-

Posts

38,189 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

Future of the hobby

Ace-Garageguy replied to GaryR's topic in General Automotive Talk (Trucks and Cars)

Perspective is everything. I, for one, have never viewed building models as "entertainment". I am, always was, and will be 'til the day I die, a hard-core gearhead. I build models because it's a logical extension of my passionate love for all things mechanical. I build CAR models mainly because the subjects I choose are cars I'd build full-scale if I had Bill Gates' money. As far as the expense goes, look at inflation, the relative buying power of the dollar, and the cost of living in general over the past 50 years. A model kit isn't really too terribly much more expensive relative to a gallon of gas or a quart of milk than one was when I was a kid with a seriously limited income. And last...there NEVER have been a huge number of people who build models WELL, or were willing to put in the hours full of frustration, re-dos, and just plain effort that it takes to master ANYTHING. Nothing new now, other than the fact that manual skills of any kind are going the way of the dodo bird, much to our peril. Thank the instant-gratification, everyone's-a'winner-for-nothing culture we've created for that. -

Some of Ed Erbecks photos, ie CrazyEd

Ace-Garageguy replied to aurfalien's topic in The Off-Topic Lounge

Nice link, Brian. I miss him too. -

Joint lines in motor

Ace-Garageguy replied to Super28's topic in Model Building Questions and Answers

I must live on a different planet. Just about every fairly recent tie rod I've ever seen (if you're talking about steering linkage) has been fabricated from seamless drawn tube (preferably) or welded tube, or fully-finished bar-stock (forged and rolled or ground). Occasionally you'll see an older tie-rod that's an obvious forging, but the tool lines are usually very minimal. Something like this is a forging, but it's also machined and finished afterwards, and exhibits almost no, if any, residual marks from the forging process. Below is a typical assembly, made up of internally threaded tube, and forged ends. Again, the ends will have been finish-machined, rolled and/or ground after forging, and will not have a pronounced line. Some of the tie-rod ends may exhibit a forge line though, as well as Pitman arms, steering arms, and idler arms. Same goes for stabilizer bars (if you mean "sway bars" or anti-roll bars). Round bar stock in most production applications, tubing in very high-performance or racing. Though the bar stock may be "forged", you never see a residual line from the forging dies.http://www.kdkforging.com/stabilizer_bars.php Late-model Corvette suspension control arms are aluminum forgings, starting with the C4, and similar designs appear on other makes as well. NOTE: Some offshore-produced "forged" replacement arms are actually cast, and have been known to produce disastrous results. I had a client bring me a set for his 2002 Dodge truck. I refused to install them. He got all huffy, saying I was trying to sell him my marked up parts. He "KNEW" all about parts and metals and his were "just as good". I showed him the door. 6 months later, one broke and totaled the truck. BOTTOM LINE TO EVERYONE: On your real vehicle, or if you're wanting to make your model parts look correct, do the research. Look at photos, and find out if parts are supposed to be cast or forged or fabricated or whatever. Or don't. -

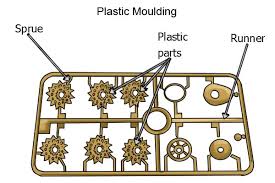

Spruce: Sprue: As far as painting small parts goes, there's always a side of the part that's not visible after assembly. Figure out what area that is. You can attach the part to a toothpick or piece of wire with a drop of superglue, or by drilling a small hole in the part. For painting something like a hood, a loop of real body-shop tape will leave no residue. If you use a cheaper tape that DOES leave a residue, a little 70% isopropyl alcohol will take it right off. I always have a bottle of 70% iso near the bench, because I ALWAYS wipe down my parts with it before primer and then again before paint...and I haven't had a fisheye since I started doing that in 2005.

-

How Old Are You

Ace-Garageguy replied to iamsuperdan's topic in General Automotive Talk (Trucks and Cars)

Or make change from a dollar without an app. -

The rapid expansion of the air as it goes through the nozzle may have two distinct condensation effects: 1) IF there's still water vapor in the compressed air, it may very well condense on the surface of what you're spraying, especially if the surface is cooler than the air coming out of the nozzle, with blushing as a possible result. 2) IF the air coming out of the nozzle is dry, there is STILL a pronounced cooling effect, and this can cause ambient water vapor (humidity in the air) to condense on the surface, with blushing as a possible result.

-

The issue isn't the compressor getting hot. Here's the science. Air gets hotter as it's compressed. Always. Basic. If there's water vapor in the air, called humidity, it gets compressed too. The air COOLS in the line going out of the compressor. Cooler air can't hold as much water vapor as hotter air, so liquid water condenses in the line. Putting the trap as far as is practical from the compressor, so you're getting the cooler air, works best. Art is a little off the mark. The pressure is reduced and the air cools even MORE as it goes through the air-brush nozzle and expands. The cooling can be so great that liquid water will actually condense on the surface of what you're painting. ONE byproduct of this is commonly called "blushing" of sprayed lacquer.

-

The manual for my new (45 year-old) Unimat.

-

Future of the hobby

Ace-Garageguy replied to GaryR's topic in General Automotive Talk (Trucks and Cars)

1) "Kids" were never competent to build models. Not 50 years ago, or 40, or 10. Just look at the plethora of horrible glue-bombs available everywhere for confirmation. "Model" cars were initially aimed at teens and young adults; look at the ads and models from Revell in the mid-1950s, and articles in the REAL hot-rod mags for confirmation of that. And just as the model railroad hobby was not for "kids" initially, dumbing-down of the products, and marketing them as "toys" produced vastly more revenue for the manufacturers who went that way. Lots of sales, not a real high percentage of well-built models. 2) 60 or 50 or 40 years ago, kids learned from their peers about building models, or in my case, from my own FATHER. But the hobby was FAR from being a universal pastime even back then. Jocks and girls thought model-builders were the equivalent of today's bespectacled nerds, for the most part. 3) Yes, some young people today might very well become interested in building models IF they were exposed to the concept. But...they have to be exposed to it, and their peers aren't going to do it. 4) The majority of parents are too busy chasing the bucks to buy stuff to impress the neighbors to have real time to take with their kids. Parking a youngster in front of the TV or computer is NOT the kind of parenting that passes on values, manners, interests, a respect for knowledge, or much of anything worthwhile. 5) Anyone lamenting the impending demise of the hobby needs to DO SOMETHING to introduce young folks to it, rather than just whining incessantly that kids have no interest and short attention spans. The manual skills and reading comprehension, problem solving, and perseverance one learns from building models will come in handy in real-life for ANYONE who does it. 6) It is the responsibility of adults toTEACH kids. Adults who can't be bothered have no room to gripe if what they see in younger generations doesn't measure up to expectations. 7) And no matter how much effort you put into introducing your own children, or grand-kids, or nieces and nephews, or the Scout Club members to modeling, some of them just are NOT going to be interested. Different personalities have their interests triggered by different things...even brothers. My father's interest was primarily aviation, and my main interest was trains in the beginning. The old man kinda lost interest in me when I didn't immediately fall in love with planes, but the model bug was firmly planted...and as I've said probably dozens of times on this and other boards, I have model-building to thank for launching me into a world where people MAKE things, where imagination and overcoming difficulties are the currency that gives my life value, both personally and professionally. SHOW A KID SOMETHING NEW, and then get out of the way. -

Joint lines in motor

Ace-Garageguy replied to Super28's topic in Model Building Questions and Answers

Because all engineers are not created equal. The team working on Mr. Musk's self-landing rocket boosters is an order of magnitude better than the divide-by-25-challenged set working on model car tooling. -

Joint lines in motor

Ace-Garageguy replied to Super28's topic in Model Building Questions and Answers

For starters, I usually first remove the "alignment pins", because they're very often OUT of alignment. Then I "machine" the mating surfaces dead flat by doing a few passes over a sheet of 180 grit sandpaper adhered to a very flat surface. And THEN, I put the parts together with plenty of liquid cement, being VERY careful to insure the parts line up as well as possible, thus eliminating as much of the gaps as possible. Let it all dry HARD, overnight, and file what little there is left of misalignment down to nothing, finish with 400 grit paper, and primer. I almost NEVER have to use any fill doing it this way. -

Psychographic has the right idea. The FARTHER you can get the trap from the compressor, the better. In the real world, we run air through a heat-exchanger to cool it as much as possible before running it into the booth, where the big water trap lives, and we run disposable final traps on the guns, as 935k3 suggests as well.

-

Anyone buying Revell kits just in case?

Ace-Garageguy replied to slusher's topic in General Automotive Talk (Trucks and Cars)

I've bought a few that were on the list of must-haves anyway, but mostly when I've seen them for really good prices. The post-bankruptcy speculators bought out a few before I got to them, so I tend to move when I see something now, rather than waiting. My income is going to be taking a massive hit in a few months, so now's the time to stock up for the future. Yeah, like I really need more models. -

Future of the hobby

Ace-Garageguy replied to GaryR's topic in General Automotive Talk (Trucks and Cars)

Well, not in the beginning. I have early issues of Model Railroader from the late 1930s and virtually EVERYTHING was scratch-built. Kits and RTR (ready-to-run) equipment opened the hobby up to many less-skilled, and that's fine. Bit what I was actually responding to is the hand-wringing about suppliers and kit manufacturers going away. Even if they DO, the people who really want to build models will continue, just as they always have. This 7-inch long model dates from the 5th or 4th century BC. -

Casting black rubber like tires

Ace-Garageguy replied to Psychographic's topic in Model Building Questions and Answers

All the products listed in the link I provided are polyurethane. That means they'll have isocyanates as a component. Some people become "sensitized" to isocyanates and exhibit the reaction you had. The thing is, just about ALL casting "resins" you're going to use for model parts will be urethanes these days. The great majority of auto-body paints are too. It's just necessary to ALWAYS take proper safety and health precautions. ALSO: These Polytek products are 2-component goo that HAS to be mixed, and they are POURABLE. Most mix in a simple 1:1 ratio. They come in an array of hardnesses (most are measured on the Shore A scale). They are also compatible with a wide range of mold materials: PT Flex rubbers can be cast in PlatSil® silicone molds without any release agent and can be cast in polyurethane rubber molds, polyurethane plastic molds and latex molds with the proper release agent (e.g., Pol-Ease® 2300 Release Agent). -

She looks good. Hope you win. Like that radioactive logo, too.

-

Very convincing. I sure would like to find a real one like that.

-

It only took me 30 years.

Ace-Garageguy replied to caine440's topic in General Automotive Talk (Trucks and Cars)

Is that an actual manual gearbox? If so, you da man. -

How Old Are You

Ace-Garageguy replied to iamsuperdan's topic in General Automotive Talk (Trucks and Cars)

Too old to pick up a 24 year-old chick in Starbucks, but not too old to rent one. -

Casting black rubber like tires

Ace-Garageguy replied to Psychographic's topic in Model Building Questions and Answers

At one point in my career, I owned an engineering consulting company that worked with inventors, patent attorneys, and made presentation models for marketing and product development. During that time, I had the opportunity to work with a vast array of materials and procedures. It's been more than 20 years since I've done much of that kind of work, but THIS company's products and technical advice have always been outstanding. https://www.polytek.com/product-type/polyurethane-liquid-casting-rubbers -

Future of the hobby

Ace-Garageguy replied to GaryR's topic in General Automotive Talk (Trucks and Cars)

Maybe because they might learn something? In one of the shops I work with, when I started, all the young guys assumed I was a past-it old fart. After they saw, repeatedly, that I had skills NONE of THEM had, and that I could fix things without getting some WRONG half-baked "instructions" from "experts" on YouTube, I've become a pretty popular guy. They come to my area to see what I'm doing. They ask questions. They want my help to try things they've never done before. And almost EVERYTHING I learned of value in the past, I learned from people a LOT older than I was. -

Cool stuff.

-

Yeah, I've noticed some of the old bugginess has been creeping back in lately. Hmmmmm...

-

Future of the hobby

Ace-Garageguy replied to GaryR's topic in General Automotive Talk (Trucks and Cars)

Then there's this apparently much forgotten concept called "scratch-building". It's pretty radical, but it's where a person actually MAKES something with his hands, and no computer interface. Modelers who are highly motivated to have something that's not easily available have been doing it since the dim recesses of time, when the idea dawned on one of our progenitors that making a miniature copy of a real object might be fun. Even if all the current model companies go away, and a global EMP event wipes out computers everywhere, hands, eyes, and a functioning mind will suffice for people willing to expend the effort.