tbill

Members-

Posts

6,139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by tbill

-

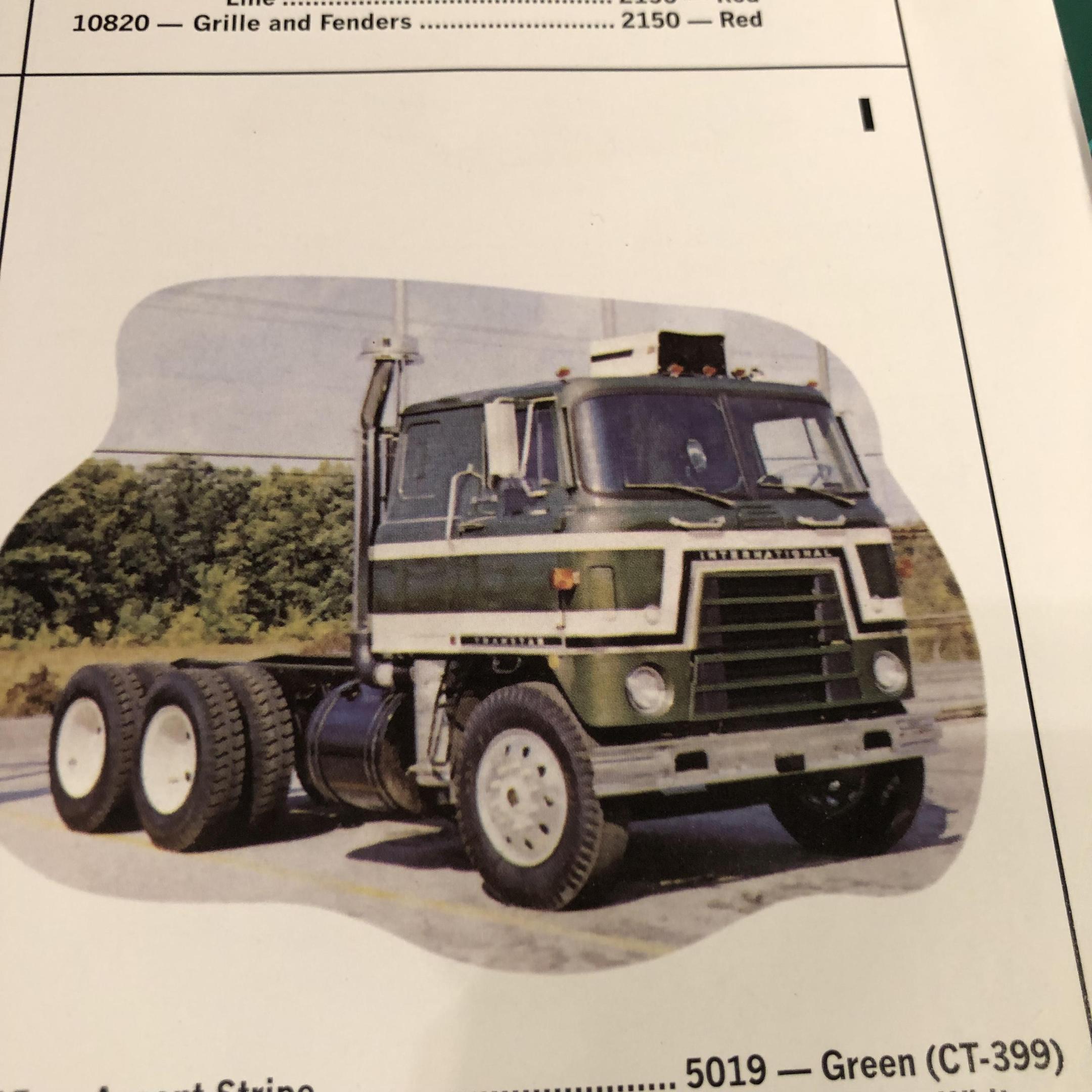

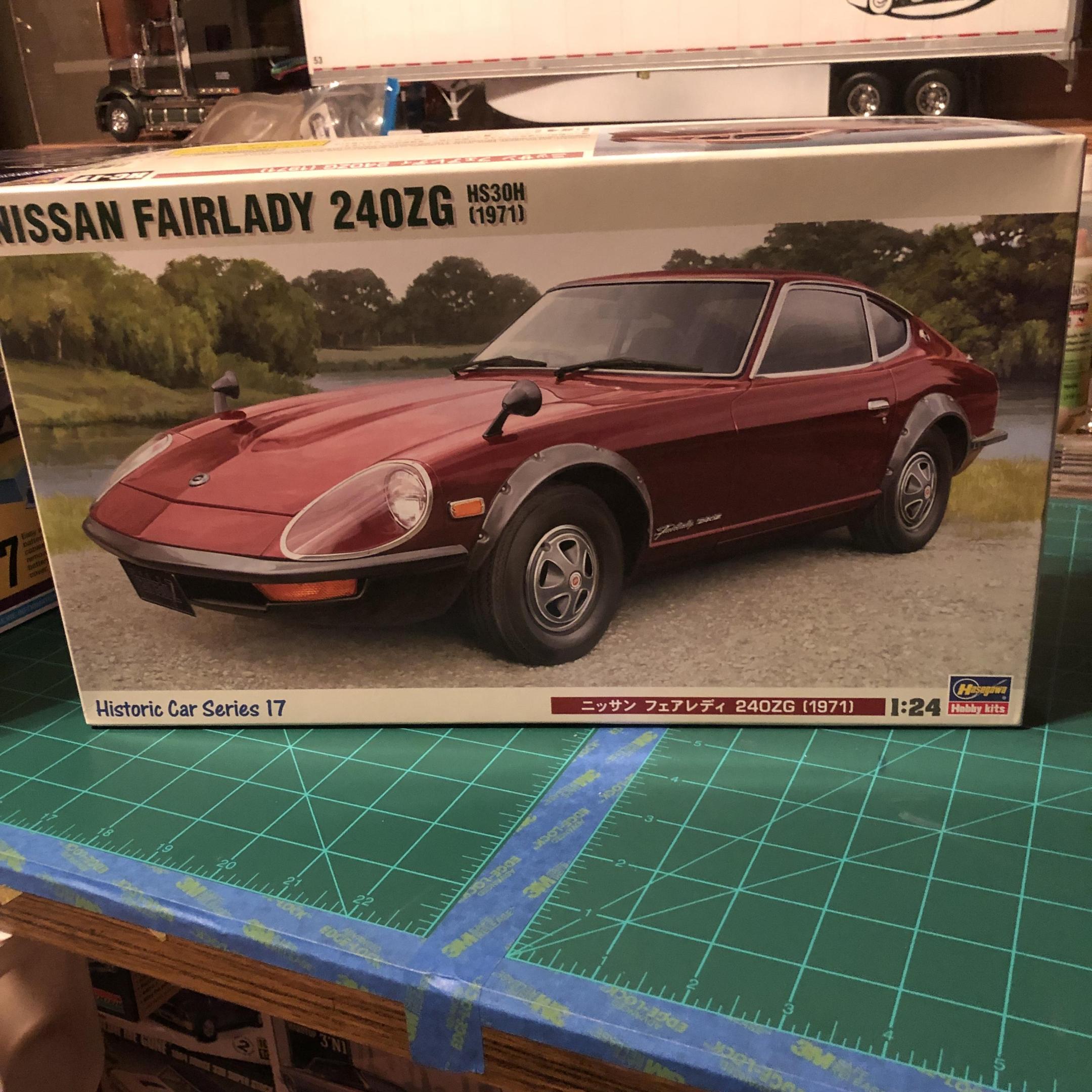

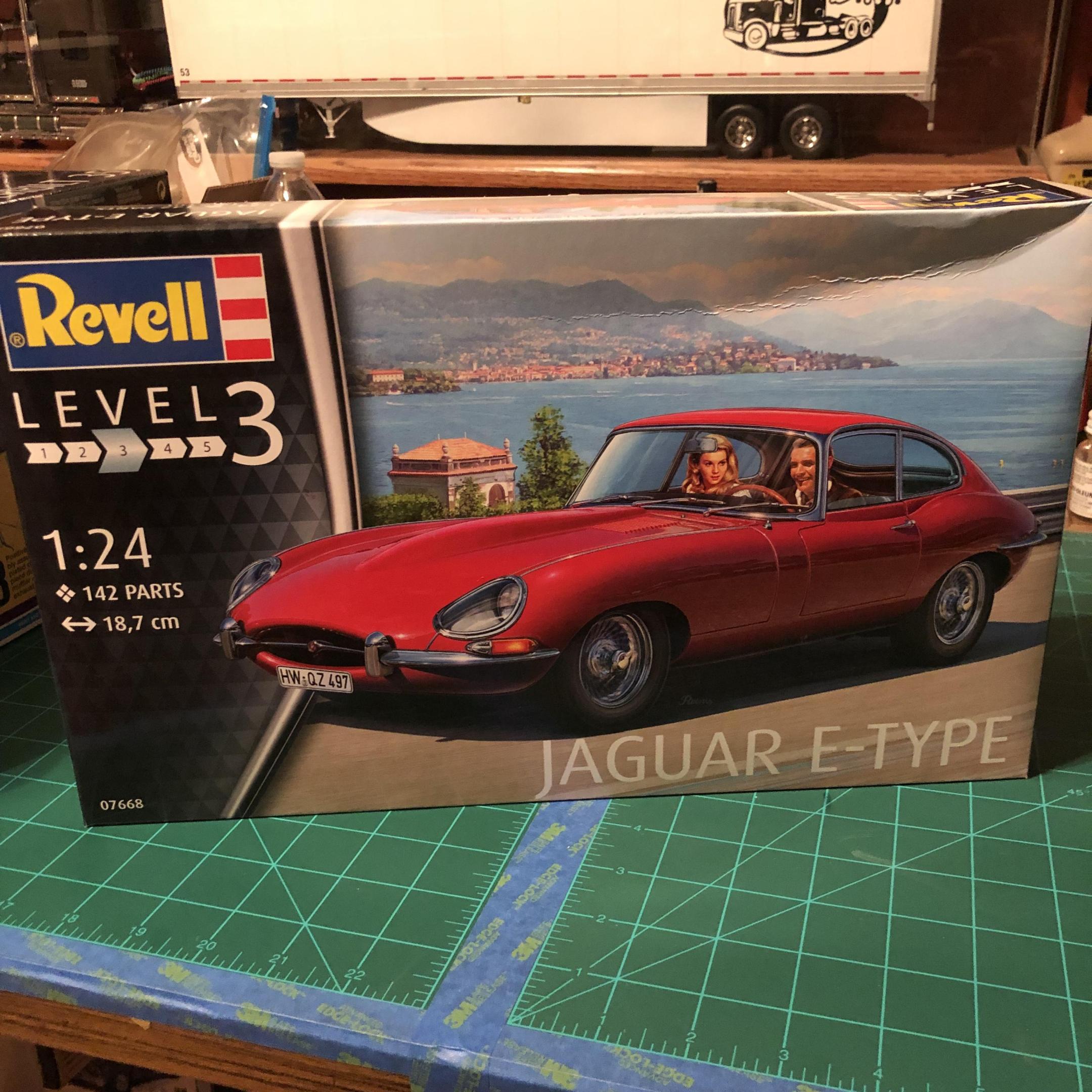

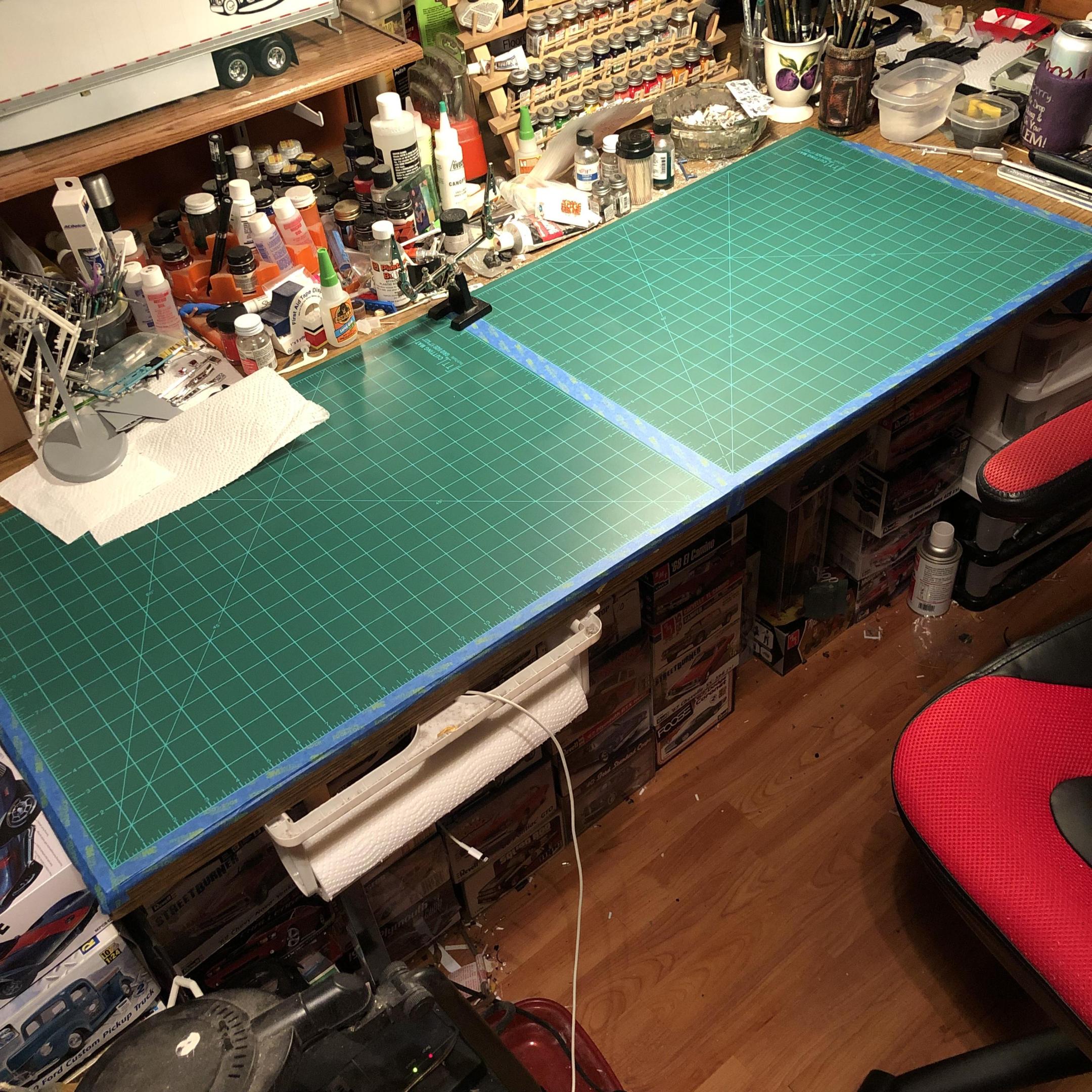

Since I managed to finish the Pete and flatbed, I was looking around the model hoard for another truck to build, and this one yelled out to me. So far I’ve got the cab paint scheme sorted out and started, and picked a trailer to put behind it, which I just got today, and happens to have some decals that I think will go great with the paint scheme of the truck.Should be a fun build, so stay tuned…..

-

Dan, you keep building at this rate, you’ll be out of kits in about 3 months! seriously, this looks to be another super ( bee) build?

-

- 39,135 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

White Freightliner Cabover

tbill replied to raisin27's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Great job on that cab, my CF build stalled for a couple of years cause I wasn’t happy with the cab…… -

- 39,135 replies

-

- 1

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

B.R.B.O 22. Pete 378/flatbed

tbill replied to tbill's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

B.R.B.O 22. Pete 378/flatbed

tbill replied to tbill's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

The Rockford files, lol -

Not sure how I missed this, but holy smokes , fantastic build!

-

B.R.B.O 22. Pete 378/flatbed

tbill replied to tbill's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

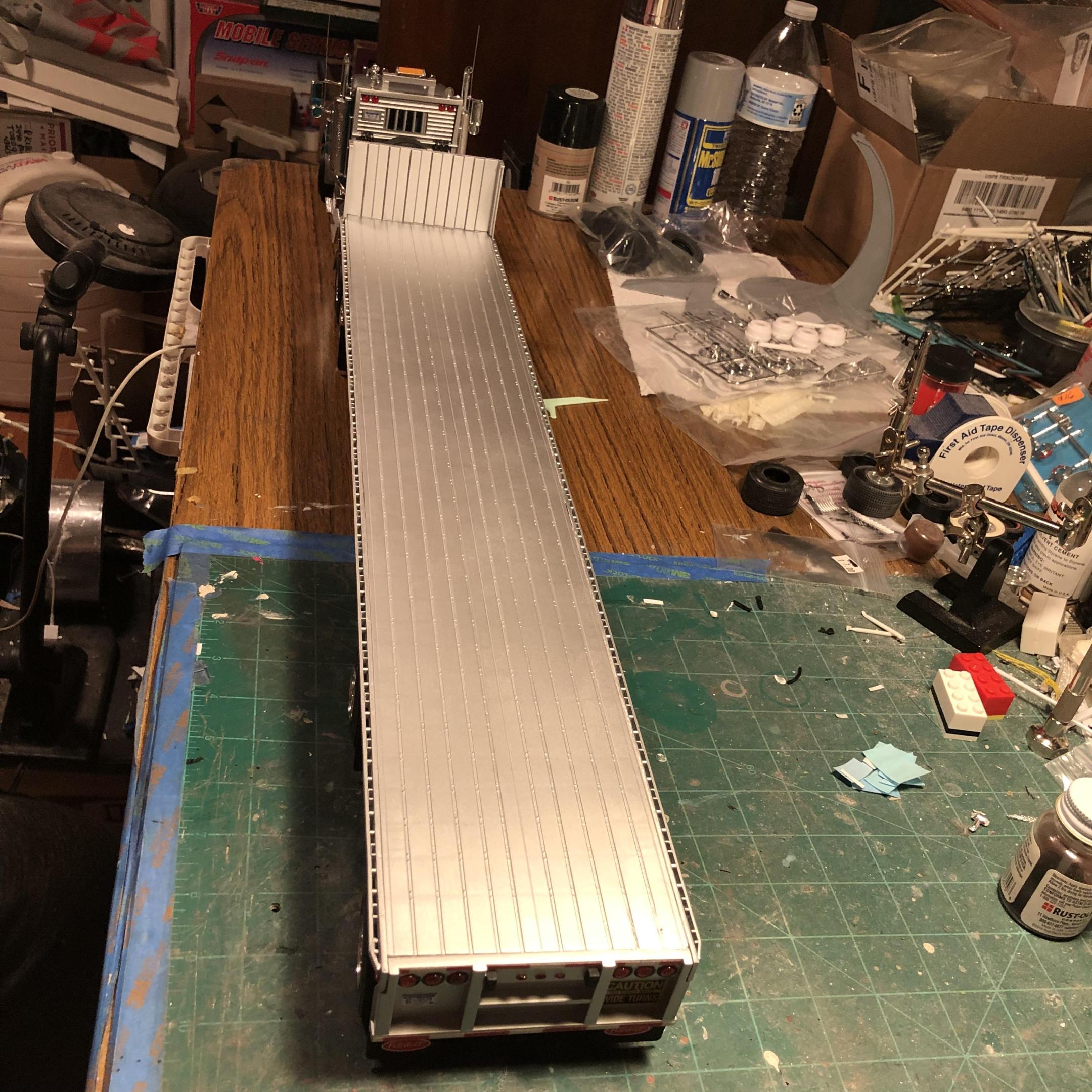

Thanks guys, trailer is up on wheels now, not much left to do, should be able to finish it up this weekend. It comes in just under 33 inches long…. -

B.R.B.O. 2022 CF Freightliner Pusher

tbill replied to DRIPTROIT 71's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Holy smokes that’s cool! -

B.R.B.O 22. Pete 378/flatbed

tbill replied to tbill's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks guys, appreciate the comments. Got more done on the trailer …..everything is in color, tomorrow should be assembly and some detail painting/decals. Should be able to wrap this project up this weekend? -

B.R.B.O 22. Pete 378/flatbed

tbill replied to tbill's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

BRBO Steveracer's Autocar Dump Build

tbill replied to steveracer's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Interior looks great, nice job! -

KrAZ-255B Bro wrecker truck

tbill replied to lwcolors's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That is cool! -

White Freightliner Cabover

tbill replied to raisin27's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Model truckin has the decals -

B.R.B.O 22. Pete 378/flatbed

tbill replied to tbill's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

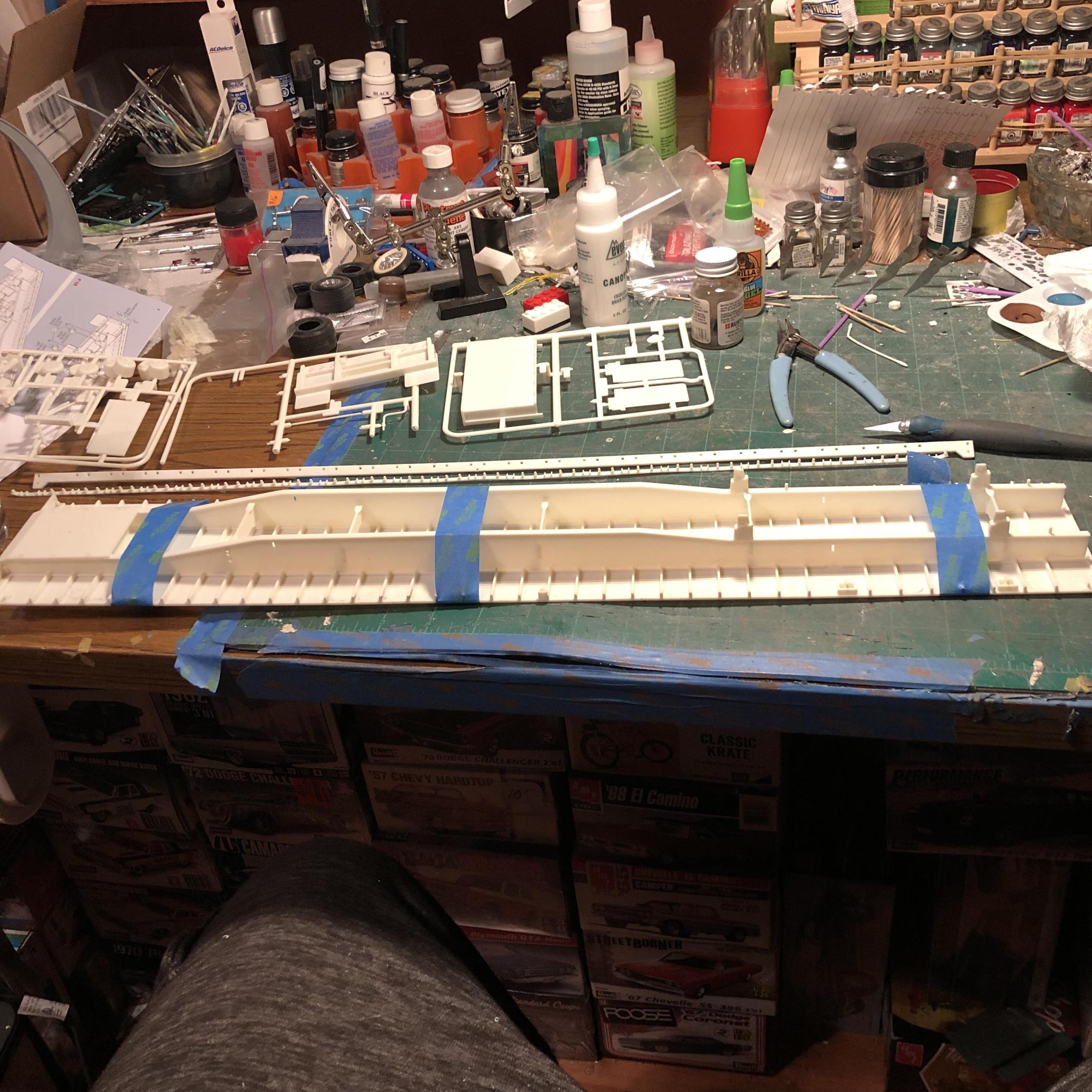

So far, it’s been pretty good, only issue I had was with one side piece and the corresponding rub rail.The two parts are together on their own sprue, the sprue was ‘tweaked’, but I got it sorted out without too much difficulty. -

B.R.B.O 22. Pete 378/flatbed

tbill replied to tbill's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

Paint peel: How to get rid of it?

tbill replied to conchan's topic in Model Building Questions and Answers

At a guess, you were too far away, and didn’t spray enough paint. If possible, wet sand what you’ve got to get it back to smooth , dry it off good with paper towels, and let it sit for a day ( unless you’re confident it’s completely dry), then take your spray can and spray ‘quick and close’, start to spray ahead of and beyond the body. Quick passes 3-4 inches away from the body. I do one side, do the other, once across the grill part of the body, once across the tail lamp area, then with a side to side motion, I trunk to roof to fender tops. Takes a few tries to get a good feel for it, but once you get the hang of it, you’ll get pretty smooth results ever time. Hope this helps. -

B.R.B.O 22. Pete 378/flatbed

tbill replied to tbill's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

Using Dupli-Color Engine Paint

tbill replied to Chevy II's topic in Model Building Questions and Answers

I’ve used tamiya primer, duplicolor primer and the no name black primer from lowes under the engine paint with no issues.