robertburns

Members-

Posts

256 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by robertburns

-

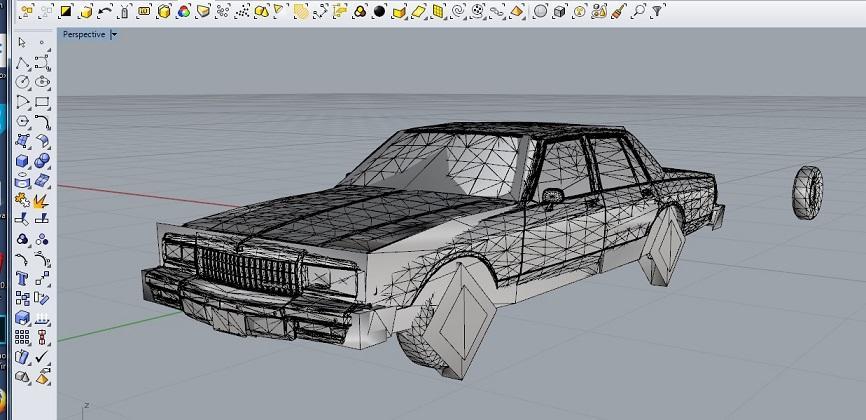

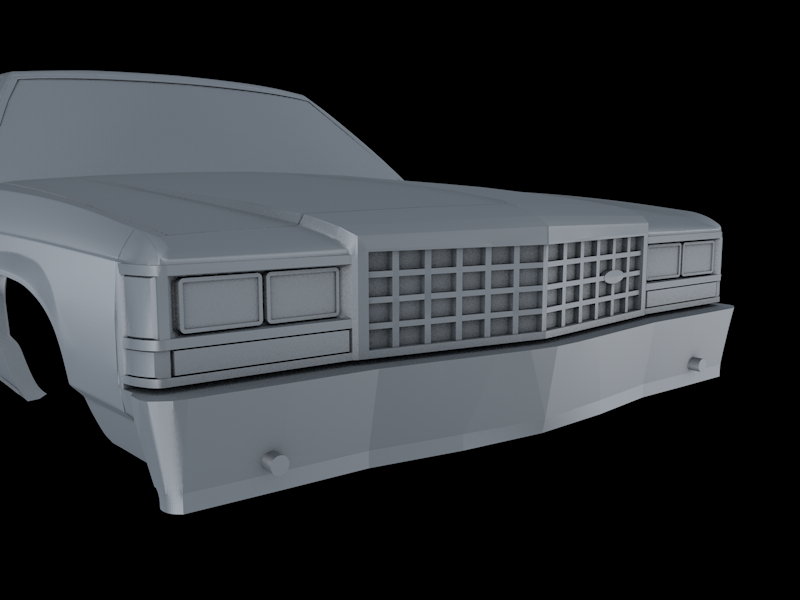

No experience with injection molding. I do have experience in manufacturing, industrial silicone and acrylic molding, casting, etc. Yes, all of these are addressed by the mold maker. They run program simulators on the parts to look for negative drafts or areas where sink or shrink marks might happen. Then they tell me where it is and I ask my CADrafter to correct them. Once I know the shrinkage rates if any, I can account for them by increasing the 3D model The undercuts are one reason for the multi part body. The other is to switch between other versions of the car like the '88 or coupe. I've simplified the tool by eliminating all undercuts. This also lowers the cost.

-

update # 1. I tried to get an estimate for injection molding at a low volume rapid injection molding shop. I didn't know they need .STP files. 3D printing files are commonly .STLs. My CADrafter is getting a program to be able to output the new files. Hopefully that's done soon because I can't wait to get the styrene numbers. update # 2. Gas door fixed. Front grille fixed. The front nose needs holes instead of pins (bumper has pins) so that will be fixed today. Then hopefully back to the printer tomorrow

-

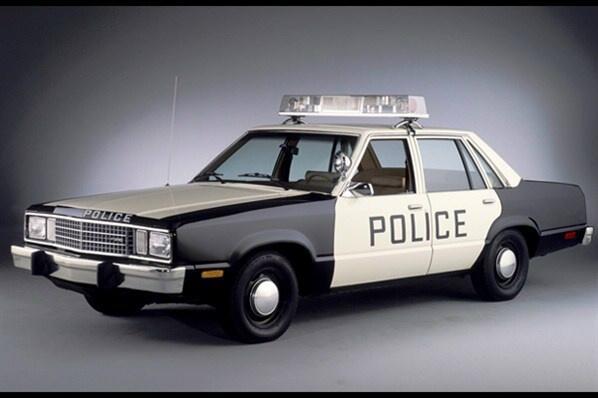

Because I do the models in CAD and 3D print them. It's not cost effective to scan an existing body into a 3D model. I want to eventually do low volume injection molding and the CAD model is the only way to do it these days. I want to eventually retire from resin casting due to the labor involved. Low run injection molding is a lot more time efficient. Let the younger guys do the resin, I want to try something not many people have done I'll still do a few limited run conversions here and there for myself. Right now I'm researching a 72 coronet and satellite 4dr for the 77 Monaco

-

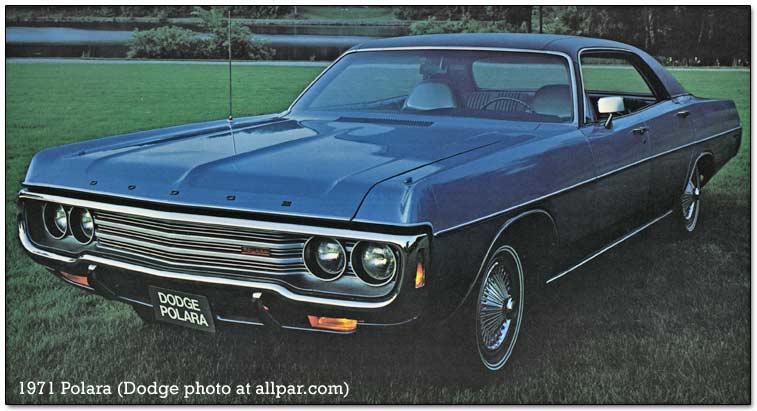

Which resin 4 door body would you buy (actually pay money to right now) out of these three, if it were available? Not really like to have, or really like to see, but actually pay money to buy. $25 1971 Dodge Polara 1984 Jeep Cherokee Ford LTD LX and Fairmont 2 in 1 1/25th scale full body with separate bumpers, grilles, lights. High quality castings. No interior or chassis like the Jimmy Flintstone cars. If sales are steady, interior and chassis parts will follow (like the Aluma Coupe and Chezoom kits). Thank you you for reading.

-

thank you Mike. It's almost like that now, we just have to crowd fund a bit if a single person is not willing to cover their whole cost. Two people cut the cost in half. A local club or Facebook group, more so. It's also getting cheaper every year. This would have cost a lot more 10 years ago and nearly impossible 15 years ago. Since I hire out professionals, my costs are higher, but some builders do CAD. Some have 3D printers. Some mold and cast. If you look hard enough, you can find people willing to chip in