-

Posts

2,113 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by BK9300

-

Making Tracks

BK9300 replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Charles, great engineering going on here. You have many skills I have yet to acquire and casting is one of them. Always educational! -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks very much, Gary - just means I have too much time on my hands! - glad to be back doing this hobby! Looking forward to that logger taking shape on your workbench. -

Before recently re-starting model building, I had spent a lot of spare time making replica First Nations artifacts. All my project ideas came from auction and museum sites. Never shown these outside of family or friends, and don't sell them - just for a personal collection. I have huge respect for those who created original work of this type, under far less ideal conditions than I worked in, at my workbench, with lots of light and a magnifying desk lamp! Read lots about other hobbies in various threads in this Off-Topic Lounge, and my past hobby certainly has nothing to do with models, but I'll post a pic of one of my projects (I can post others along the way) and would be interested to see pics of your "other hobbies", too. Kiowa moccasins - year unknown

-

Great subject car - wanted one when I was in school - amazing level of finishing!

-

Beautiful car - looks really good photographed outside.

-

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Charles, I appreciate you having a look and thanks for the compliment! Working out how to make the sander body removable - have figured that out for the sander’s hoses and attachment to frame but not for the eventual wiring. Should still be able to see a lot of the detail (I’m hoping) -

I needed another project....T800

BK9300 replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

It’s scarce - last bit I have I was from Moluminum, but that was a long time ago - thanks -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I used some pulleys I had in my "aftermarket" drawer, the supplier's tag long gone. The Allison might not have worked in real life for a truck like this, but it was a topic for consideration for awhile at the shop. I remember some fairly big, Halliburton, down hole cement pumper trucks in Fort St. John that were automatics (or the driver of the truck I saw could shift really fast!). The Allison was plausible, so I used it. Thanks for looking in! -

First time poster, long time lurker

BK9300 replied to Stuck Fingers's topic in Welcome! Introduce Yourself

Welcome to the forum, Bill - lots of new ideas in the builds here! -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

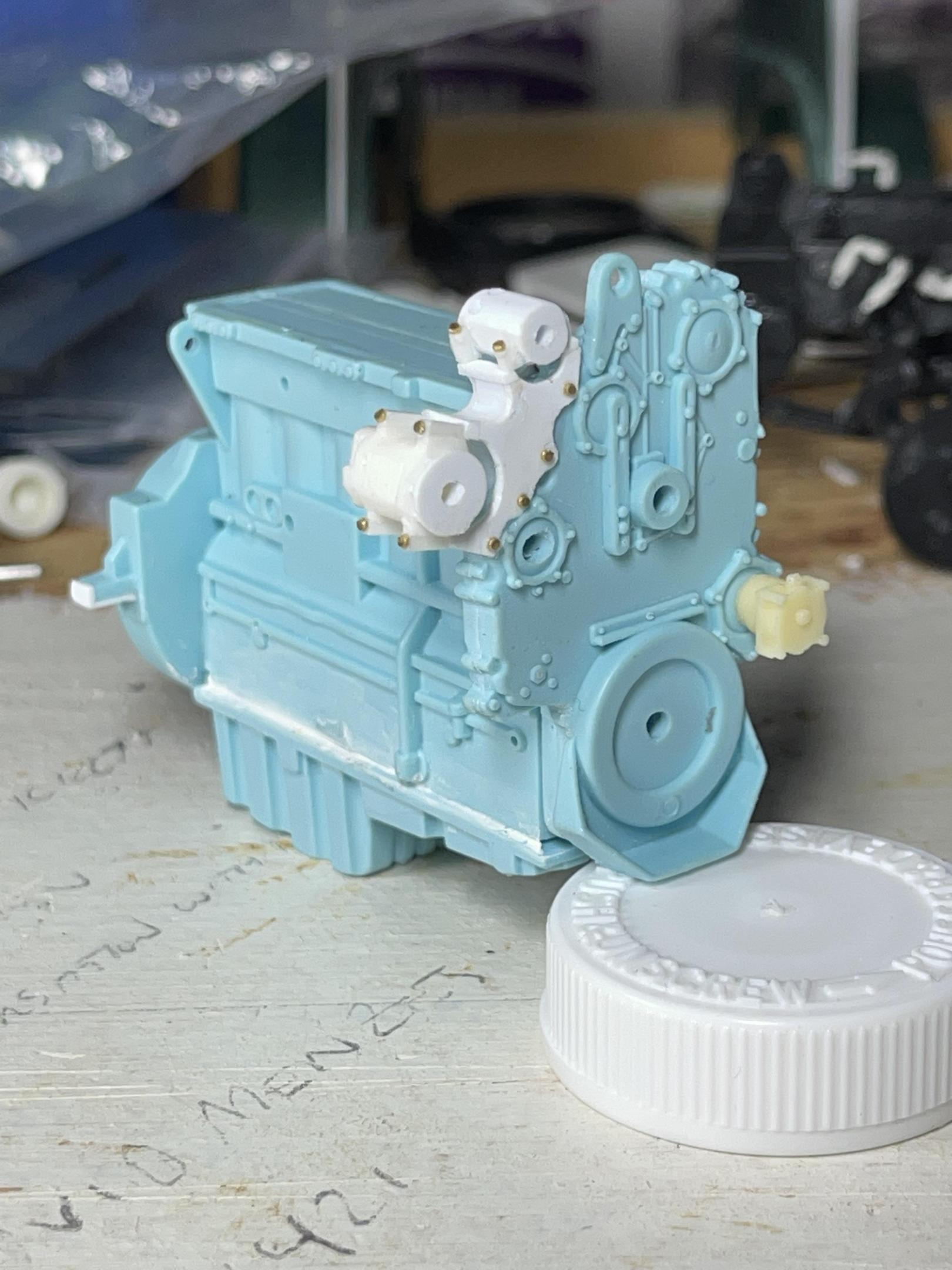

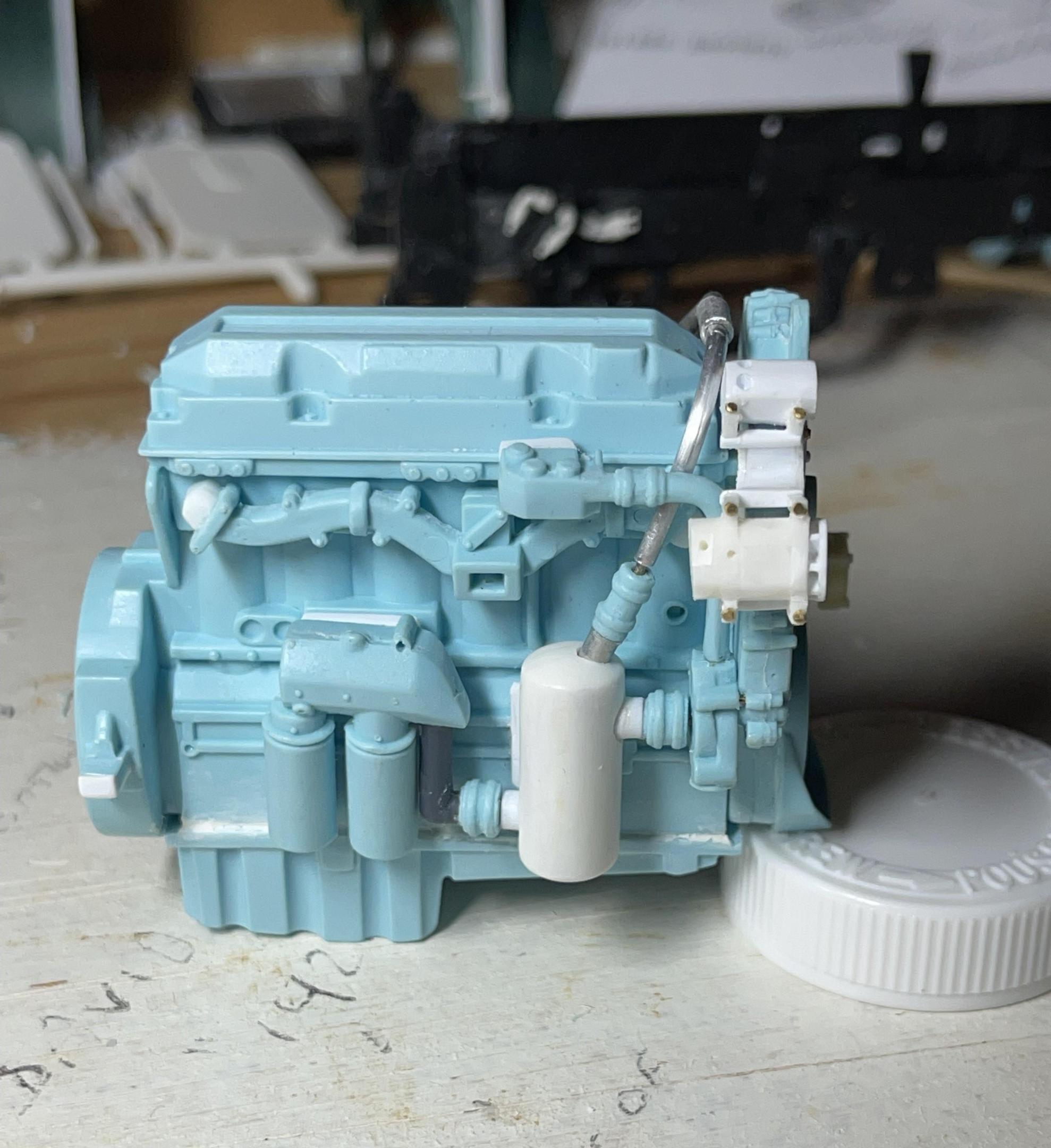

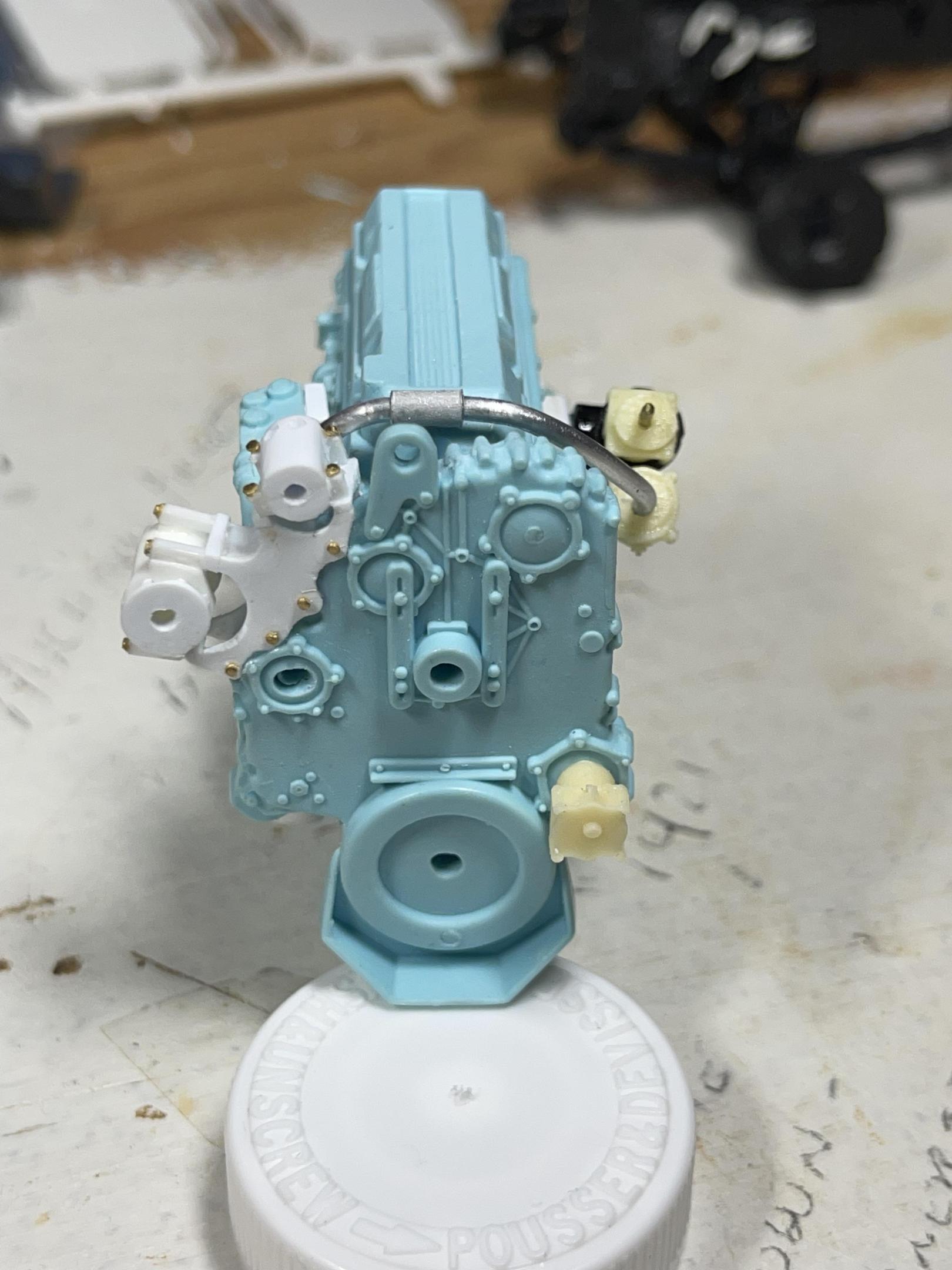

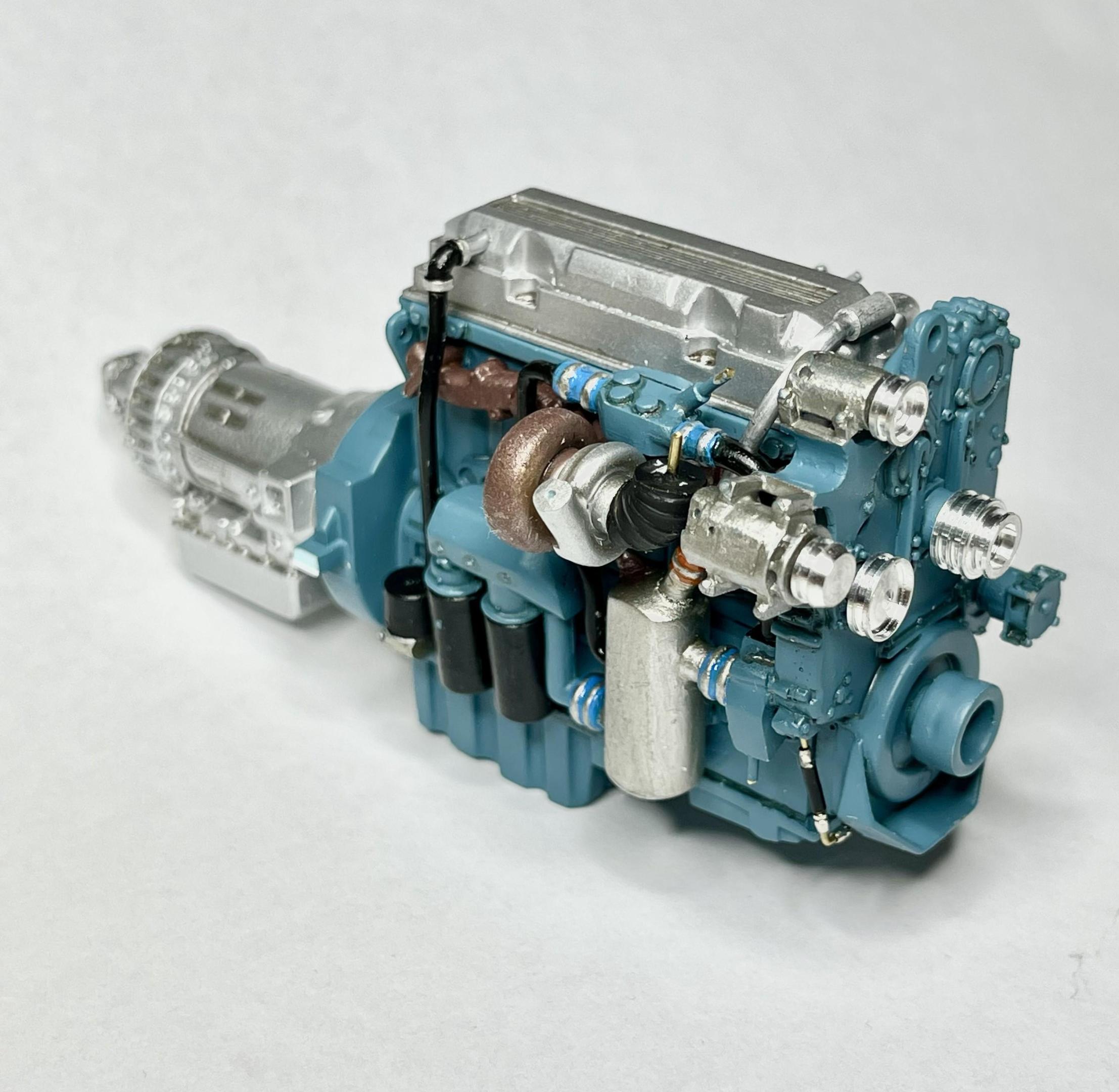

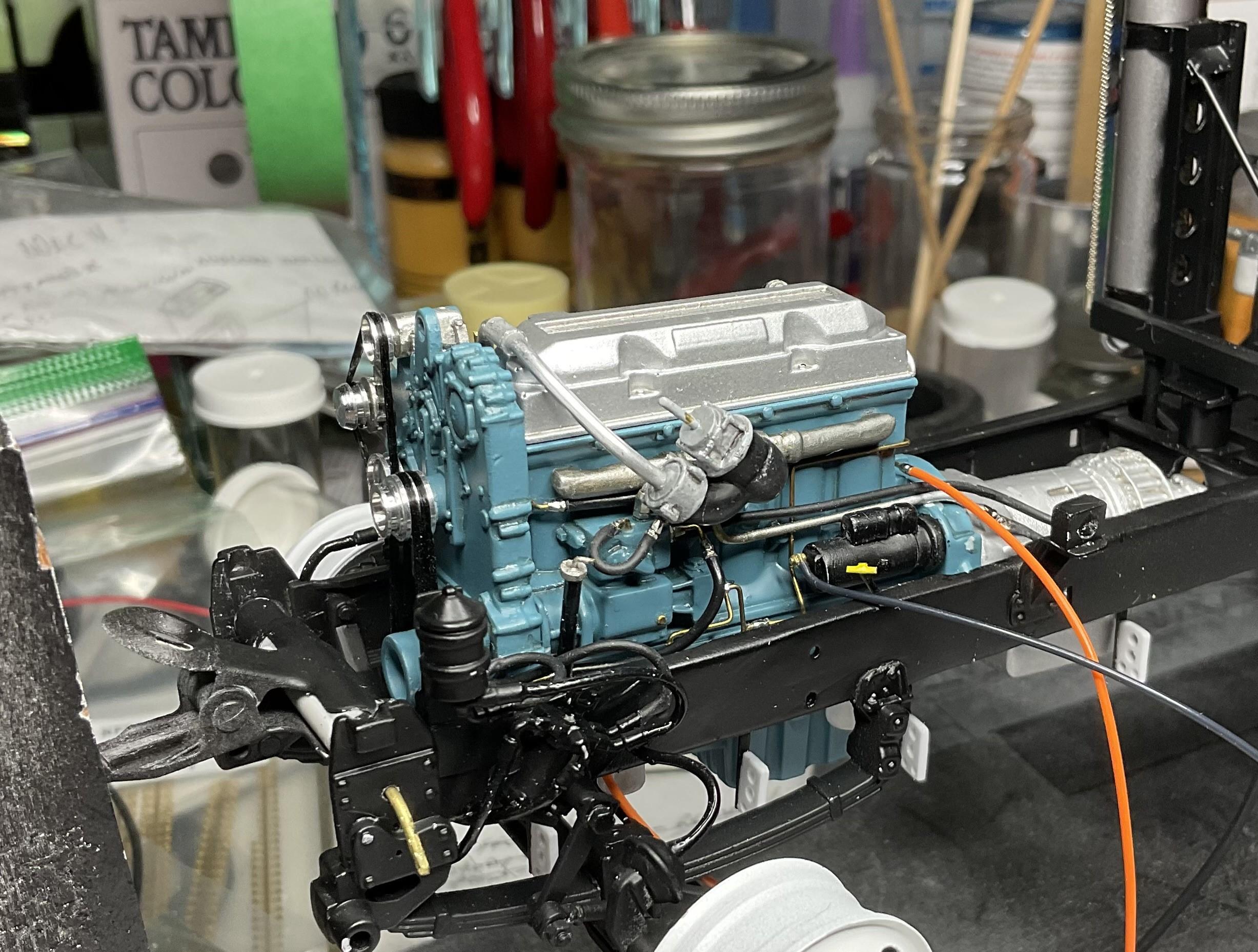

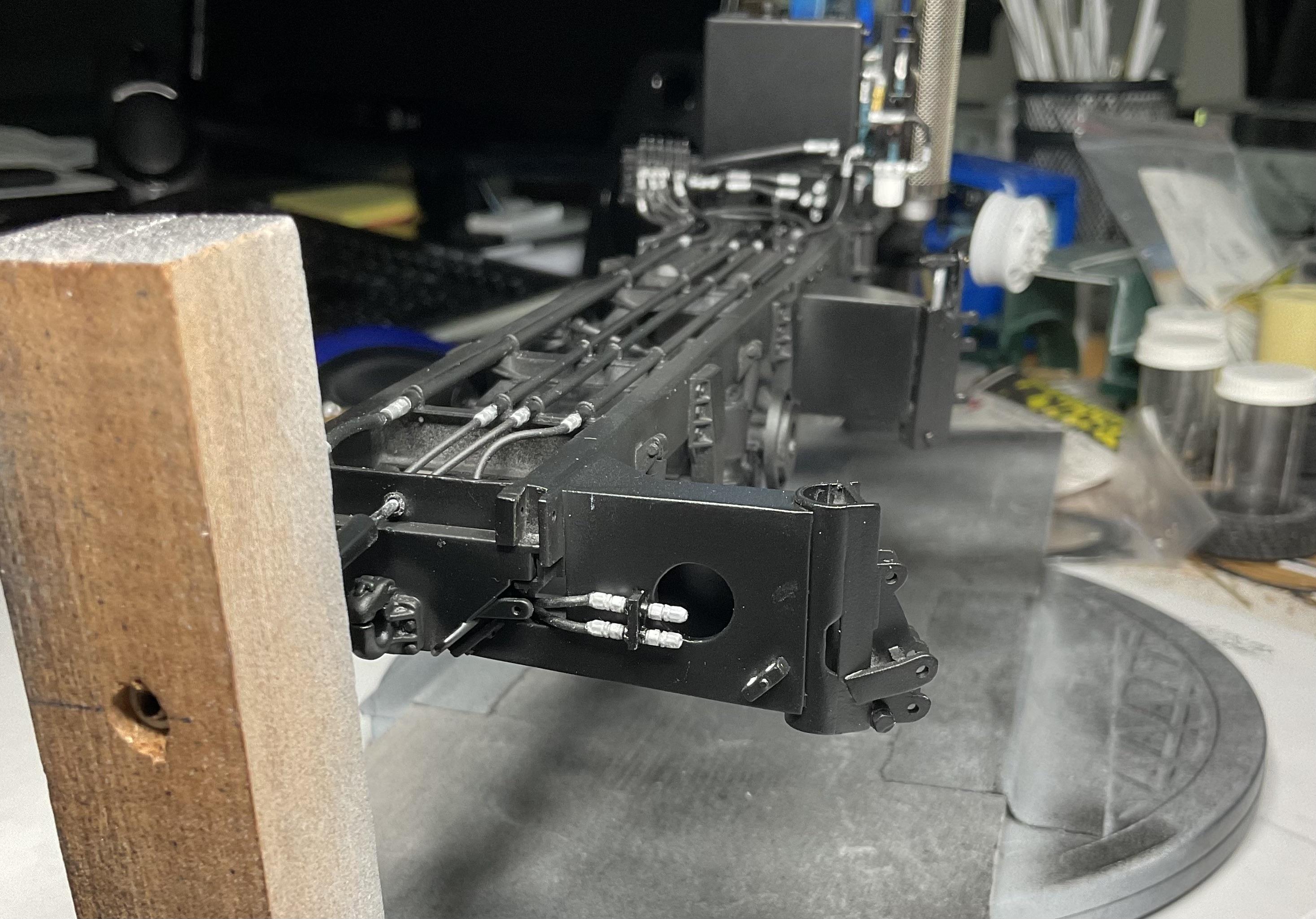

The engine in the real truck is a Detroit 60 Series and I purchased a resin one from Auslowe in early 2023. I worked on the engine on and off during the early part of the build and it got to the point that I needed it in the truck to carry on with the hydraulic line runs. Will need to add some more detail once the cab, radiator and front plow lift group are in place. Didn't take many pics back when I was working on it, so here is what I have so far. As always, I appreciate your comments! fabricated a Delco Remy alternator, an AC pump and mounting bracket real truck had an exhaust gas recycler, so had a go at that had to create plumbing for EGR back to intake manifold So, I couldn't find (or identify) an Eaton Fuller manual transmission in the few kits I have, but I remember a conversation with one of our shop managers - there were musings about trying out automatic transmissions in our trucks (that didn't happen in my time with the company). It may not be practical, but I used an Allison automatic transmission from Moluminum; added a vent tube from valve cover to crankcase; added aftermarket pulleys (many of the connections between delicate parts were pinned with brass rod to strengthen them) Engine installed, belts installed, added an oil filler spout to this side of engine, as well as a dipstick with yellow handle, connected power steering hoses - more detailing needs to happen now that engine is in frame. You can see the plastic hose run hangers attached to the bottom of engine and transmission Engine needs a bit of a wash to bring out highlights more - this truck didn't have many miles on it when I took the pics Now the final hydraulic runs can be made to front of truck! -

AMT Fruehauf Tank Trailer

BK9300 replied to OldTrucker's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

For all the grief the prep has given you, it’s coming along great. -

Everyone has already said it all - a superb build, with a touch of humour in your second pic!

-

I needed another project....T800

BK9300 replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Looking good, Jeff! Where are getting your red and white reflective tape from? -

1992 Ford F-150

BK9300 replied to Chuck Most's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Great build - the wheels / tires (and whole truck) look very realistic! -

1992 Ford F-150 XL Work Truck

BK9300 replied to av405's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Fabulous build! -

Beautiful interior, Dennis - right down to the finished edges of carpet on driveshaft tunnel!

-

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

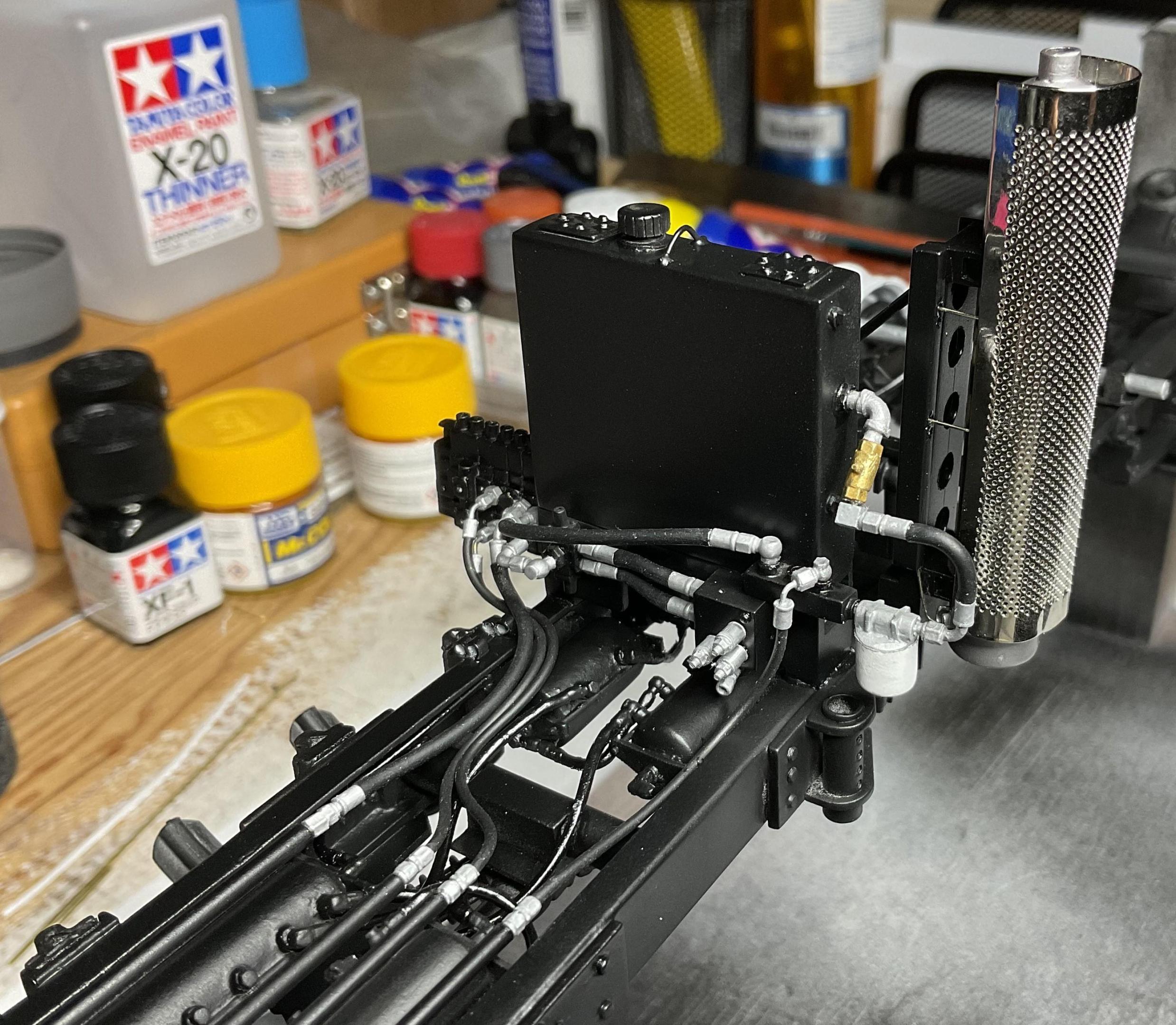

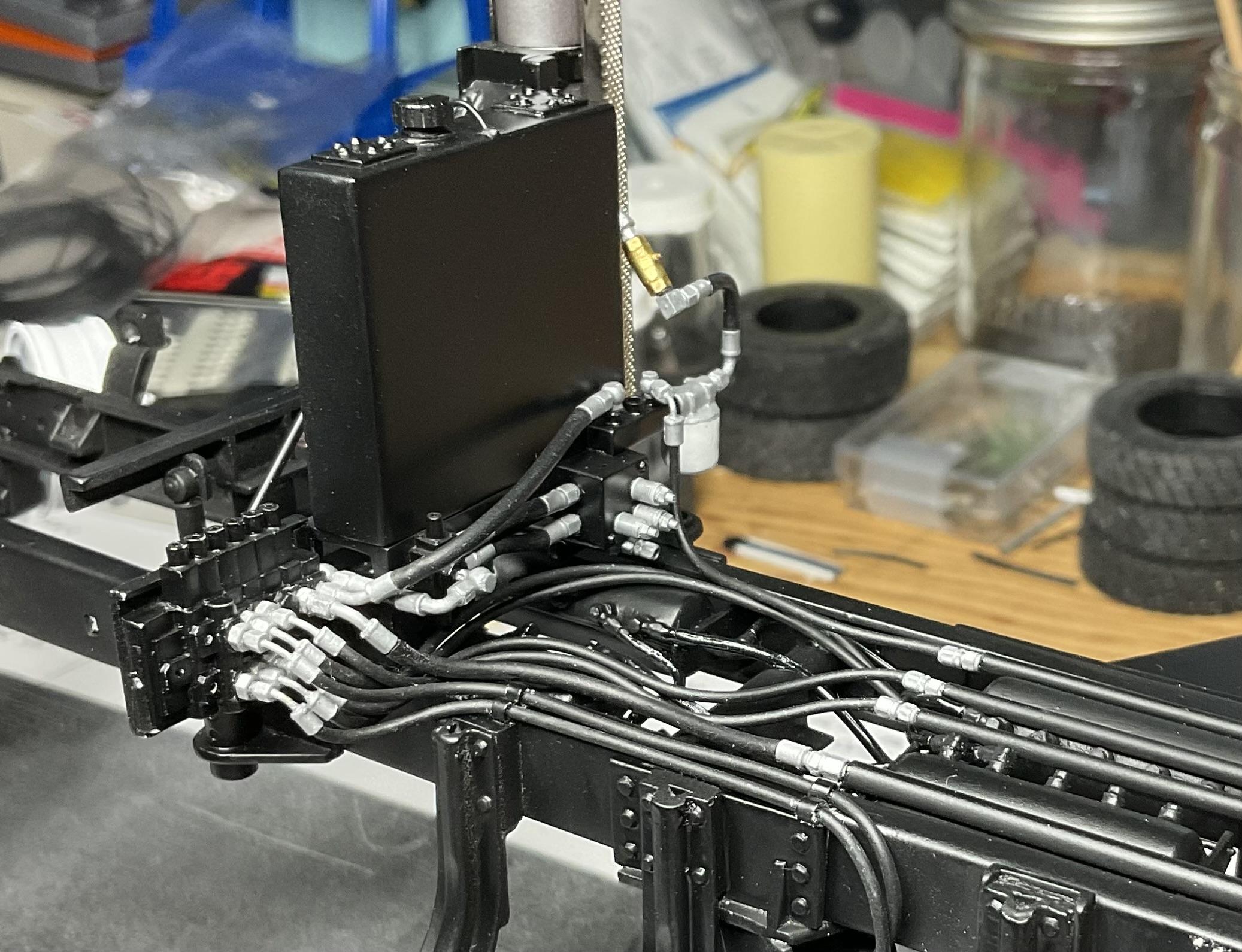

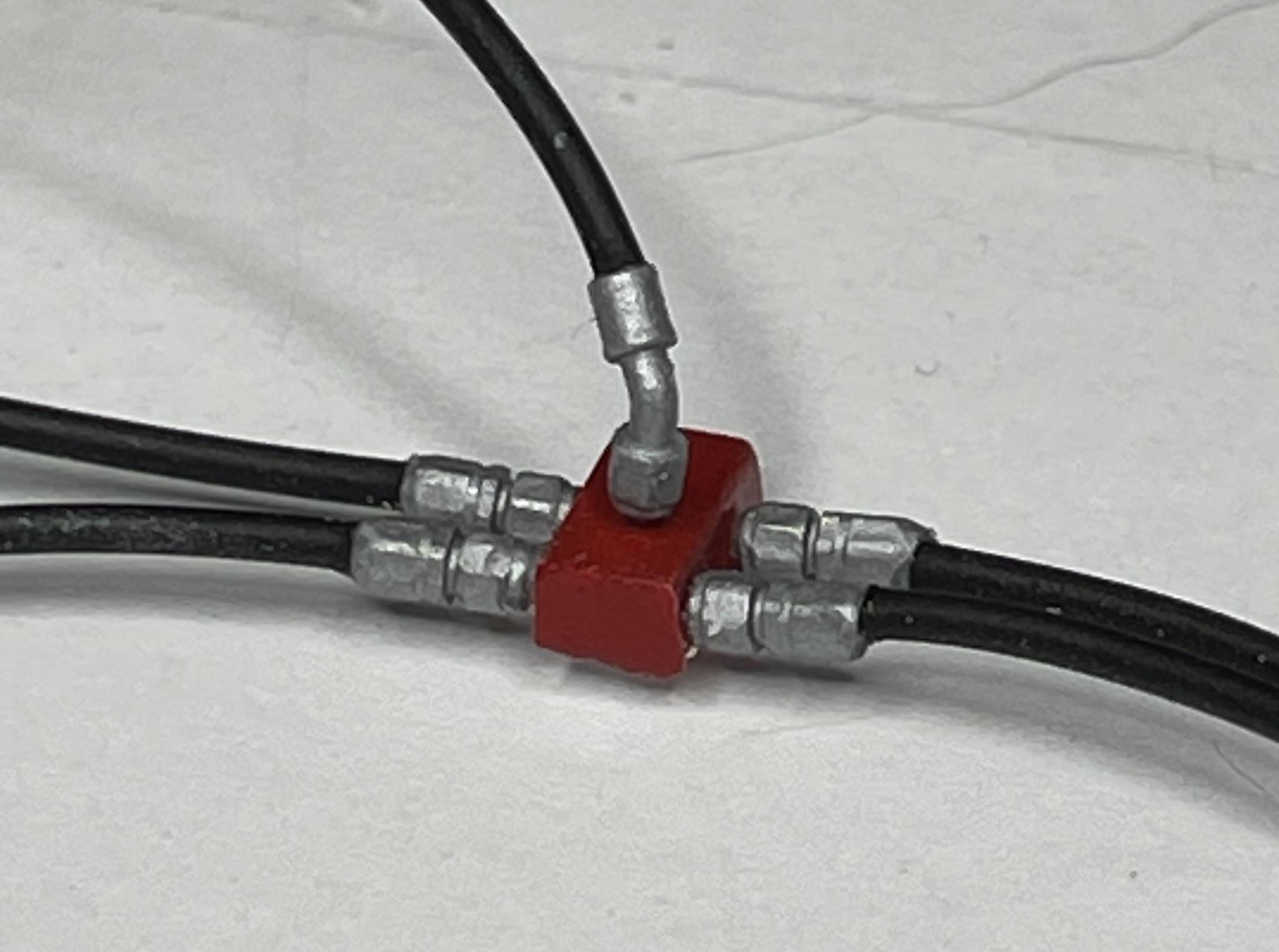

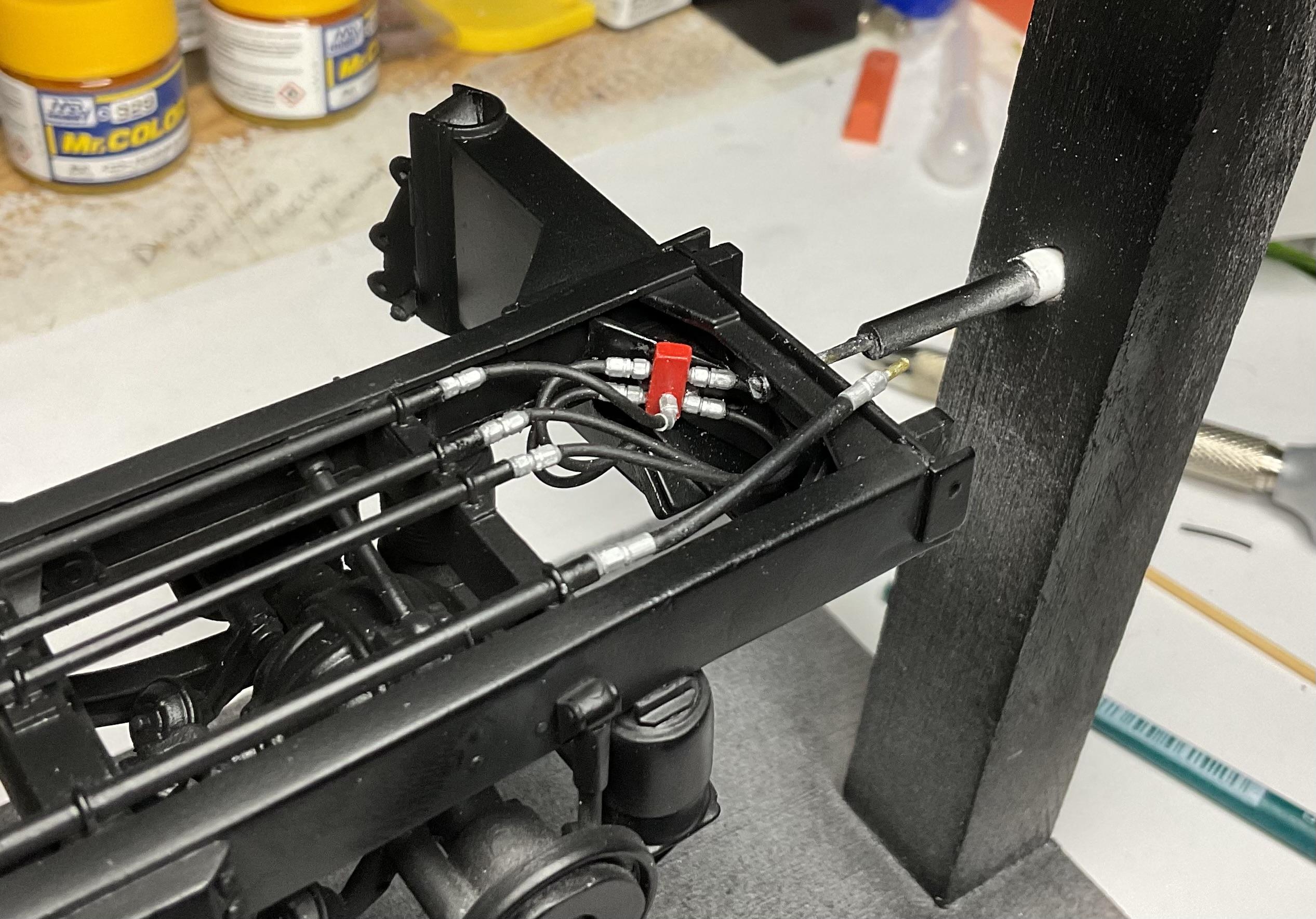

This series of pics finishes the hydraulic line runs from the valve manifold to the wing plow (front mounts), to the hard lines (for the wing plow rear mount and the main line run for any trailer use) and the underbody plow. Runs left to go are the lines to the front plow, and the low pressure line from the bottom of the hydraulic tank to the pump and the return, high pressure line to the inlet of the valve manifold (need to buy more hose from Ted's Modeling!) four hard lines connected lines hanging by front fuel tank hanger are for wing plow, front mount; lines hanging by rear fuel hanger are for underbody plow wing plow, front mount lines attached underbody plow lines attached all runs to wing plow, underbody plow and rear of truck now attached to valve manifold I understand this to be a control valve for the pressure lines to both sides of the cylinder piston that raises and lowers rear of the wing plow. Control valve in place; unfinished hard line extension (for trailer use)will exit out center of rear crossmember once frame is off rotisserie two pressure lines for cylinder that raises/lowers rear of wing plow Enough for today! I appreciate your comments and thanks for looking in. -

1992 Ford F-150 XL Work Truck

BK9300 replied to av405's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Just a great build for this utility pickup! I learned a couple things along the way to boot. -

Western Star 4900 FA plow truck

BK9300 replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks, Steve! Patience, well, yes - I know there are lots of pics to wade through, but there is a lot to cover. -

1/32 Aerodyne refurb

BK9300 replied to Rockford's topic in Model Trucks: Big Rigs and Heavy Equipment

Steve, you do amazing work on your fleet of 1/32 trucks - must have an impressive display area! -

Mack DM800 work over

BK9300 replied to Jürgen M.'s topic in Model Trucks: Big Rigs and Heavy Equipment

Looks great, Jurgen - good for another 100,000 miles! -

Must have a very steady hand doing the pins (I’ve lost more than a few small parts that shoot away from my tweezers while trying to place them) - and no glue marks - great work!

-

Marvel's Hydra coupe 1/12 scale full scratch build

BK9300 replied to François's topic in WIP: Model Cars

It’s going to be an elegant beast! -

1955 Ford F-100 Street Rod

BK9300 replied to Zippi's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

I just took a tour of your YouTube channel, Bob - just amazed at one great build after another - commendable work!