Art Anderson

Members-

Posts

5,052 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Art Anderson

-

I started all over on my 1944 Ford GPW Jeep project!

Art Anderson replied to Art Anderson's topic in WIP: Model Cars

Yes, prior to the War Production Board's decree in the early summer of 1942, both Ford and Willys had their logo's stamped into the right rear corner of Jeep bodies. GMC, Dodge, Studebaker and other truck makers for both the US Military and for Lend-Lease even used their own cabs and civilian front end sheet metal--leading to concerns as to the ethics of private companies having such a very visible advertising situation during that wartime crisis situation. Art -

I started all over on my 1944 Ford GPW Jeep project!

Art Anderson replied to Art Anderson's topic in WIP: Model Cars

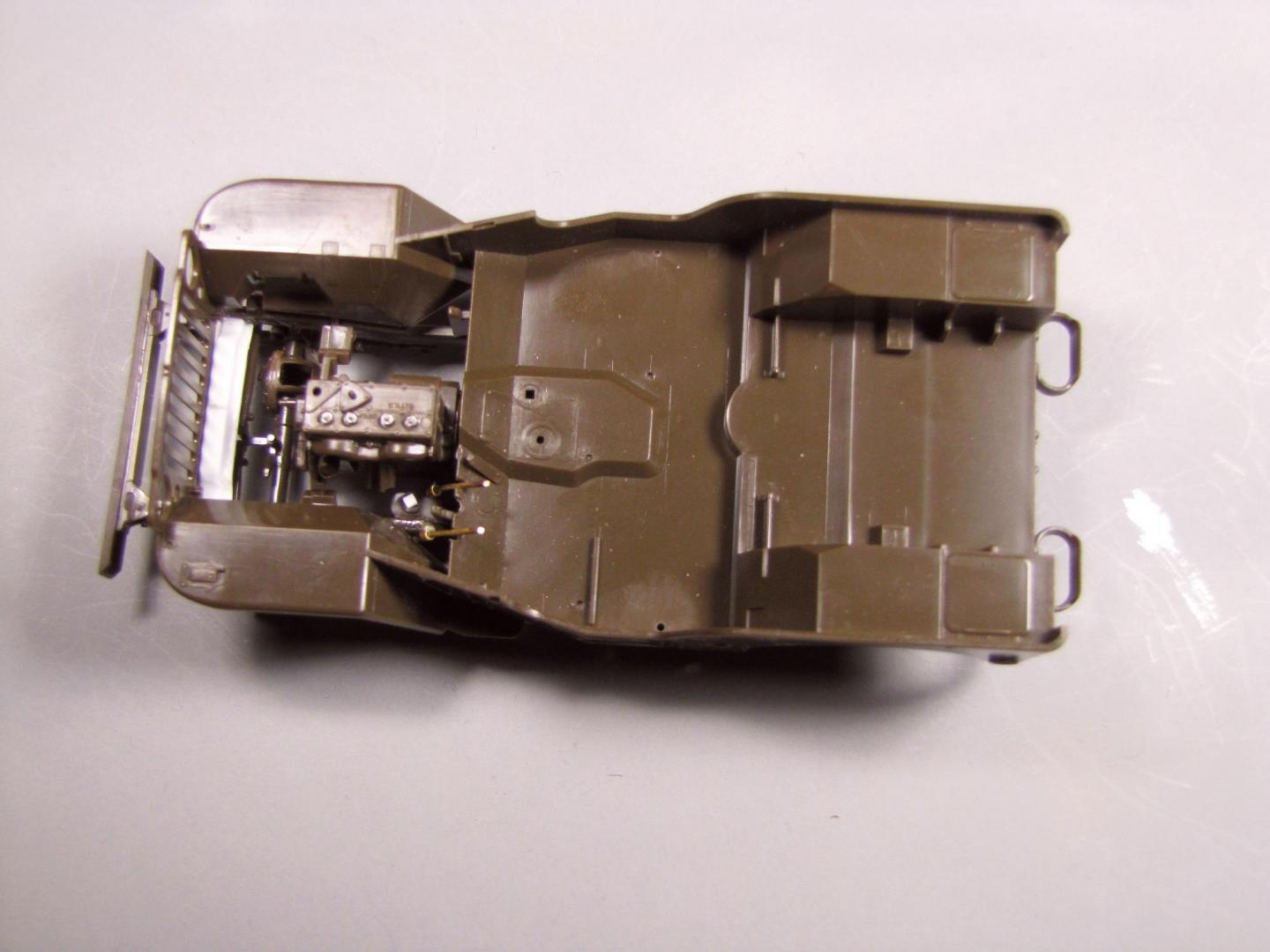

Many might ask "DID Ford actually build Jeeps?", and the answer is, yes, they did! The sudden ramping up of US War Department orders for Jeeps (along with just about every orther form of war materiel) in early 1942 was more than Willys-Overland could possibly supply, so Ford was brought in as a sub-contractor to increase production. Willys provided Ford with initial chassis stampings and components, while Ford's people got to work creating the necessary stamping dies in order to handle this. Willys (or their supplier) continued to provide the Willys "Go-Devil" flathead 4-cylinder engines, along with transmissions, transfer cases front and rear axle assemblies. American Central Mfg of Connersville IN took over production of Jeep bodies for both Ford and Willys, further ensuring a consistent supply. Fairly early into Ford's Jeep production, their engineers came up with a more conventional channel-section front crossmember which supplanted the Willys tubular unit--and with the deletion (by WPB decree) of all external manufacturer logos, that front crussmember (along with the various data plates) remained pretty much the only quick indentifying characteristic--so that's why I chose the GPW Jeep as a model subject. One fairly large (and visible) detail missing from the Hasegawa Jeep kit (and I think from Italeri's 1/24 scale Jeep kit as well) is all the brake and clutch pedal linkages underneath, so I made those from bits of K&S brass, and installed them (I know now why these parts were omitted--they make setting the body shell on the chassis quite interesting indeed, but it can be done. -

I've never seen such a styrene shape. It would almost have to be injection-molded, or perhaps extruded. Art

-

On the heels of the Heller Ferguson TE-20 tractor!

Art Anderson replied to Art Anderson's topic in Truck Kit News & Reviews

Now, if some enterprising model company would step in, make us a kit of the Ford 8N, life would be even better! -

And Revell Germany just announced, today, a Porsche 108 farm tractor.

-

Tom (and all), The JoHan '59 and '60 Cadillac Fleetwood 60 Special 4dr sedans are a mixed bag as for dimensions. While the overall length of the models in question is too short, and the body is exactly 1/8" (three scale inches too narrow), believe it or not, the "greenhouse" (roof from the bottom of the windshield to the bottom of the back window is right on the money for length. I know, as when I mastered the '59 Biscayne 2dr (all GM two- and 4dr 6-window sedan bodies used the same roof stampings as well as the same A & C posts!), I took copious measurements off the real 1:1 '59 Biscayne 4dr sedan that was in my driveway at the time (1994-95). I simply widened the Cadillac sedan roof with a strip of .060 X .125 inch Evergreen styrene, used the windshield frame & header from the AMT Trophy Series '59 El Camino for the correct height ('59 GM sedan roofs are right at 2.5" higher than the harddops and convertbiles). I also had to widen the JoHan rear window glass by .125", and use that and the El Camino windshield as vacuum-forming masters. Art

-

That gear puller was pretty universal--it works on pressed-on pinion gears. Art Anderson

-

The only styene Lotus 19 Body I've ever seen, was made by Strombecker, as a 1/32 scale slot car body. Art Anderson

-

Indy Ford

Art Anderson replied to Lizard Racing's topic in General Automotive Talk (Trucks and Cars)

1964 was indeed a black year at Indy! I was in the infield, at the exit of Turn 4 that day (a friend of mine had his camera out--his pics of that gawd-awful crash went viral when Life Magazin published them!. That was the most sickening day I ever witnessed at Indianapolis! -

Indy Ford

Art Anderson replied to Lizard Racing's topic in General Automotive Talk (Trucks and Cars)

Living as I do, growing up in Lafayette IN just an hour NW of the Indianapolis Motor Speedway, and being an Indy 500 fanatic since boyhood--it was inevitable that the rear engine revolution was going to happen, Lotus or no. If one reads the several books written on the subject (and I have every one written) it was Ford Motor Company who sparked that "revolution".after seeing Jack Brabham's run at the 1961 Indy 500 (I was there that day!). Couple that with Dan Gurney's run with the rear-engined Buick stock block in 1962, the move to rear engined cars was inevitable--I saw him qualify for the race, but had to miss the 500 that year due to my HS class' graduation picnic on Race Day. I missed the debut of Lotus at Indy in 1963 as I was driving home from Iowa with the first Model A Ford I acquired when in college--missed the 1964 race as well for very similar circumstances--but in 1965, I got to see Jim Clark qualify in the Lotus 38--his helmet was so low in the cockpit it seemed as though that car had no driver@ -

Moebius '65 Mercury Comet Cyclone news

Art Anderson replied to Dave Metzner's topic in Car Kit News & Reviews

Yep! That's how it works! Moebius is based in Florida. -

Next question- Racking parts to be replated

Art Anderson replied to gtx6970's topic in Model Building Questions and Answers

Interesting, considering that no chemicals are used in the vacuum-plating process, other than the pre-coat and protective clear coat over the otherwise bare aluminum! With the sheer thousands of parts I've had plated (from several plating houses) I never once saw any evidence of any chemical reactions from using silicone adhesives to mount the parts. Art -

Reshaping resin

Art Anderson replied to Perspect Scale Modelworks's topic in Model Building Questions and Answers

Absolutely! Unlike styrene, which has a pretty long "range" for warming up the plasic for correcting misshapen parts, polyurethane resin can go from solid to "limp spaghettii" in mere seconds. I might suggest "forcing" the reshaping with the resin body at room temperature--a styrene firewall will be much stiffer. Art -

Next question- Racking parts to be replated

Art Anderson replied to gtx6970's topic in Model Building Questions and Answers

I've had literally thousands of model parts plated in years past--and the spacing looks pretty good to me (I used both LMCC and Chrome-Tech). Just be sure that the outside diemensions of your rack(s) meet the requested specs from the platers. I used DAP (formerly GE) Silicone II clear adhesive to attach parts to the racks--held the parts just fine, and yet they were easily removed after I got the racks back from the plater. Art -

Good modeling products

Art Anderson replied to BIGTRUCK's topic in General Automotive Talk (Trucks and Cars)

Bill, I had the very same clogging problem with the Touch-&-Flow, until I landed on a neat, and very EASY little trick! Seeing as I use mine as I learned to do in HS Chemistry Class and glass pipettes, meaning I used my own suction to draw the MEK up into the tool, why not put the tip of the Touch & Flow back into the bottle of MEK (the tip down into the MEK!) and simply blow all the leftover liquid cement back into the bottle--that has the advantage or removing any melted styrene residue from the needle--the result being, I've used this one for about 2 yrs now, with nary a clog! Art -

Good modeling products

Art Anderson replied to BIGTRUCK's topic in General Automotive Talk (Trucks and Cars)

For my money, when gluing, NOTHING beats the Flexi-File "Touch & Flow" applicator: It's a thin glass tube, with a hypodermic-sized length of stainless steel tubing fixed in one end. Use with any of the MEK-based pure liquid cements out there (Ambroid Pro-Weld, Tenax, or Flexi-File's own liquid cement--NONE of these have any of thickens--are pure solvent--much thinner even than water!). Just touch the tip to the joint to be glued, and the liquid glue flows right into the joint, leaving ABSOLUTELY no residue behind. http://www.flex-i-file.com/adhesives.php Art -

I've not searched the net for such information, but it's hard for me to believe that there hasn't been at least one website showing how to chop a REAL '49-'51 Mercury. The techniques (as regards to where to cut, how to fit the various panels back together) will be remarkably similar on a 1/25 scale plastic model though! After all, take away the difference between 1:1 sheet metal and 1:25 scale plastic, the altering and modifying the various pieces in any chop are very, VERY similar! Art

-

I'm afraid you are in for a total scratchbuild here, as that Dodge shares nothing more than perhaps tires, with any model car kit I've ever seen. Art

-

Ferguson Tractor from Heller

Art Anderson replied to carsntrucks4you's topic in Truck Kit News & Reviews

In the US, most certainly in farming "row crops", an exhaust running down and underneath the tractor would be a serious fire hazard, particularly at harvest time, due to all the dried crop vegetation below the tractor! For that reason, almost universally, farm tractors, certainly back in the years of gasoline engines, had exhaust pipes that went straight up, well away from any otherwise combustible crop stubble, even uncut by ripened and dried out wheat and similar grain crops. While the hinged, counterbalanced "flap covers" were available, not many farmers around here bothered with them, given that common used empty tin cans were a dime a dozen around any home by the 1930's and beyond--farmers kept a lot of those around their barns and implement sheds (they didn't often park tractors outdoors in the weather back then). so, shut the tractor down, grab a tin can, turn in upside down on the end of the exhaust stack--that kept rainwater, snow, even the morning dew out of the exhaust system. Art -

Correct. That's just about the only pre-1930's Dodge of any style that I can remember! Art

-

WHAT BUGS YOU

Art Anderson replied to PARTSMARTY's topic in General Automotive Talk (Trucks and Cars)

Of course, the complex shap?es of bumpers for say, American cars circa 1949-the end of chrome-plated steel bumpers with the 5mph-hit-with-no-damage-mandate from the US Congrress in the early 1970's, would be do do such bumpers in multi-part assemblies, with joints at each bumper guard (but what to do about bumpers for which bumper guards were an extra-cost option?) A multi-part die with moving "slides" might be an option, but already on boards like this, modelers bitch about the price of a kit--the more complex the tooling, necessarily the higher the price (after all, sales of any model kit simply MUST amortize the cost of tooling, and fairly quickly--if you want that company to design, tool, and introduce more new kits!!!! Art -

WHAT BUGS YOU

Art Anderson replied to PARTSMARTY's topic in General Automotive Talk (Trucks and Cars)

Ahh, but consider this: That clear coat serves three vital functions: 1) It gives a very polished, high-gloss surface on which to apply the literally few molecules thick coating of pure aluminum (which is what vacuum-plating has ALWAYS been--going all the way back to the WW-II era!)--and that is almost a black art, as was explained to me back 40 years ago, when I was doing box-art models for AMT Corporation and visiting their now legendary plant at 1220 Maple Road in Troy MI, on average about once every 6-8 weels (approximately 250 miles from my long-time home town of Lafayette IN). and 2) That clear coat, in addition to making (ideally) a high-gloss surface for the vacuum plating, also provides adhesion, so that the aluminum plating doesn't simply flake off in a heartbeat, and 3) The second clear coat protects that micro-thin layer of aluminum from simply seeming to disappear (pure aluminum is a very reactive metal--easily affected by contaminants in the ambient air around it--such stuff in the air in one's home (regardless of the existence or lack thereof) such as cooking fumes, and most certainly tobacco smoke can eat that micro-thin plating away in a very short time. Many of us are old enough to remember early Revell kits with vacuum-plated parts whose plating would literally "fade away" within a few months upon exposure to air--not sure what enabled that, unless there was no clear top coating applied. Art -

WHAT BUGS YOU

Art Anderson replied to PARTSMARTY's topic in General Automotive Talk (Trucks and Cars)

Unfortunately, the styling of so many bumpers (certainly by the 1950's) meant rounded, finished ends that while great looking on the real car, present a real problem with getting molten styrene to flow into such an area--necessitating a sprue attachment point right there to make sure that there won't be problems with "shot shot" (where the plastic doesn't flow into that part of the mold--so some sort of sprue attachment simply has to happen at that point on many bumpers. A similar problem arises with designing the tooling so as to make those bumpers removable from the mold--there cannot be any "undercuts" to prevent the easy release of such parts from the mold once the model kit plastic has cooled, solidiified--simply put, there just has to be a a mold parting line there to allow for tha. Art