robertburns

Members-

Posts

254 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by robertburns

-

Motor City's 1973-5 Ford Econoline van

robertburns replied to Eshaver's topic in Truck Aftermarket / Resin / 3D Printed

I'll do it eventually but it won't be as good as the one Tom Ellifritt made -

Is the Chevy C60 Cab available any where?

robertburns replied to R.J's topic in Truck Aftermarket / Resin / 3D Printed

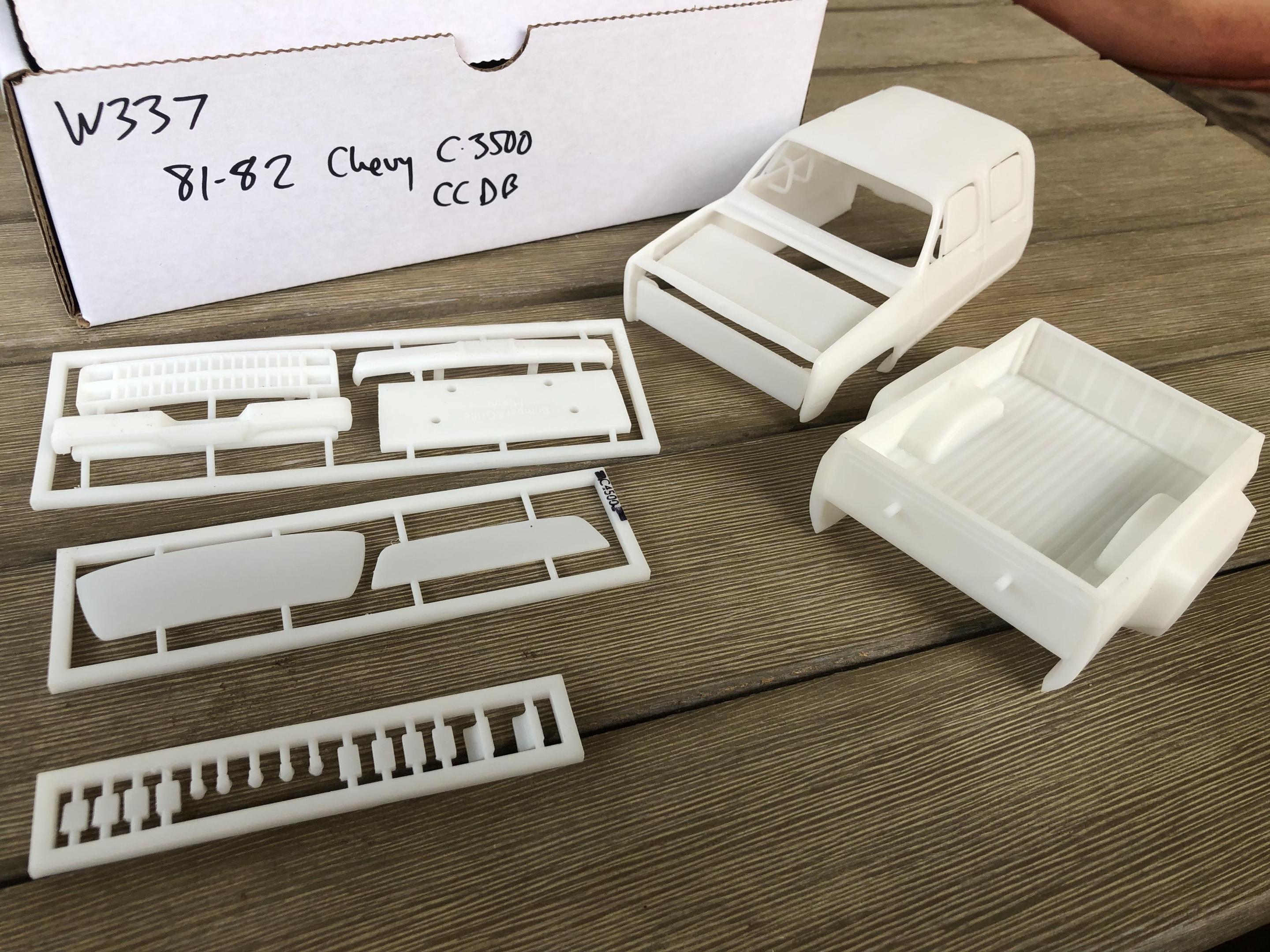

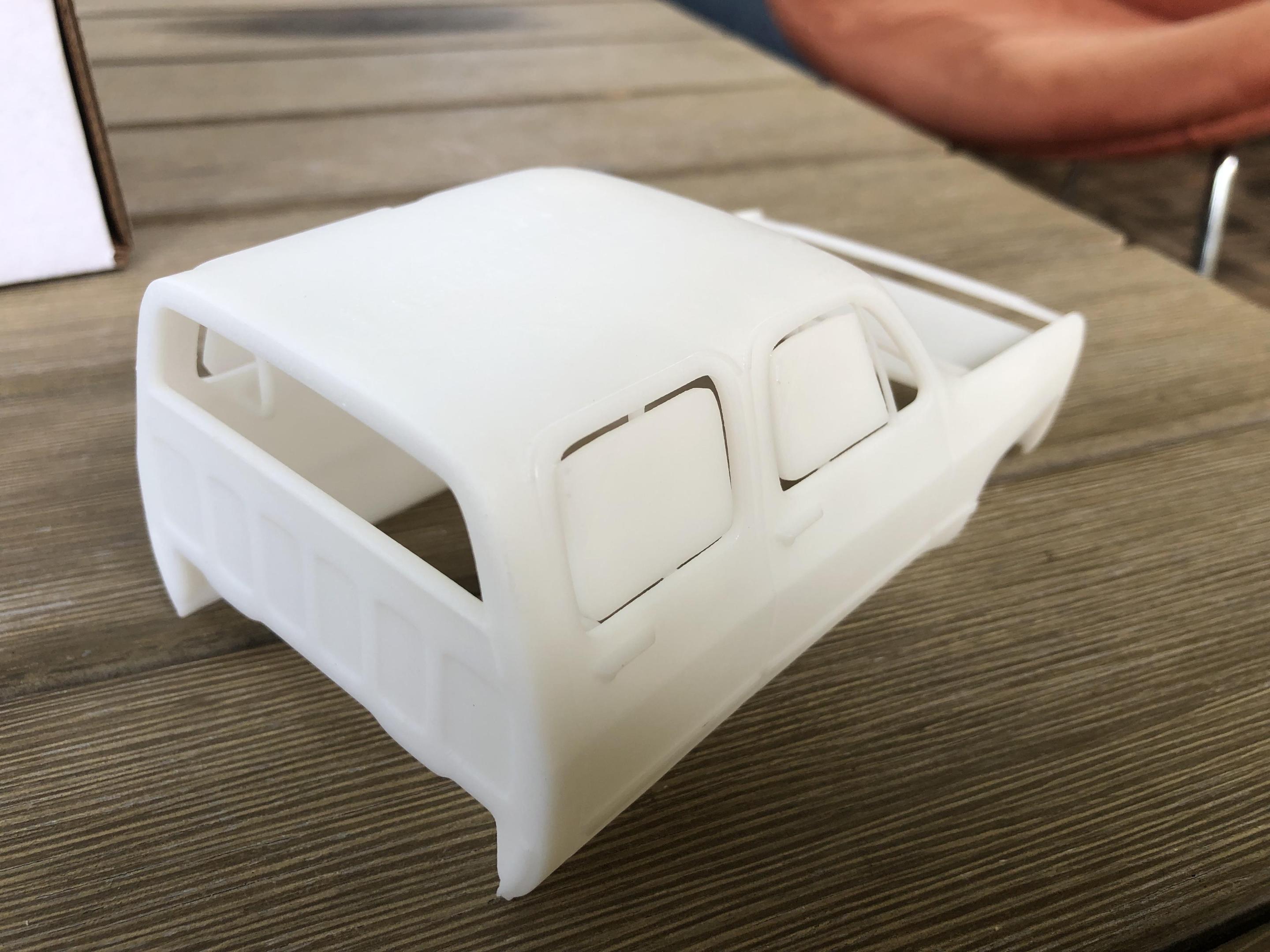

Yes crew cab and single cab. Try Too Many Projects on Facebook or email robertburnsjr101@yahoo.com -

I'll have one on ebay in a few weeks

-

1973-74 ? Pontiac Grand Am in resin ?

robertburns replied to davysmodels's topic in Car Aftermarket / Resin / 3D Printed

Please either check out Too Many Projects on FB or email at robertburnsjr101 @ yahoo.com Thank you -

Looking for a model of 1970 Riviera

robertburns replied to peteski's topic in Car Aftermarket / Resin / 3D Printed

Try Too Many Projects on Facebook Vido -

1973-74 ? Pontiac Grand Am in resin ?

robertburns replied to davysmodels's topic in Car Aftermarket / Resin / 3D Printed

No, sorry. Missing link does one already. I think I'll do the Sprint in the future though, along with the Apollo and the Omega -

I'll have a 68 and 69 Skylark coming by the end of the year

-

1973-74 ? Pontiac Grand Am in resin ?

robertburns replied to davysmodels's topic in Car Aftermarket / Resin / 3D Printed

If you're on FB, I'll open the order period on February 1st. The page is called Too Many Projects. Thank you - Robb -

1929 Model A Roadster ArtDeco/Coachbuilt/Streamliner -DONE!

robertburns replied to Impalow's topic in WIP: Model Cars

Agreed with all the above statements. This will be one of my favorite builds to watch this year -

That's a cool kit! I hear ya. I added time for stuffing boxes but did not add time for creating masters. In this case, the master pattern cost was repaid in the first run. This is the second run but the master was modified, which was listed. I'll be adding master pattern cost in the next two project posts. Included would be research, correspondence with vendors, etc. One was 3D printed and the other modified from a kit. I'd really like to get more of your input (and other casters here) because my costs (and ways of adding them up ?)will be different from yours.

-

Thank you. Yes, my rates are low in the model car world. It's based in what I think I can get for the kits. In the Sci Fi genre, I'm able to go a lot higher. I've sold small kits for $400 and large kits for $1250 so it all equals out. If I only did car stuff, it probably wouldn't work out, but the Sci Fi parts make it worth it It's all good. I get my fill serving the communities I love by making cool stuff.

-

thank you. But I still don't know how I would know how I made a profit if I didn't quantify my hours spent making one kit. Also, what if I trade it to other resin casters (I've done it in the past) What if I spent 100 hours making it? can you you please give me an example using my numbers in the previous page?

-

thank you Pete and yes that's a good point. You're right that time is undervalued. I look at it this way: My hourly rate at work is slightly above this rate and I do almost the same thing (but without the project management part of it) I don't do this as my primary income, and don't wish to. If I did, I would have to charge more, but do to car modelers buying habits, I would sell less and have to make more range of smaller kits to compensate. $50 per hour would make it out of reach for most people. I do it in my leisure and is my part of the hobby Artists rates, as you said, are almost always undervalued. I accept this as a fact to deal with. I see it as good practice to learn business and project management skills. For me that's a cheaper education. Your post brings up a great point for others others wanting to get into resin casting. Ask yourself Why you want to do this: Learn, make a living, have satisfaction, have a hobby, or a little of each? Knowing these questions and answers will help determine your experience

-

Good question. In my case, my work has a molding and casting department where I'm allowed to work off the clock. As long as I bring my own resin and silicone, I'm allowed to use the equipment and small consumable supplies as a perk of the job. Really good deal as this process uses a lot of those. Thank you for the question

-

Is it scaled up equally or is the center the same as the one you have with a larger rim?

-

Now that the costs are out of the way, I'll share the benefits: Making someone happy with a one of a kind model Taking pride in making a kit Knowing someone will build and display my work Having fun while creating something out of nothing Making a new item available to the community Serving the community Learning about engineering and problem solving Learning about marketing and sales Keeping my hands on skills sharp Donating to a good cause. The next case study will be a regular sized car model, so the expenses will be more in line with average resin kit makers. Thank you for reading

-

Total invested - $1027.57 Resin $400 Silicone $367.57 Master Prep $260.00 Kit sells for $165.00 Costs $102.63 Master Prep $2.60 Silicone $10.74 Mold prep $4.80 Casting prep $1.20 Resin $13.55 ebay $16.50 Pay Pal $5.09 Shipping $16.65 Donation $16.50 Handling $15 Total cost to make $102.63 (profit is $62.37)

-

Misc expenses not listed above: Supplies & materials like latex gloves, resin tint, safety equipent, tools, boxes, shipping packaging, shipping tape $N/A Ebay fee $16.50 per kit Pay Pal fee $5.09 per kit Shipping $16.65 (included but I can charge for this if I need to) Donation to Doctors Without Borders $16.50 (optional through eBay) Handling (packaging, shipping, and time on eBay) 1 hour X $15 is $15 per kit pressure pot, vacuum chamber, maintanence, etc $N/A Master pattern research, blue printing, CAD model, 3D printing, scratch building, etc $N/A (paid with proceeds from previous run) Note: These numbers are based on selling at $165. I sometimes take a Best Offer, so some of these numbers may change)