-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by KMcc

-

Belly Tanker and Transport

KMcc replied to slownlow's topic in Other Racing: Road Racing, Salt Flat Racers

Very nice! I followed your WIP on this. I have always wanted to do a belly tank. -

Alfa Romeo GTV Bathurst 1967

KMcc replied to ShawnS's topic in Other Racing: Road Racing, Salt Flat Racers

Excellent! Did you tint the windows or do they come that way? That SMS chrome looks really nice. -

i know the feeling Bill, I do purchasing at work, and most of our vendors are terrible. Attach a PO to an email and wait. Might take a week to get an acknowledgement. One time I got the product before I got an acknowledgement. Trying to call them on the phone will drive you crazy. The best vendor I have is a hardware company in China. Acknowledgements in 24 hrs. and product in a week. Go figure.

-

Trumpeter Ford GT40 with my twists

KMcc replied to kensar's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Looking forward to following this also. -

Martin, I can't get over how much I admire this model. Every time I visit the forum, I have to look at the pictures again. Thank you for sharing this.

-

Martin, I can't get over how much I admire this model. Every time I visit the forum, I have to look at the pictures again. Thank you for sharing this.

-

Best beginner Fusion 360 Project

KMcc replied to olschoolkid's topic in Car Aftermarket / Resin / 3D Printed

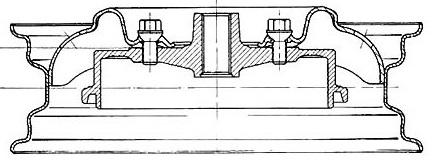

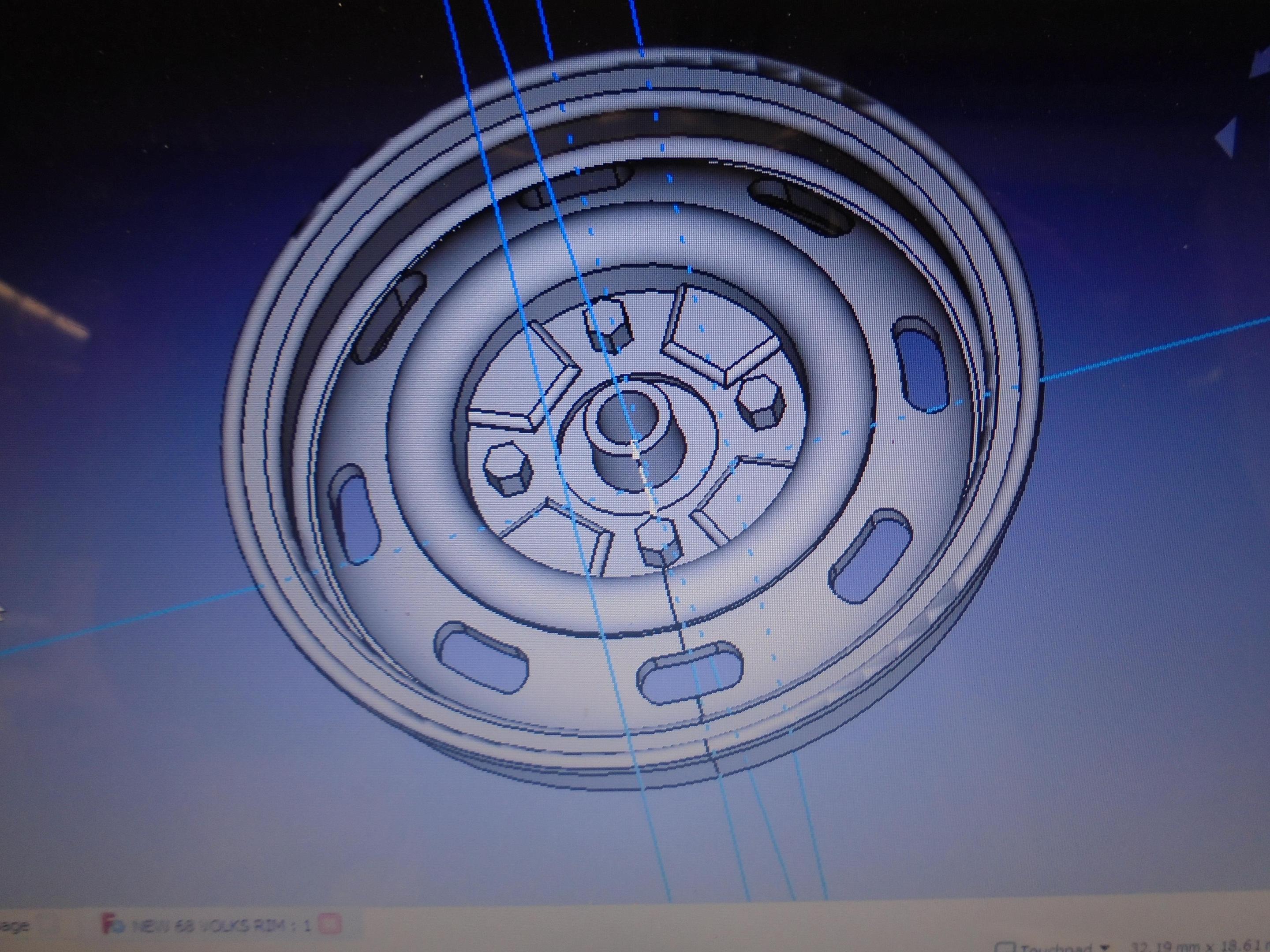

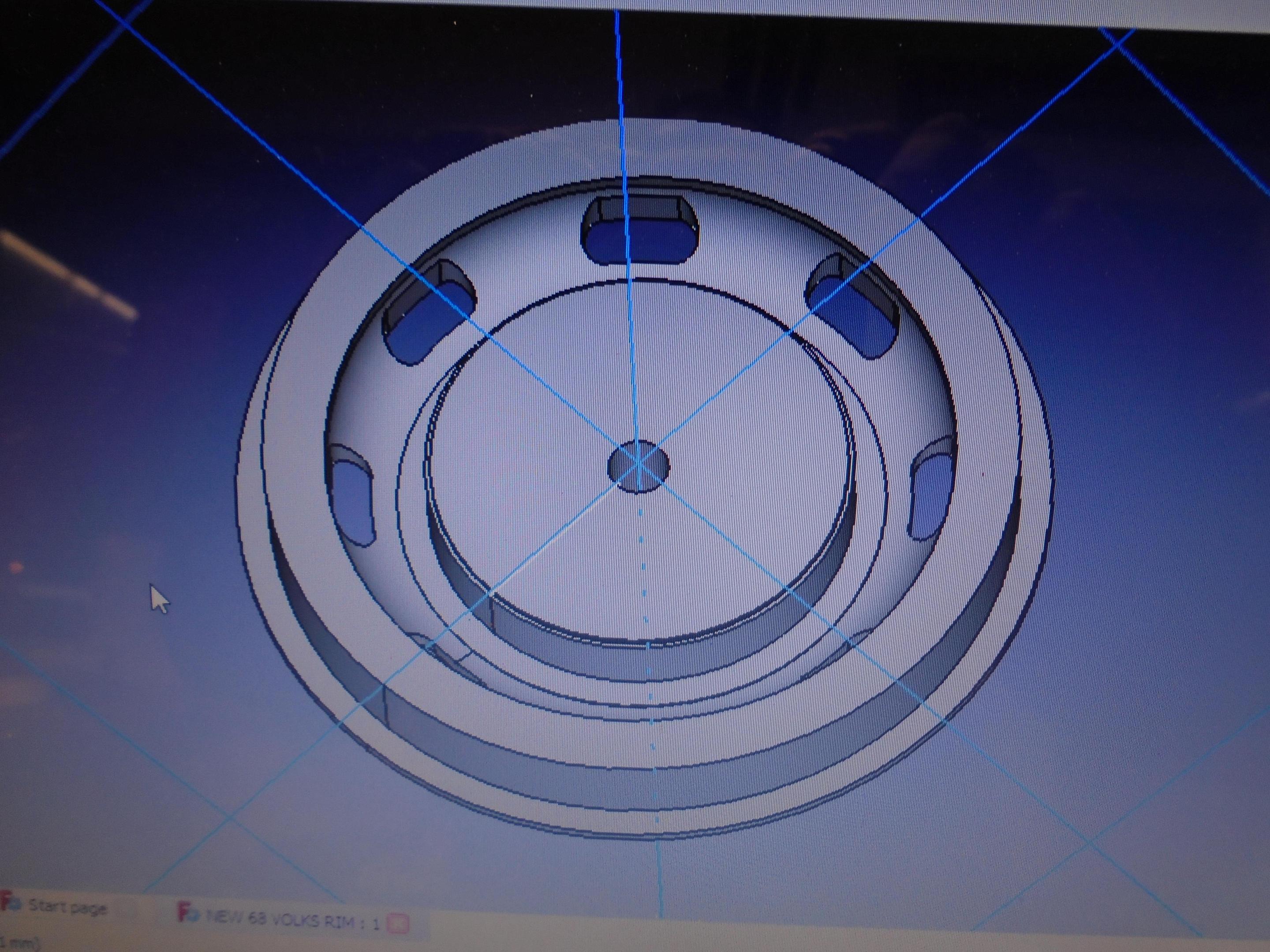

Hi Mathew, I started solid modeling about two years ago using Freecad , which is also parametric like Fusion 360. Watching Youtube videos helps a great deal. My first effort to model something I needed, was a Volkswagen steel wheel. I gathered photos of the wheel and also found a cross section drawing. I was able to import the drawing into Freecad and scale it to size. I drew the geometry to emulate the backside of the kit wheel so that when it gets 3D printed, it will fit into the kit tires. Then I rotated the geometry and punched in the slots and added fillets. I haven't printed them yet though. Trying to draw up a bunch of things to print over a weekend when I can exhaust the resin fumes out of my basement. This is also my first time posting pictures, so I hope this turns out OK. Good luck. 3D modeling and printing has consumed a lot time that otherwise would be used to build models. But hey, I'm having a blast. -

Very, very nice. My favorite year Cutlass. Did the file include the interior?

-

Acceptance of 3D printed models?

KMcc replied to jdhog's topic in Model Building Questions and Answers

I decided to get into 3D printing because I needed parts for subjects that couldn't be found at aftermarket suppliers. Having a job that required CADD skills was definitely a plus, but I also never contemplated buying one of those mini machining centers because, even though I admire the parts that modelers on this forum make with them, it's just not something I would get into. Everybody has their own comfort level when it comes to handling the tasks to put together their models. As said earlier, "parts is parts". -

When I was five (1965), at the end of our dead end street, a 17 year old kid and his dad were putting together a '63 chevy II station wagon for the local drag strip. Every single evening, I would go check out what was going on. My parents would always tell me to stay out of their way, so I would stand on the wall at the side of their driveway and watch. They were so cool about telling me what they were doing and occasionally asking me to hold something or hand them tools was always a big highlight. A couple of times my father and I followed them to the strip and my dad would put me on his shoulders to see better when it was their turn to run. I told everyone around us in the stands that I helped them build the car. They all chuckled, including my dad, but to me, it was the greatest feeling in the world. Thank you Kenny and Mr. Baker, wherever you are!

-

When I was five (1965), at the end of our dead end street, a 17 year old kid and his dad were putting together a '63 chevy II station wagon for the local drag strip. Every single evening, I would go check out what was going on. My parents would always tell me to stay out of their way, so I would stand on the wall at the side of their driveway and watch. They were so cool about telling me what they were doing and occasionally asking me to hold something or hand them tools was always a big highlight. A couple of times my father and I followed them to the strip and my dad would put me on his shoulders to see better when it was their turn to run. I told everyone around us in the stands that I helped them build the car. They all chuckled, including my dad, but to me, it was the greatest feeling in the world. Thank you Kenny and Mr. Baker, wherever you are!

-

Some drunk chick drove down my street New Years Eve and hit all three of my vehicles plus two other cars farther down. Police found the car with the fresh damage and matching paint colors. She denied everything but they could only cite her with hit and run along with some other violations. Had to spend New Years day all ticked off waiting until Tuesday to call the insurance company. Thankfully, the cars are drivable, but I'm still pretty steamed. Thanks for letting me vent. Keith

-

Jaw dropping gorgeous! Your work always amazes me. Not that it matters, but what do the rear side window decals say?

-

Mercedes SSK coversion from Roadster to Racer....Revell 1/24 scale

KMcc replied to louis Carabott's topic in Model Cars

Very nice indeed. May I ask what you used to make the leather hood strap? It looks perfectly in scale. Something I need for an upcoming build. Thanks in advance. -

Very simple question for anyone in the know...

KMcc replied to V8tiger's topic in General Automotive Talk (Trucks and Cars)

I think I may have misunderstood what you were asking. In Freecad, when I'm ready for printing, up in the top left hand corner, I click on 'file' and when the options cascade down, I click on 'export', and what cascades down is a plethora of options showing file extensions to convert your present screen file to. I always click on '.stl' because that is what my photon slicer uses. Again, I'm not familiar with Polycam, but there should be a similar way to convert that file inside the software. Once again, I hope this helps. -

Very simple question for anyone in the know...

KMcc replied to V8tiger's topic in General Automotive Talk (Trucks and Cars)

Seems to me that you need to export the scanned file in a compatible format that is accepted by the lychee slicer. I draw solid models in Freecad which uses its own file extension (.FCStd), before I can import the file in my Photon slicer, I have to convert the file into an .stl file, which can then be imported into the slicer. Not familiar with a Polycam scanner or the Lychee slicing software, but it sure sounds like a file compatibility problem. Hope this helps. -

TJ, my go to chili recipe is from Pierre Franey. Years back, he used to write a recipe column for The New York Times. https://www.pierrefraney.com/recipes/pork_and_ham/chili_a_la_franey.html Also, Andy, Cincinnati Chili is a tasty spaghetti dish. Cincinnati's signature food (think: Philadelphia Cheese Steak). https://www.allrecipes.com/recipe/206953/authentic-cincinnati-chili/

-

Holy cow, that is stunning! I stared at the pictures for twenty minutes. It seems to me that part of the realism lies in the tree branches and buildings across the street that are reflecting in the perfect paint job and back window. The only giveaway that it is pictures of a scale model, are the leaves behind the fence, and that nobody should ever park a car that nice in the middle of the street in front of a gas station. My word, this forum is loaded with highly talented modelers. Gives a less talented modeler hope.

-

3D Printing........Scratch Building or Not?

KMcc replied to Bugatti Fan's topic in General Automotive Talk (Trucks and Cars)

This is a very interesting question. For several years I've been interested in making a 1/25 scale Ford Model AA dump truck. After I found some Model AA reference material, I ventured into scratch building the components for the frame and rear suspension components. I used 2D cad software to sort things out and after several attempts, had moderate success shaping and laminating the leaf springs. Last year I began to realize that resin 3D printing was the perfect solution to creating all these parts. I loaded Freecad on my laptop and started creating the solid models of the components for the truck. It's a technology that fits into my CAD designing background and a more comfortable solution for me. The planning is the same as scratch building, but the ends to the means is a more accurate and detailed result. After all that, I guess 3D printing should be called "scratch creating'. It will require new skills to manipulate the CAD software, but hey, I'm still learning how to lay down a nice paint job on my car bodies. -

Figured I'd mention Greased Lightning with Richard Pryor playing Wendell Scott. Haven't seen it for years, but it is 'racing themed'.

-

Hmmm.... faded away on modern cars? how about young girls wearing halter tops and hot pants. Joking aside, I had a 73 Nova in the early 80's that I changed motor oil and lubed the front end (remember grease fittings?), checked the plugs, ignition breaker, and front wheel bearings every 3K miles. Didn't realize it then, but I loved every minute of it. Sold it when it had 80,000 miles on it for $1200. The odometer didn't have a digit for 100,000 miles like everything does now, but I recently sold a 2006 Chevy pickup with 250,000 that never needed a spark plug change. I miss most of the nostalgia of older vehicles, but modern vehicles are very solid compared to years ago. My neighbor, when I was a kid, had a 67 GTO with air shocks, and he would open the trunk and pump air into the 'tire valve' to raise it up for race night. I thought that was cool stuff!

-

What was your first model car?

KMcc replied to Kit Karson's topic in General Automotive Talk (Trucks and Cars)

AMT 1967 Buick Riviera. $2.00 at Woolworth's. I was seven. No paint, just glued it together. My friend and I would build together on a card table in his basement. I remember painting outside while it was snowing one time. His Mother would always warn us that "it will all come to an end" if she smelled paint in the house. Never lost the passion to build, but adulthood got in the way until I finally set up a place to get back into it four years ago. This time with a paint booth. My wife is eerily similar to my friends Mother. -

Sketchup to design model car parts?

KMcc replied to V8tiger's topic in Truck Aftermarket / Resin / 3D Printed

Hi Joe, While I am not familiar with Sketchup, I have been using Freecad for designing parts for build projects. So far, I have created wheels, leaf springs, differential and tires for a Ford AA truck with great success. Youtube video tutorials are invaluable. I also have been using Autocad for thirty years, so I'm used to digital drawing environments. You need to make sure Sketchup can convert 3D solid files into .stl files because that is the type of files the slicer software needs to create the file that will get sent to the 3D printer. I have an Anycubic Photon Mono, which comes with slicer software called Photon Workshop. An .stl file displays the 3D shape with all the triangles on the surface. Freecad has the ability to adjust the resolution of the triangles created, which makes the finished print smoother. It also produces large file sizes. I had to get a new computer with more memory to handle these file sizes. I have to say, 3D modelling and printing is significantly cutting into my build time. But, I am having a lot of fun, and in the end, my models will really be one of a kind. I hope this helps you, and I wish you luck diving into this game changing part of the hobby. Keith -

Stunning model! Especially at that scale. Reminds me of 'Driving Miss Daisy' Seriously, the skills I see on this forum is impressive and inspirational.