-

Posts

491 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by PHPaul

-

Hobby Lobby downsizing?

PHPaul replied to Gizzy's topic in General Automotive Talk (Trucks and Cars)

Unfortunately, HL is the ONLY hobby shop within reasonable driving distance of me and that one is 60 miles away. I was just there yesterday. The model section consists of both sides of one short aisle. Decent selection of plastic, didn't pay any attention to the diecast section as that's not my thing. Their selection of scratch building supplies is extremely limited. Some K&S brass sheet, tubing and rod in limited sizes and a paltry collection of Evergreen plastics. Tool selection is not much better. They do have a reasonable assortment of Testors and Model Master paints but overall, it's not really worth the trip. Used to have a really great Mom and Pop place about 20 miles away had a full display of K&S, Plastruct and Evergreen, models out the wazoo and pretty much anything you wanted in HO train stuff. Sadly, they closed up shop 4-5 years ago. Thank Goodness for online shopping. -

We had a combination corn crib/equipment shed on the farm I grew up on. It's visible in the upper center of the home place picture. Decided I wanted one for the diorama, couldn't find anything even close in kit form so scratch built it from scale lumber. Just needs a little more weathering on the corrugated roofing. Oh...and an addition onto the diorama table so I have some place to put it...☺️

-

Now, THIS is a Car!!!!!

PHPaul replied to stavanzer's topic in General Automotive Talk (Trucks and Cars)

Step awaaaaaaaaaay from the crack pipe... -

No direct experience, but I have some VERY tiny cog belts from scrapping old printers that might well work.

-

For years, I thought 9/16ths and 10mm wrenches had microscopic little legs and walked off on their own. Back when I was young and limber enough to crawl under cars, I had a dog that loved to "help" me. He had two favorite tricks. One was to catch me when I was wedged in a position I wasn't at all sure I could get out of and then give me an exceedingly thorough tongue bath. The other was much the same, except that he'd lug off a tool on his way out. Exceptionally smart dog, he knew precisely which tool I'd need next...

-

64 Dodge D100 Pickup Pro Street

PHPaul replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Yes, I wondered about the rigidity. Don't have a need for it right now, but I do keep a stock of brass tubing on hand. When I get around to trying it, I'll post up the results here. Assuming, of course, that it isn't a complete disaster..."8^0 -

Nice work! And I hear ya on hibernating. I've spent most of the Winter in the basement working on my farm diorama and associated builds.

-

64 Dodge D100 Pickup Pro Street

PHPaul replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Thank You, Francis. I'll have to try that. I'll need to mount my vise on the mill and get it squared up. -

64 Dodge D100 Pickup Pro Street

PHPaul replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Wow! VERY nicely done! Question for my own learning: How did you cut the quarter rounds out of the .500 tubing? I can see that being a very useful trick. -

Biggest pet peeves on builds.

PHPaul replied to LL3 Model Worx's topic in General Automotive Talk (Trucks and Cars)

Just finished reading the entire thread (waiting on Step 437 to cure before taking on Step 438. Scratch-building a structure in 1:64 using near-scale 2x4's is time consuming...) and laughed out loud several times. Great to see that a little humor is allowed. I've been on too many sites that were so straight-laced it made my teeth hurt. One of my personal mantras is "If you want to get better at something, hang out with people that ARE better at it." This is that kind of place. I'm in no danger of ever achieving Perfection, but my standard of Good Enough goes up a little with every build. Regarding pictures...I regret posting the picture of the milk hauler in the truck section. It REALLY pointed up the errors and how bad the silver metallic paint looks. Should have waited until I could find something to better simulate polished aluminum. Now I'm going to have to take it apart and start over... -

Had to reverse the link (put the site designation on the end) to get it to work, but yup! Should have thought of that. Thanks!

-

I've seen several references to "polishing" models, either to restore the finish or as a final step to a new paint job. I scanned through the "Future" thread (and learned a lot about that product and it's uses in modeling) but didn't see anything specific about polishing the paint. So... Are we talking about applying a coat of wax, or using rubbing compound and actually rubbing/buffing out the paint? Is there a tutorial somewhere I'm missing about how to do this?

-

Things are progressing. Have done a LOT of filing-to-fit on various pieces. Thinking gloss black fenders, almond bodywork, chrome trim and still contemplating the interior. Initial thought was perhaps teal green upholstery, but need to see the colors next to each other to decide. Choice B would probably be a tan leather look. On a whim, decided to see how diecast/zamac responded to polishing. I'm pretty pleased, the picture doesn't really do it justice.

-

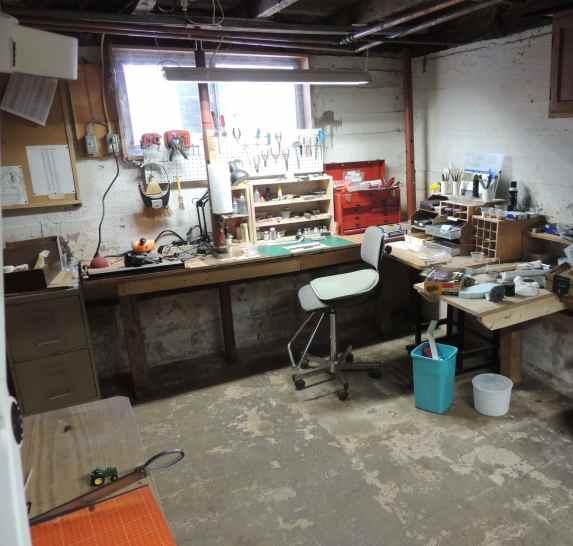

+1 on the Horror Fright/Wallaby Mart LED's. I tried one on a whim, and now have 4 in my wood shop, 2 over the heavy bench in the garage, 2 over the junk spare parts area in the garage, one over the lathe/mill in the basement, and 2 in the hobby room. Thinking I may replace the motley assortment of leftovers in the laundry area with another one.

-

I wondered if you could solder zamac. Might have to experiment with that a little. There's a problem with top-to-body fit issue that would be a lot easier to fix if it was assembled. Off to work on daughter's 1:1 Pontiac, I'll let y'all know what I wind up doing. Thanks for the information!

-

Perfect, thanks! Something else that occurs to me: the body is split in halves vertically (a left and right side) which means there will be a seam right down the center of the body. I'd assume the best way to minimize that would be to sand/fill/prime/paint the body as a unit. Unfortunately, the body halves are used to capture all of the interior parts so that won't be possible. Unless someone has a better suggestion, I guess all I can do is dry fit them and do what I can before assembly and hope for the best.

-

Thanks, Mike! I'll look a little harder at their stuff then. I've about half decided to build it as a stocker due to the oddity of the 1/20 scale. Don't really want to spend a lot of time and money chasing down appropriate parts for a $10 model. That being said, I do plan detail it, add a few custom touches and paint it as nicely as I can within the limits of my skills and equipment. Which leads me to a couple of questions: 1. Will BMF work with diecast metal? 2. Did Ford paint the engines from the factory anything other than basic black?

-

I've been out of car modeling for 50 years, so most of this stuff is new to me. The Shapeways stuff...is this a complete, ready to detail and paint engine or just the software to print one one a 3D printer?

-

Cool, thanks. I paid $10 plus shipping for it, so that's right in the ballpark. 1/20 is sort of an odd scale, I want to put a parts pack motor in it. ideally a Chrysler Firedome. Would that look grotesquely out of scale?

-

I picked this kit up off Craigslist. Model A coupe produced by Hubley Division of Gabriel Industries. Date on box art is 1975 if I remember my roman numerals correctly. (MCMLXXV) I can't find any mention of scale anywhere on the box or instructions, but it appears to be 1/24 or 1/25. Decent metal castings but a LOT of flash. Seems pretty straight, may be missing some of the plastic parts as the sprues have been separated. If it's not especially valuable as a stock model, I'm thinking of building a rod out of it.

-

I print 1/64th scale decals without problems. As long as your printer's resolution (DPI, dots per inch) is fine enough they'll be readable. I print 1/64th stuff at 300DPI and it's fine. Waste a lot of decal paper tho.

-

Well, you nailed it! "8^) I'll try your method on the paint, appreciate the input.