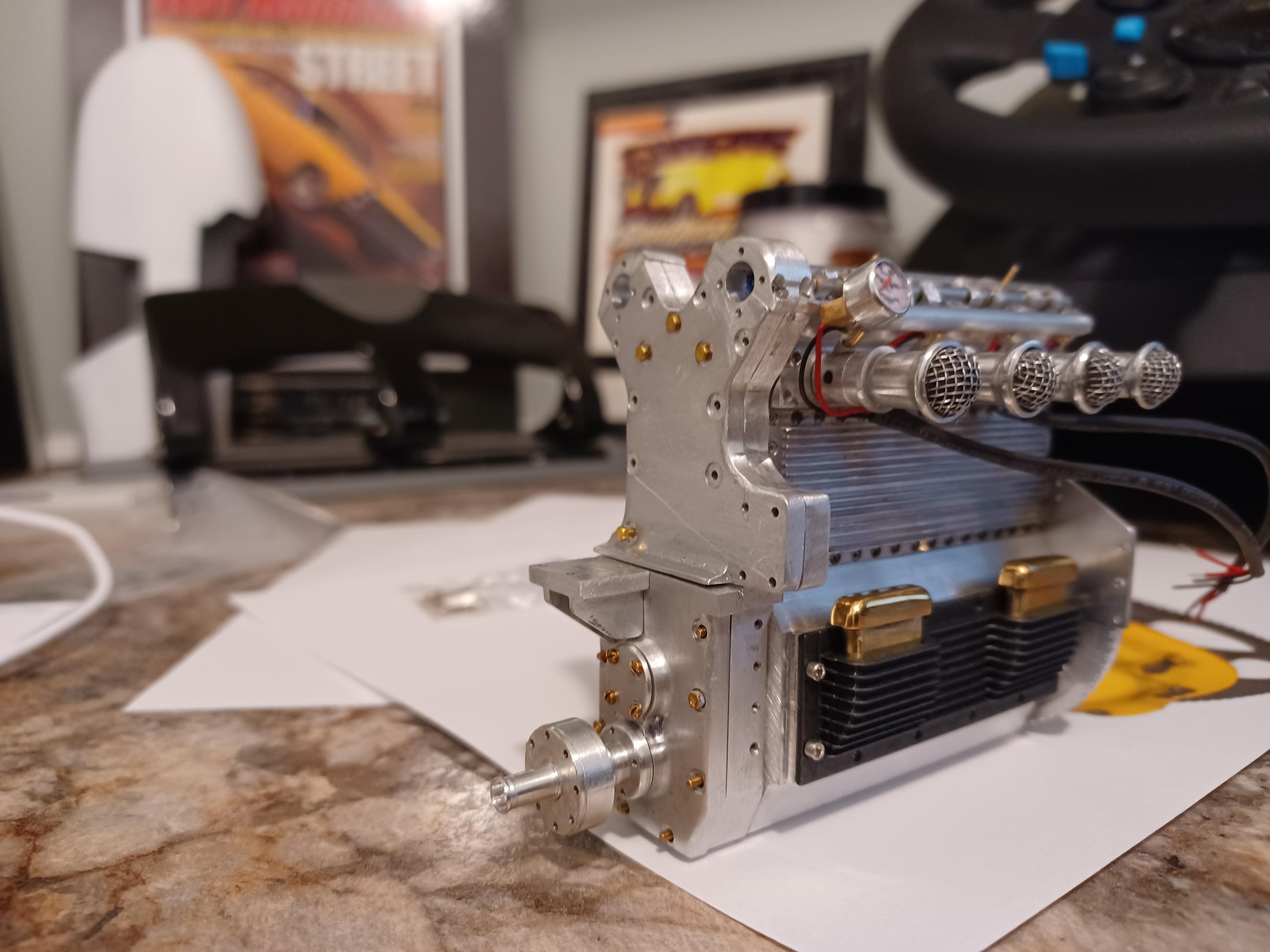

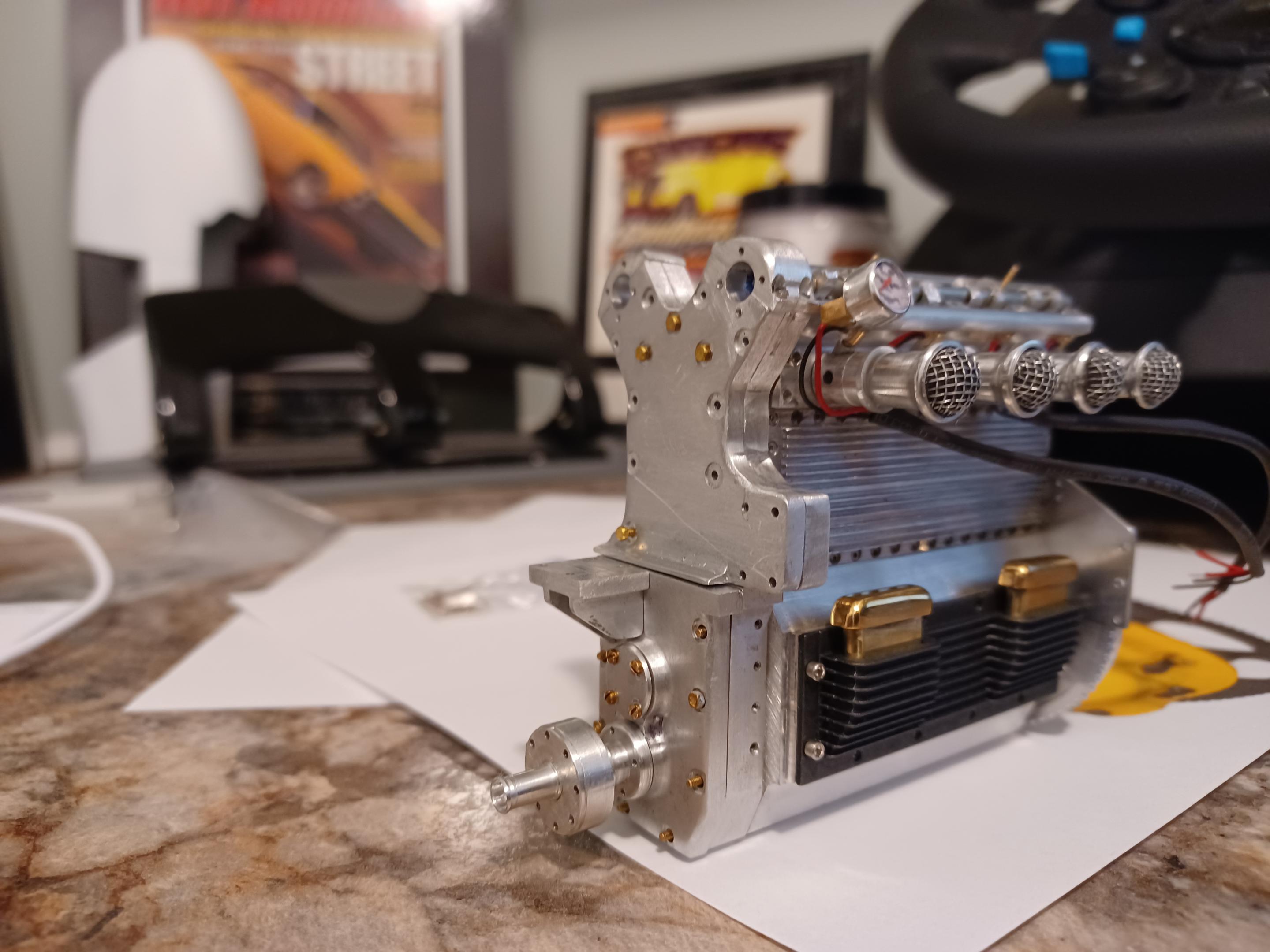

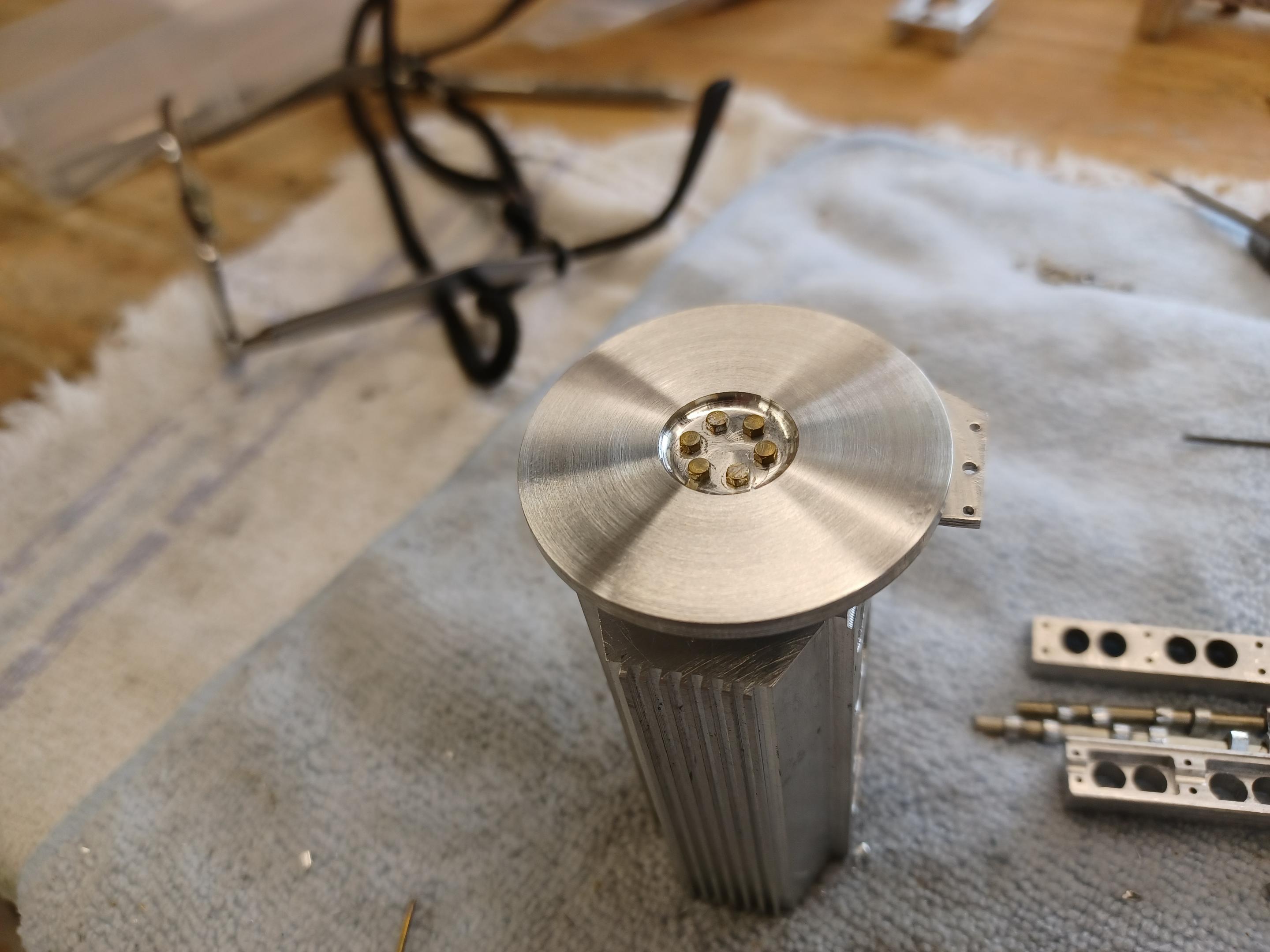

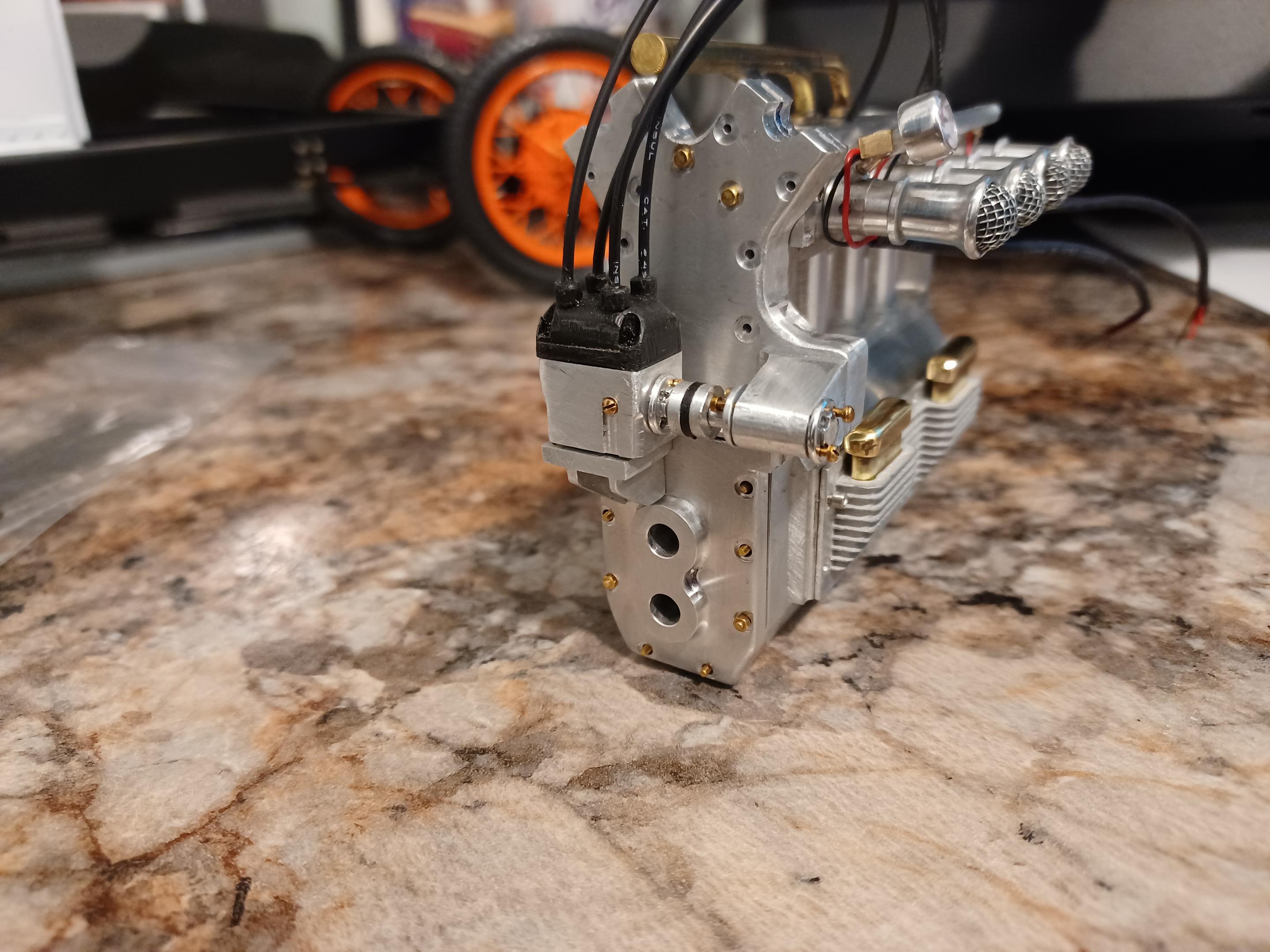

hi andrew, using plating solution that i made with vinegar and salt. . i learned on you tube , it seems to work great. yeah i anealed at the bend points and made a bending fixture for the final shape. daniel ,thanks for looking and your kind comments. francis,i made the plating solution as per 2 or 3 you tube videos that were very informative. it works great. it only took about 5 minutes at 15 volts and 1.5 amps to cover it. you have to move it around in the solution to aim it at the anode to cover all sides evenly. am purchasing the dyes and acid this week for anodizing. hope it comes out as nice as yours. the flywheel and ring gear came out really well. the clutch is next. i got a little carried away and did cams and lifters, but i have the time. hope you all enjoy. i painted the lower crancase covers to see if i liked them in black before i anodize them . i like them in black so i will strip them and anodize them . do you think the upper finned panels in black would be to much?

-

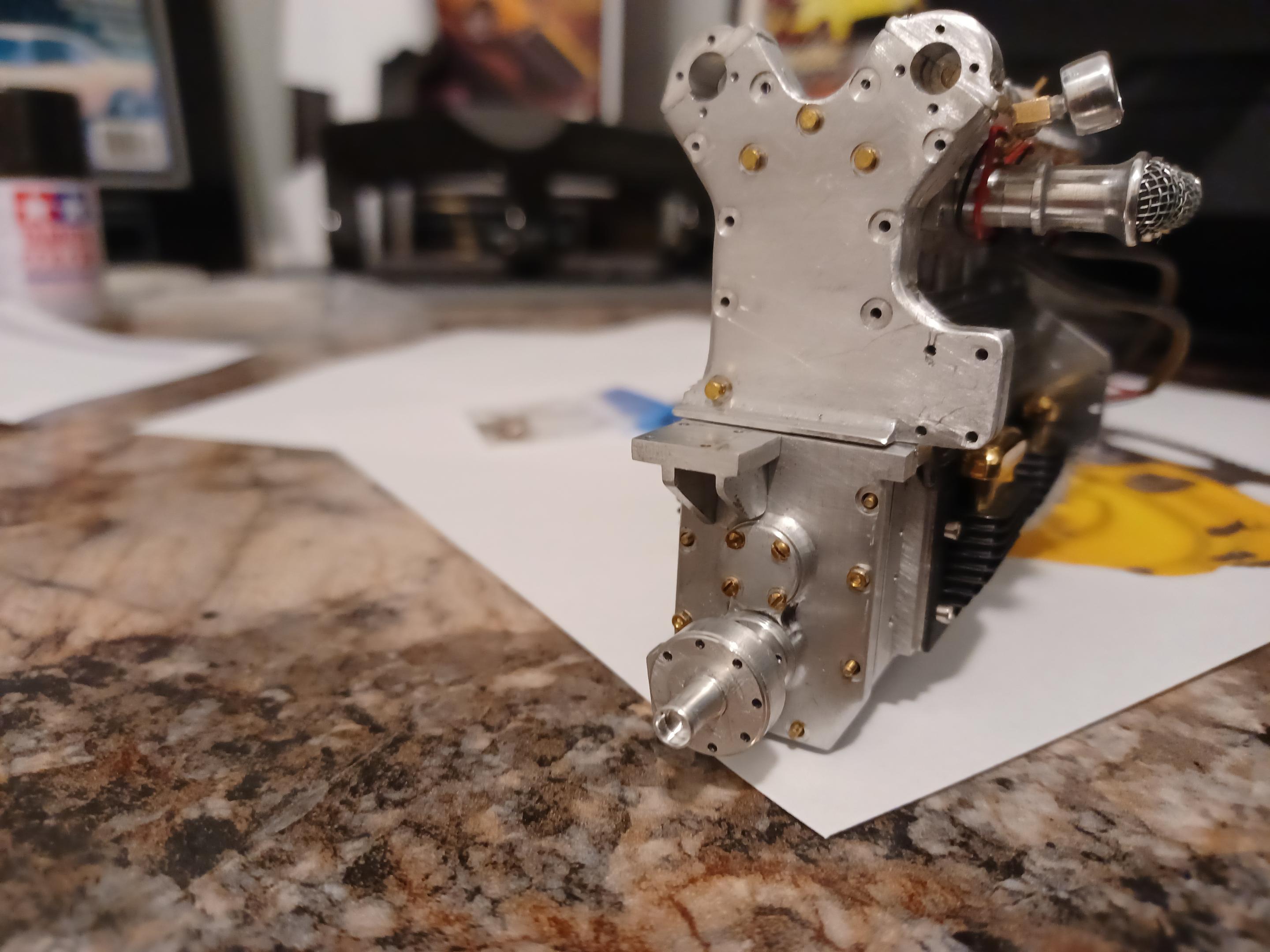

hi you guys, thanks to all of you. i have just made my nickel plating solution and plated a piece of brass tubing as a test. it took about 3 minutes to plate this small piece. tomorrow i am going to plate the motor mount that i just finished that is bolted on the front of the offy. thats the water pump on the bottom of the front cover under the mount. i got to get a small window air conditioner francis , i have got to purchase a few more things to try anodizing. got to wait for clearance from my wife. i didnt like my first magneto so i made a new one, in case you noticed its not brass anymore.

-

PACERS, Fuel Altered, 1:16 brass, 1965

charlie libby replied to Mike Williams's topic in WIP: Drag Racing Models

just found this thread from francis ,american muscle fan. your project looks great. you have done some awesome work. very time consuming.i will be keeping an eye on your progress.charlie -

hi tim wheels and tires look perfect. i have not been on looking at much but i love to check on your progress whenever i can

-

sorry guys its 1/8 scale . but thank you all for your nice comments and thank you for looking.

-

it was 87 here and i wish i had a garage. i work in a 12 by 12 shed atached to my house with no air conditioner. i dont have a thermometer in my shed ,it would make it feel even hotter to know.by 2 or 3 in the afternoon thats about it for the day its pretty hot by then. i really don't mind the heat but cant survive without fans. got the upper water line done toay.it bolts on to the top of the head. nice to hear from you andrew if you are up this way please contact me and stop by to visit. i am thinking about a wall mount ac unit. as you can see the shop is well insulated.thank you for looking

-

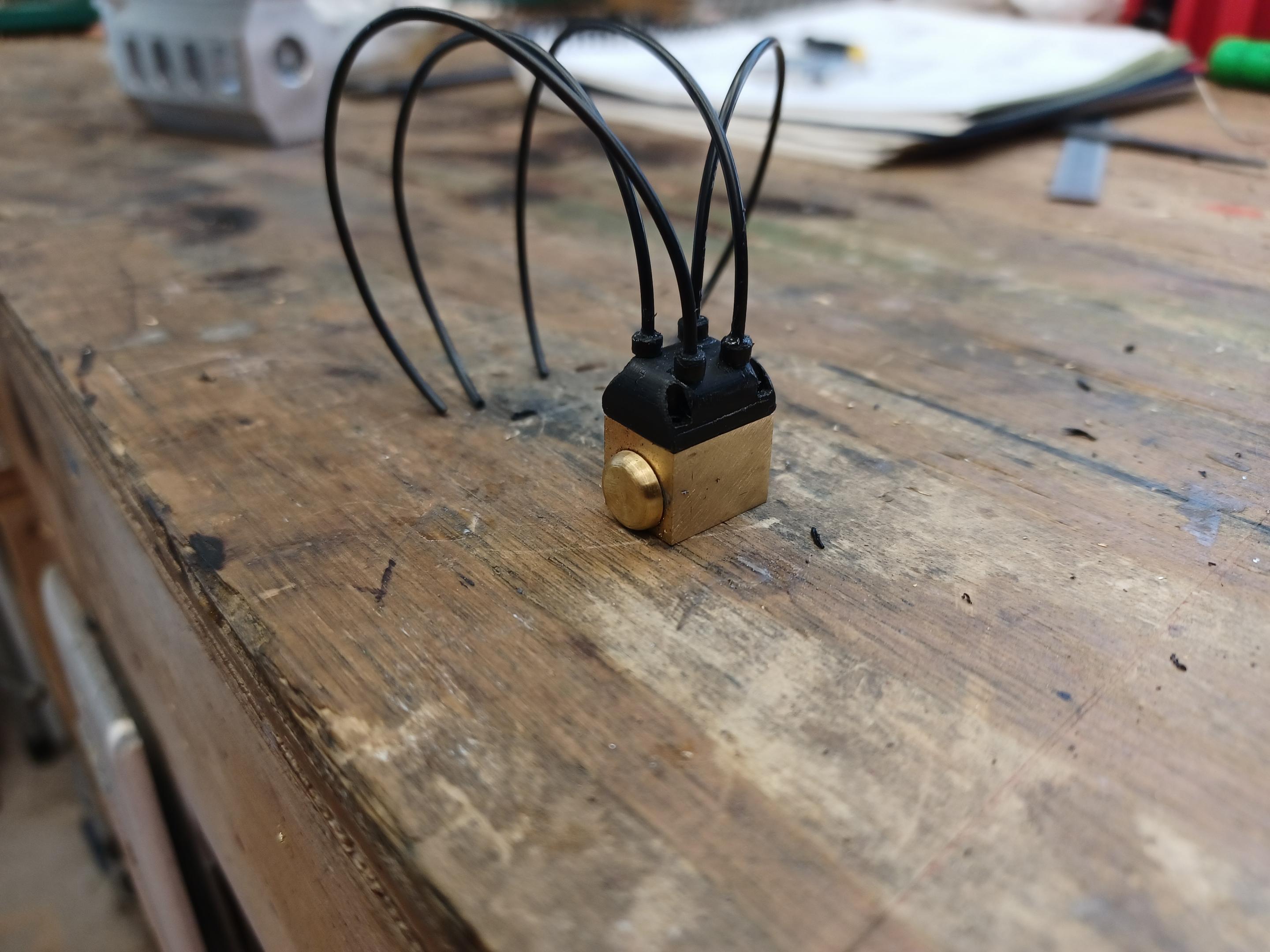

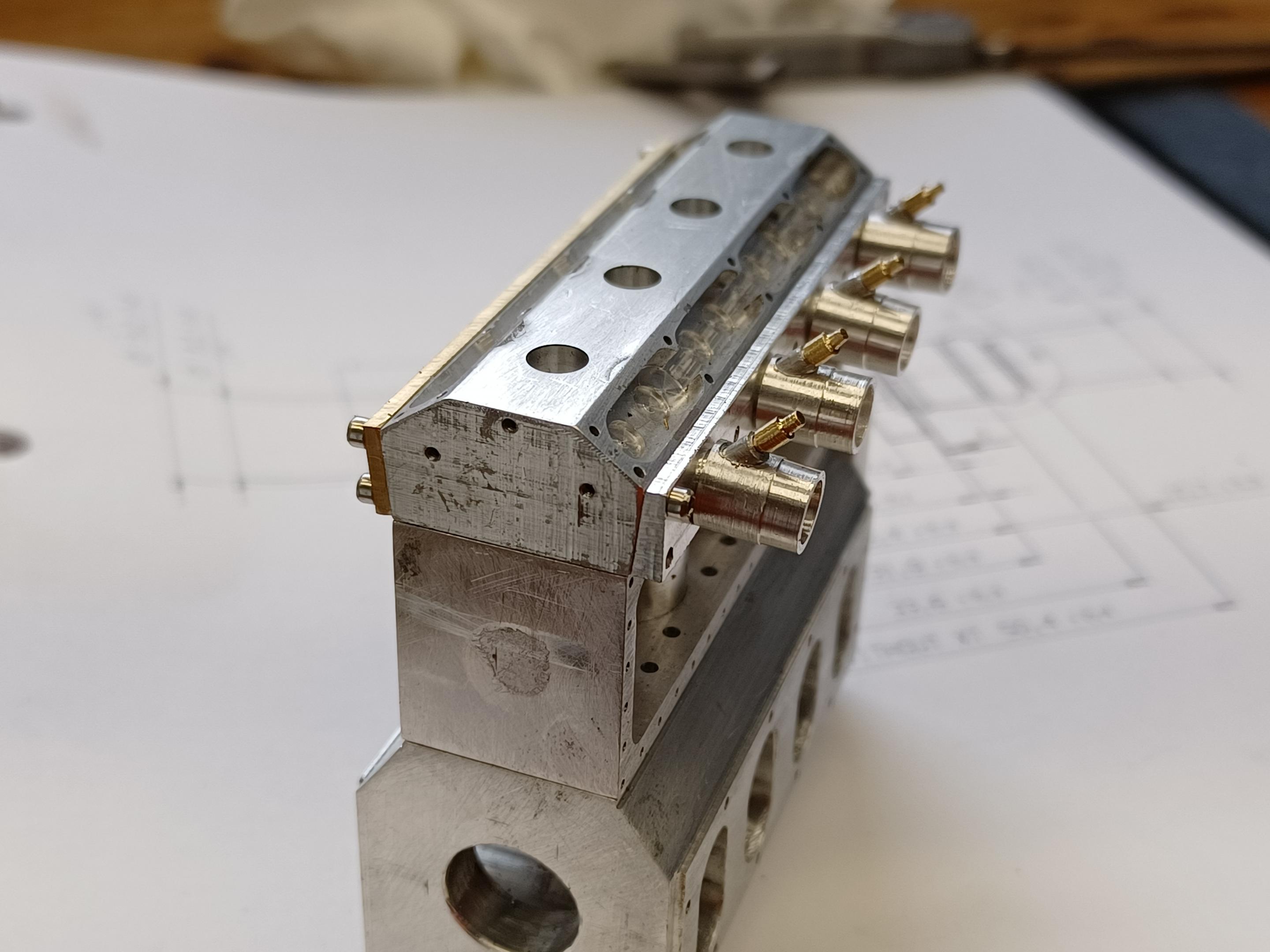

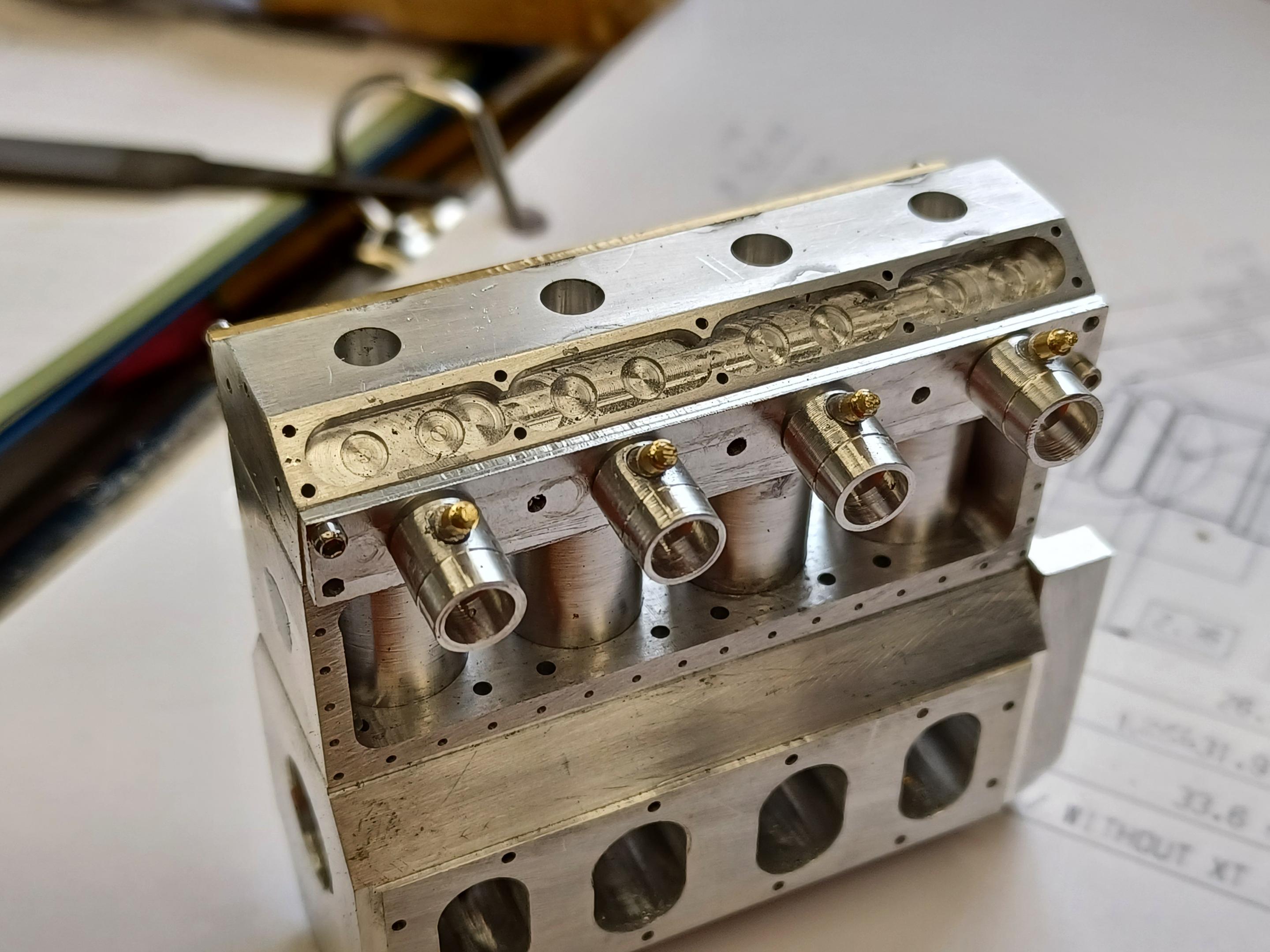

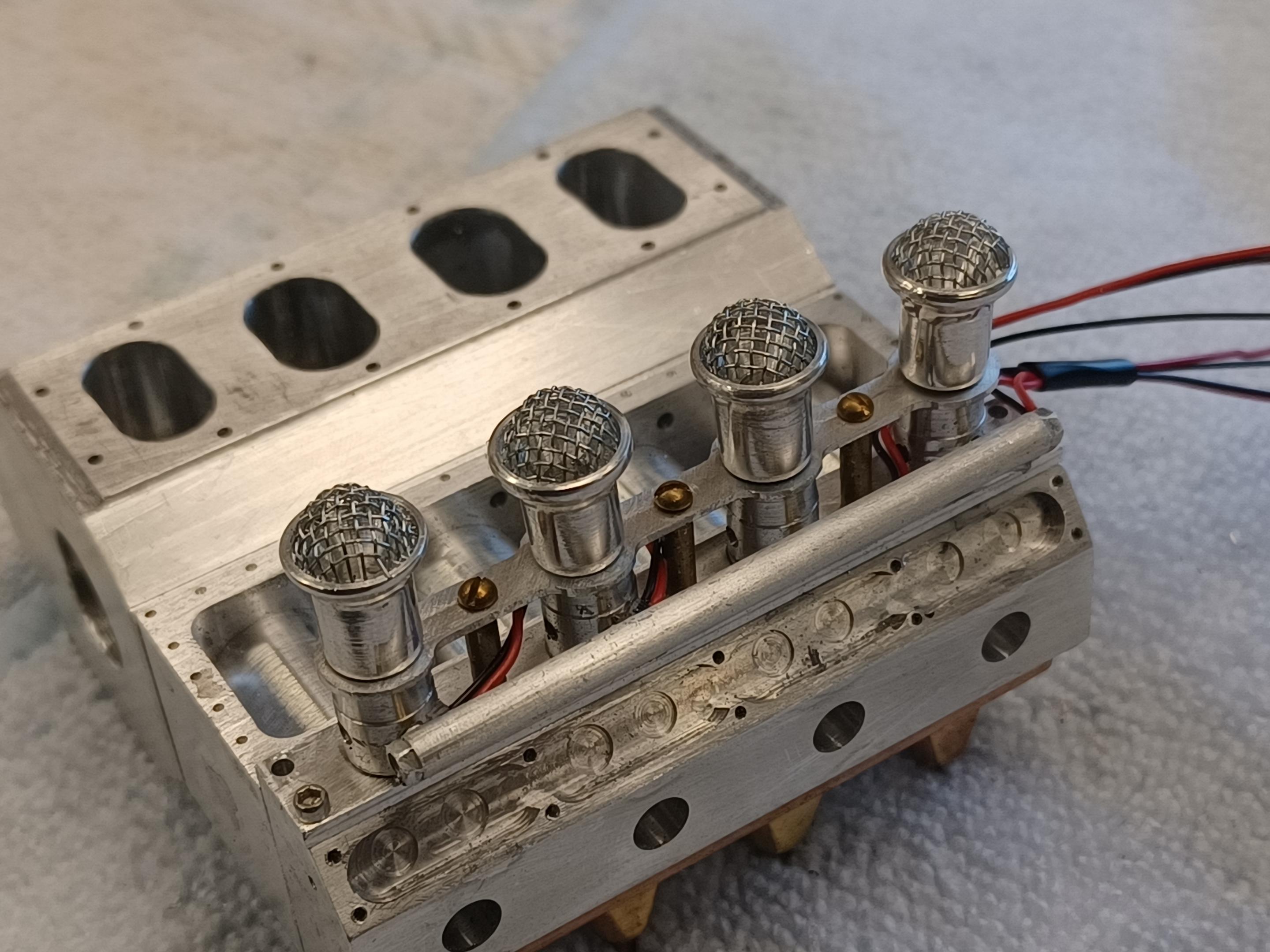

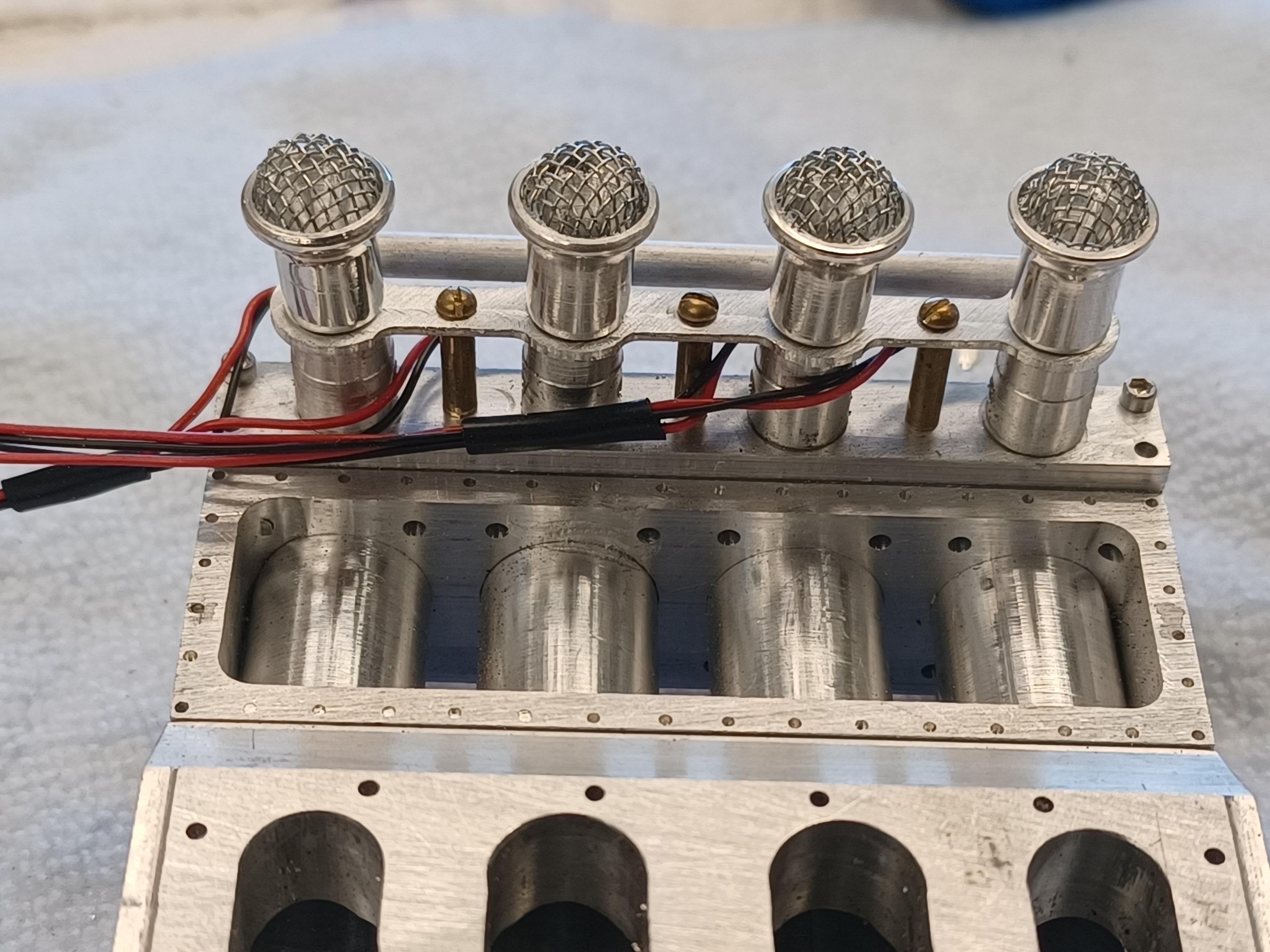

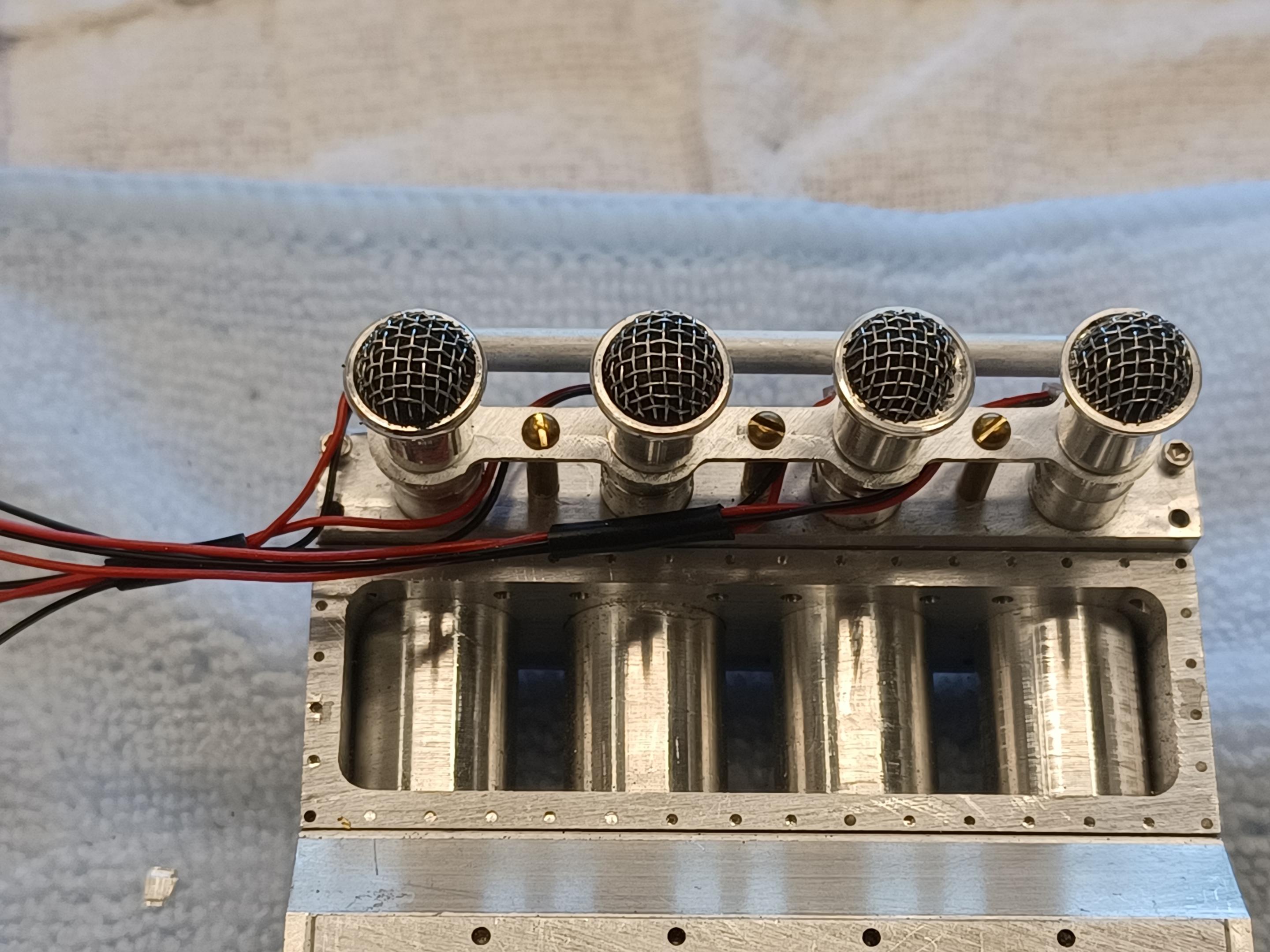

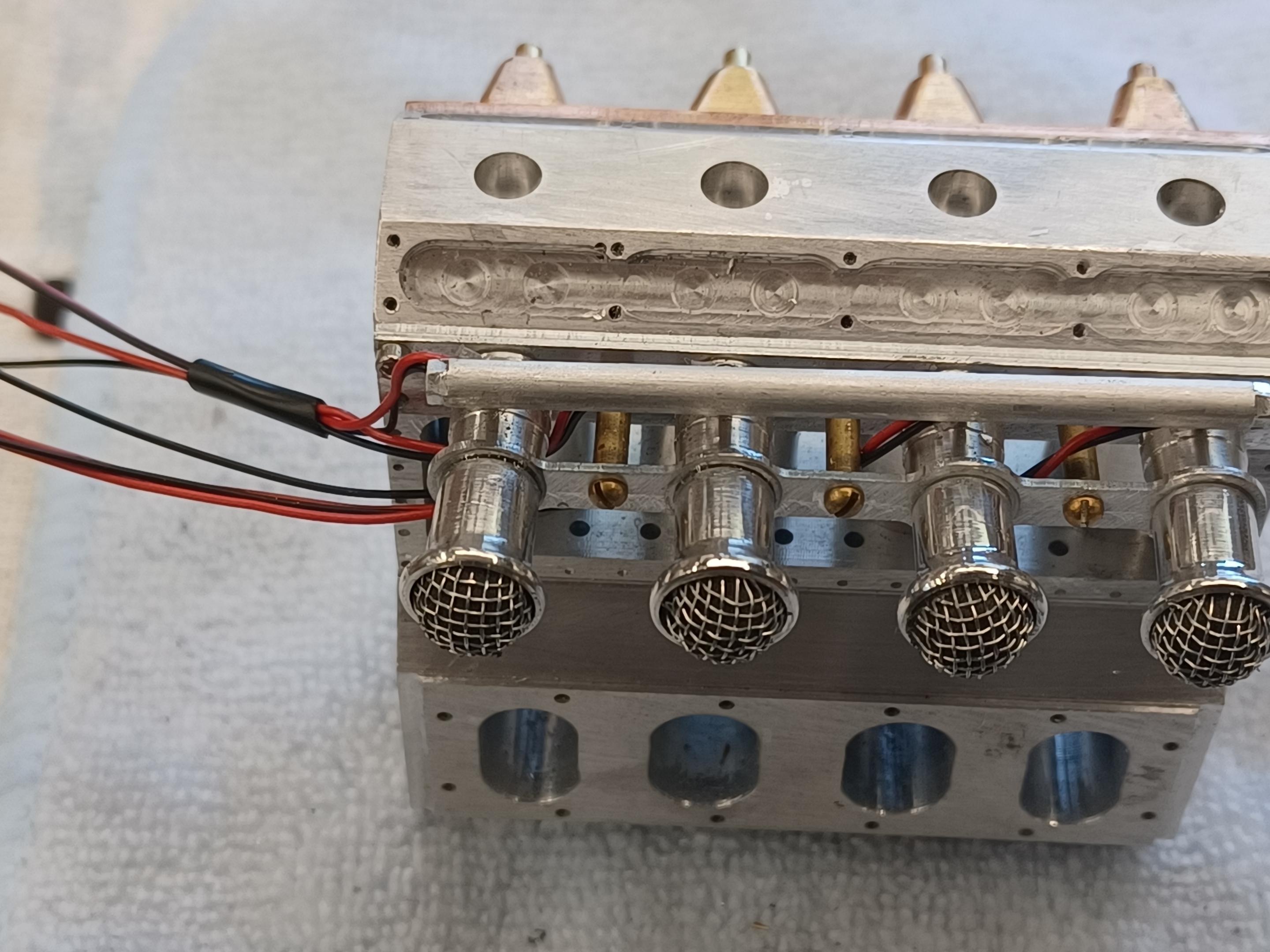

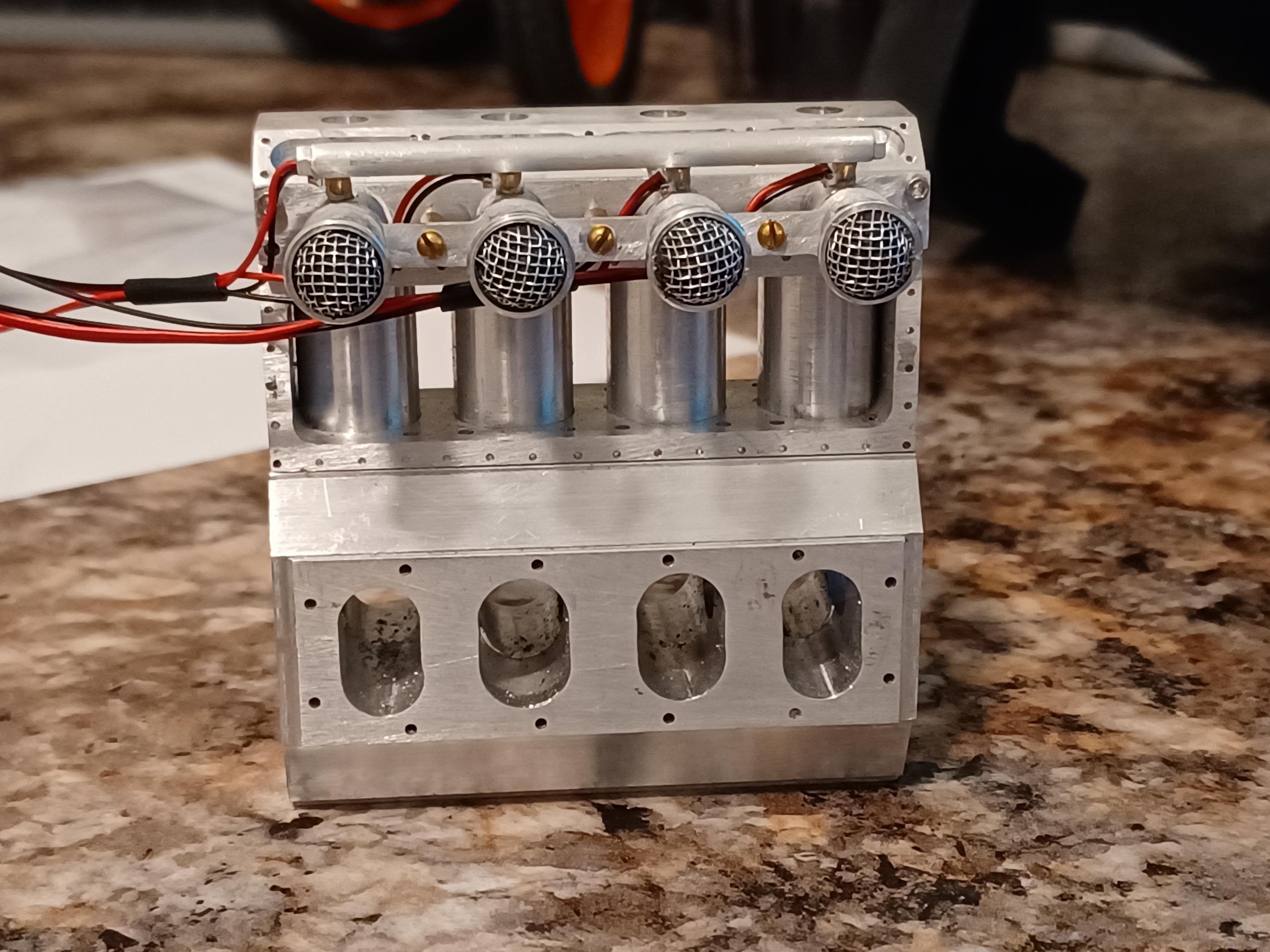

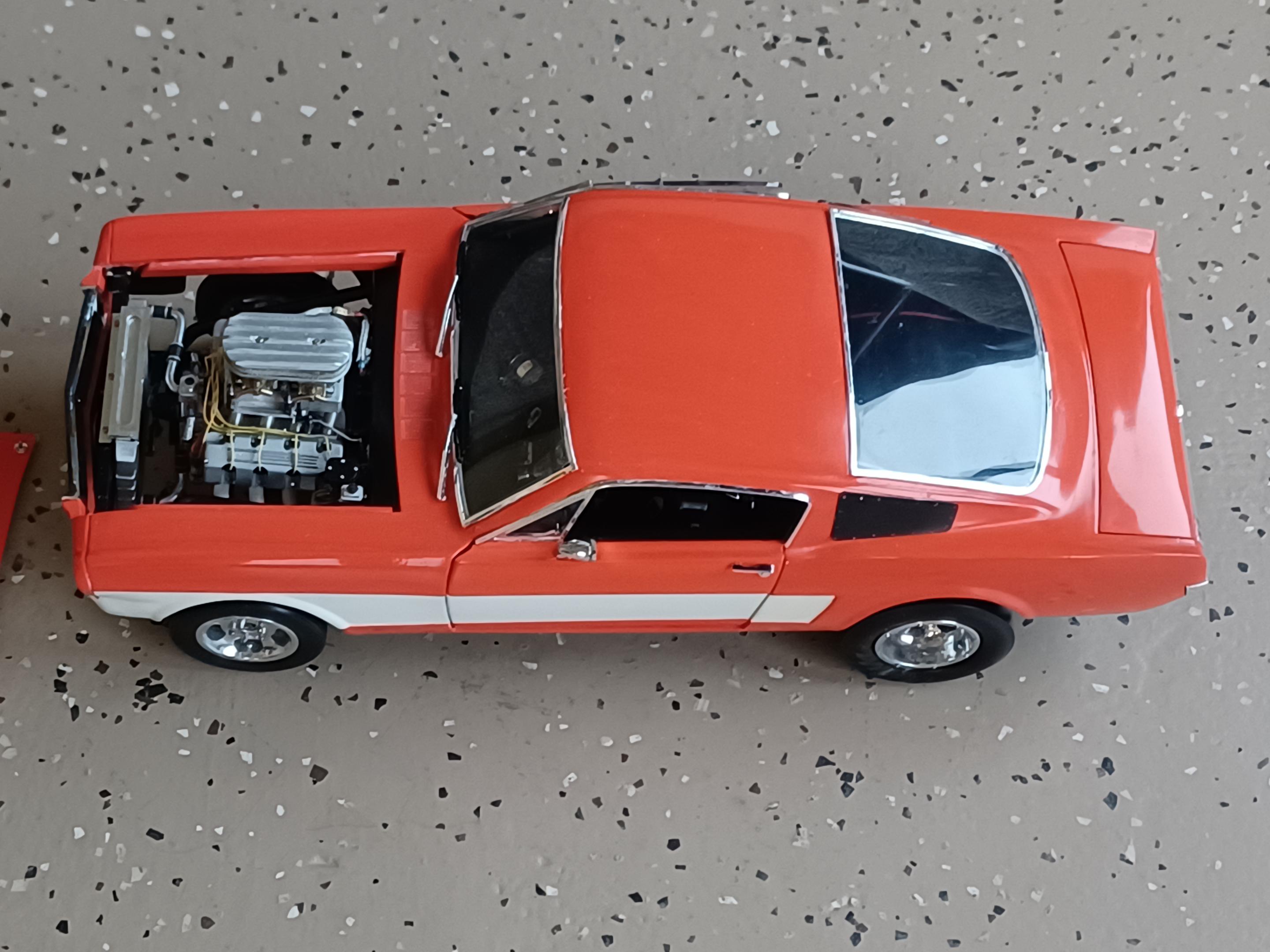

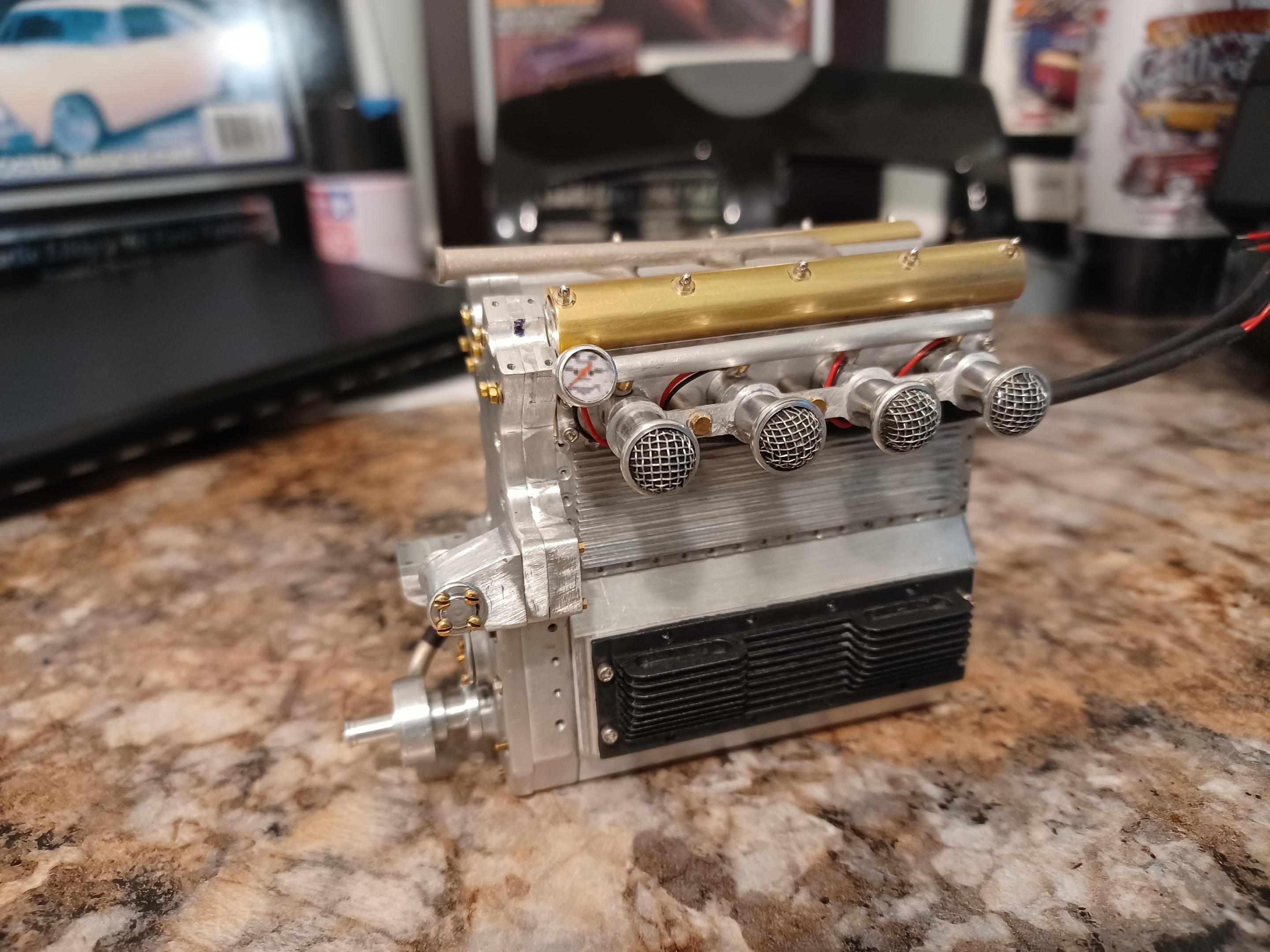

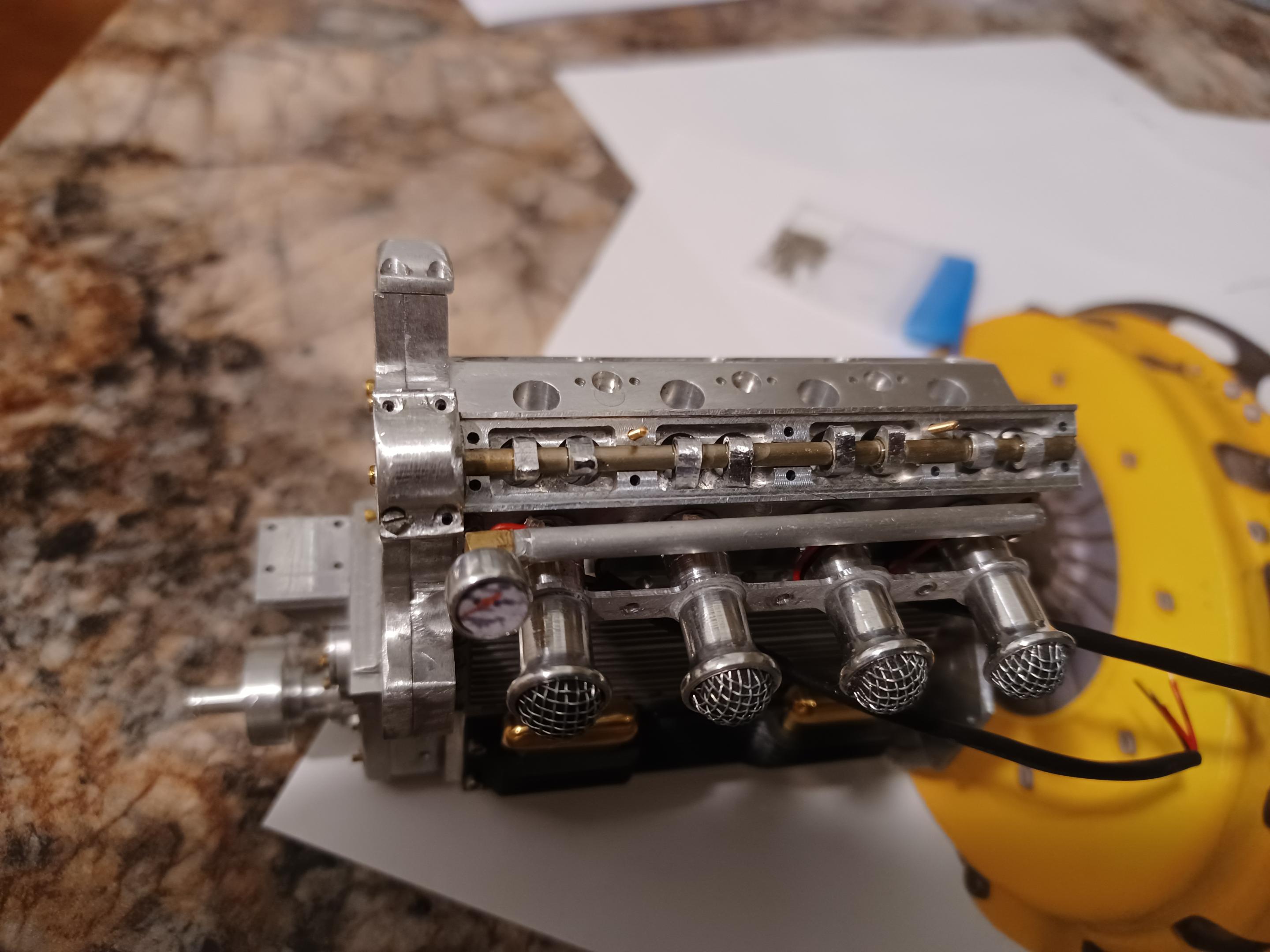

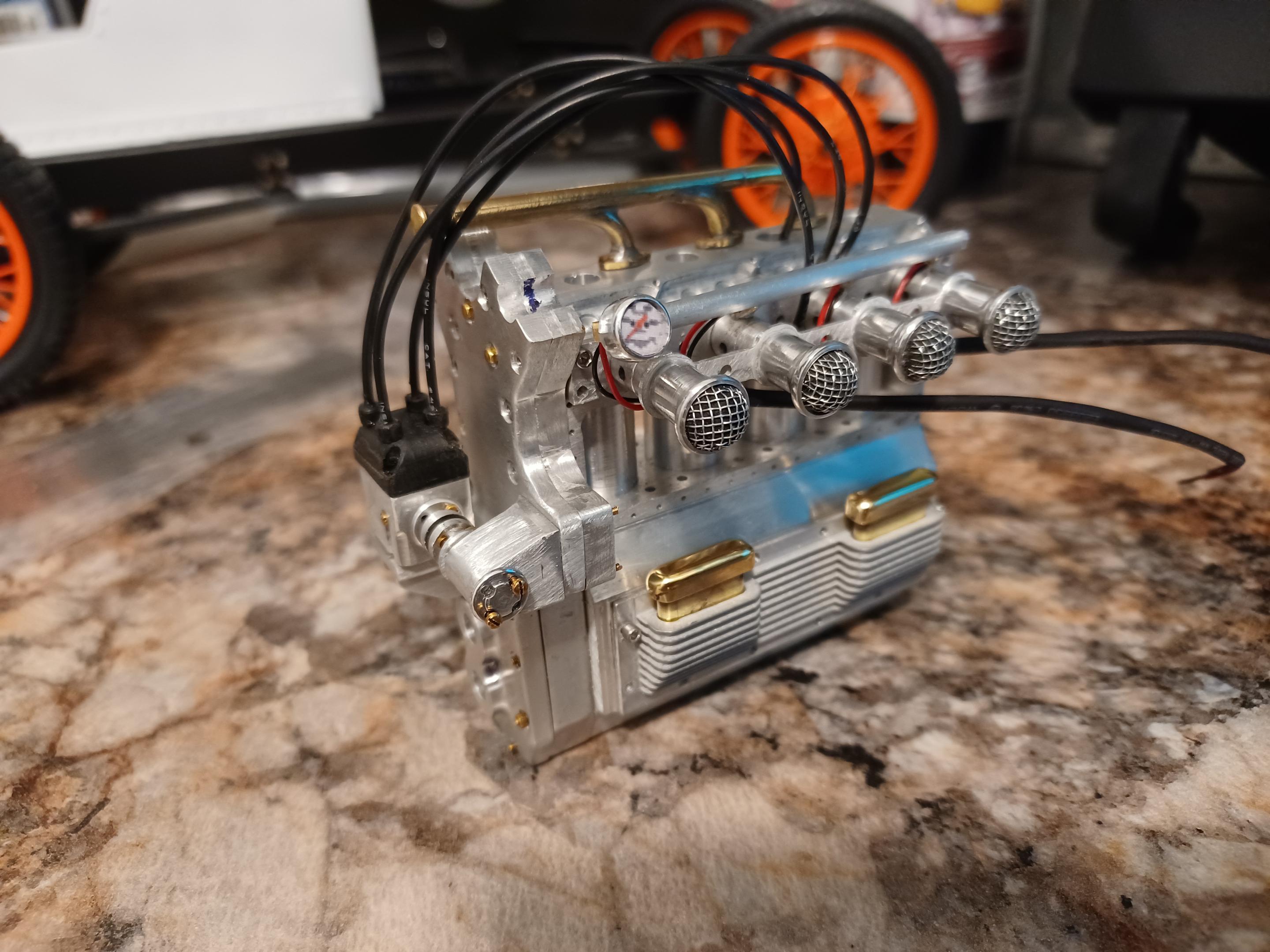

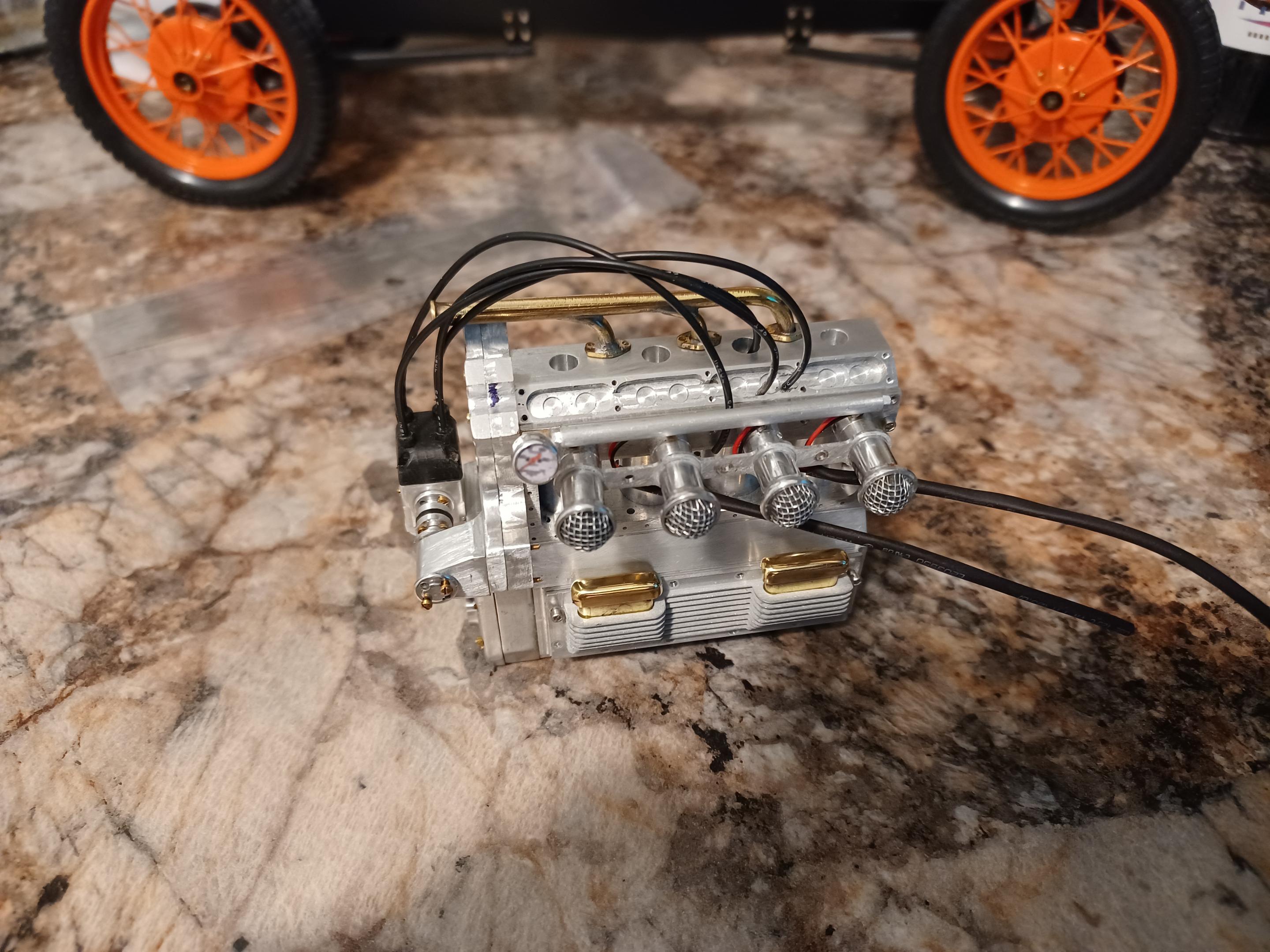

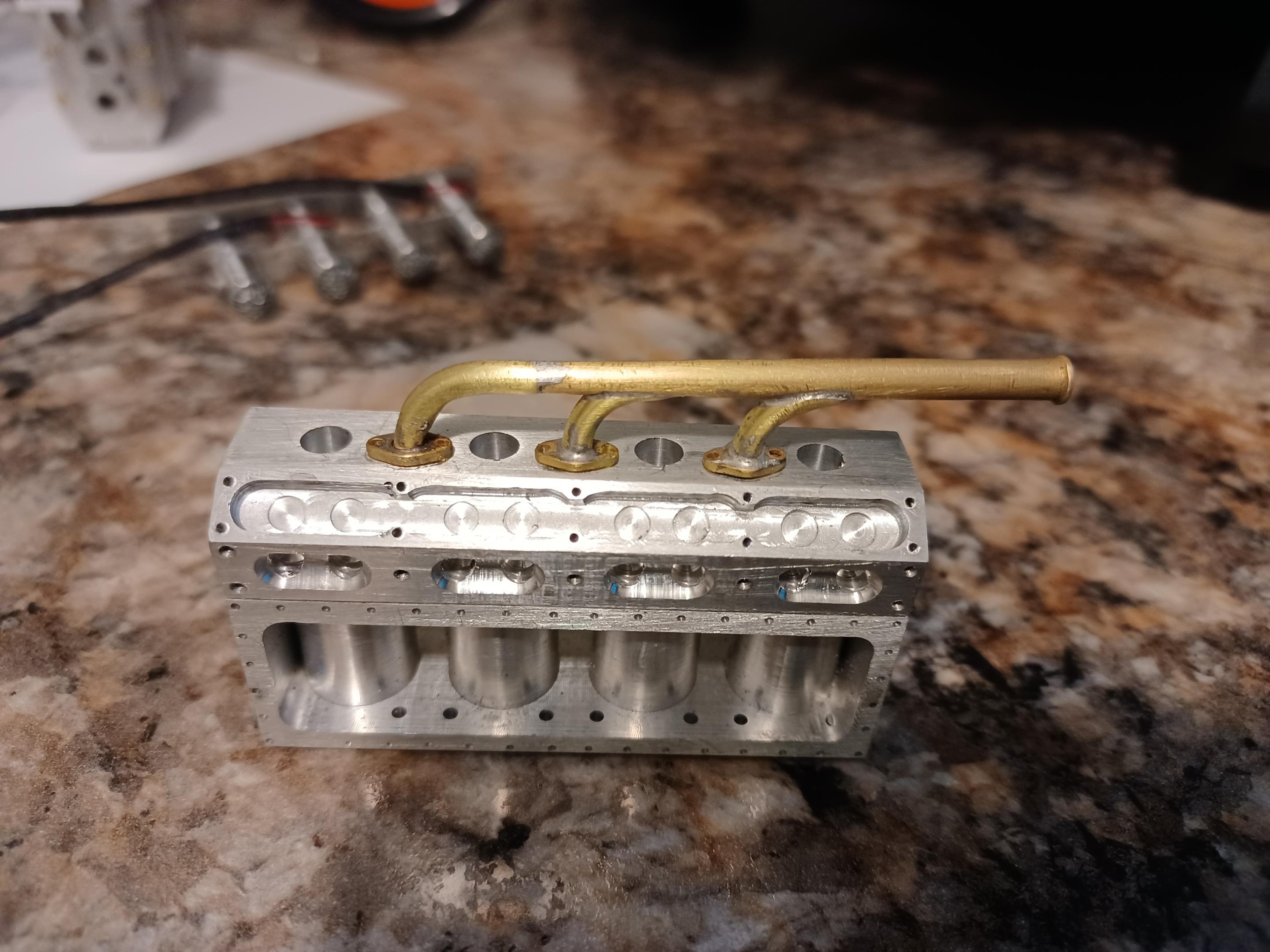

havent ben on much lately. i have done some work on my projects the mustang gasser is done and i am continuing on my offy project. it seems to be coming along fine. trying to do the front of the engine , the gear tower and mag drive and the exhaust and intake flanges. i have started on the magneto the cap is done but the mag is not . the fuel injection is electronic , the car will be more modern than the an original. the clear plastic parts are the connectors for the wiring on the injectors. they will be painted black with the injectors. the breather flanges and horns came out nice. the foam breathers under the screen were a little difficult to form,a few got lost because my fan blew them around.it is warm down here right now. all for now thank you for looking

-

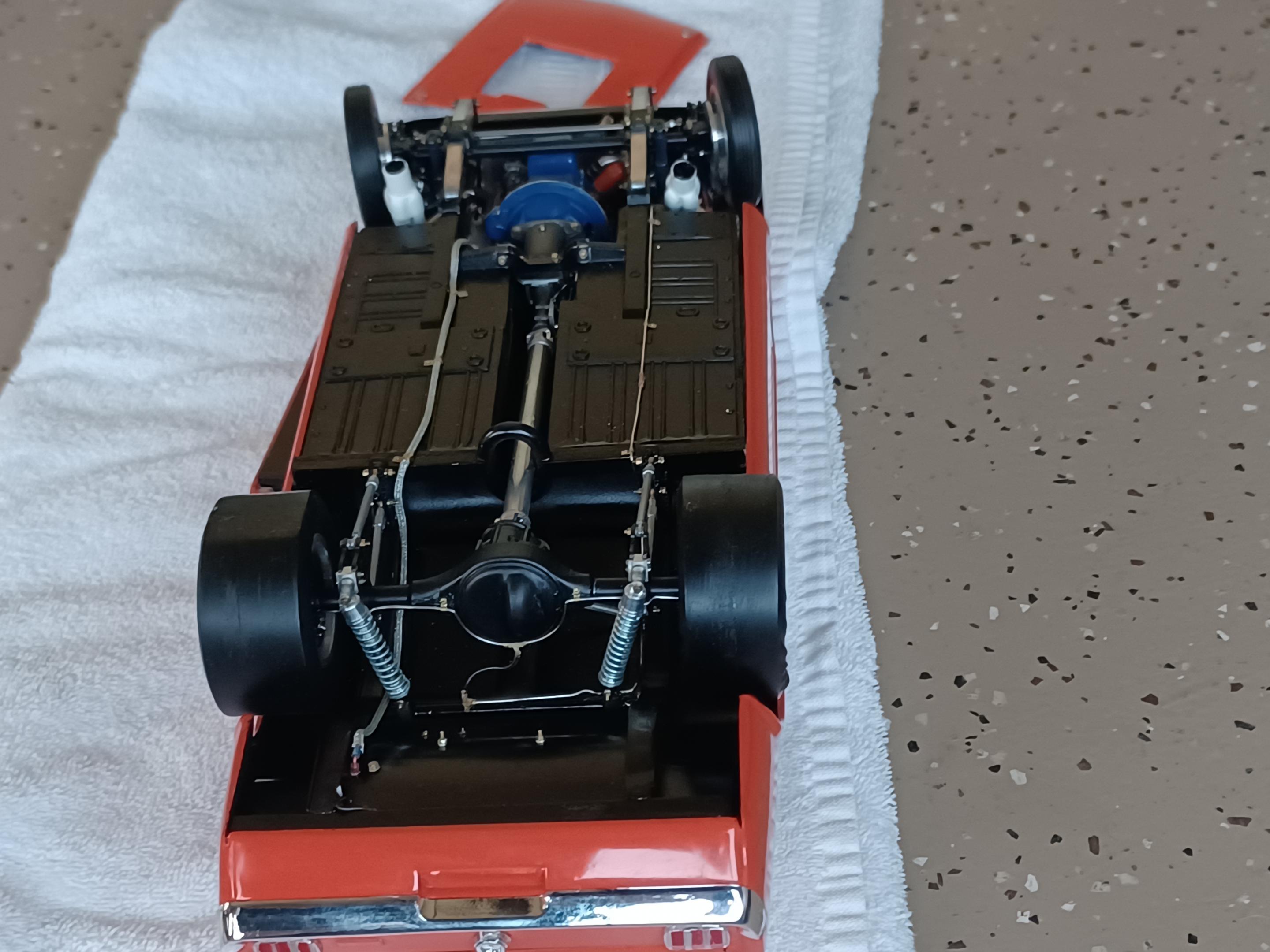

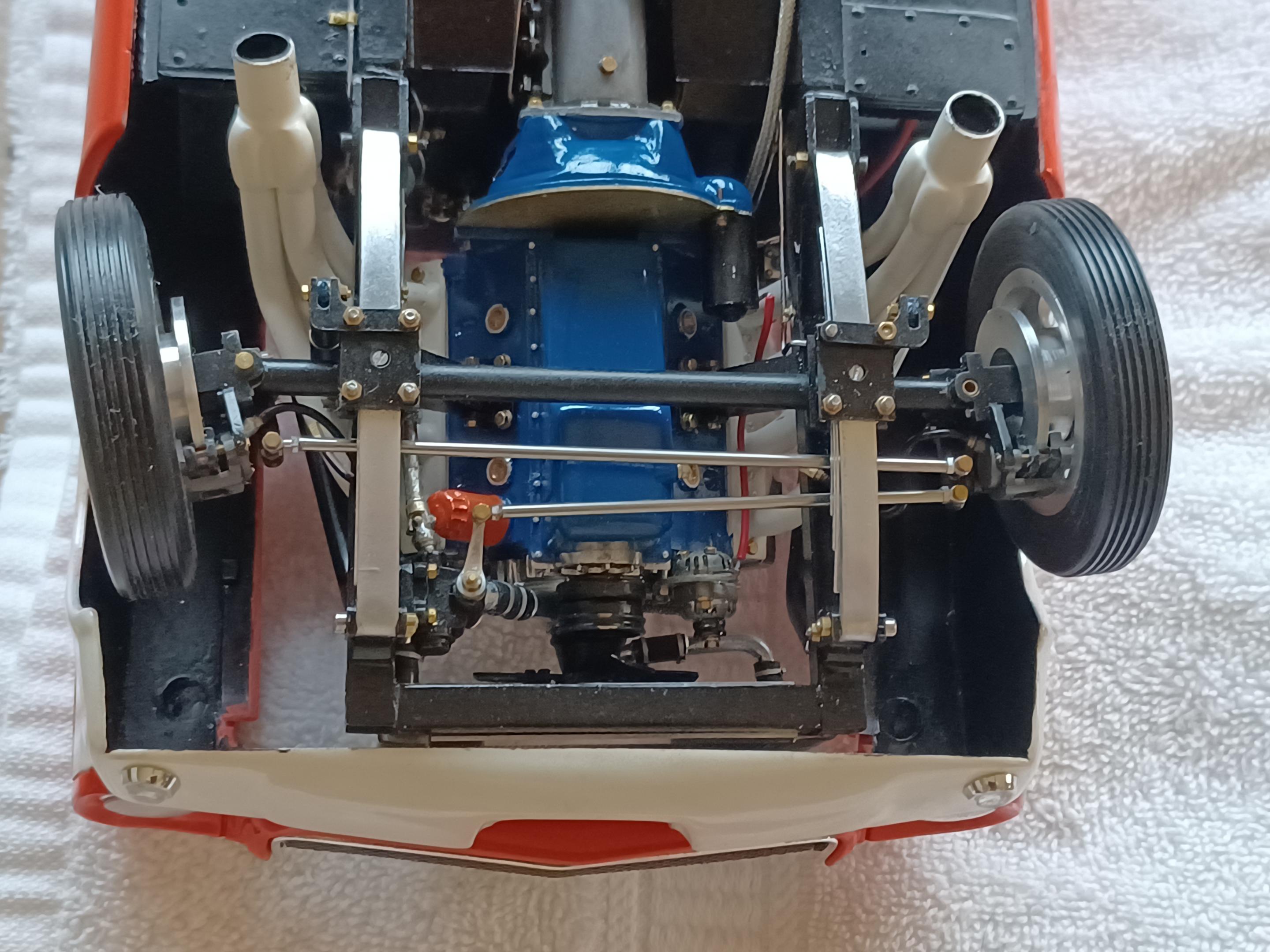

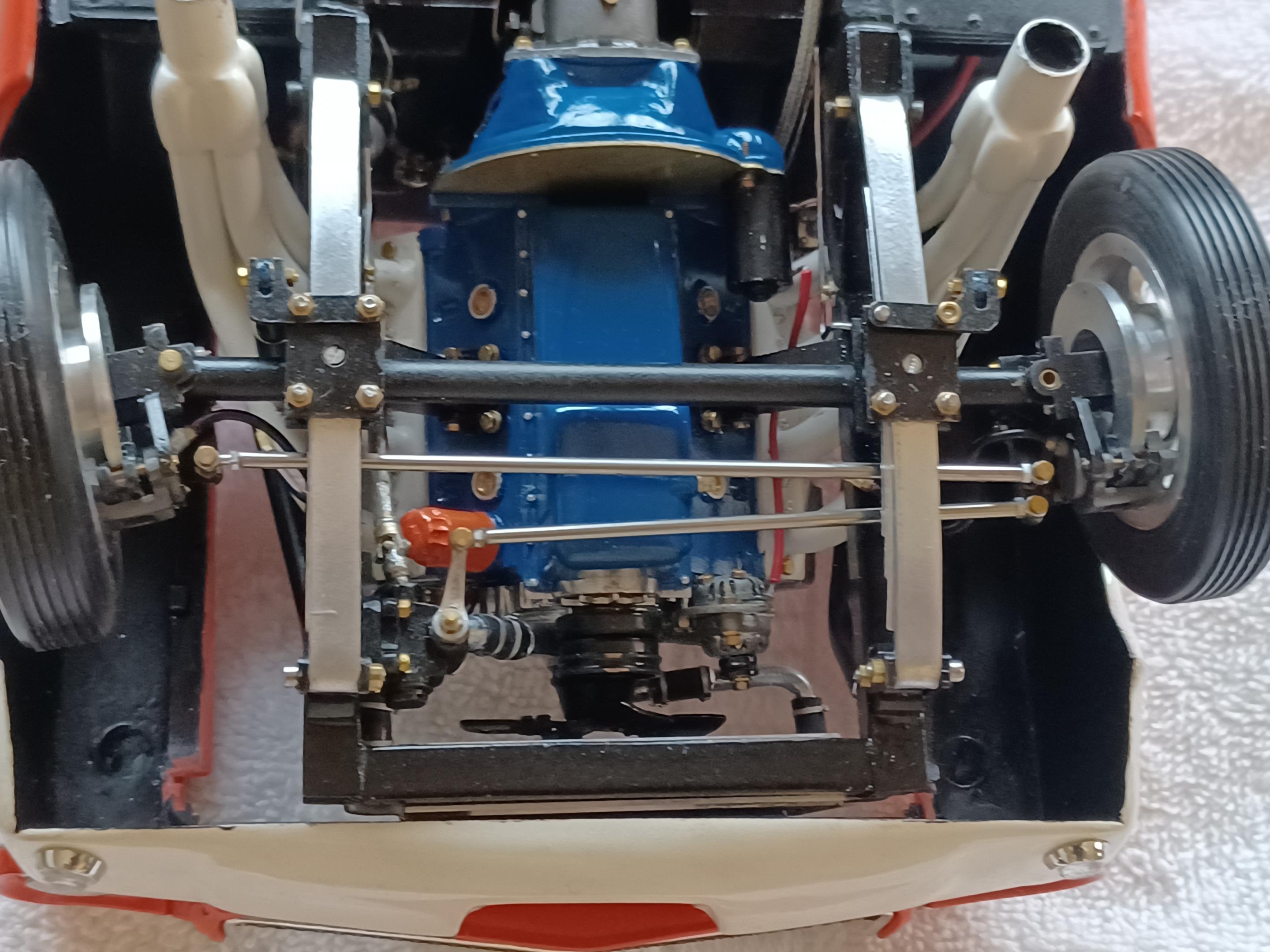

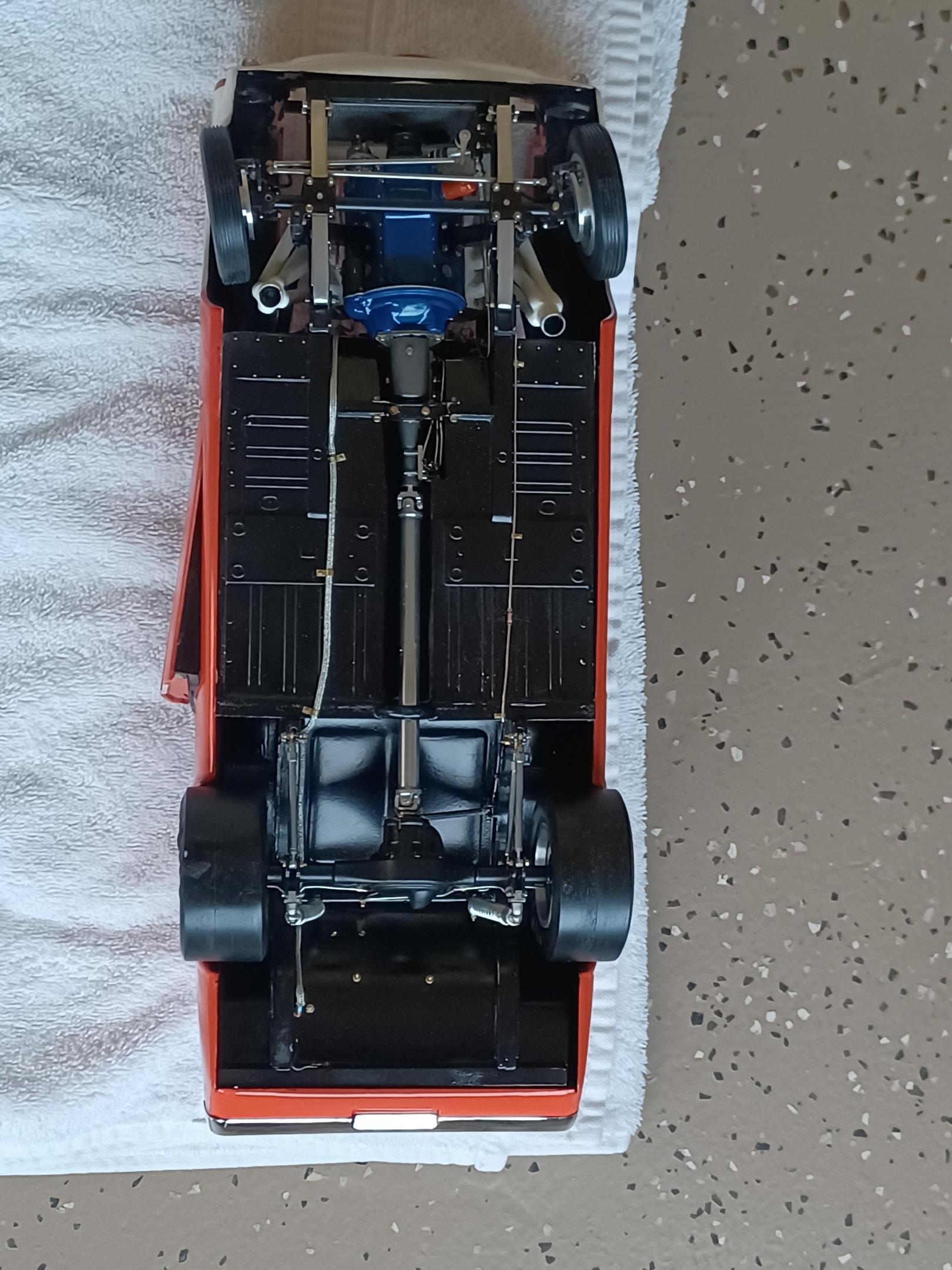

here is my finished mustang gasser. long project and i like the way it came out. like all projects you do ,you always think of ways it could be better. i learned alot from this as always and from the projects that you all have built. please keep up with my new project and any help or suggestions are always welcome . thank you all. please let me know what you think of it .

-

charlie libby 1965 mustang dragcar

charlie libby replied to charlie libby's topic in WIP: Drag Racing Models

i think its done .i will put pictures in the finished forum. thank you everybody for looking at my project.i really enjoyed all of your comments. look at my new project in the road race forum. -

charlie libby 1965 mustang dragcar

charlie libby replied to charlie libby's topic in WIP: Drag Racing Models

thank you bob i had a geat time creating it and i am happy people like it

.thumb.jpg.a0c0e722c6379e6d32e766b5fa99e95c.jpg)