-

Posts

856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Big John

-

Litter here a little there and it all ads up!

-

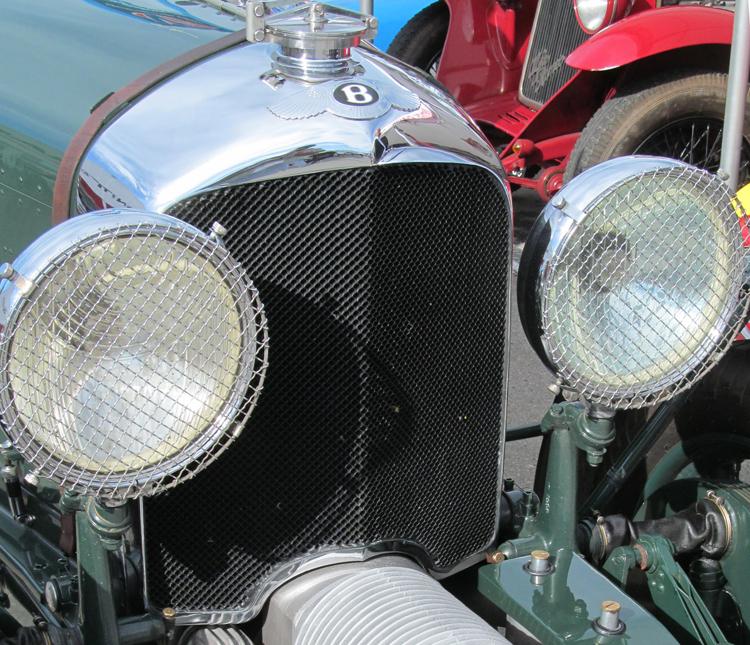

you nailed the radiator shell with the Revel chrome! Straps look great too.

-

Ahhhh, I remember thos days of Real leather seats in metallic finishes. Our Lincoln ha powder blue, so comfy!

-

Lisp ing to Port the watch call out to the Captain!

-

Circa 1954 Movie "Them" started with an invasion of giant Ants in Ludlow CA, so now, every time I pass that way I keep a wary eye out for antenna on the horizon!

-

Trust is Earned.

-

I remember having the original kit back in 1961 and the engine wasn't anything to write home about. I bet this one doesn't have the metal rod axles.

-

Definitely subject and scale. In my youth it was a broader spectrum but I've always been an Indy fan so I have a large stock of 1/24-5 kits dating back to the 60s. However, more recently I am into Speed Record cars, again in that scale. Thank you FPP! I can pretty much work with anything if it is close to accurate.

-

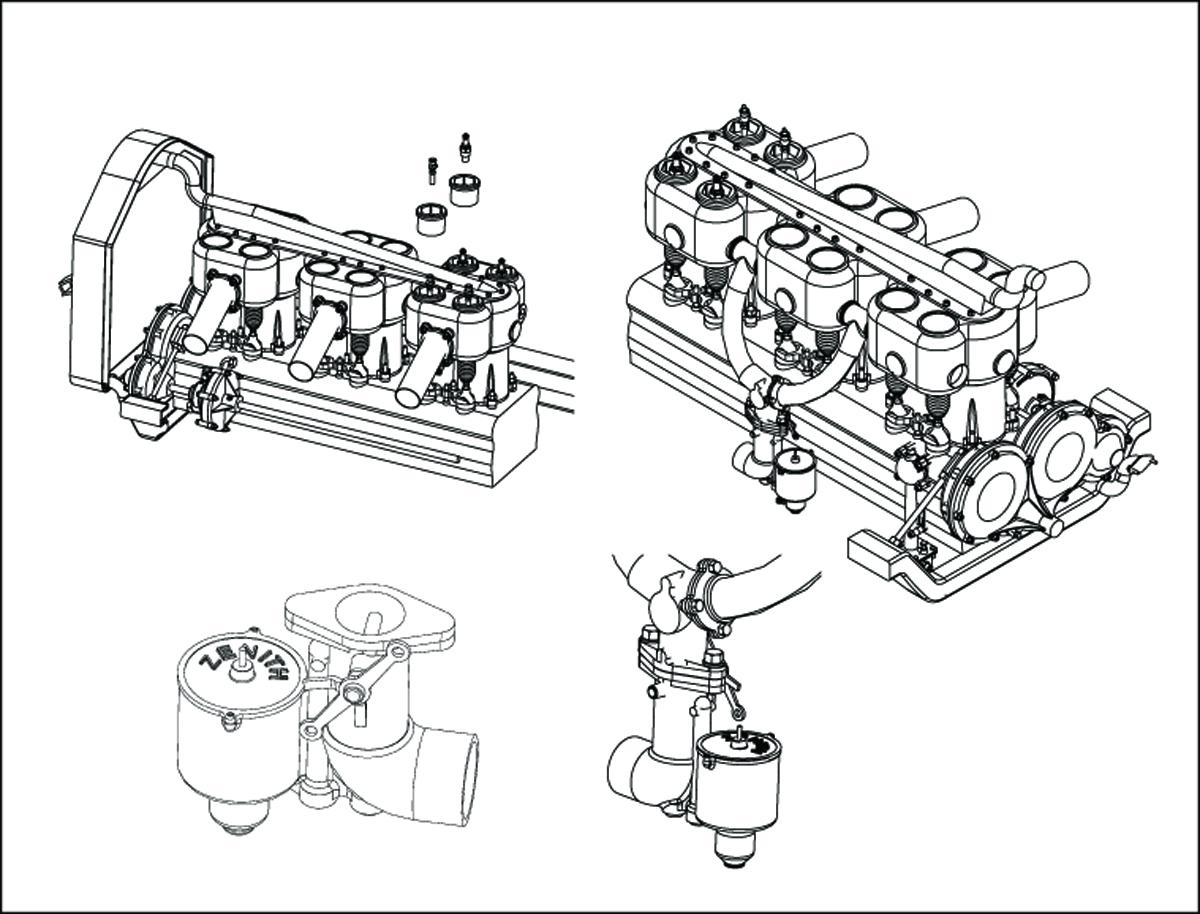

Looking good EG. I've been stumped on the cone clutch and the bottom of the engine,/oil pan, what do you have for reference for those parts? Since this screen shot I've added the magneto and shaft linkages.

-

What would a car modelers Hades be like:

Big John replied to GLMFAA1's topic in The Off-Topic Lounge

the only wheels and tires you can find are old Merit kit clear wires and skinny GP tire that don't match. -

What would a car modelers Hades be like:

Big John replied to GLMFAA1's topic in The Off-Topic Lounge

You clear coat your crapy enamel paint job with lacquer, which is all you can get, and then stripping it down the styrene body melts into a gob of goo. And it was the last of those 'find no more' kits that cost you your life savings because you just Had to have it. -

Streaming behind me were All the other competitors!

-

-

Well the Bonnet ought not blow off at speed with that nifty holdfast!

-

Just 4 more to go! Those are outstanding! But, then, the whole build demands it. Including the nipples in the 3D print is insightful.

-

Relationships are hard to come by when both desirable and Undesirable women run screaming at the sight of you.

-

Some modelers prefer smaller scales, some larger, and some the whole rigmarole.

-

Alternate-Reality 1935 Allison-powered LSR car

Big John replied to Ace-Garageguy's topic in WIP: Model Cars

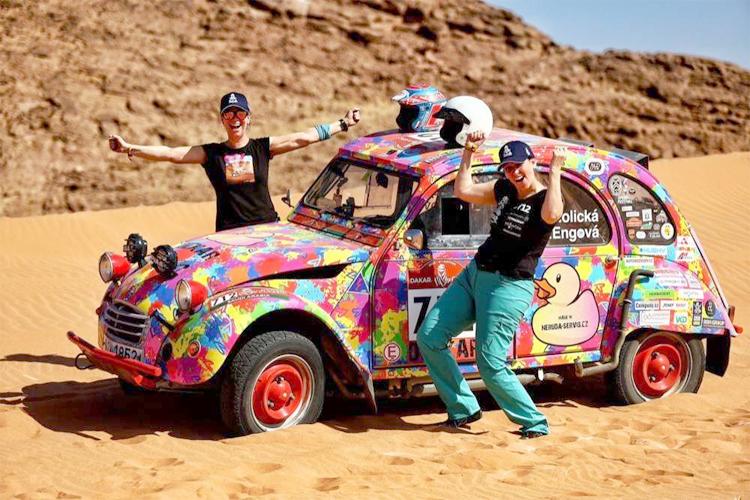

The LBC looks like it would be a pretty cool LSR but I am not sure about the Dusi spoked wheels for aerodynamics. I think I finally have my color scheme sorted out the the Bug LSR. -

AMT 1955 Chevrolet Cameo

Big John replied to landman's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Can't see it from my house. -

Looks Sweeet Pat! Must have been fun to drive in the day. I was just going to say 'is the pipe laying dozer next'? Is there room in the garage?

-

It is more like driving a Land Yacht.