-

Posts

2,435 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Len Woodruff

-

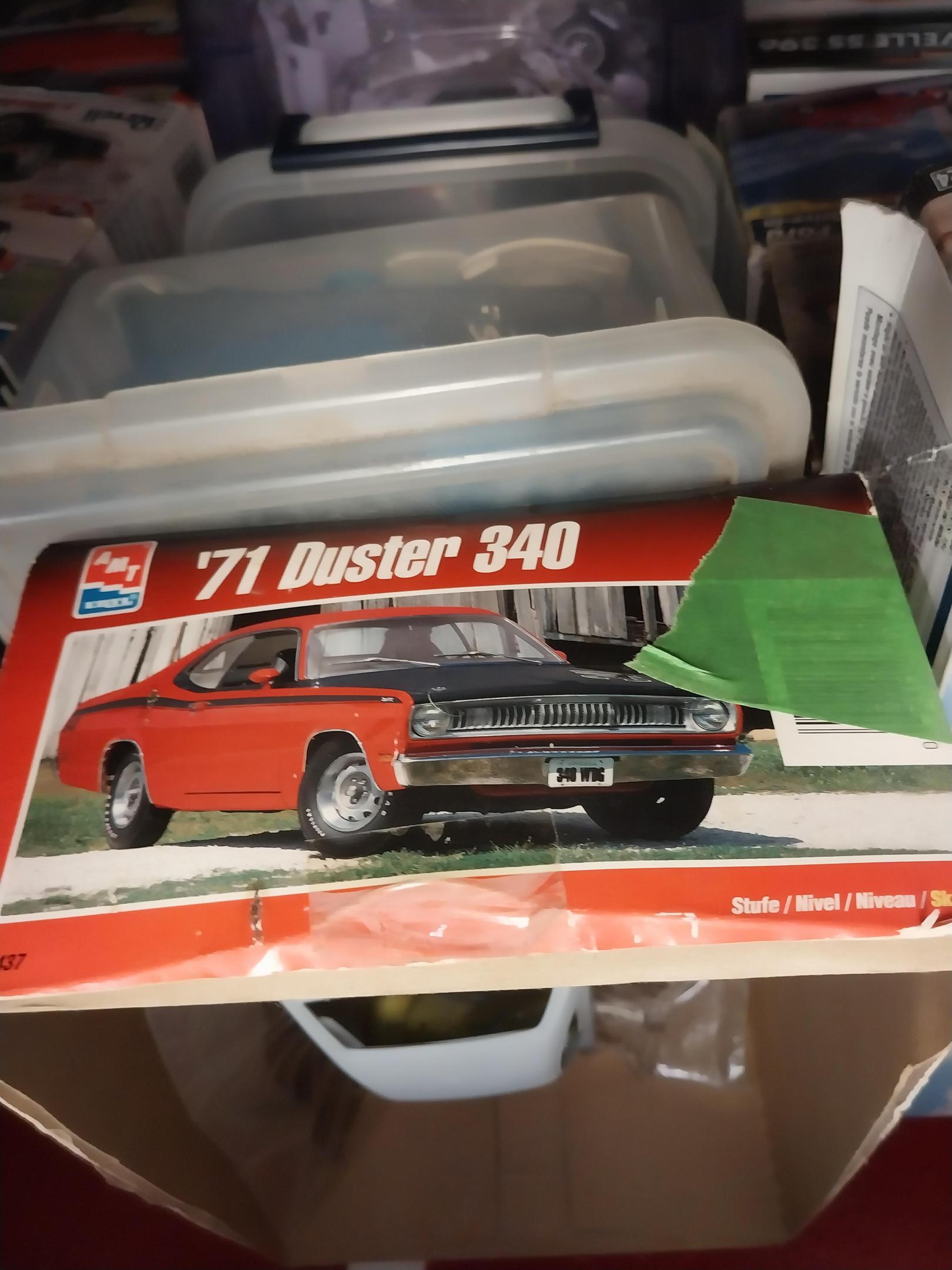

AMT 71 Dodge Demon Final Assy Problem

Len Woodruff replied to Len Woodruff's topic in WIP: Model Cars

I am going to my buddy's house today to work on this car. I will post an update when I get back home with the progress. -

The Official EBay Discussion Thread

Len Woodruff replied to iamsuperdan's topic in General Automotive Talk (Trucks and Cars)

I have cancelled the bids on buyers who don't pay in 4 days or so & don;t respond to my e-mails. In this case I might cancel the bid just because he might claim that the wheel/tire is missing after he gets the kit and try to force a refund. -

AMT 71 Dodge Demon Final Assy Problem

Len Woodruff replied to Len Woodruff's topic in WIP: Model Cars

We gave up on the quater windowws. They are longer than the slot that is in the side panels and dn;t seat well. -

AMT 71 Dodge Demon Final Assy Problem

Len Woodruff replied to Len Woodruff's topic in WIP: Model Cars

Thanks Roger. I will do more of that when I go back to my friends house next week. -

AMT 71 Dodge Demon Final Assy Problem

Len Woodruff replied to Len Woodruff's topic in WIP: Model Cars

-

AMT 71 Dodge Demon Final Assy Problem

Len Woodruff replied to Len Woodruff's topic in WIP: Model Cars

Steve this is not my build. I am just helping my buddy who has Parkisons do the final assembly. I have test fitted this several times but still can't find the issue. Since I don't buiId Mopars I am just looking for people who have built this kit and resolved the issue. This is one of the newer AMT kits. I would have thought they would have better fit than what I am experiancing. -

AMT 71 Dodge Demon Final Assy Problem

Len Woodruff replied to Len Woodruff's topic in WIP: Model Cars

Thanks. I have done somee of that. I also noticed that the interior panels are too wide at the dash board -

Has anyone successfully been able to get the chassis/interior to correctly seat in the body at the windshield? I thinned the bottom of the windshield & sanded the front edge of the dash but it still won't seat. Here are some pics.

-

AMT 1970 Chevy Corvette LT-1 in Dark Plum.

Len Woodruff replied to Dragonhawk1066's topic in Model Cars

Luv it! -

My Future 3D WIP's (LOTS of pics)

Len Woodruff replied to MrObsessive's topic in Car Aftermarket / Resin / 3D Printed

Thanks Bill. I love this 3D stuff. -

The Official EBay Discussion Thread

Len Woodruff replied to iamsuperdan's topic in General Automotive Talk (Trucks and Cars)

Thanks for the info Scott. I will make sure I check my listings to make sure about the box size. -

The Official EBay Discussion Thread

Len Woodruff replied to iamsuperdan's topic in General Automotive Talk (Trucks and Cars)

What problems are you haveing with the shipping calculator on eBay Scott? I been using it for severals years and hadn't notice anything??? -

Nice. Luv Vette race cars.

-

Nice. Don't see a 73 in a model very often. I love Vette's.

-

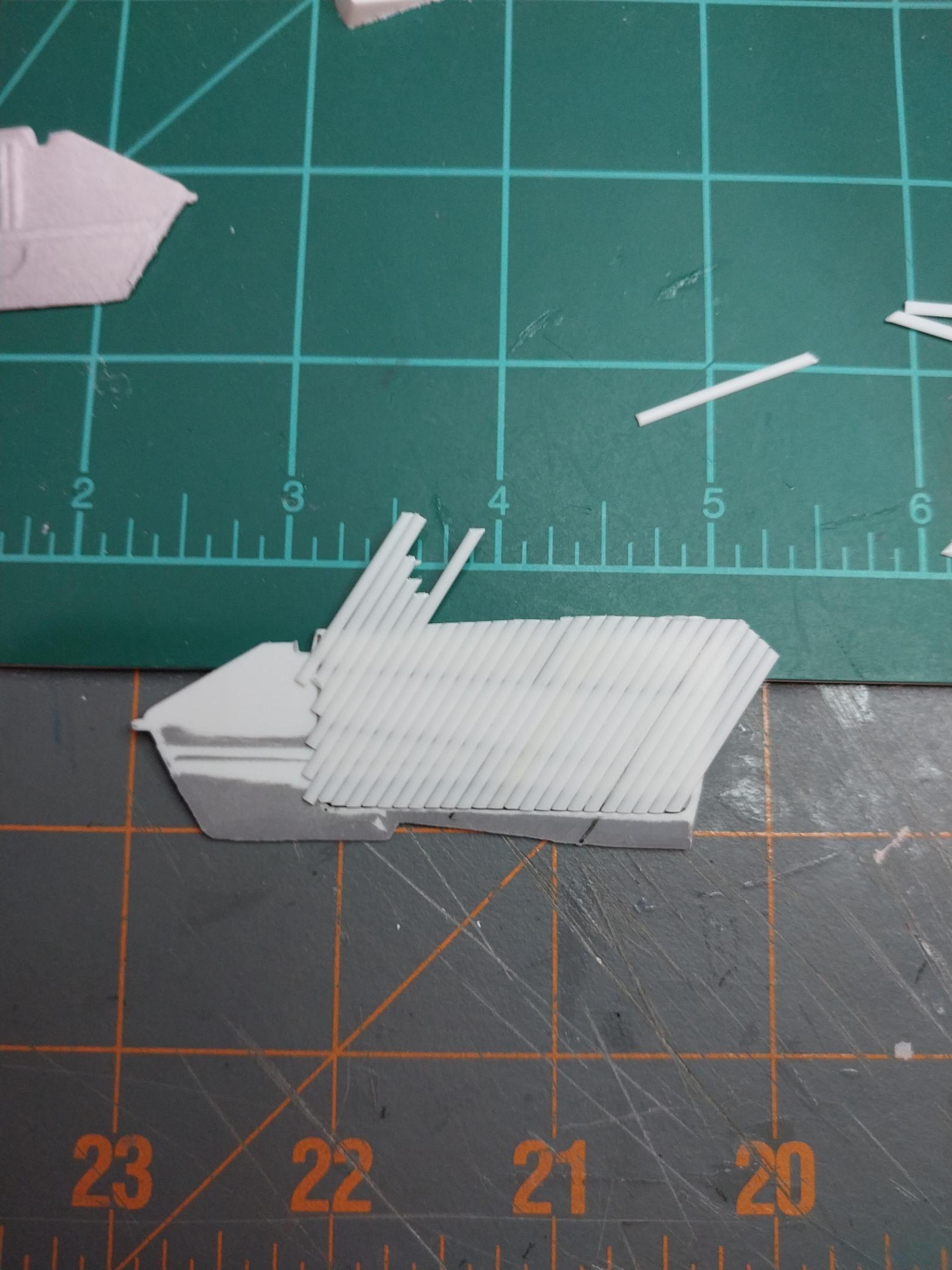

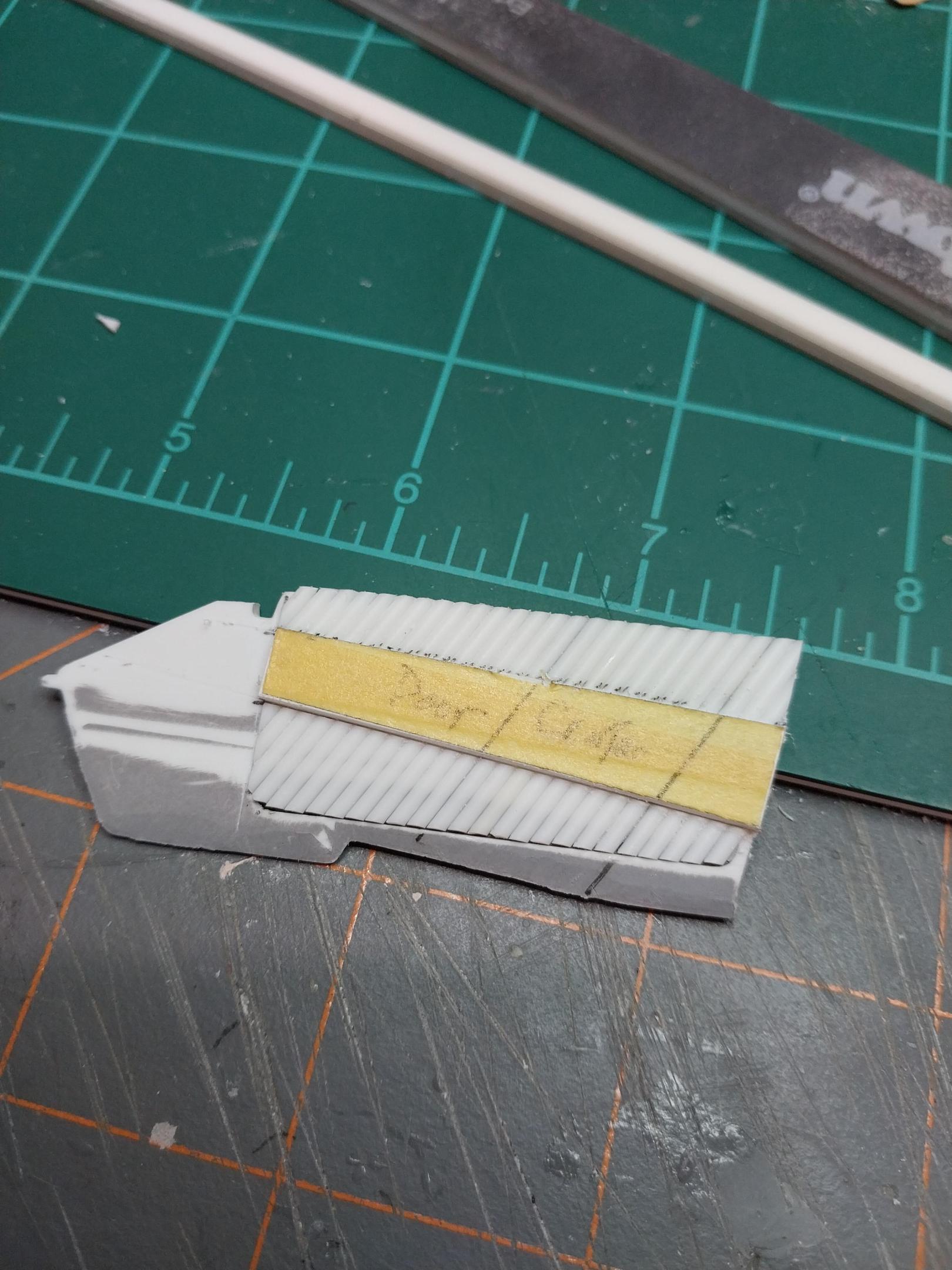

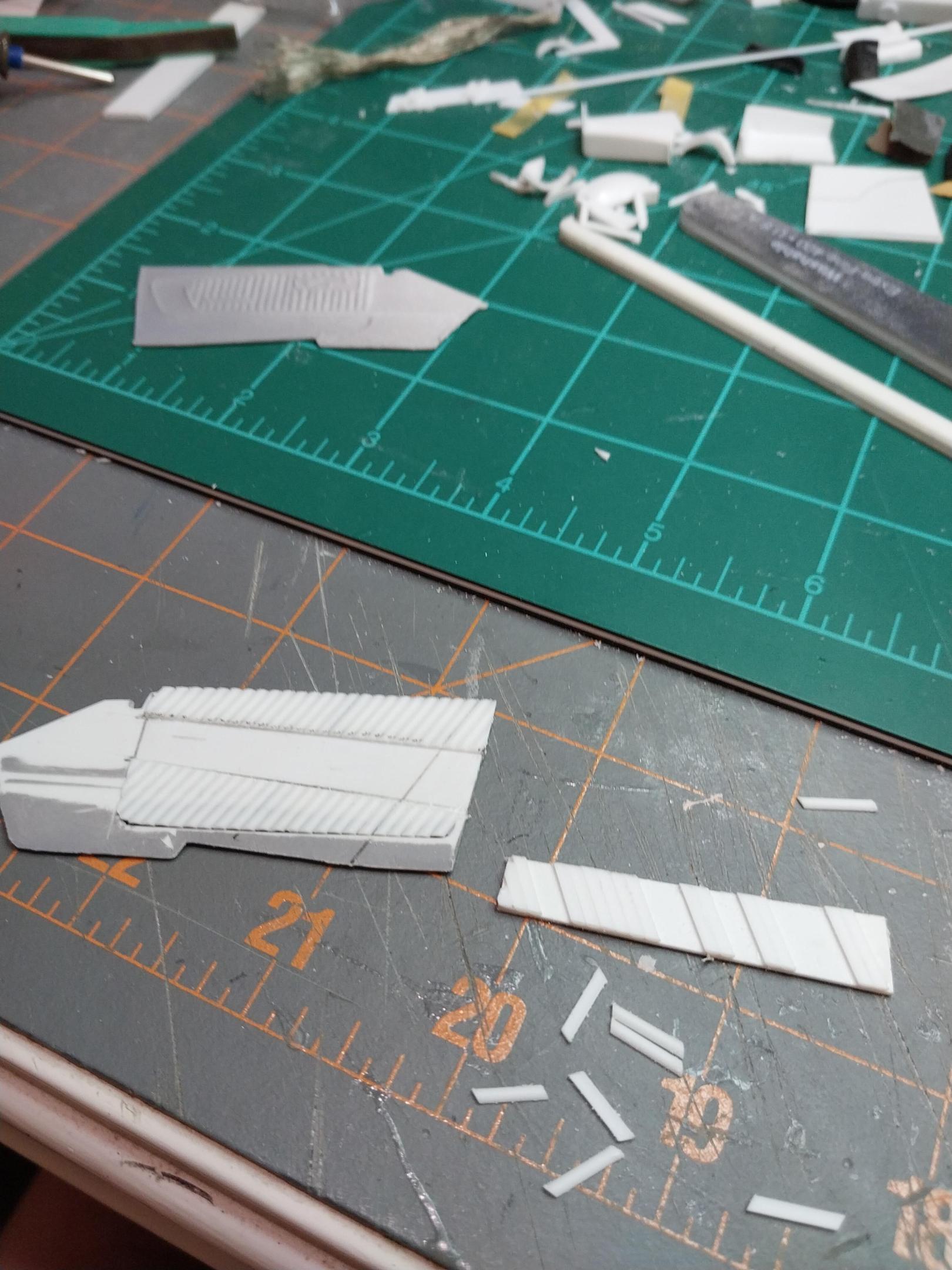

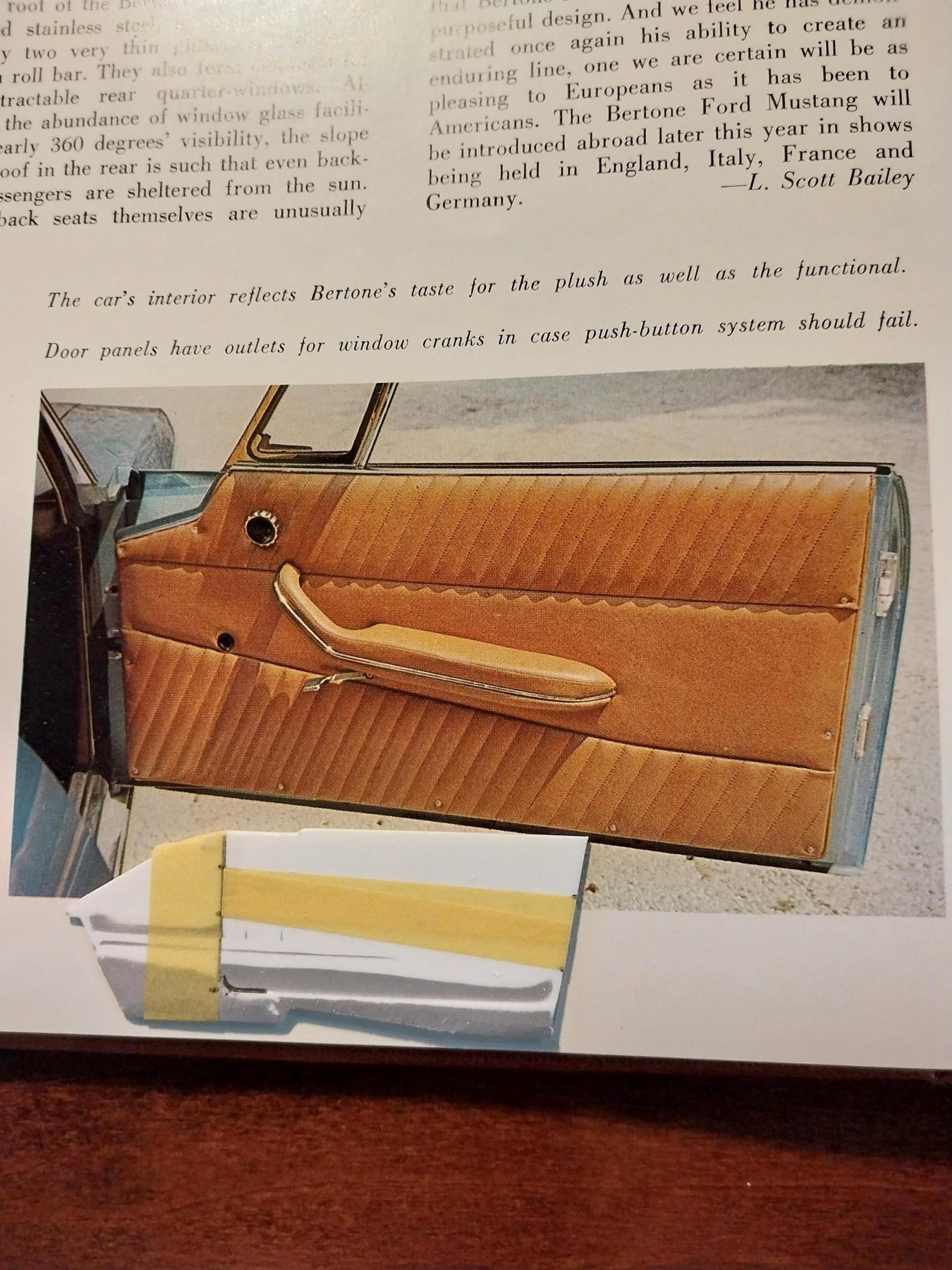

Thanks for all of the ideas guys. Here are some progress pics of 1 door panel. I glued all of the 1/2 rounds in place skipping the area in the center. Then I made a tepleate for the center and glued it to the center pieces. This was my saw guide. When I finised the cut the center pieces came out with the center piece template. Here's a few pics.

-

That looks like what I need to do. But the number of pleats dictate that we need to use the .060 1/2 round size. But more than that I was looking at how to match the upper & lower pleats. The pleats appear to be at a 30 degree angle but I am not sure the center section is the same angle to cut the pieces. I thought of using pieces to cover the whole door but exclued glue from the center section so I could easily cut it out to insert th flat piece.

-

I need to do upper & lower pleats in this door panel. The problem I see is that it has a plane section seperating the 2 sets of pleats. I haven't found any sheet plastic with this style of pleats. So I assume I will need to use 1/2 round? Any suggestions on how to do this? Thanks in advance for your help.