-

Posts

856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Big John

-

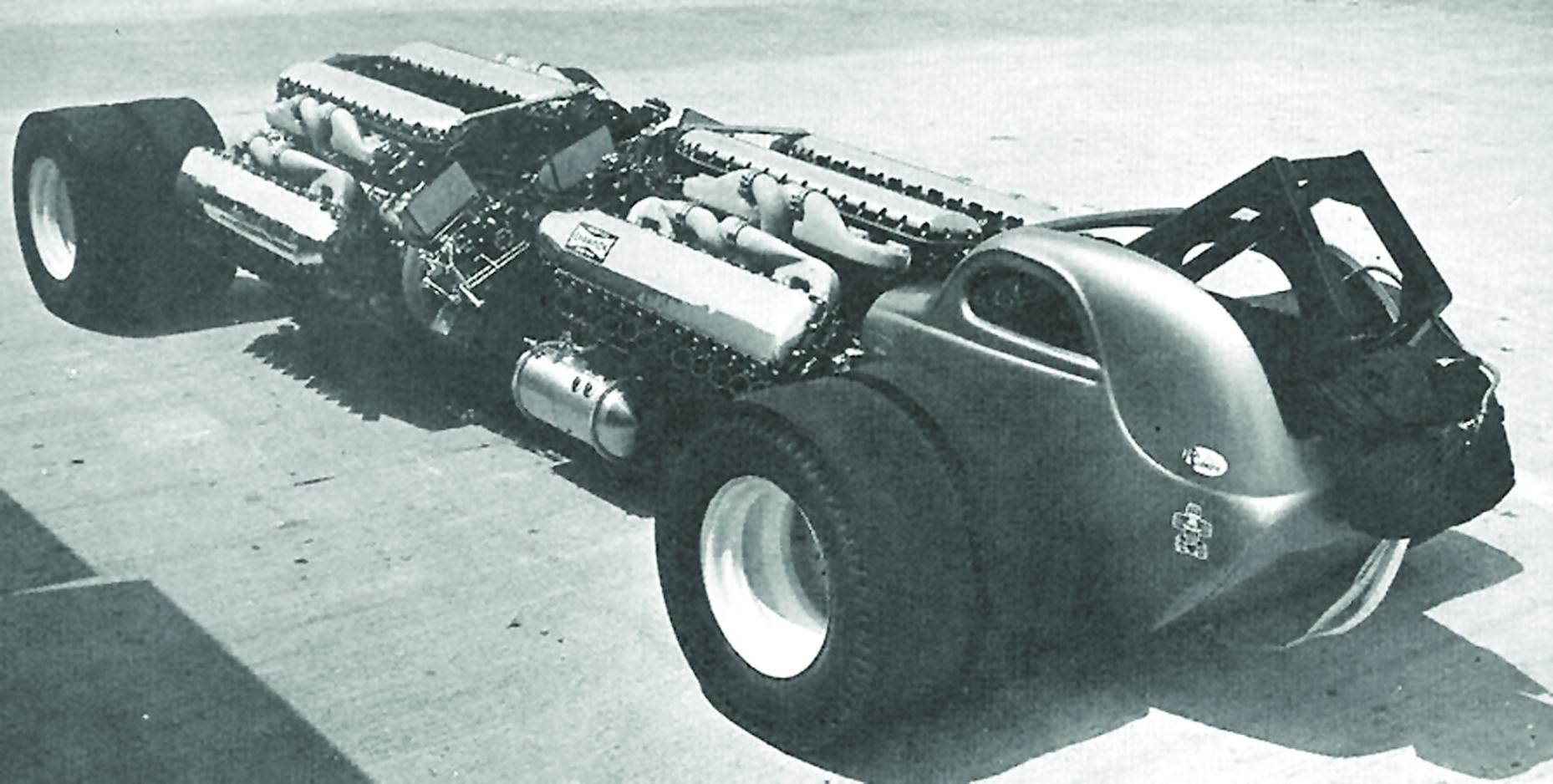

Interesting thread, there is also the old Red Baron by Monogram. Personally I am looking for a 1/24 scale GE J79 afterburner exhaust for a proposed Spirit of America Sonic 1. I've seen some really detailed F104 afterburners 3D printed in 1/32 or 48th but get no reply to inquiries. Hang in there. Pic for those Allison fans.

-

Calves come between ankles and knees and are quite delectable.

-

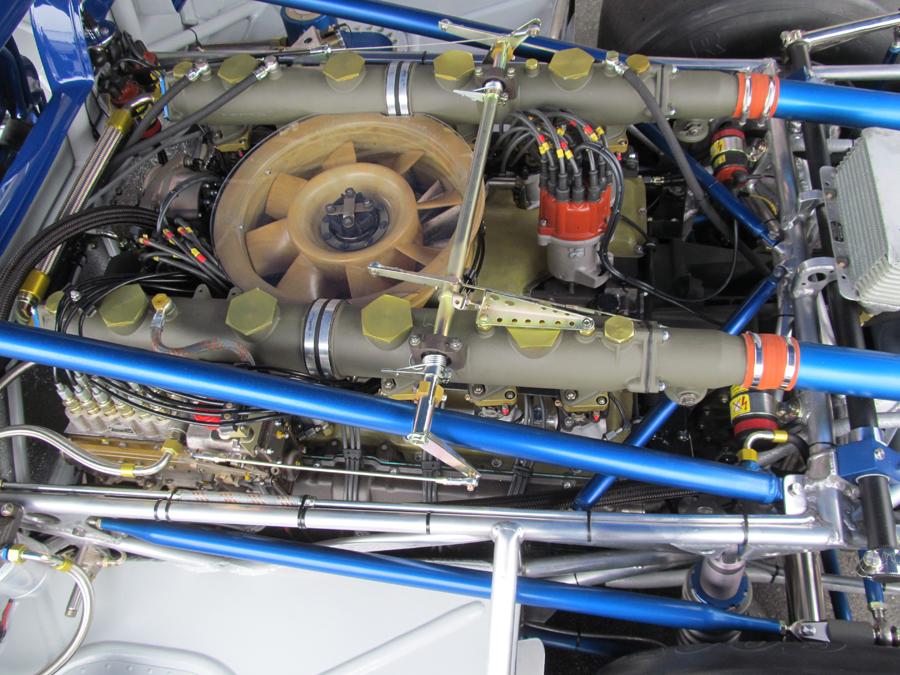

Model factory hiro Porsche 917/30

Big John replied to Brudda's topic in WIP: Other Racing: Road Racing, Land Speed Racers

-

Maserati A6GCS Spyder

Big John replied to absmiami's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Oh the things we'll do just in the name of research! -

Rotation is what makes the wheels go round.

-

If it were in a museum setting the truss would be black so it didn't distract from the focus of the show, if in a garage setting, most probably white to reflect the most light on the project. As in the 1:1 photos.

-

What shade is Bugatti Blue? guess it depends on the year?

-

Who doesn't love a mock-up? Let's see yours!

Big John replied to Belairconvertable's topic in WIP: Model Cars

kind of both mock up and orphaned project. Started this back in the late 1990s from the old Rod & Custom 'Paper Wasp' how-to article from around 1962. So much is incorrect that I am not sure if it will be resurrected. -

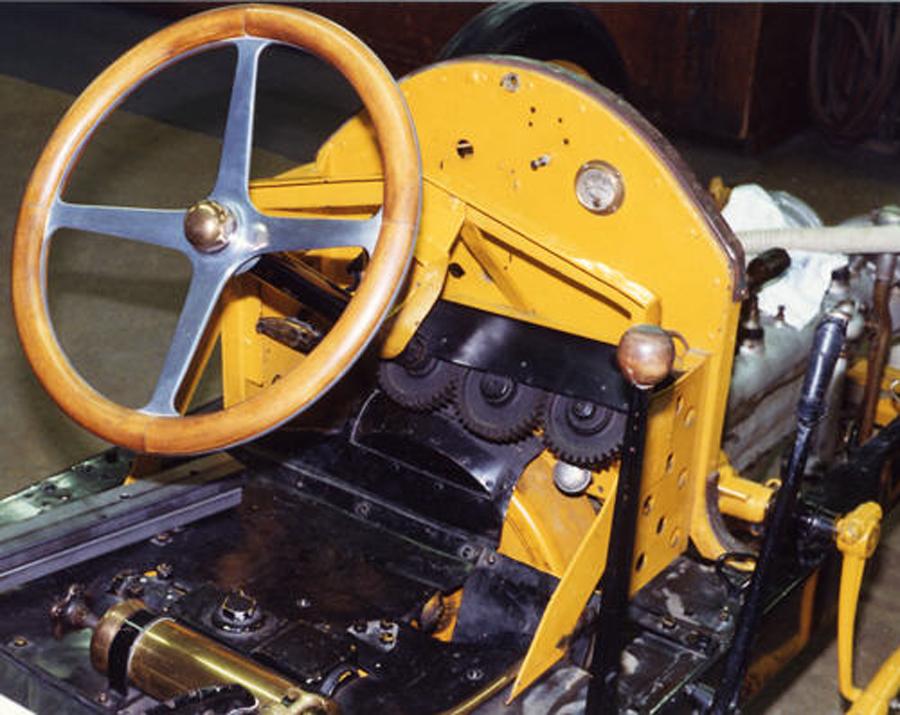

Good start on the firewall EG. Here are a few more detail photos that may help. There appears to be a cast metal part that holds the steering gears inside the cockpit. Closeup photos are courtesy of a fellow maned Tom from Carousel-1 (I failed to note his last name but am eternally grateful for his offering) Hope they help

-

Yes, just kidding about the wicker chairs in the Bentley.? The trolley, like the rest of your build is superb in detail and accuracy.

-

I don't know if the wicker chairs are right for this project, may not fit in the bodywork as is. Interesting concept though, maybe in the Raj period.

-

Wet is the way I put them away after riding them hard!

-

1965 Dodge Pickup by RMR

Big John replied to landman's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

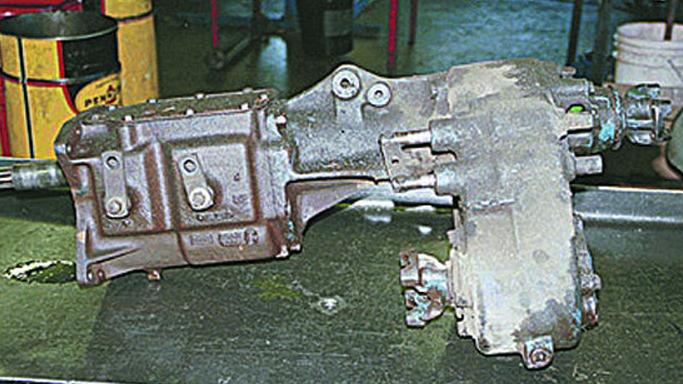

Hi Pat, Fun build, always liked the old civilian Power Wagons. I think you will want the rear drive shaft to go straight through from the engine drive line and only the front shaft is offset, unless you have other reference. -

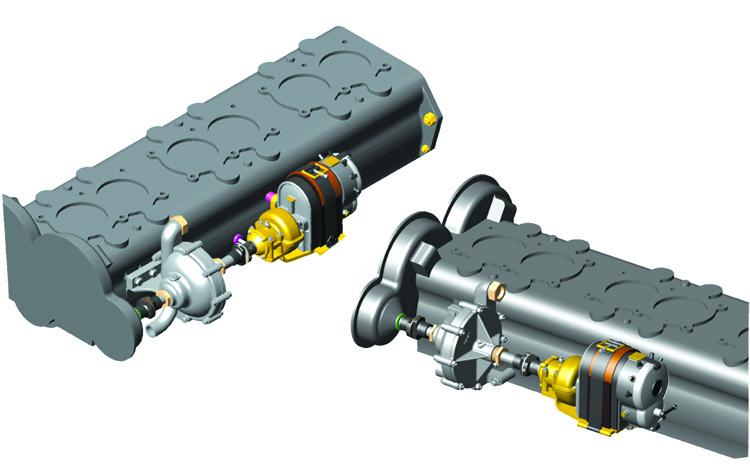

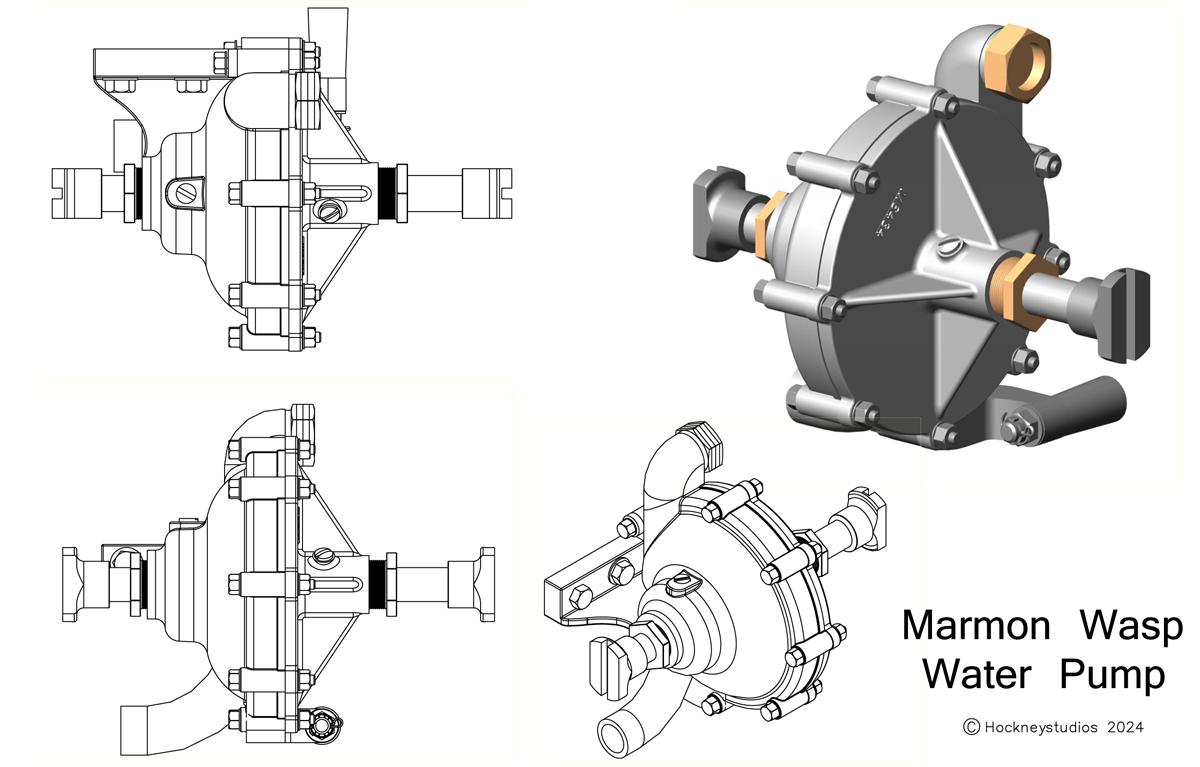

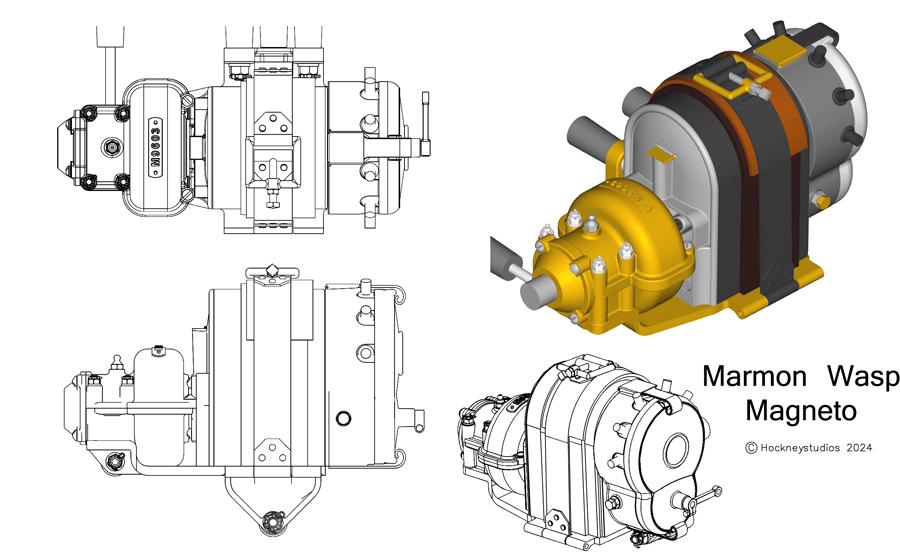

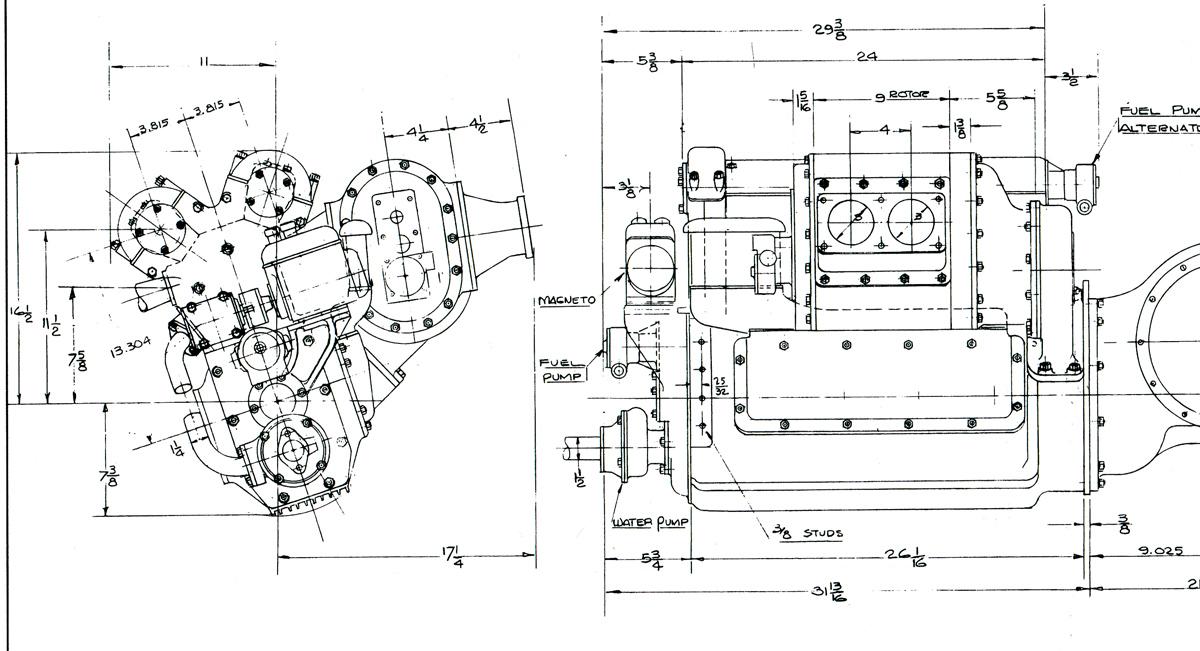

Fantastic work EG! Looks like you got your reference info from Indy on the clutch linkage, transaxle, and brake linkage. Finished my layouts for the water pump and magneto.

-

T41 Bugatti sport coupe

Big John replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

-

Them giant Ants are BACK!!!!

-

T41 Bugatti sport coupe

Big John replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

thanks for the thanks Charles, Take a search look at the post war Bugatti type 73C, and 102, which were to use 4 cyl. twin cam engine with a front mounted roots type supercharger. It looks like it is pretty much what you are going for. Since this is a fantasy car anyway, what ever you build will be great. -

T41 Bugatti sport coupe

Big John replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

As the story goes, Leo Goossen was a Draftsman working with machinist Fred Offenhauser to develop the racing engines for Harry Miller in the early 20s>30s. The Miller 91 engines use two head-in-block cylinder blocks on a common crank case. Legend has it that Ettore Bugatti purchased one of the Millers to use as a reference for the development of the Bugatti DOHC engines. The Offy engine as we know it today is the offshoot of Miller’s smaller 4cyl. Marine racing engine. So it stands to reason, in my thinking, that the Offy blocks would be a good jumping off point for the updated Bugatti engine. Goosen also went on to work on the development of the Ford 1964 DOHC Indy engines. -

Oh and Tesla batteries weigh in excess of 1,800 lb. So maybe a giant slot car track, or an overhead grid like real bumper cars.

-

At least you can put a fuel fire out.

-

Pony tail hanging down, wiggle when they walk, but watch your step when the they raise up in front of you!

-

Them batteries Blow Up REAL GOOD!

-

Vindaloo Who, said Horton.