-

Posts

2,505 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Gary Chastain

-

Haha haha, me too. The tool and die maker in me, took over. Not the first time I have totally lost it, but kinda excited to take on the challenge or I will have a really big piece of junk on the shelf. Going to make a fixture and try to split some round tubing for the 1/4 round corners. Rear doors are still undecided, barn doors or overhead door. Also just added a Dremel scroll saw to my workbench. Rivets will be here on the 18th.

-

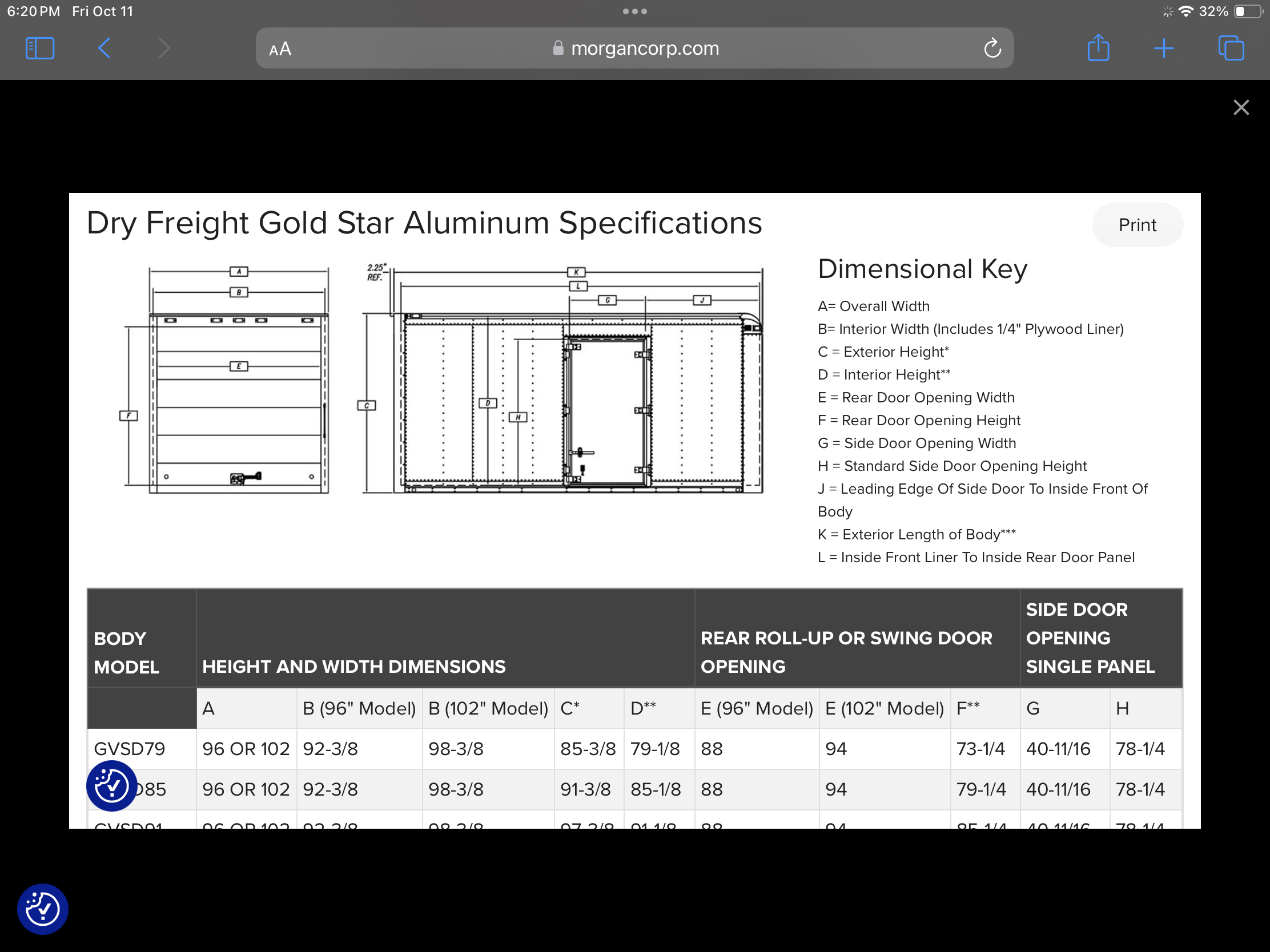

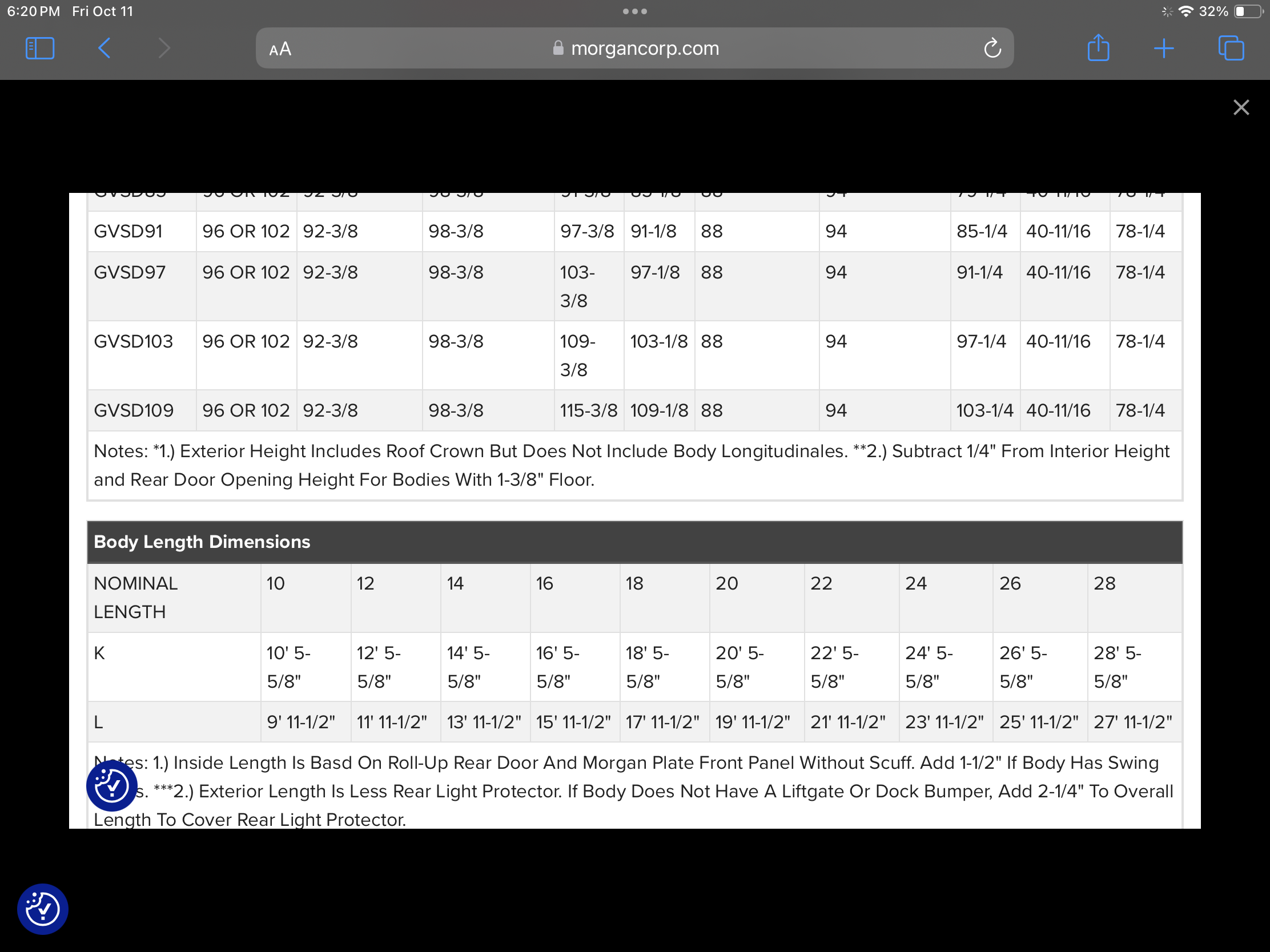

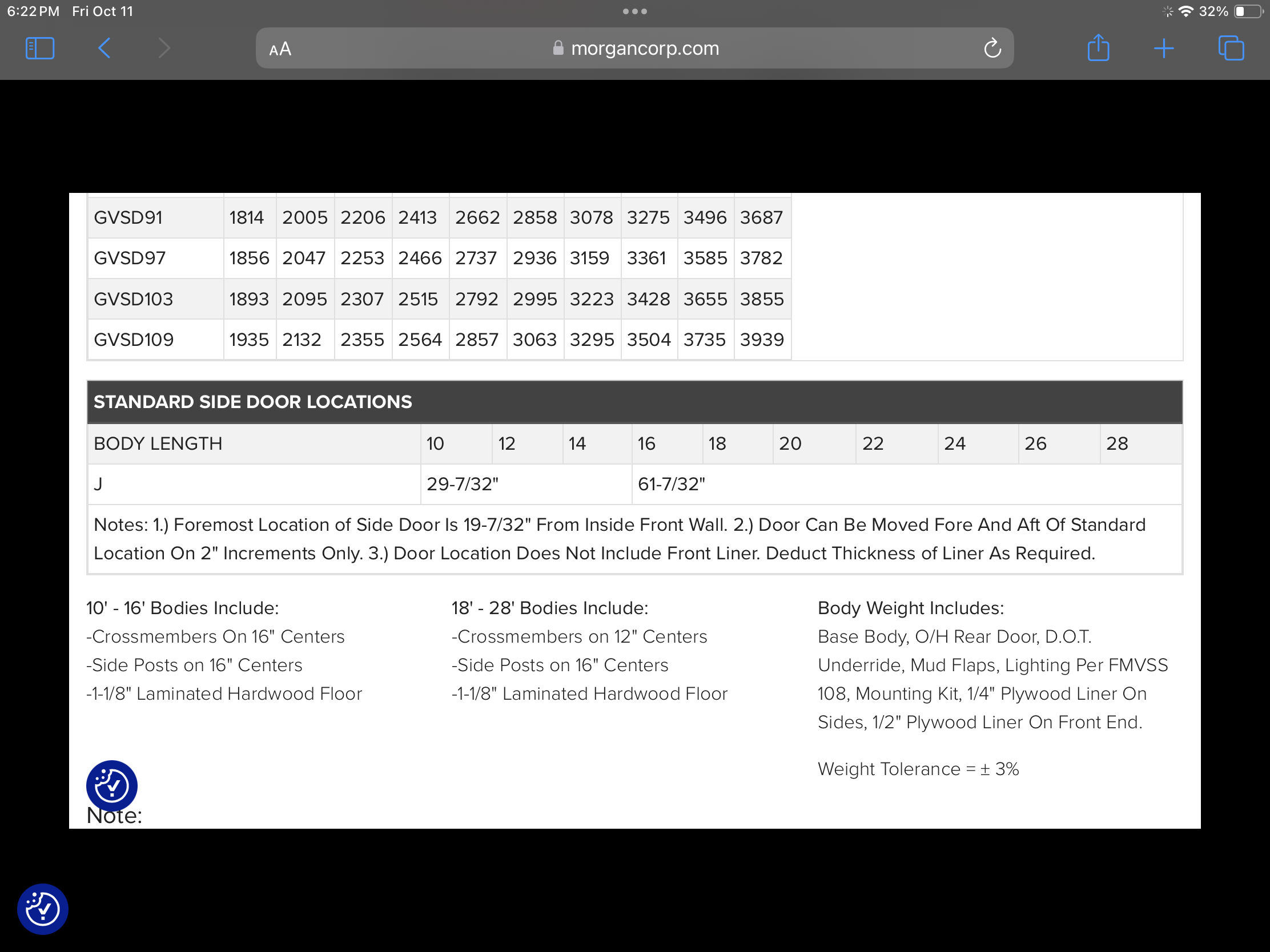

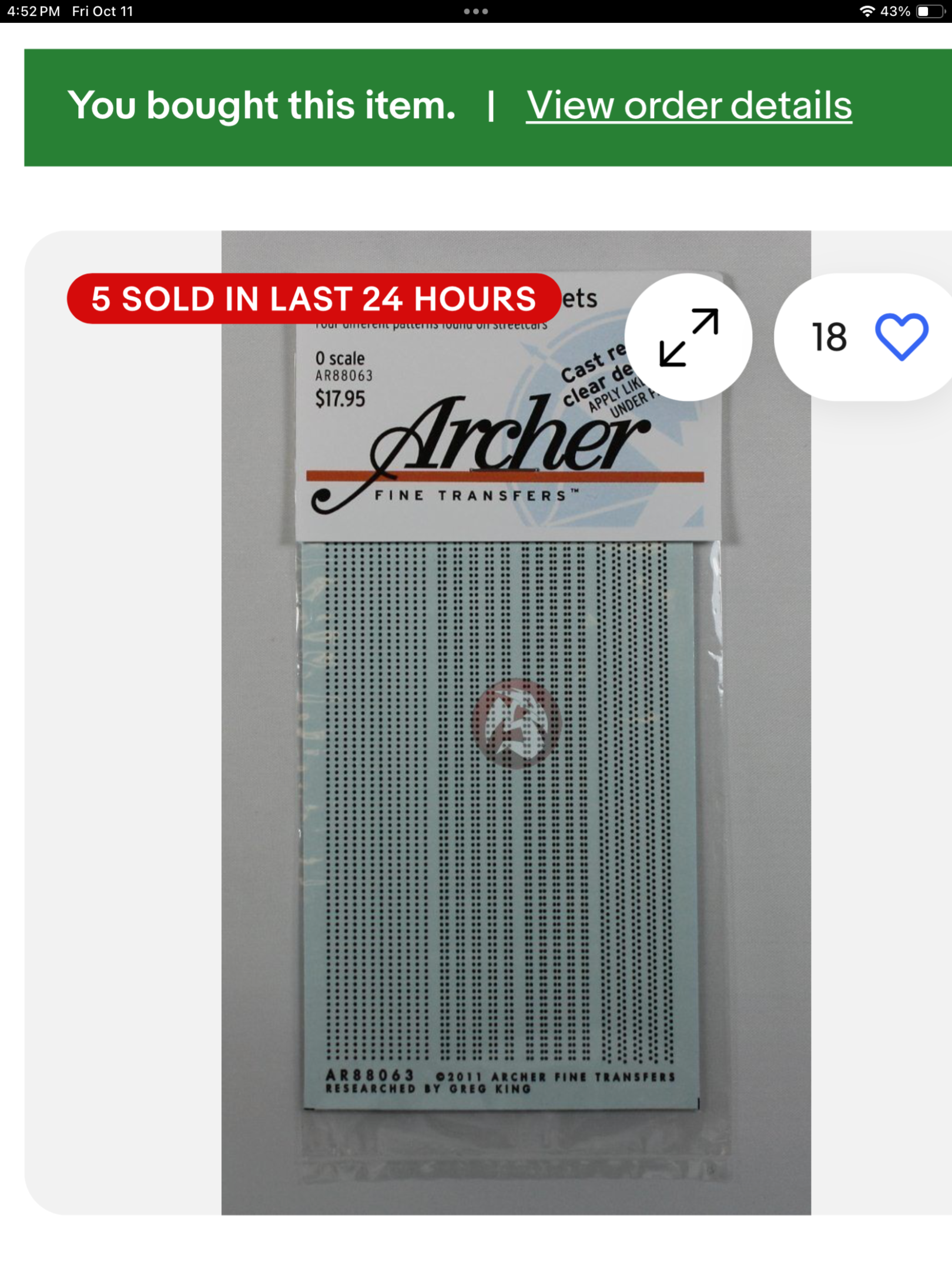

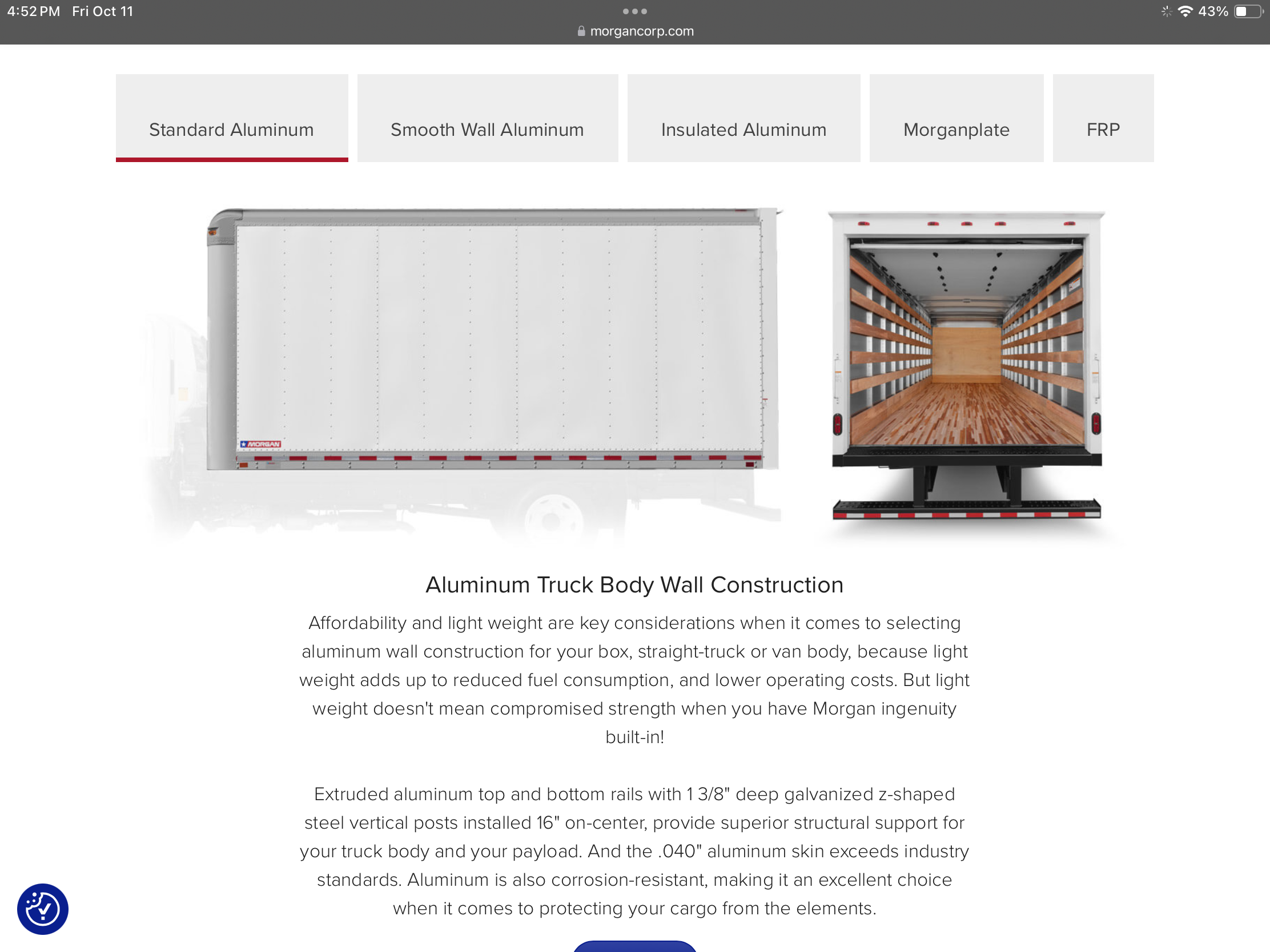

Well I am going off the deep end of this build. Decided I didn’t like the two truck bodies I have. I am going to attempt a Morgan truck body. I have built many flat beds and drop deck trailer from scratch but this will be a first for a scratch built Morgan box van. Their website is good info, found the Archer rivets ( I think “O scale is close to 1:25 scale) and the red and white safety strip. Just picked up the Evergreen flat stock to build with.

-

Service Truck Kitbash

Gary Chastain replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

The local logging company has a similar truck, using a Kenworth. The bed comes midway to the back window, with a small crane, compressor and welder mounted on top of the bed. There is also a set of torch bottles inside the bed. Like where this is going, will be following this build. -

Western Star 4900 FA plow truck

Gary Chastain replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Love watching your build, and might steal some ideas. The level at which you and a few other guys are building are at another level. Makes me not wanna post my basic builds. -

JM, yes it does dry slow, i usually don’t touch for about three days. What I like is the chrome doesn’t fingerprint when working with the parts. I am still learning about using the Revell chrome paint , as of now I am not clearing over it. I am not that guy, don’t see you doing any copy cat. You can post anything on my post and I am not getting upset, we are just having fun. Besides, be interested in what you build, might wanna copy you ???, I have several COE cabs and would like to build an old beer truck, maybe a flat bed with a stack of beer kegs or something.

-

The attachment points to the runner always bugs me on chrome parts. By dechroming the parts, it allowed me to remove those bad areas, blend them in and I also filled the hole in the top grill front where the GMC logo attaches. Everyone of these GMC kits have broken or damaged GMC logo. I will be using a decal instead. Painting the Revell chrome is really no different than painting, just give extra attention to dust, as it really shows up on chrome.

-

Farm Floater Truck 1/24th scale

Gary Chastain replied to Randy D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

If your fingers were not in the picture, I would say “that is an awesome picture of the real motor”. Outstanding detail, well done. -

Lonestar

Gary Chastain replied to TopherMcGinnis's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I have the very same kit but I have been reluctant to open and build. Seen some gorgeous builds with this kit. Interested in the responses -

AMT Ford LN 8000

Gary Chastain replied to OldTrucker's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Lookin good -

GMC General (Coca Cola kit)

Gary Chastain replied to henry57's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I have built a couple of these and the tooling for this kit is really not in good shape but Jeff is correct, with a little patience they build up nicely. Well done on your progress. Will be following. -

If I had a Real Pete

Gary Chastain replied to Biggu's topic in Model Trucks: Big Rigs and Heavy Equipment

You really did this kit justice, very well done. -

If I had a real Pete

Gary Chastain replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

The details are addictive, looks good -

ongoing oilfield project

Gary Chastain replied to cdntrucking's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very cool project and lots of detail, fun to watch this come together. -

Decided to fill the hole where the GMC logo goes on the grill, as they are almost always broke or damaged. I have a nice GMC decal from a pickup kit that fits there nicely. So stripped all the chrome from around the grill , reworked everything and used Revell Chrome spray. Turned out so well that I am stripping the headlights and bumper to clean all the molding marks off.

-

Pete 352 day cab

Gary Chastain replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Your moldel building strategy exemplifies the future of our hobby, where a 3D printer is a standard tool on everyone’s bench. We are so limited in options of complete kits. Building a newer model truck or an older truck not offered anywhere, for instance, I can purchase a late model cab from one vendor, then go in search for a somewhat correct motor from another vendor, then I need some kind of donor kit for the frame and axles which may not be correct, the purchase wheel set from another vendor, oh, and some detail parts. All along spending hundreds of dollars. Sometimes this effort is fun and others times it gets frustrating. But I keep doing it??? -

A&N Kenworth W990

Gary Chastain replied to RoninUtah's topic in Model Trucks: Big Rigs and Heavy Equipment

You did justice to a very expensive kit, well done. -

If I had a real Pete

Gary Chastain replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Wow Jeff, that is looking really good. I am a big fan of the PE and CTM stuff, always adds a good bit of detail. -

Making Tracks

Gary Chastain replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Another high quality build going on there Charles, well done.