R. Thorne

Members-

Posts

787 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by R. Thorne

-

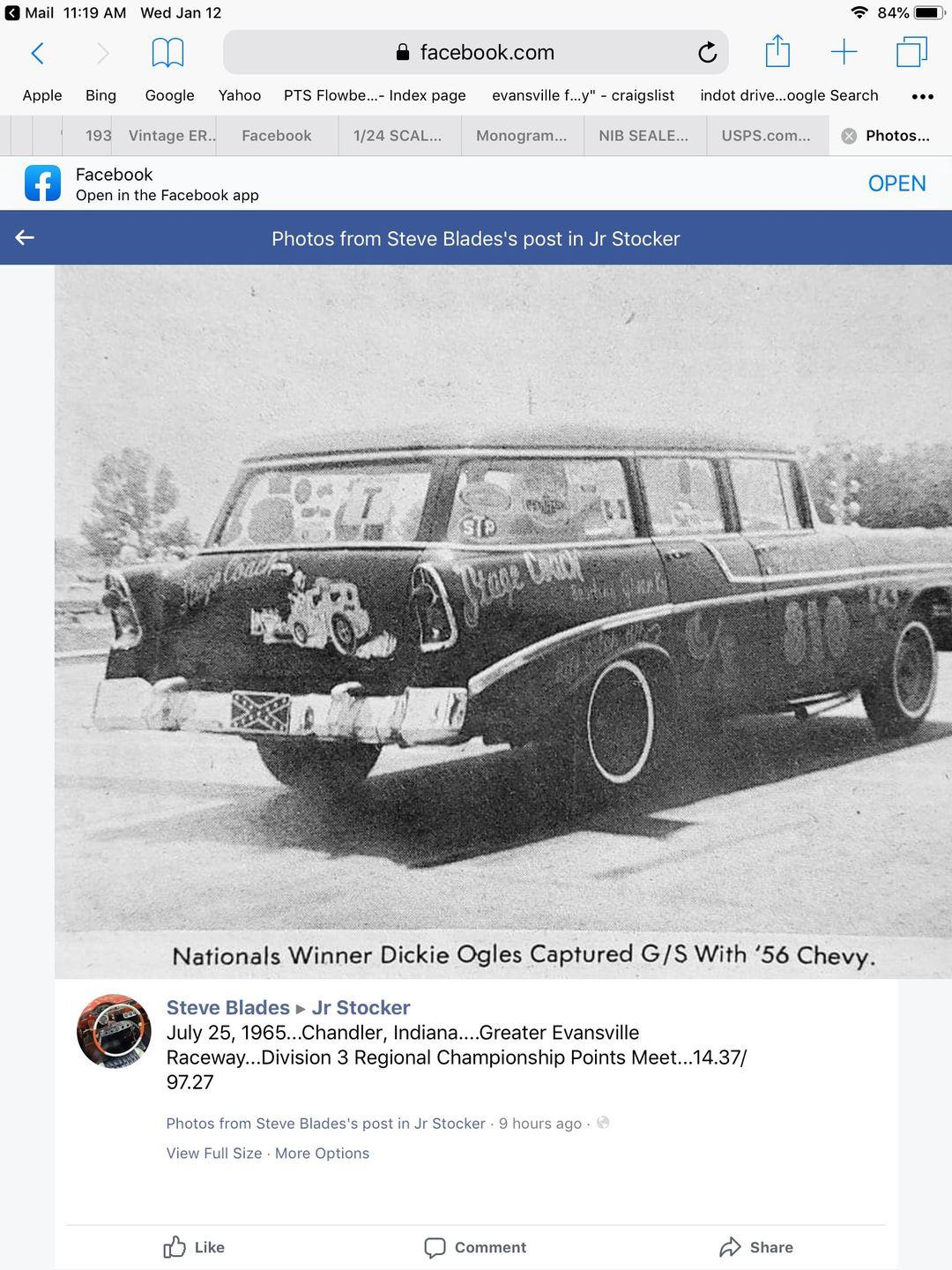

56 Chevy Junior Stocker circa 1960’s

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

-

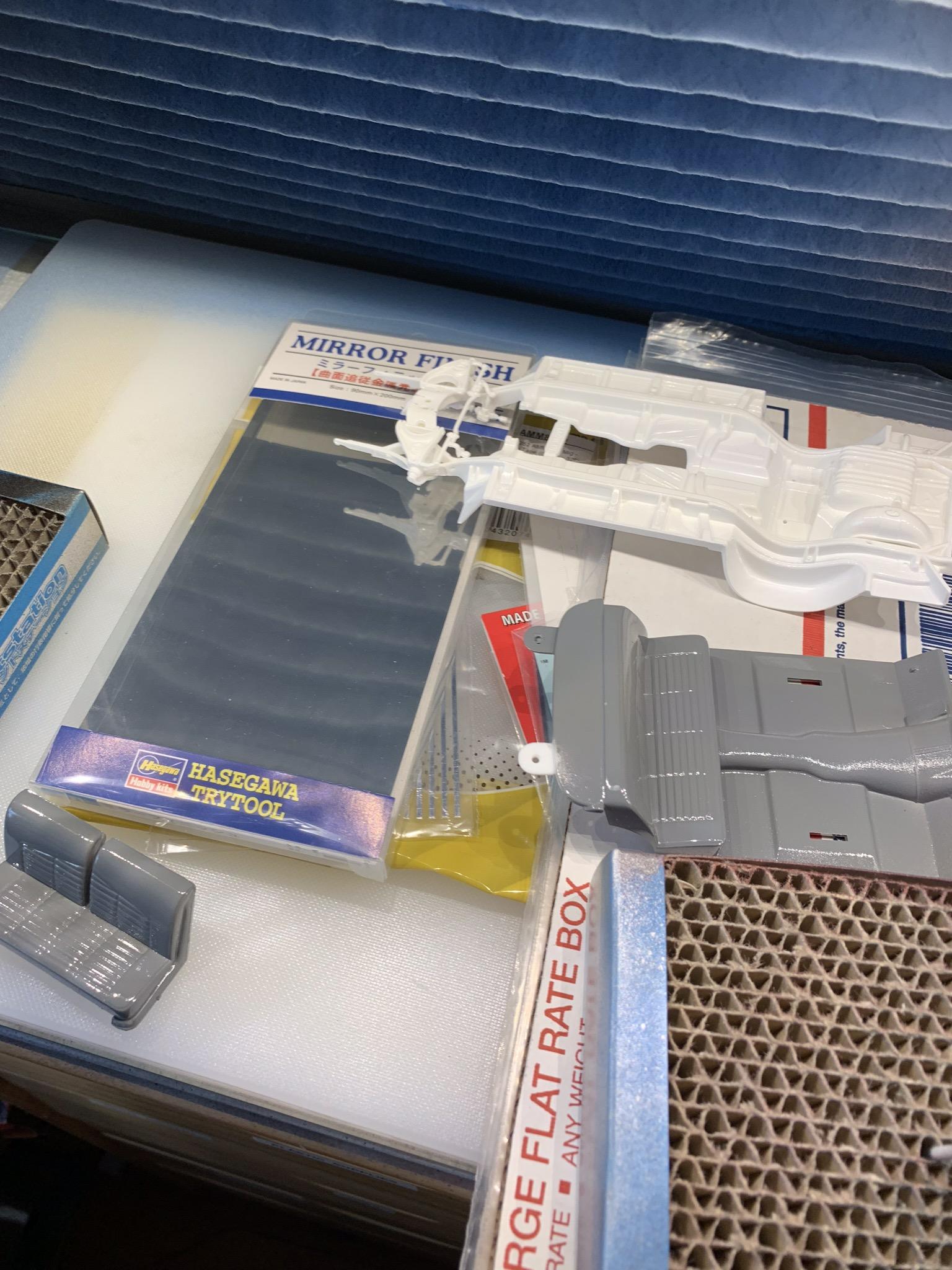

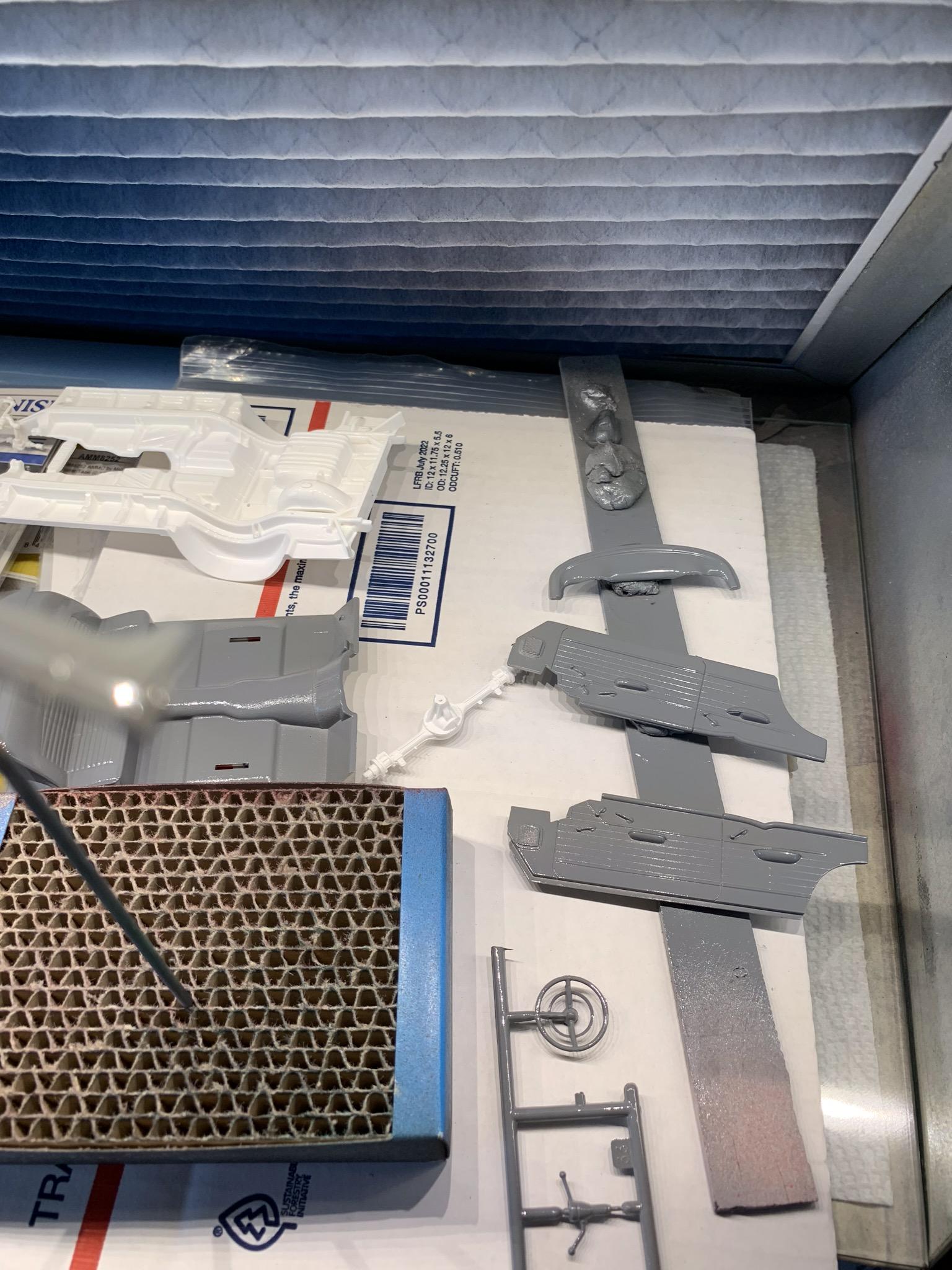

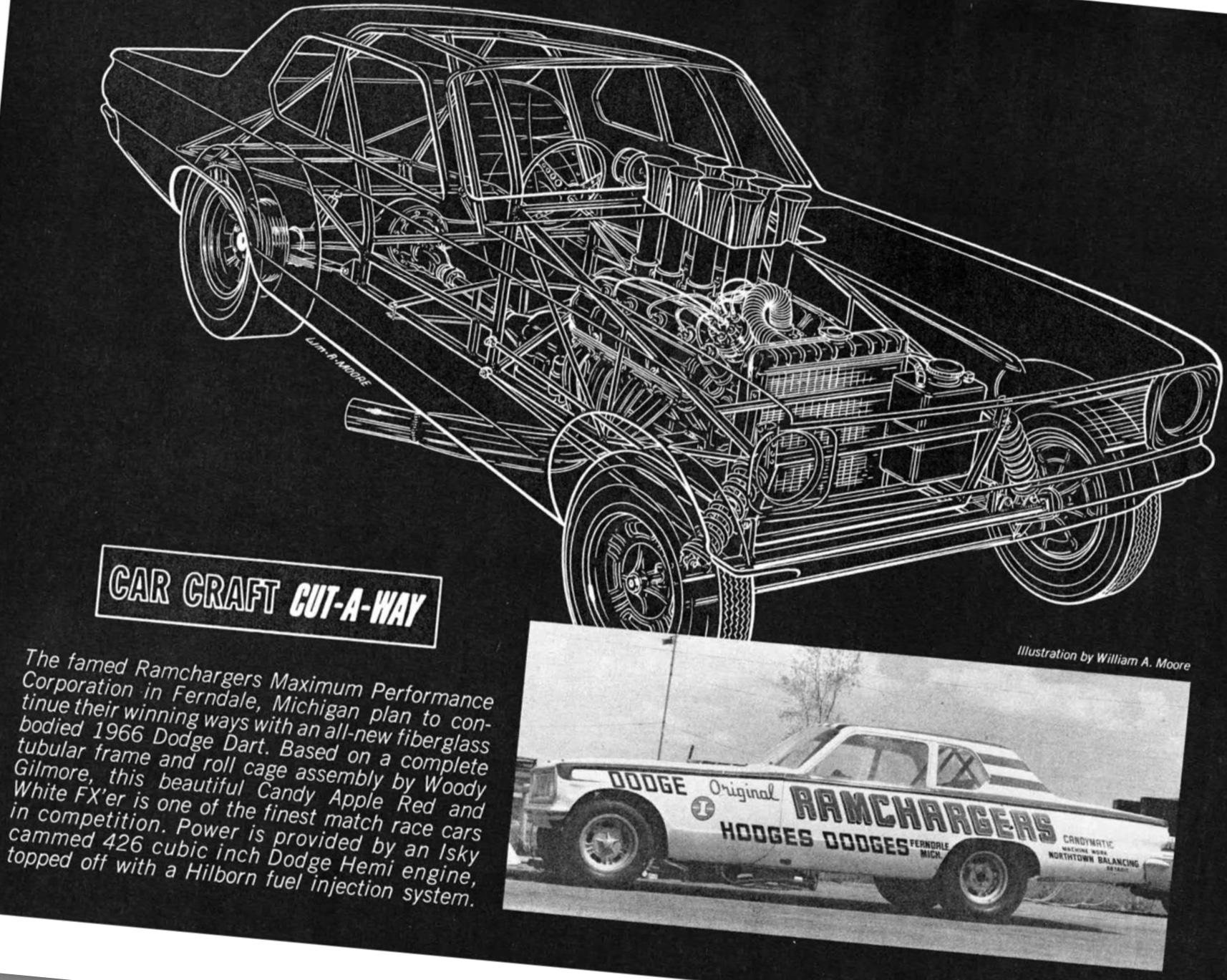

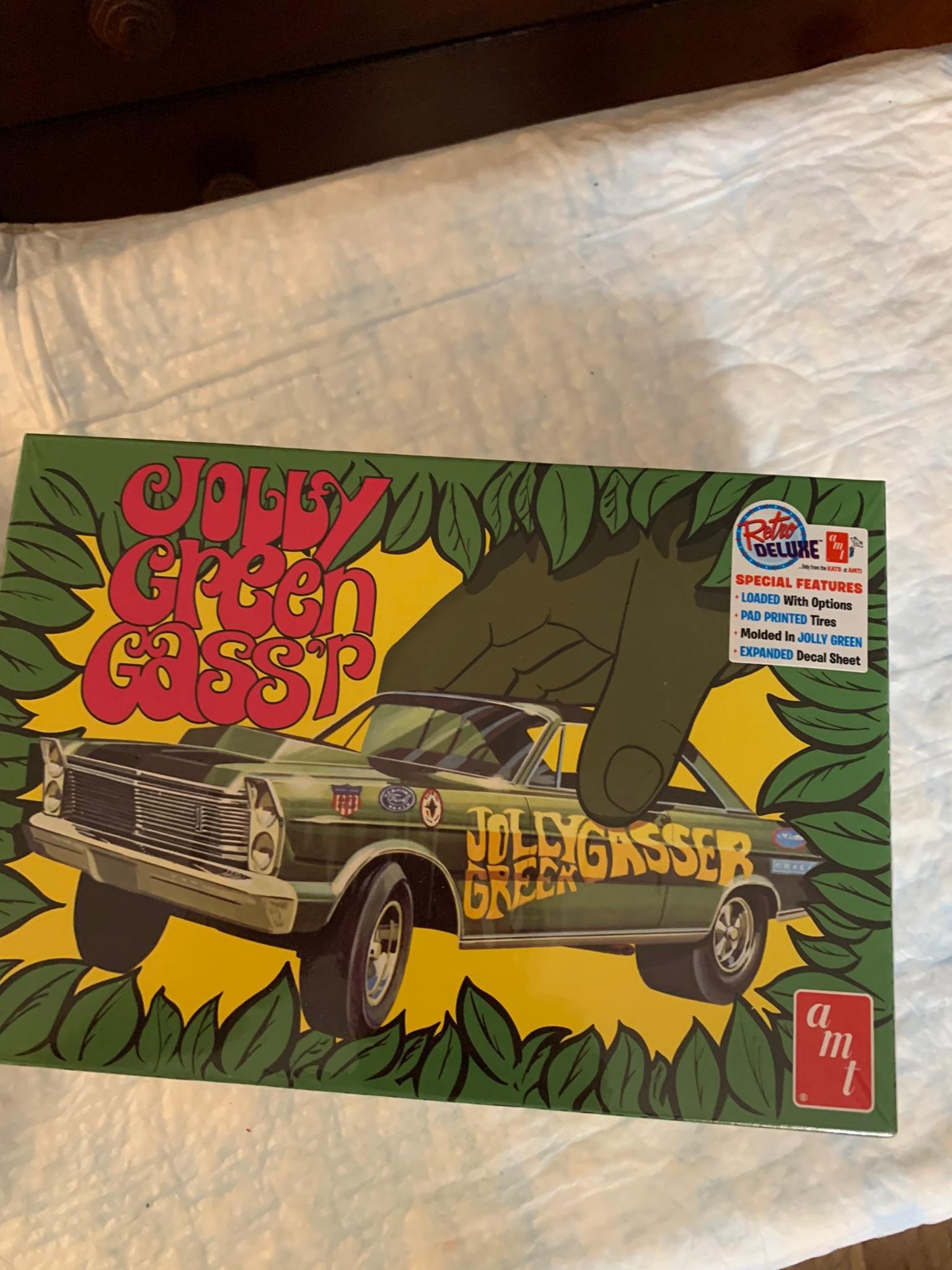

My third build on here at the same time. Seems like I am always held up by parts or tools. Well, anyway, I wanted to build a replica of Bruce Wilkinson’s station wagon (one of the guys I ran against in those days), but since there is no practical way of obtaining a wagon, I decided to build something like Buddy Ingersol ran, but with a Wilkinson type of paint job. Clear as mud, huh? This is the kit and some assembly pics. Got the interior painted Rustoleum grey and the chassis painted Tamiya pure white. Some more pics later.

-

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

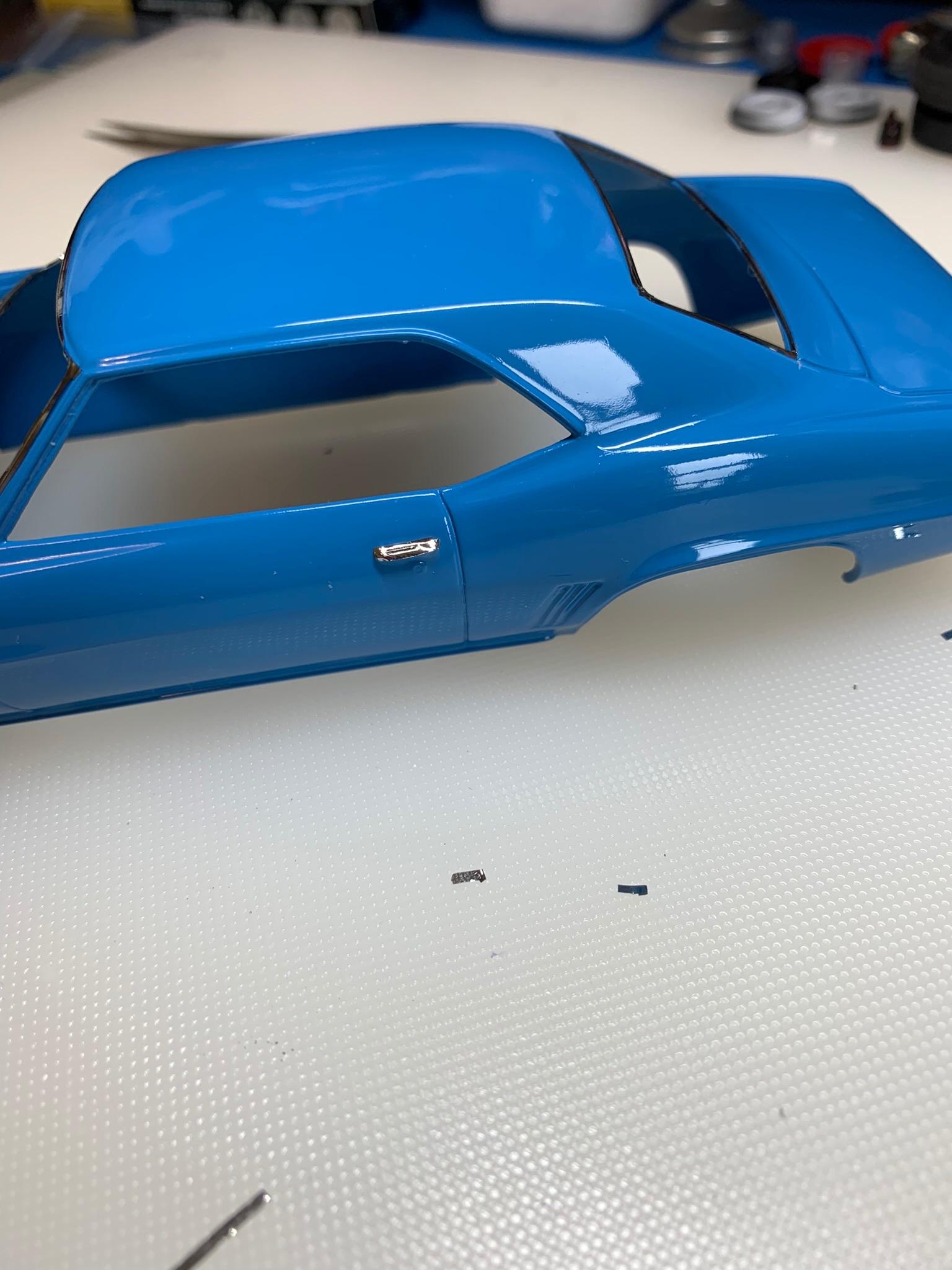

Stuck some chrome on the door handles with scrap pieces. Looks like I am gonna be held up on this build for a few days. Had to order some class designation letters and numbers. I will work on the 57 Chevy C/MP or start a new build on a 56 Chevy jr. stocker. -

Gluing in Acetate Windows

R. Thorne replied to DoctorLarry's topic in Model Building Questions and Answers

-

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

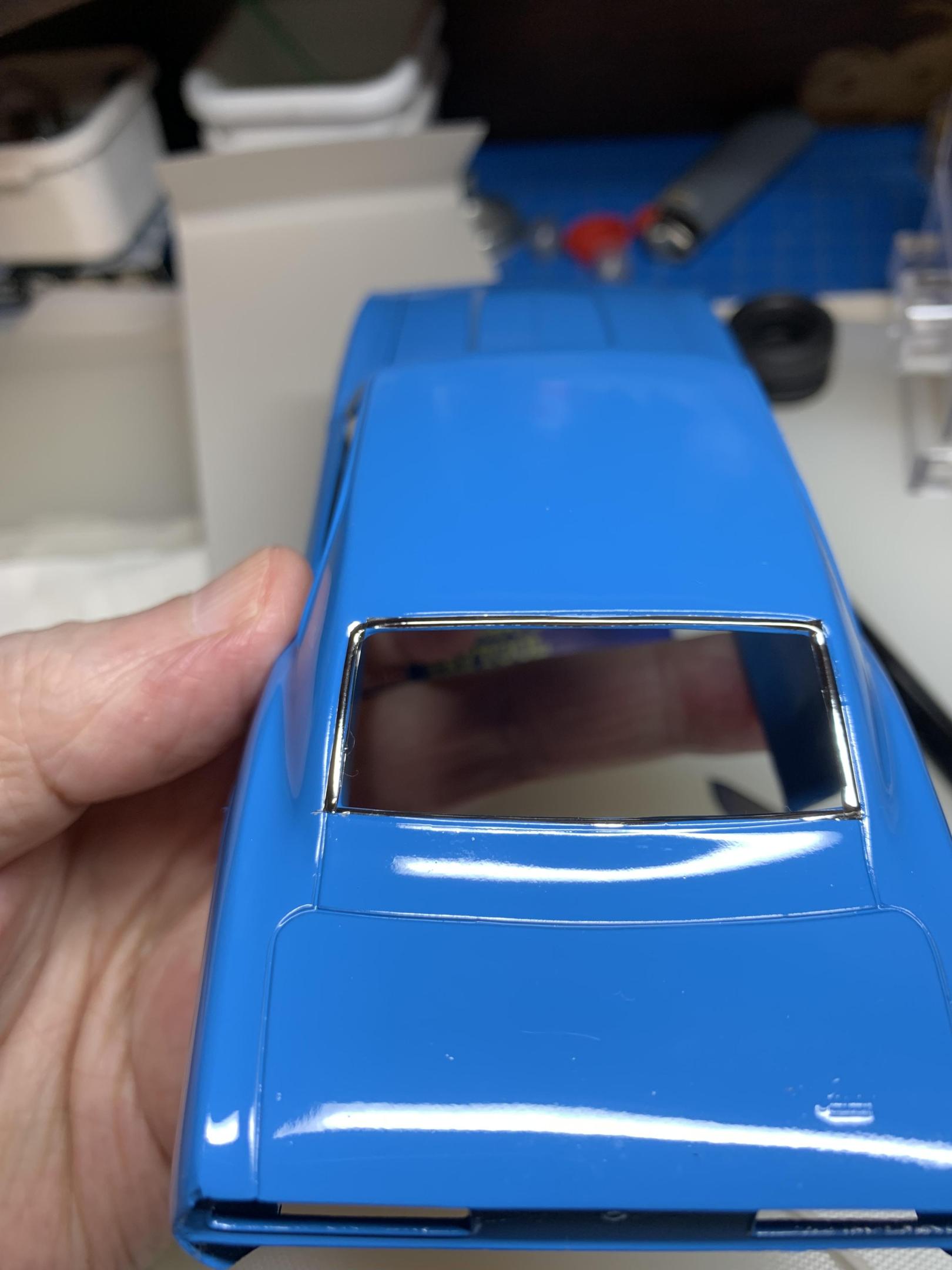

Well, another day, another error. Forgot to sand off the wiper blades, as very few stockers keep them on. A few more strips of Hasegawa chrome and they will have to do. Windshield chrome looks ok. The stuff is harder to cut than bmf,but, luckily, there is very little trimming to do with the narrow strips I use. Now, on to making some side windows, installing windshields, and making some class numbers and letters. There is a 25 watt bulb at the end of this tunnel. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

Thanks, Tony. As I have mentioned before, I am a ceaseless experimenter. It is time for the “chrome” trim. My second time using the Hasagawa stuff. My first time with the short scalpel with the curved blade. I also use the 1 mm double hobby knife blade and cut out narrow strips as opposed to trimming on the car. A couple of pictures that, hopefully, will allow you to see the results. I like it, myself. Relatively easy to apply this way, little buffing, definitely less wrinkly than bmf, and shiny. Took some pics of the car before I started to give you some idea of what it looks like before. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

-

How do you prep your glue surfaces???

R. Thorne replied to Vinny G's topic in Model Building Questions and Answers

I used to scrape the paint off with various devices but, now I just use ca glue in thin, medium, or thick, to vary the drying time. If strength is a major factor (seldom for me), then scraping and model cement is the answer. -

-

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

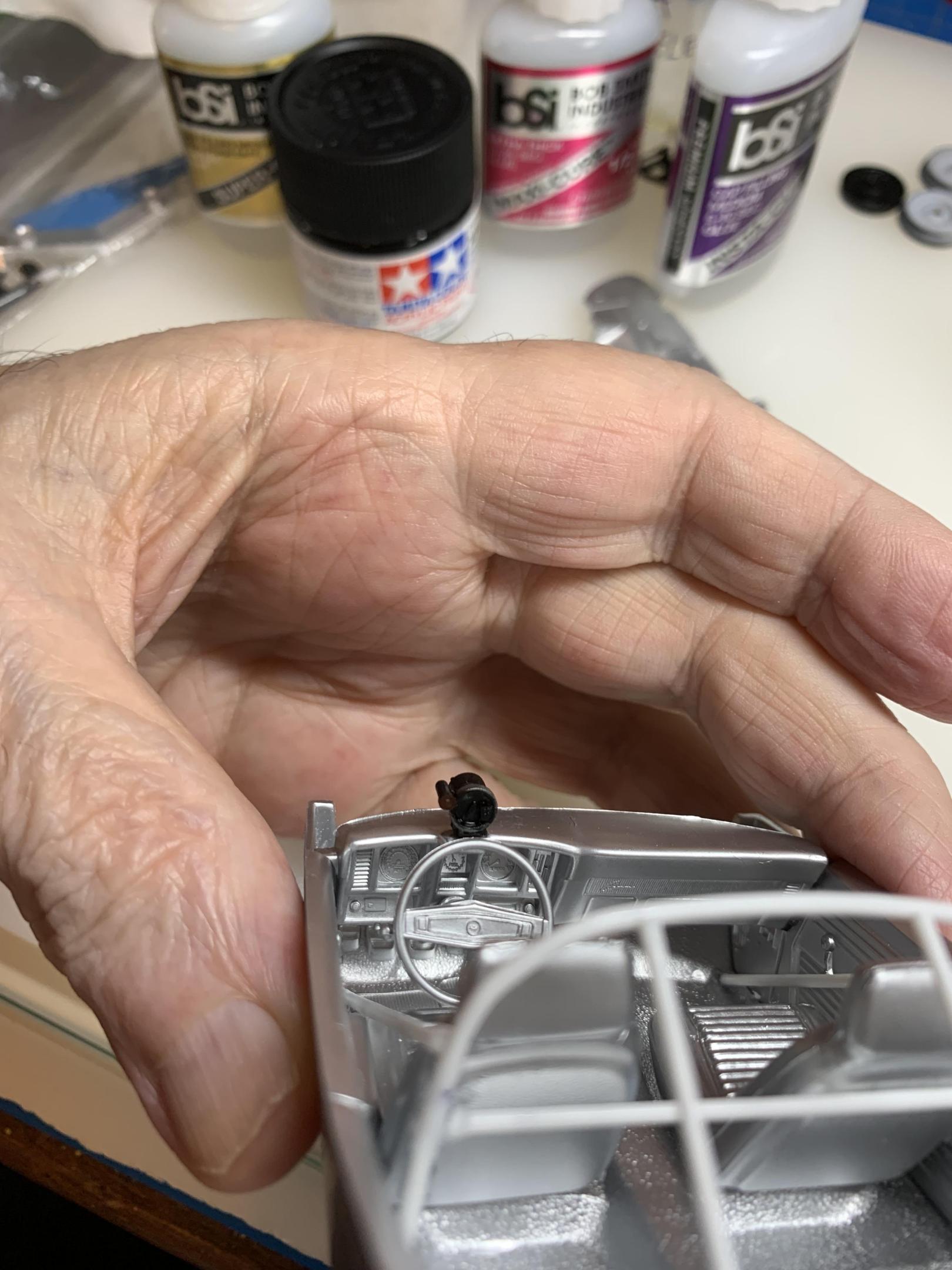

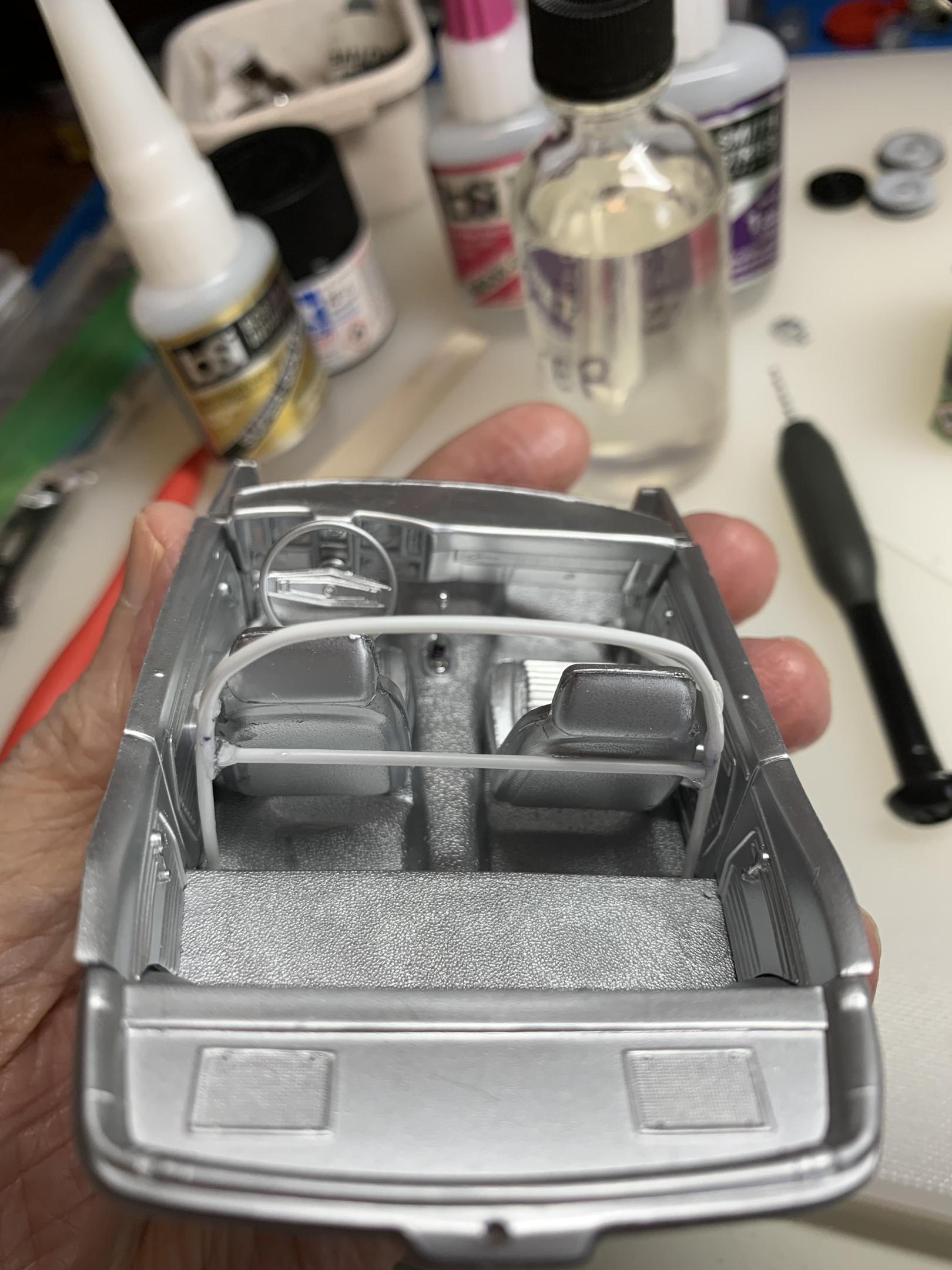

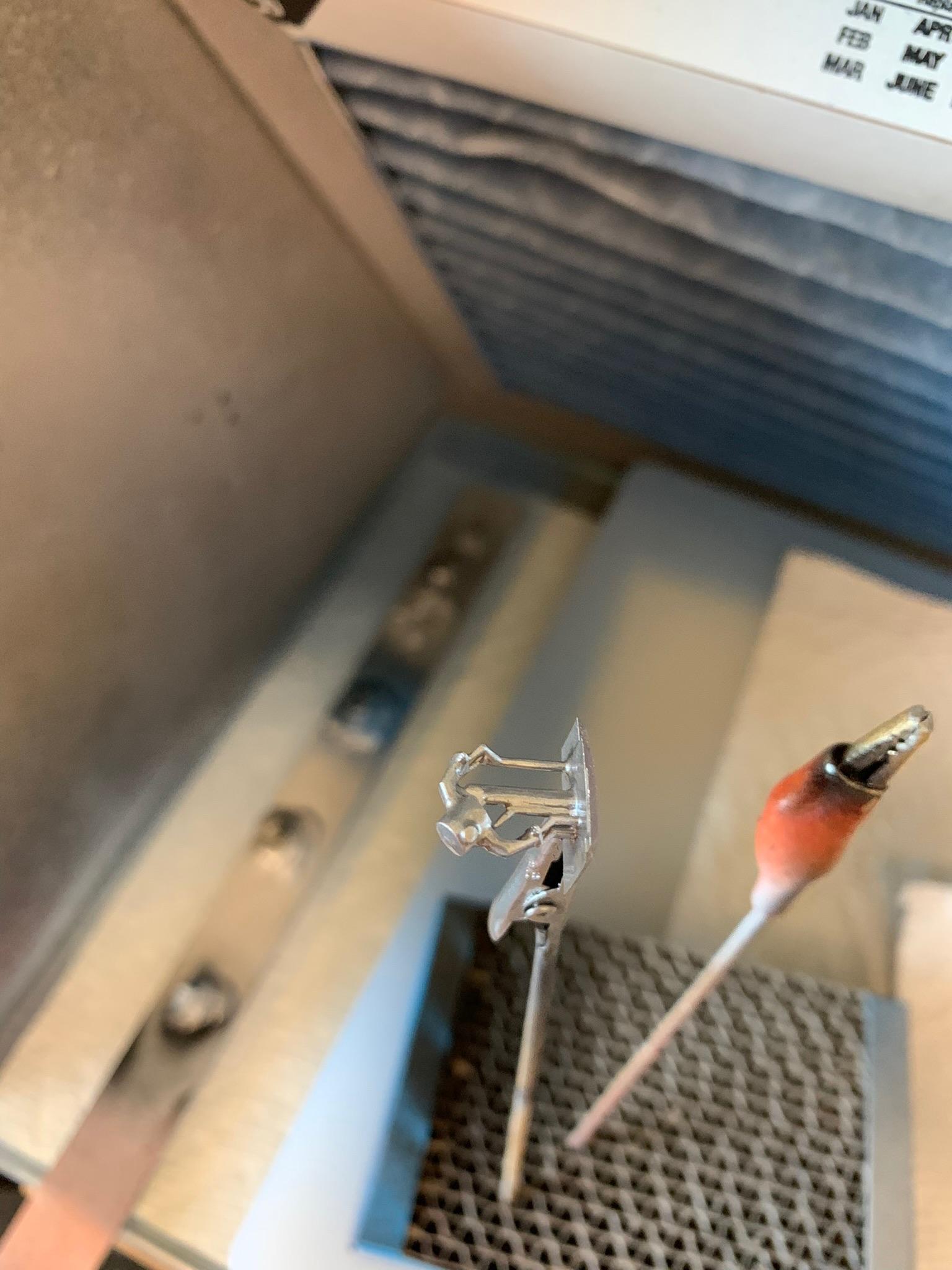

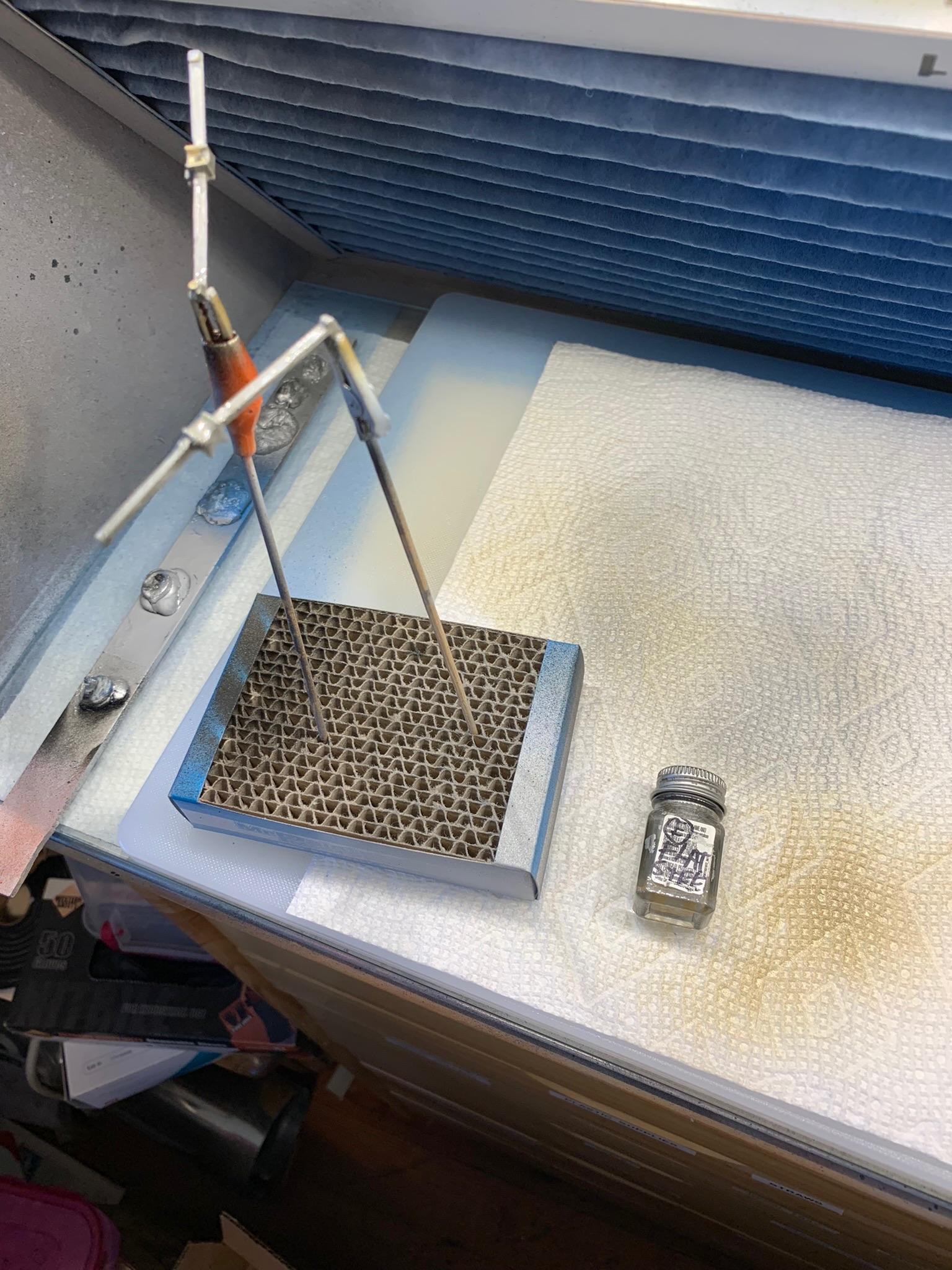

Cobbled (and I do mean cobbled) together a 6 point bar with some super glue resulting in the ugliest “welds” I have done on a model. The super glue was not cooperating, so some kicker was used, also, and my shaky hands didn’t help, either. Every model is an experiment for me. Sometimes you learn what doesn’t work. This model has gone on too long and my impatience is showing. Though tempting, I try not to hide my errors. -

Obviously dedicated to accuracy. What Super Tricks and front tires are you planning to use? 1/16” styrene rod for the six point bar? Putting one in my Camaro stocker today. I make the main bar way too tall, then install the interior tub temporarily, and it finds its correct height as the holes in the floor board allow the bar to slide down. Keep up the good work.

-

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

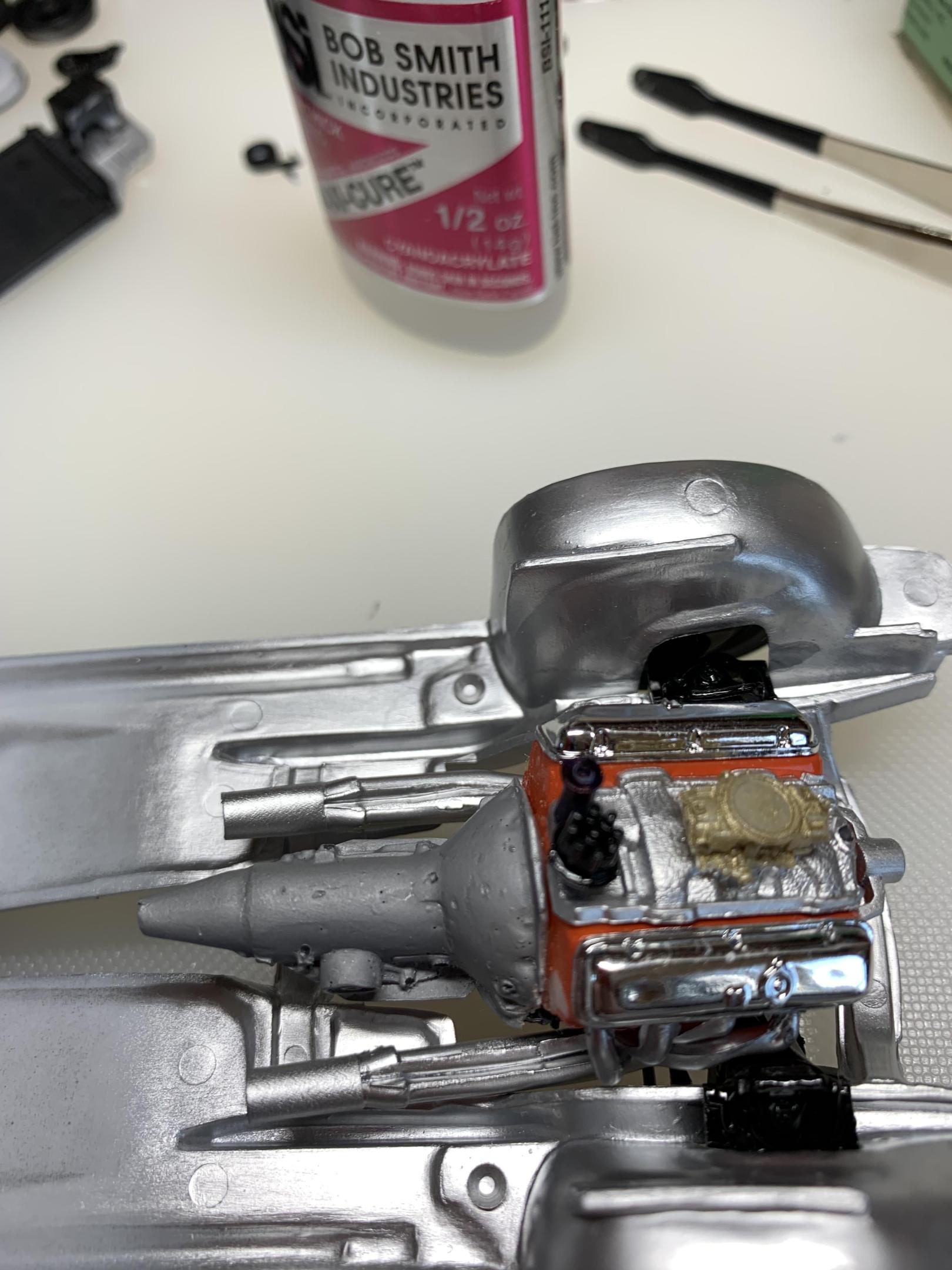

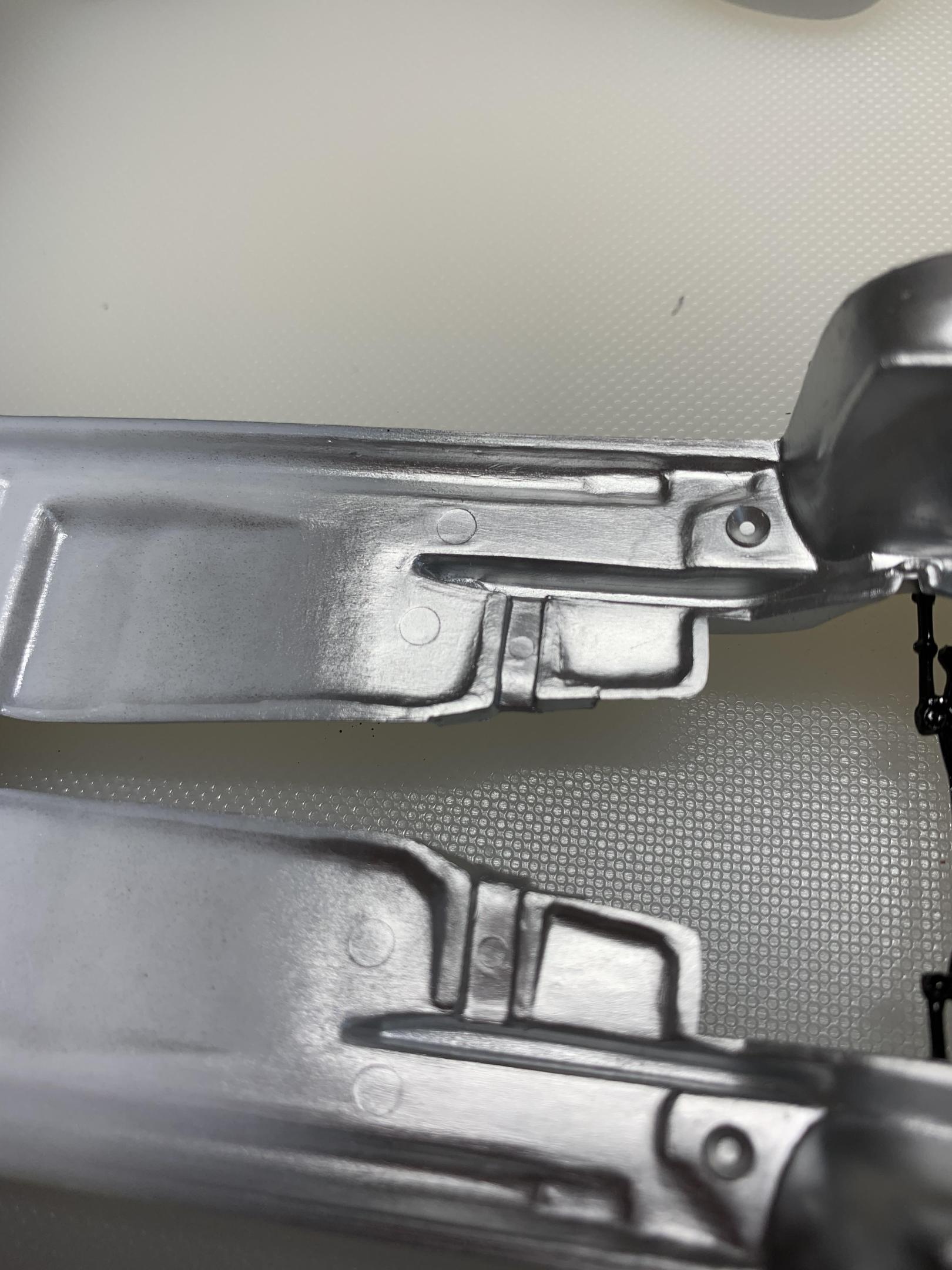

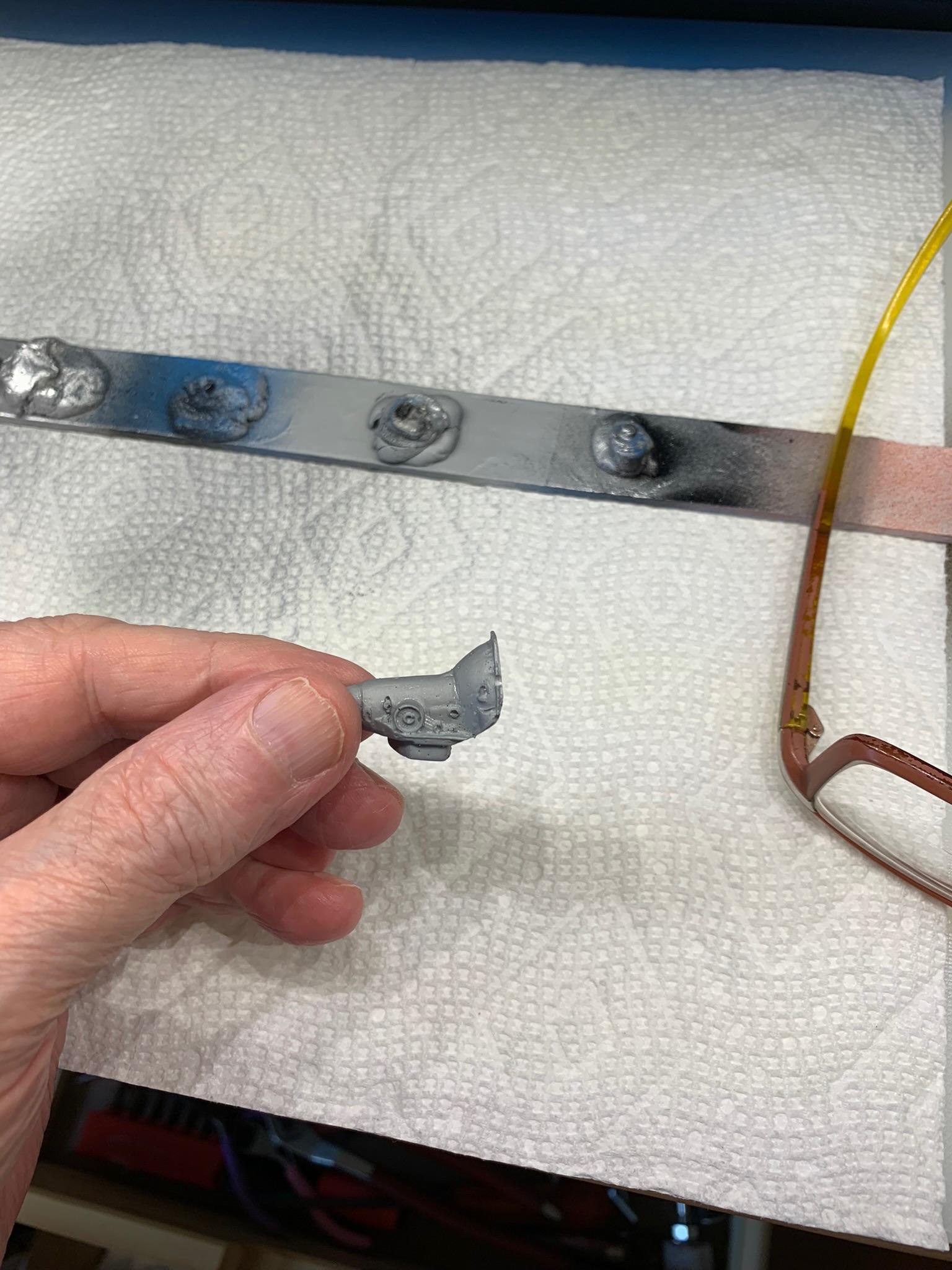

Installed radiator support and hose, then worked on firewall removing heater box and master cylinder backing. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

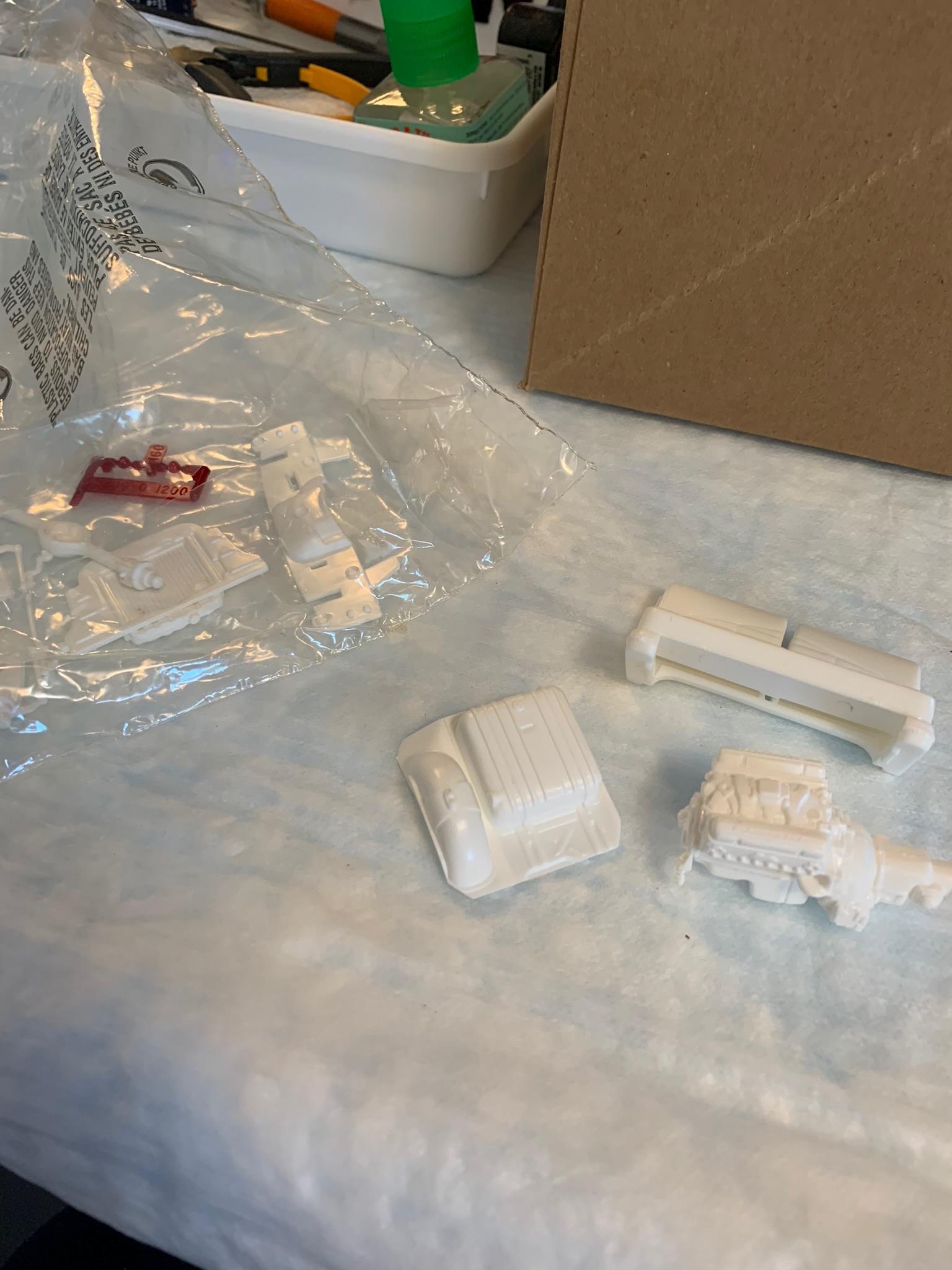

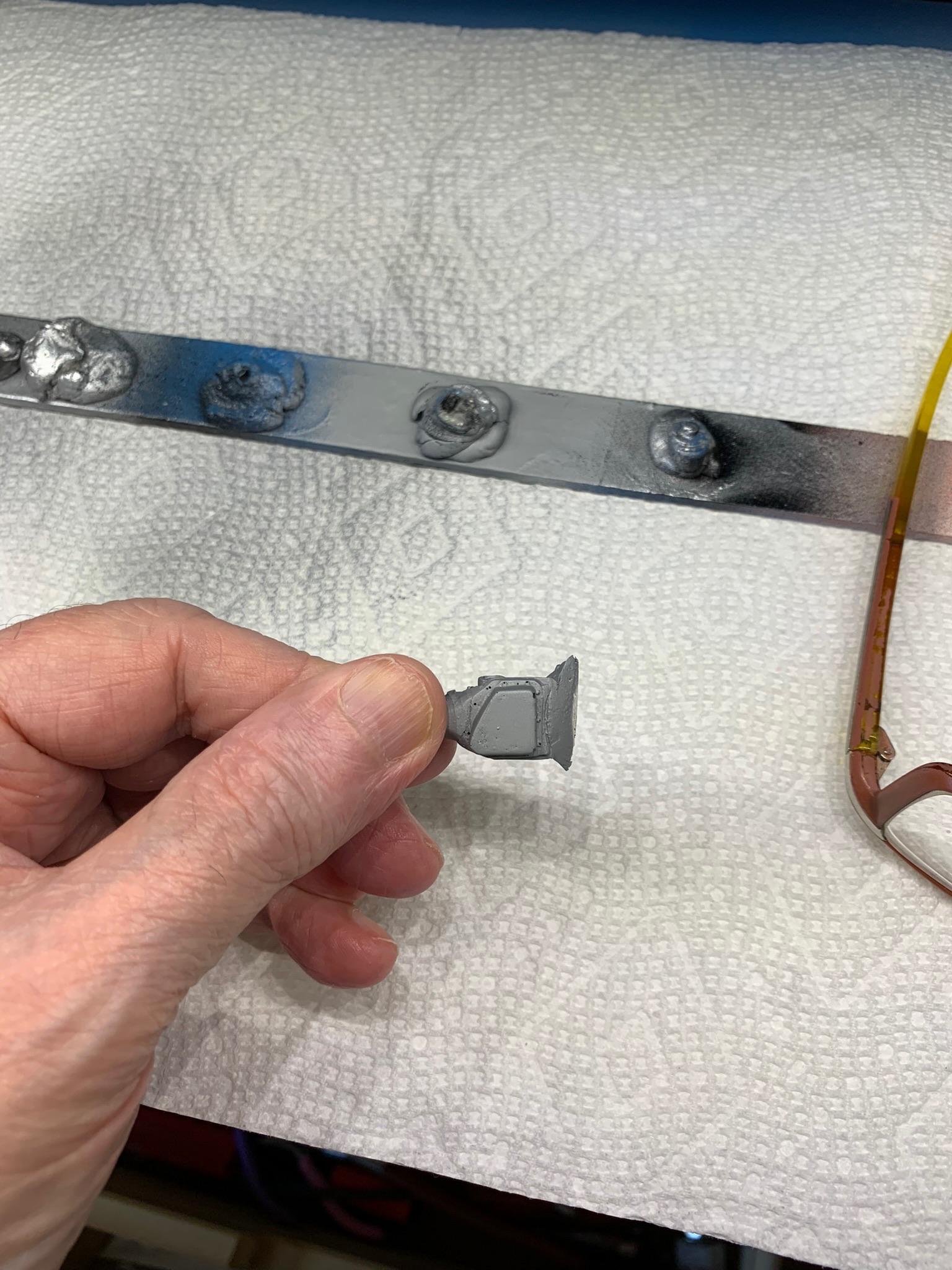

Shapeways. Ron Olson. 3D model specialties. $6.50 per pair in 1/25 scale. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

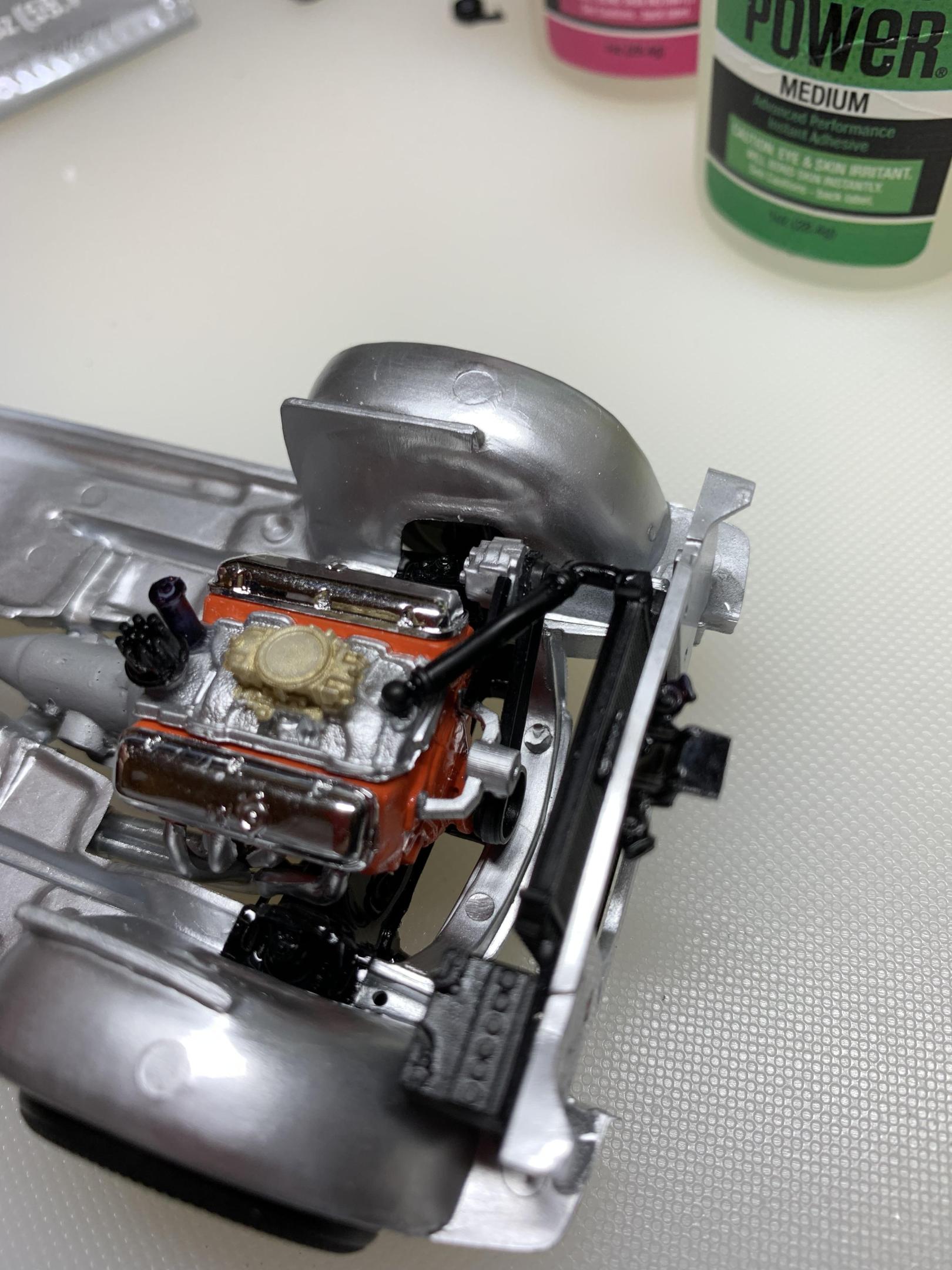

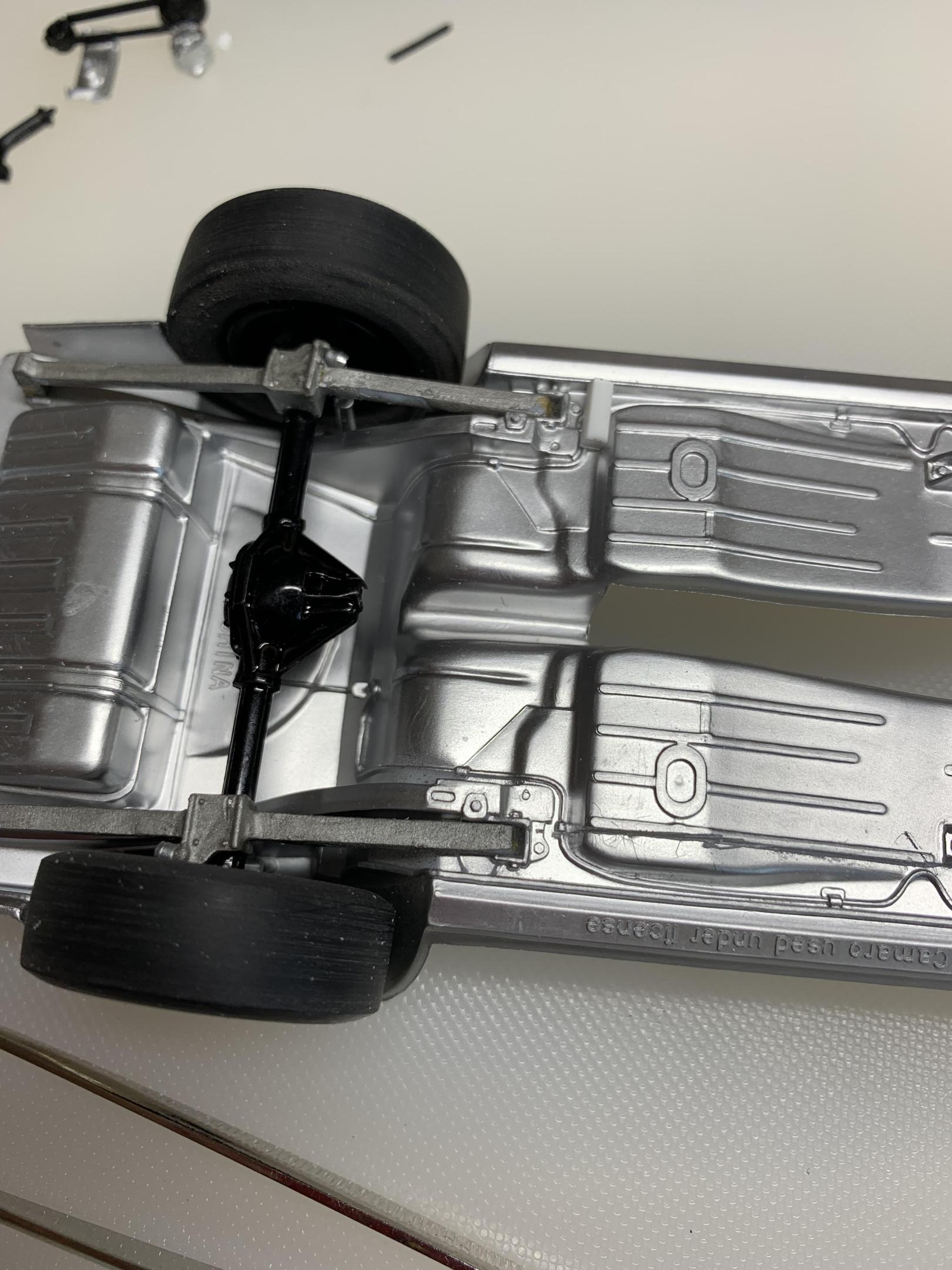

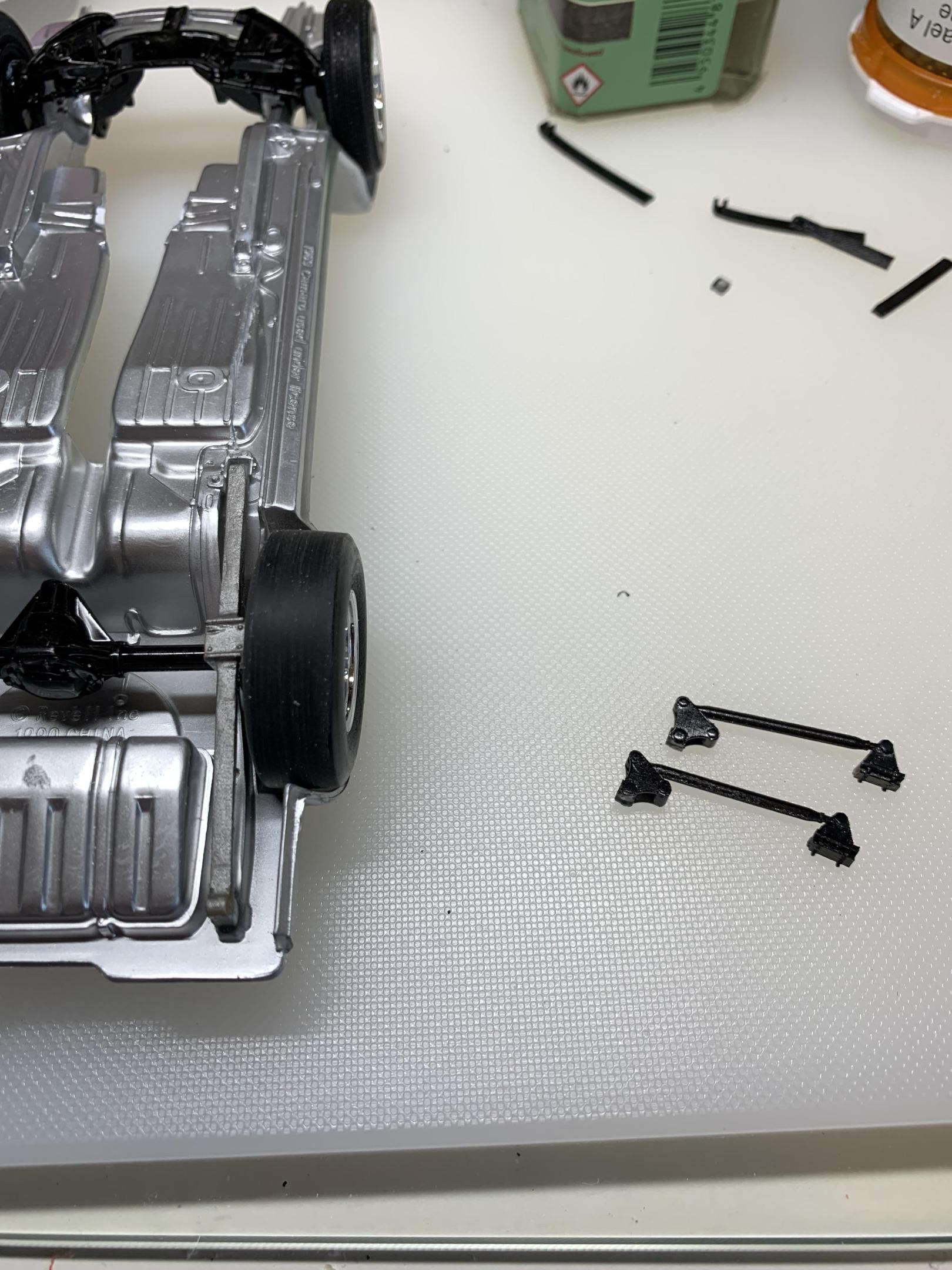

Glued the engine in by the front mounting points, let that dry a bit, then installed the crossmember that I had cut off. Finally, glued on the driveshaft. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

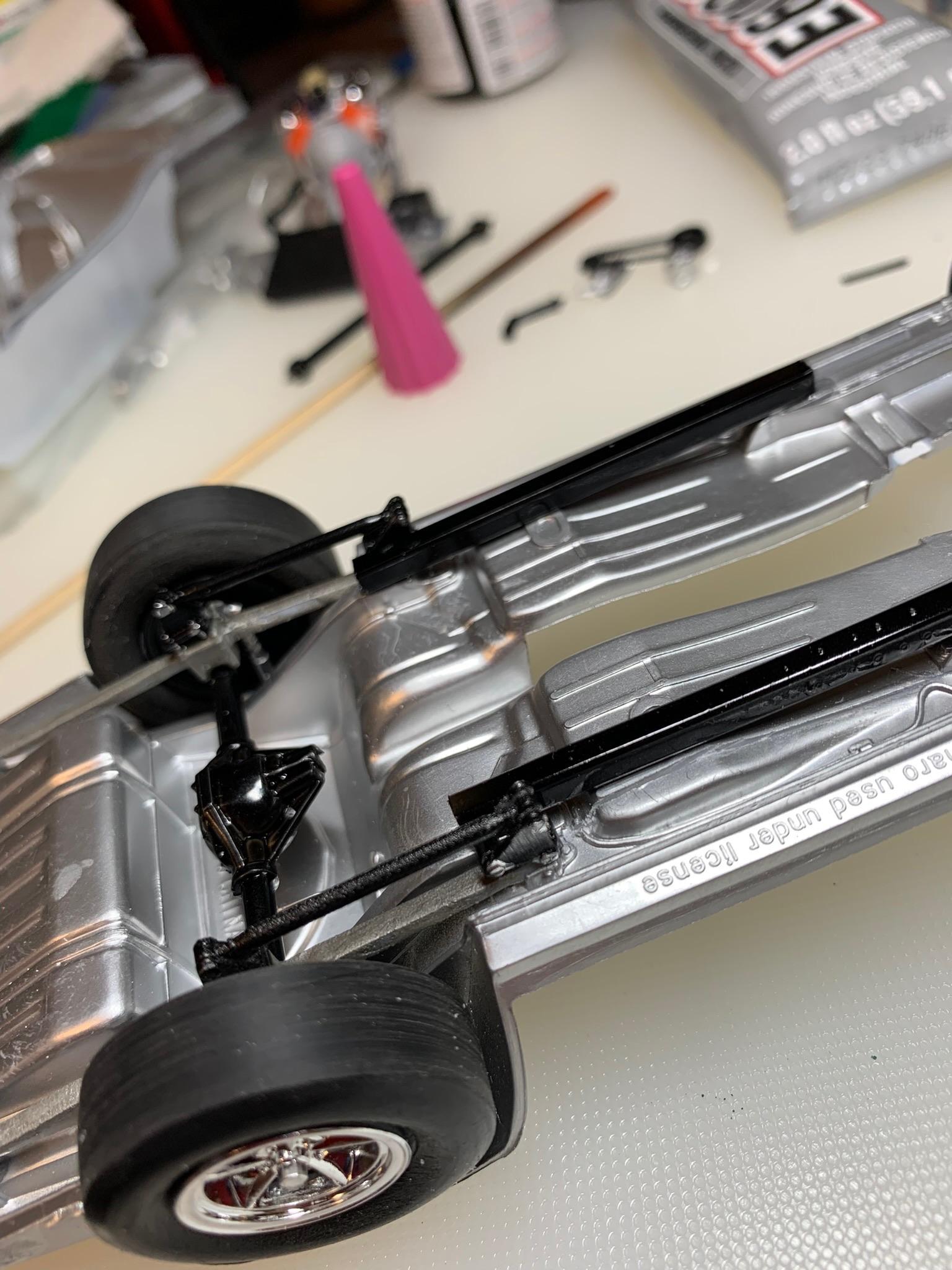

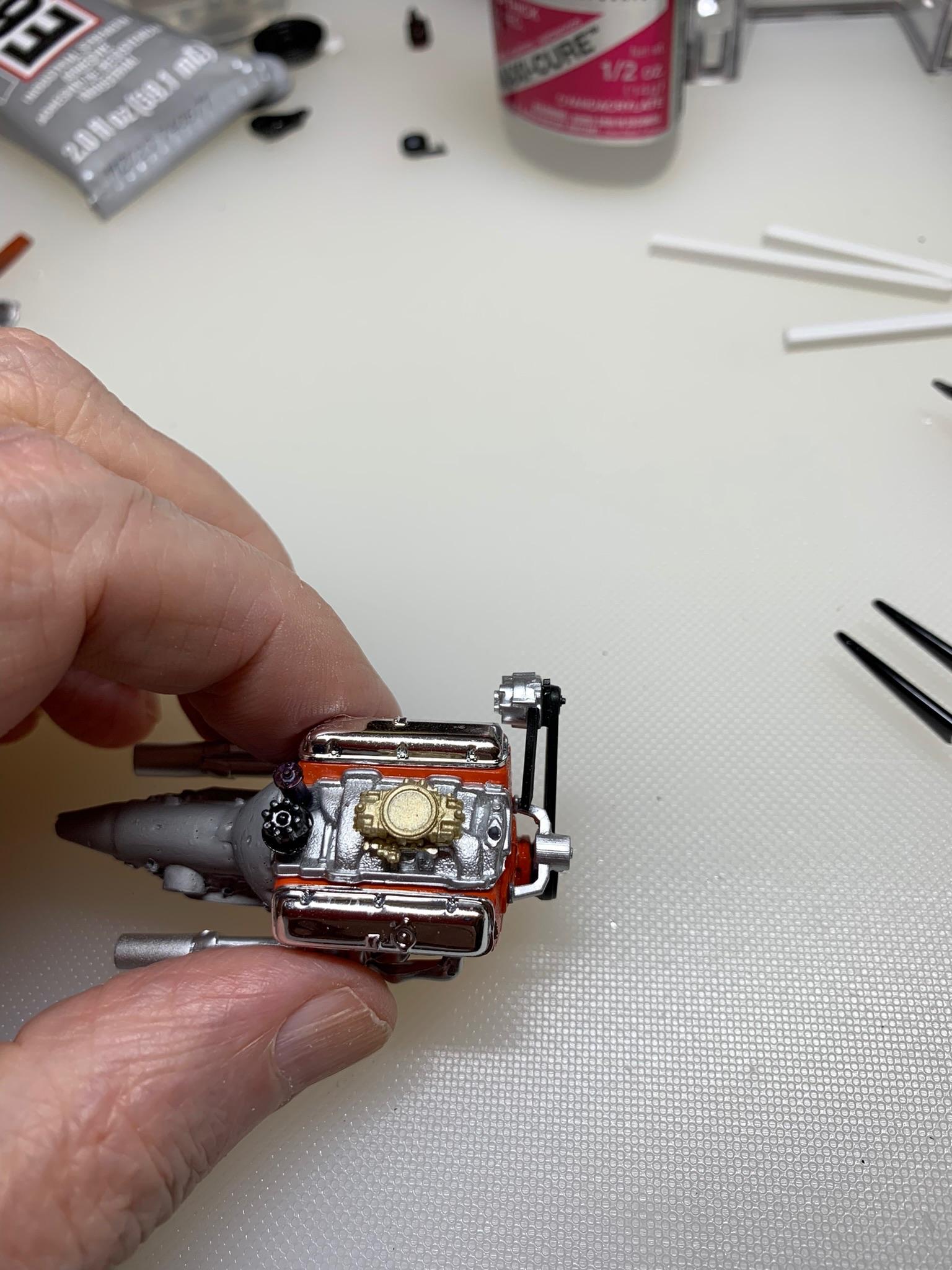

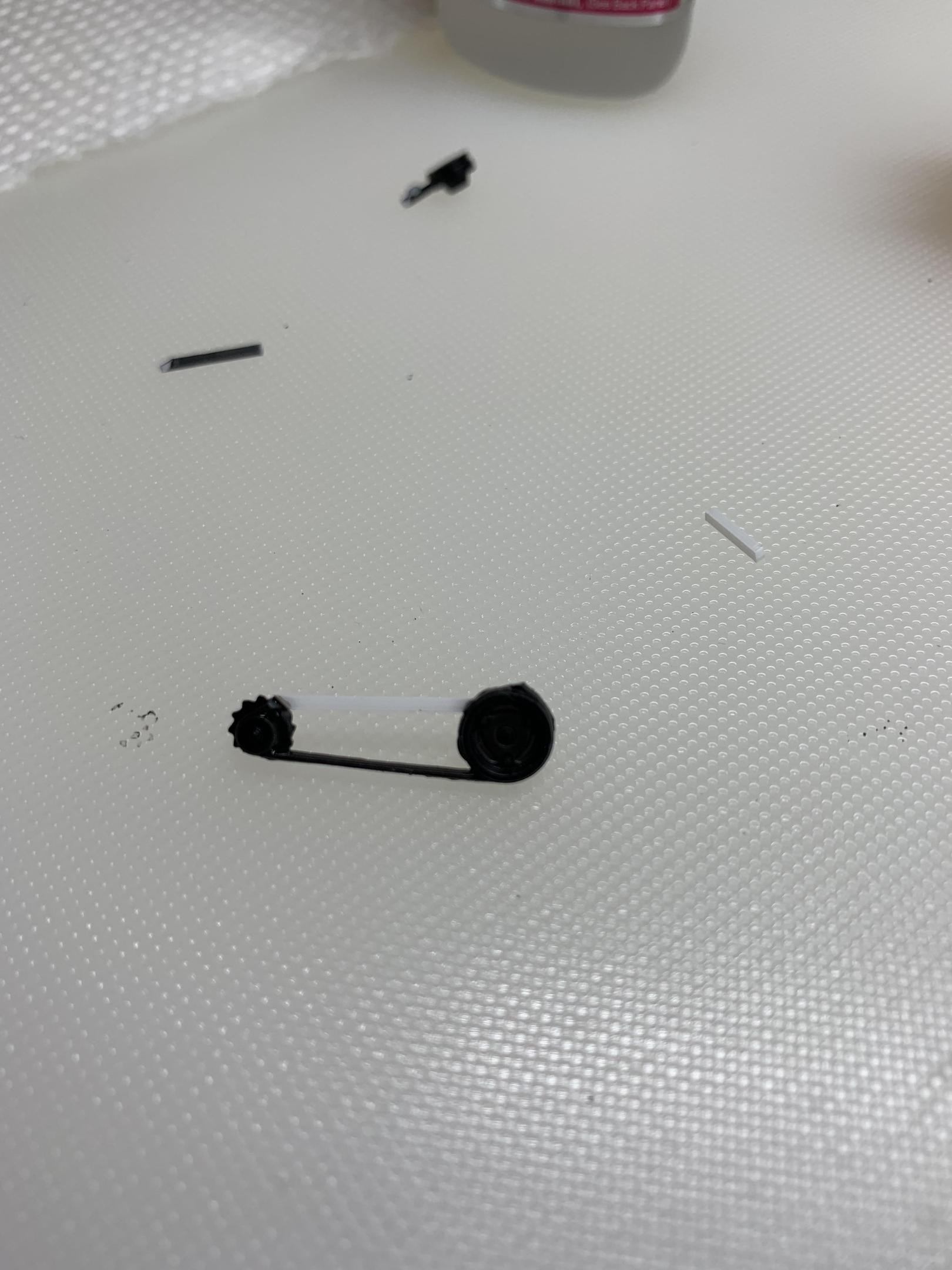

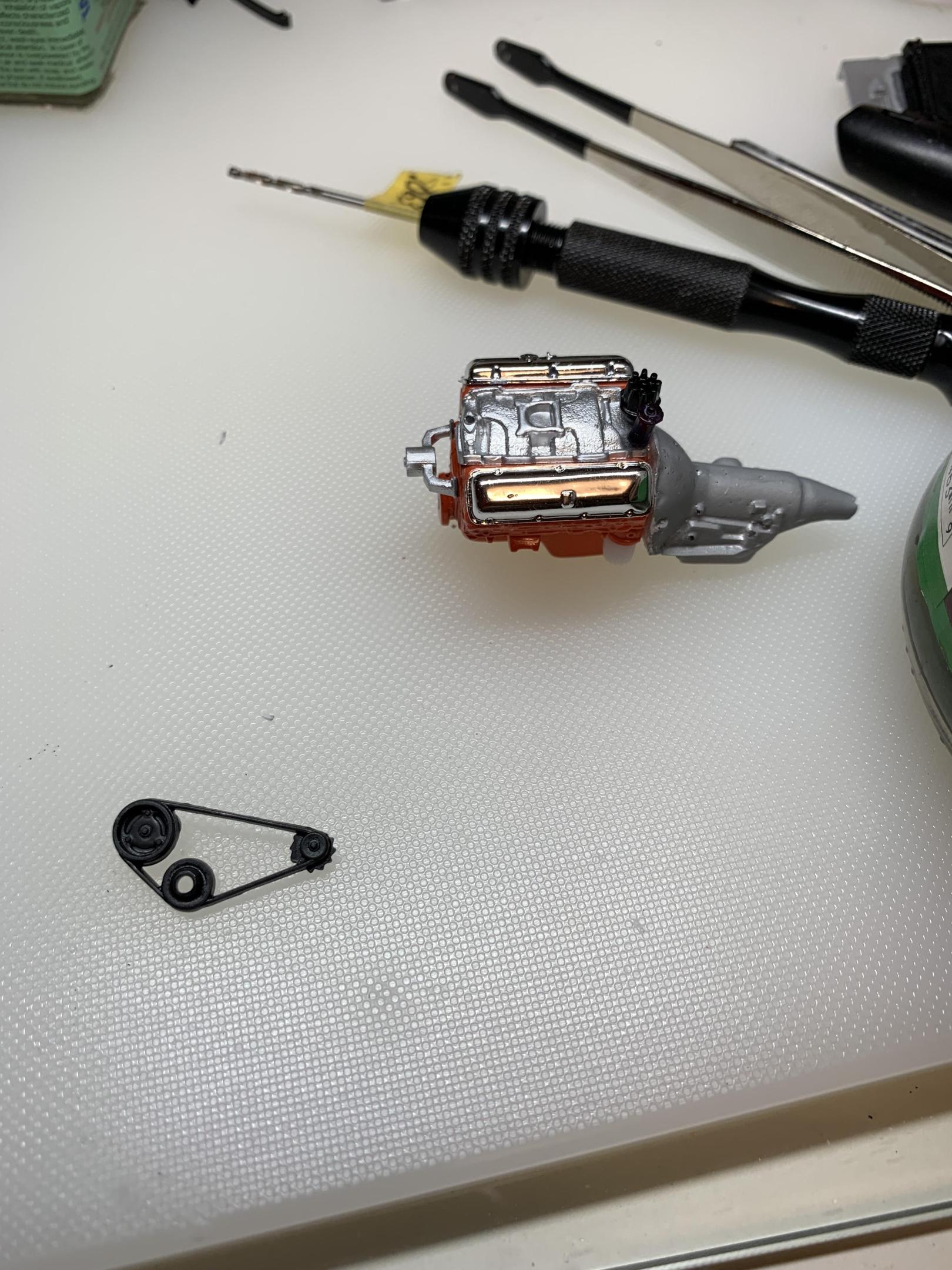

Thanks, guys. Still plugging away. Installed sub frame connectors and CalTracs. Then, alternator and hub pulley. Made a piece of scrap from original belt to use as an alternator bracket. An homage to Harry P. RIP. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

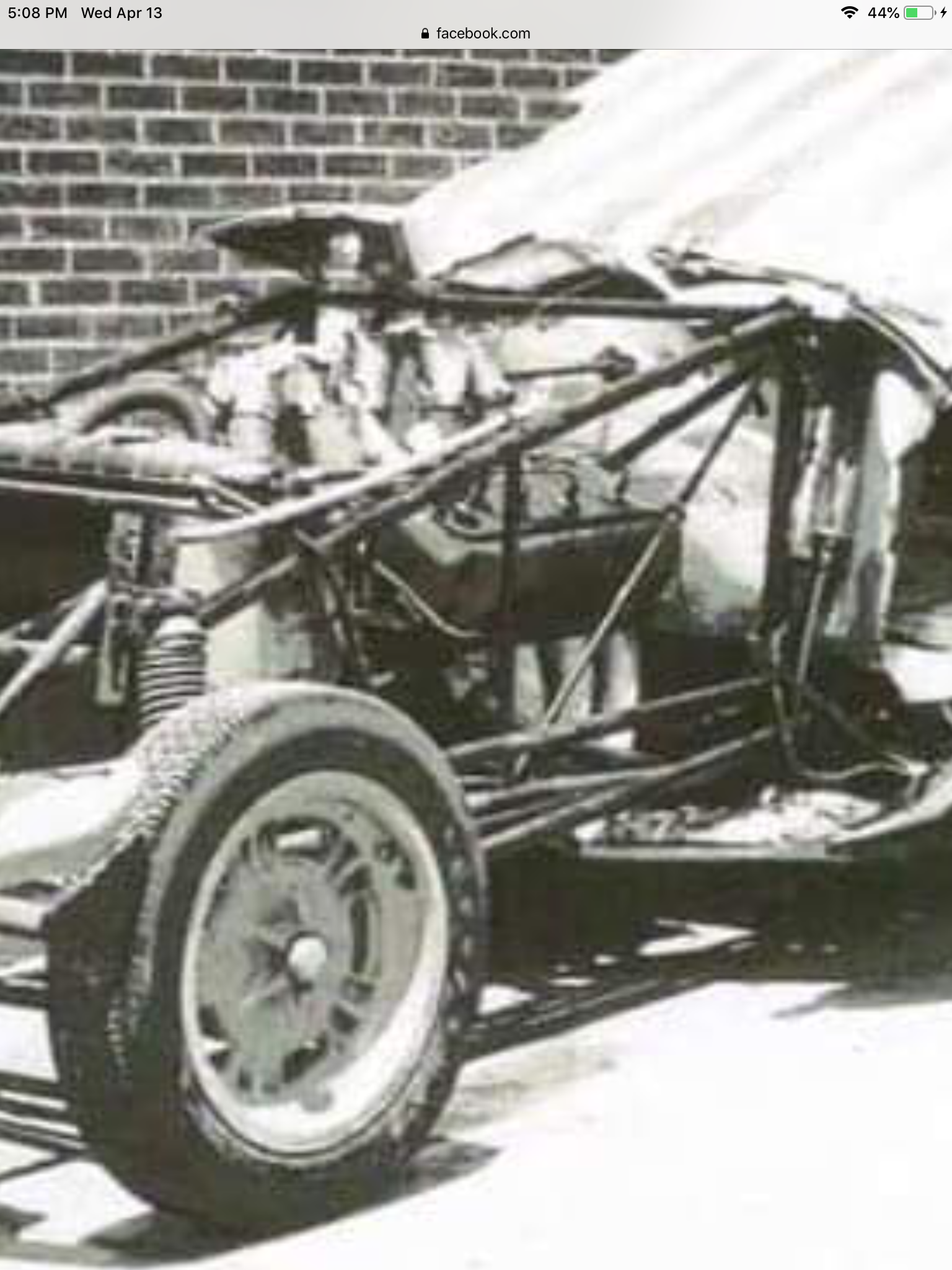

Next, sub frame connectors. Started to cut floor boards out to sink connectors in, but, with other stuff already installed, decided to mount them to existing sub frames. No cutting of floor. Made them from square tubing. Trimmed the “bolt head” from rear sub frame so connectors will “weld on” flush. Will install tomorrow. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

-

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

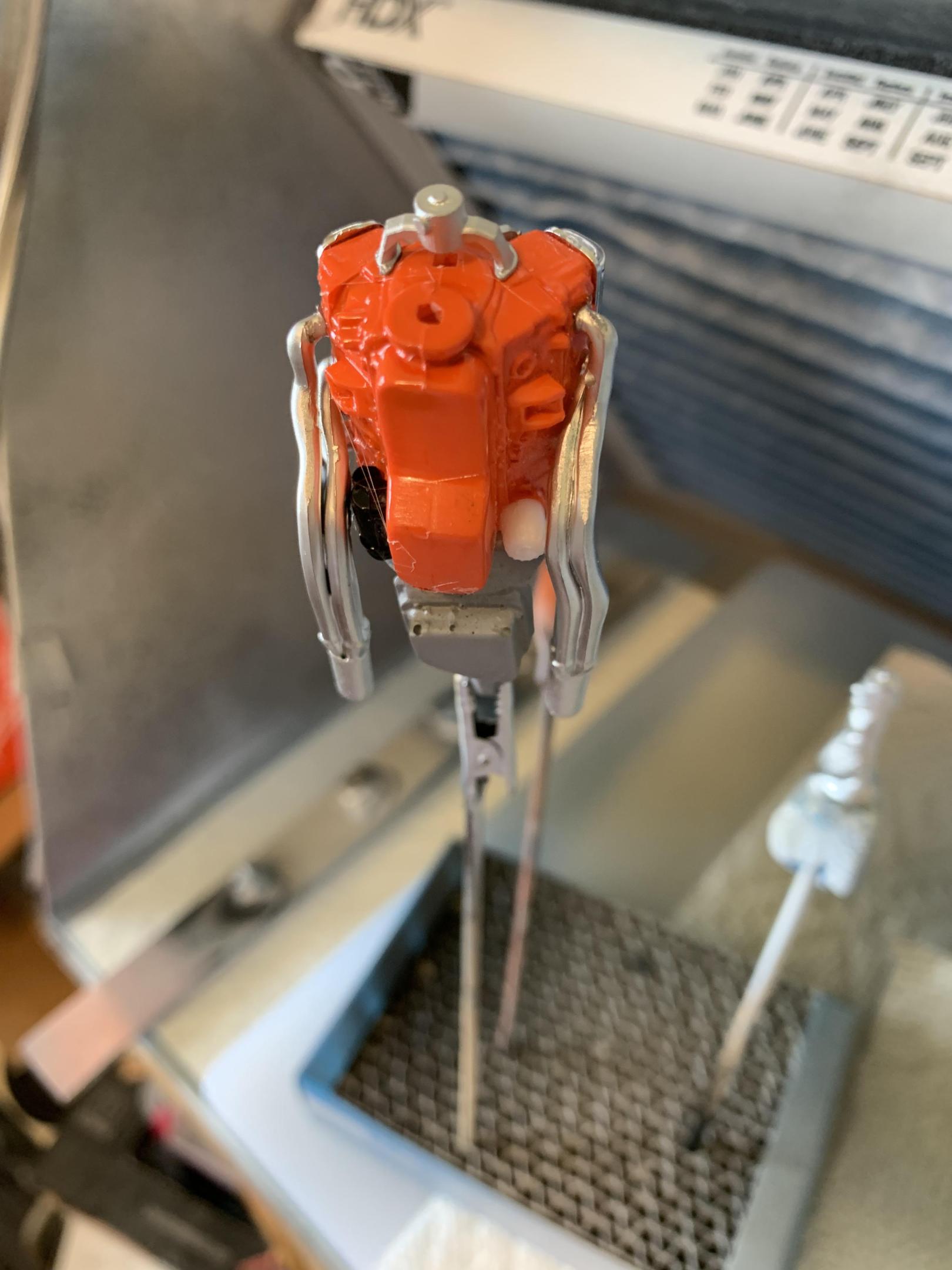

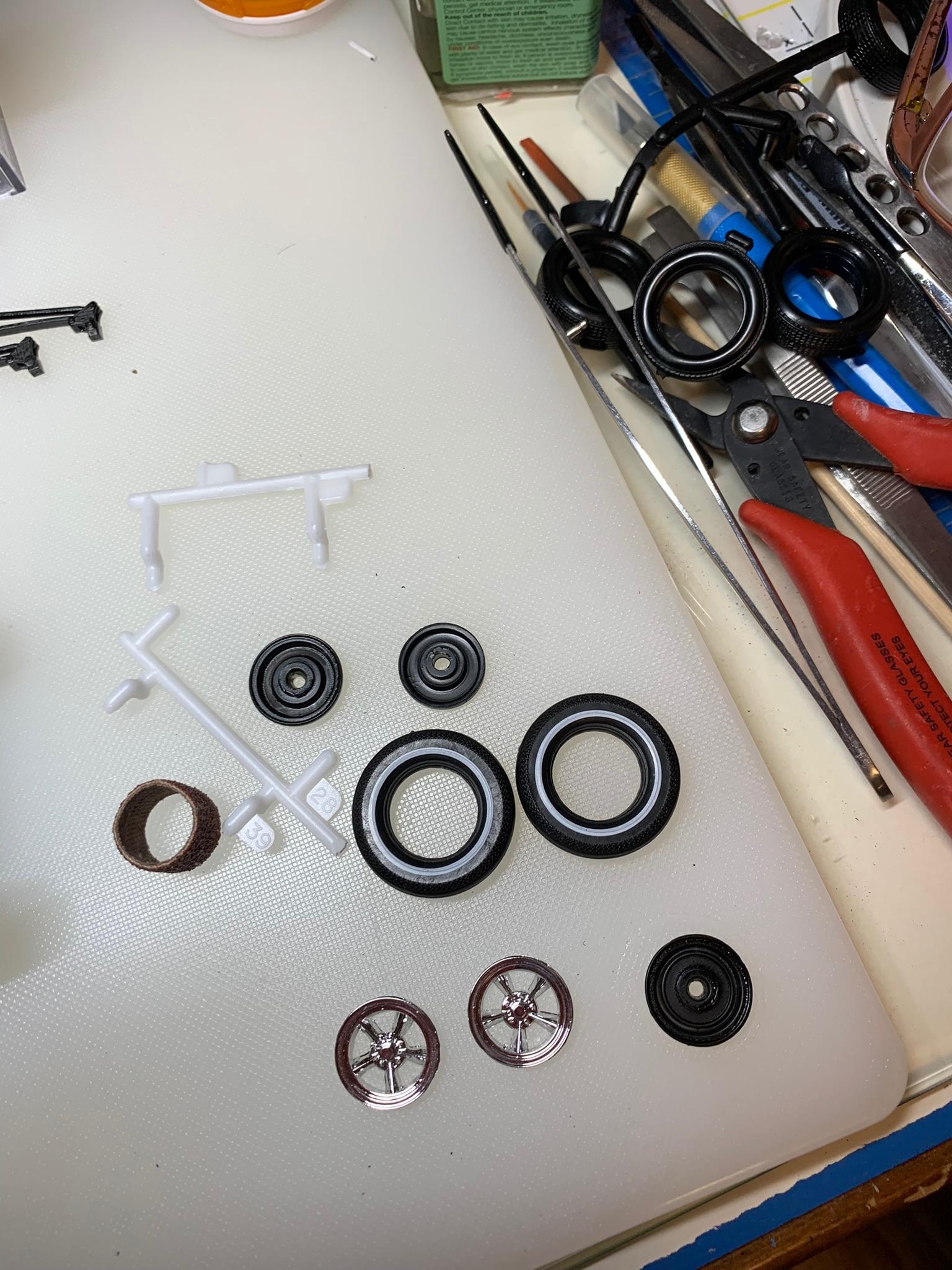

They aren’t Firestones (no markings), but are very similar in tread and diameter, and they fit the wheels. Modified the pulleys and belts to fit the pump, installed headers. Then, of course, the engine wouldn’t fit with headers installed, so, cut trans crossmember off, will reinstall after engine is mounted. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

Some assembly work, putting engine and trans together (after some sanding and a couple of couplings that didn’t go right), plus some engine pieces including the electric water pump. -

-

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

Appropriated some front tires from this future Bob Glidden build kit, put some rubber black on the white walls, decided to use these mags and forego my friend Thomas’s replica. I have no wheels to use like his. Put some ts30 on the electric water pump. Glued the wheels on last night. The wheels came in the original Camaro kit. -

Holloman & McKinney 57 Chevy C/MP circa 1964

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

Thanks, James. Hopefully, get back on this build soon. -

1969 Camaro A/SA (possibly Thomas Arnett’s)

R. Thorne replied to R. Thorne's topic in WIP: Drag Racing Models

Thanks, James. Some slow progress. Put some flat clear on the trans, made it look like primer again. Was hoping for a flat aluminum look. Sanded leaf springs down to appear like mono or split leaf springs like most guys use. Painted them with some steel enamel. -

-