-

Posts

3,662 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by bobss396

-

I use mainly #71 to #76 drills, a #65 and #37 for 1/32" clearance, 1/32" and 3/64" for tight clearance with installing pins. I have a pill vial with various other drills with paper tags on them, 2 old end mill cases, one is .026" to .062"-ish, the other .065" to 1/8". Then my trusty Huot number drill set, #1 to #60. I have to replace some missing drills.

-

What Did You See In Your Yard Today?

bobss396 replied to Tim W. SoCal's topic in The Off-Topic Lounge

-

62 F at 5:30 am. Cloudy, as was yesterday. Monday high was 70 and I got some garden work done. Pool went from 73 to 68.

-

Moebius 1946/7/8 Chevy Announcements

bobss396 replied to Erik Solie's topic in Car Kit News & Reviews

I picked up 2 of the Galaxie issues last year, complete for $25 each, bad boxes and decals. Spotlight Hobbies had fresh decals for $8 per. -

Need help with attaching AMT mirrors

bobss396 replied to JerseeJerry55's topic in Model Building Questions and Answers

I pin mirrors in place. I try to use the biggest "pin" that the mirror mounts will accept. That with CA glue holds them on pretty well. -

Friendly loveable Squirrels..

bobss396 replied to A modeler named mike's topic in The Off-Topic Lounge

We were sitting outside on the deck after dinner and one of the squirrels was poking around. So I got some peanuts out for him/her and the bluejays. The little thing was pretty friendly and hungry. 20250615_171334.mp4 -

Sunday was cool, never got past 64 and no sun. We had a FD gathering outside, got drizzled on a bit, the real rain started after 8 PM. Today, a light rain and 59 F.

-

Do you also have 1:1 project cars?

bobss396 replied to ctruss53's topic in General Automotive Talk (Trucks and Cars)

Very possible. I will take another look at it. They were a pain to get in place. The indent for the bottom is very shallow and fiddly to hold. -

I'm a widower for 11 years now. My late wife despised the hobby. I have been dating a nice lady for almost 8 years, she likes cars, even models tattoos and firearms. She has a pistol permit and a couple of nice pistols. Ammo... I laugh when I read of an arrest somewhere and the perp's house has 1000 rounds of ammo.

-

56 F and cloudy. Yesterday was a monsoon all day, slowed down around dusk. Possible rain today.

-

I had at one point around 80 in my bedroom closet alone. Now I have maybe 6 in there. The basement is another story, about 200 in the boiler room, 50 in the finished basement side and around 100 that I take to sell at shows in a big closet. I know of a local kit seller that has a truly psychotic amount of models and another former club member with a stash of 5000 and growing.

-

Do you also have 1:1 project cars?

bobss396 replied to ctruss53's topic in General Automotive Talk (Trucks and Cars)

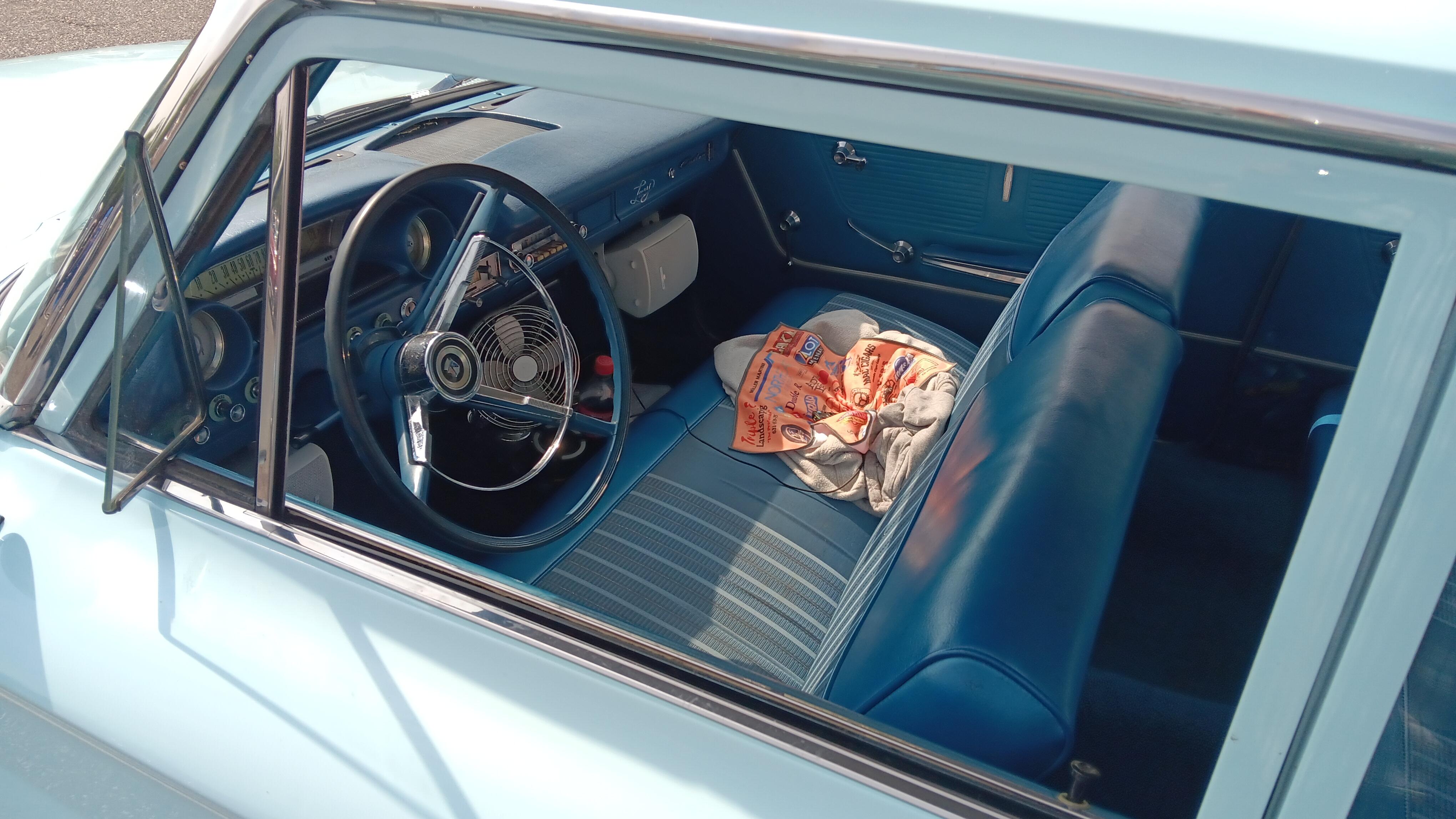

Splurged for new repro mirrors for the Belair. The old ones were too short, likely for a smaller car like a Nova. Now I can drive a little more safely. Changing lanes is no longer an issue. -

Yesterday was nice, the afternoon was around 75. I put new side mirrors on the Belair and me and a buddy went to a cruise (Bellmore train station). I get a text from my girlfriend who was about 45 miles north and east of us... it was pouring by her. Not a drop by us, everything was dry, but light rain now and 61.

-

Cleaning Resin car body & parts before priming

bobss396 replied to Chevy II's topic in Model Building Questions and Answers

What a radical concept... doing what the manufacturer recommends... -

Where to find these Firestone Supremes

bobss396 replied to hedotwo's topic in Model Building Questions and Answers

Those look like older AMT issues to me. Possibly going back to the 1960s annuals. -

What Did You See In Your Yard Today?

bobss396 replied to Tim W. SoCal's topic in The Off-Topic Lounge

I had some weed vine I had to remove. The clematis vine is delicate and thin, dark too. It took a bit of work but I got it. -

What Did You See In Your Yard Today?

bobss396 replied to Tim W. SoCal's topic in The Off-Topic Lounge

A little before and after. The clematis survived another winter, but the rest was full of weeds. I added 4 more Elijah Blue plants to go with the other 3. -

Nobody sounded like them. Great vocals!

-

62 F and looks like rain... surprise! It poured yesterday for about an hour, overcast from there all day long.

-

For paying jobs, I'd buy drills in packs of 12, usually screw-machine type, some TiN coated. The costs were figured into the job. I still have a crazy assortment of drills, end mills, saws and various cutters. I have an account with one tool house, but the warehouse moved too far to be convenient. eBay is my tool go-to lately. I shop the industrial section and can usually find made in the US drill packs.