Mark W

Members-

Posts

332 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Mark W

-

Salt Flats Streamliner

Mark W replied to Dave B's topic in Other Racing: Road Racing, Salt Flat Racers

Great flats racer, there’s not enough of these around. Enjoyed seeing this. -

ARII Chaparral 2C

Mark W replied to Mark W's topic in WIP: Other Racing: Road Racing, Land Speed Racers

My guess is that Steve would have a tight squeeze in there. -

ARII Chaparral 2C

Mark W replied to Mark W's topic in WIP: Other Racing: Road Racing, Land Speed Racers

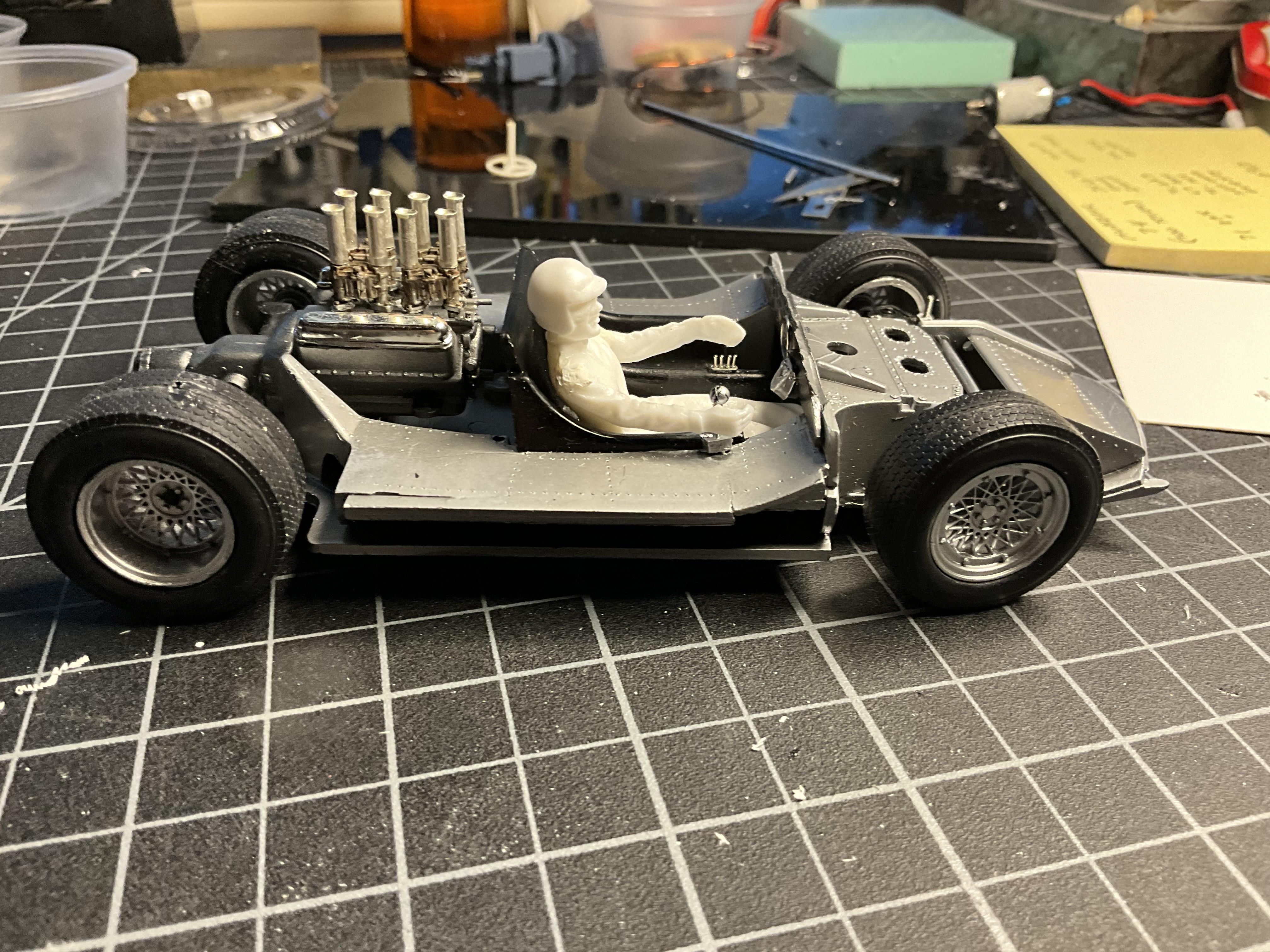

Got some Alclad on the wheels and mounted them. Jim now has both arms and is ready for paint. Injector stacks are on the Webers and I’m calling the engine done. The exhausts will be mounted separately. Next, a bit more polishing and the body will be ready for it’s screens. -

Sharp Chevelle, nice detailing.

-

Nice paint and interior, beautiful build!

-

Good job. The BMF turned out great. The Halibrands are a nice touch.

-

Link-Belt HC-218 Truck Crane

Mark W replied to redneckrigger's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Tom, I agree with everyone else, this is truly impressive build. Not just because of the skills involved, but it’s informative on how this equipment works. Following with pleasure. -

ARII Chaparral 2C

Mark W replied to Mark W's topic in WIP: Other Racing: Road Racing, Land Speed Racers

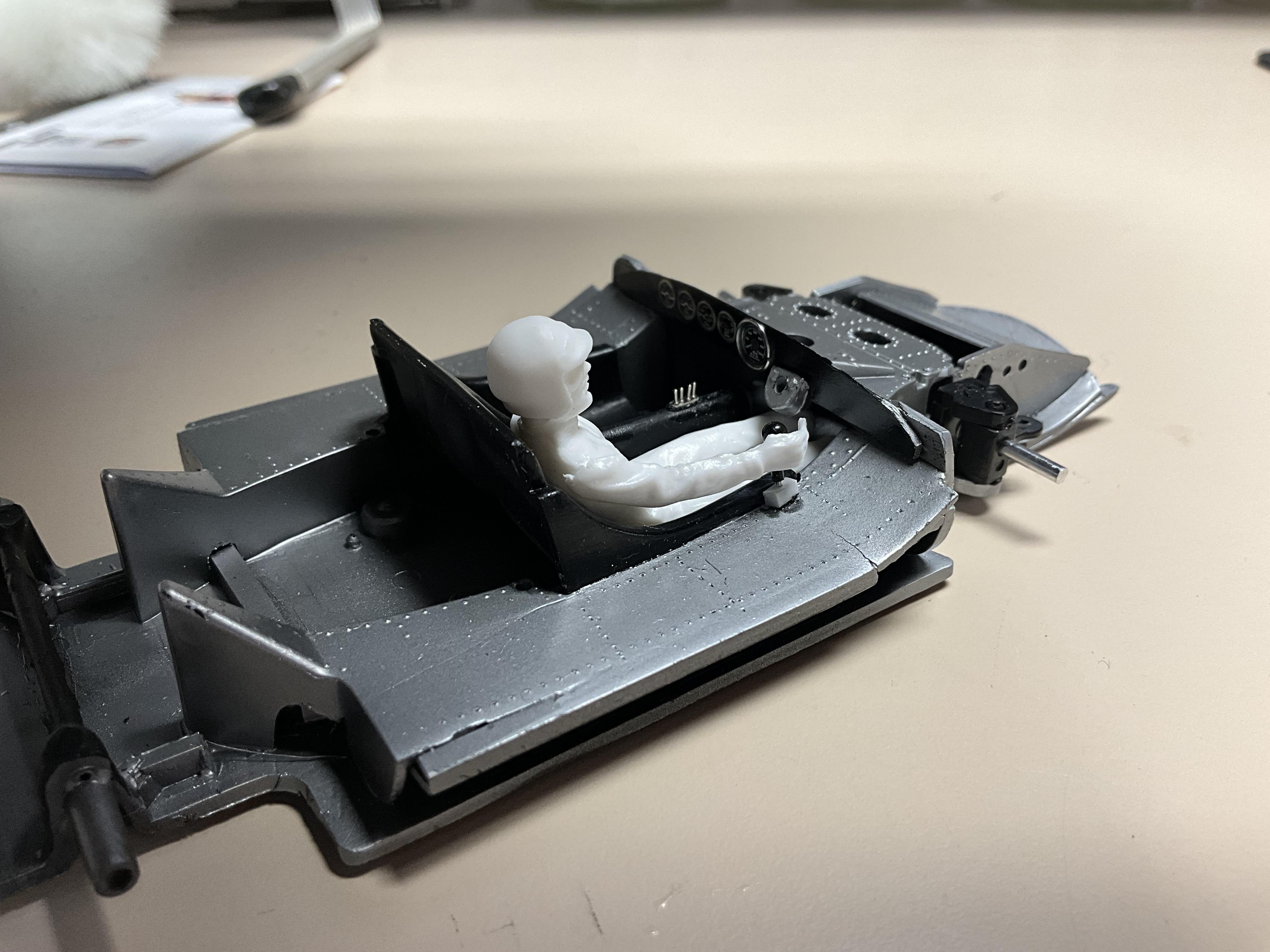

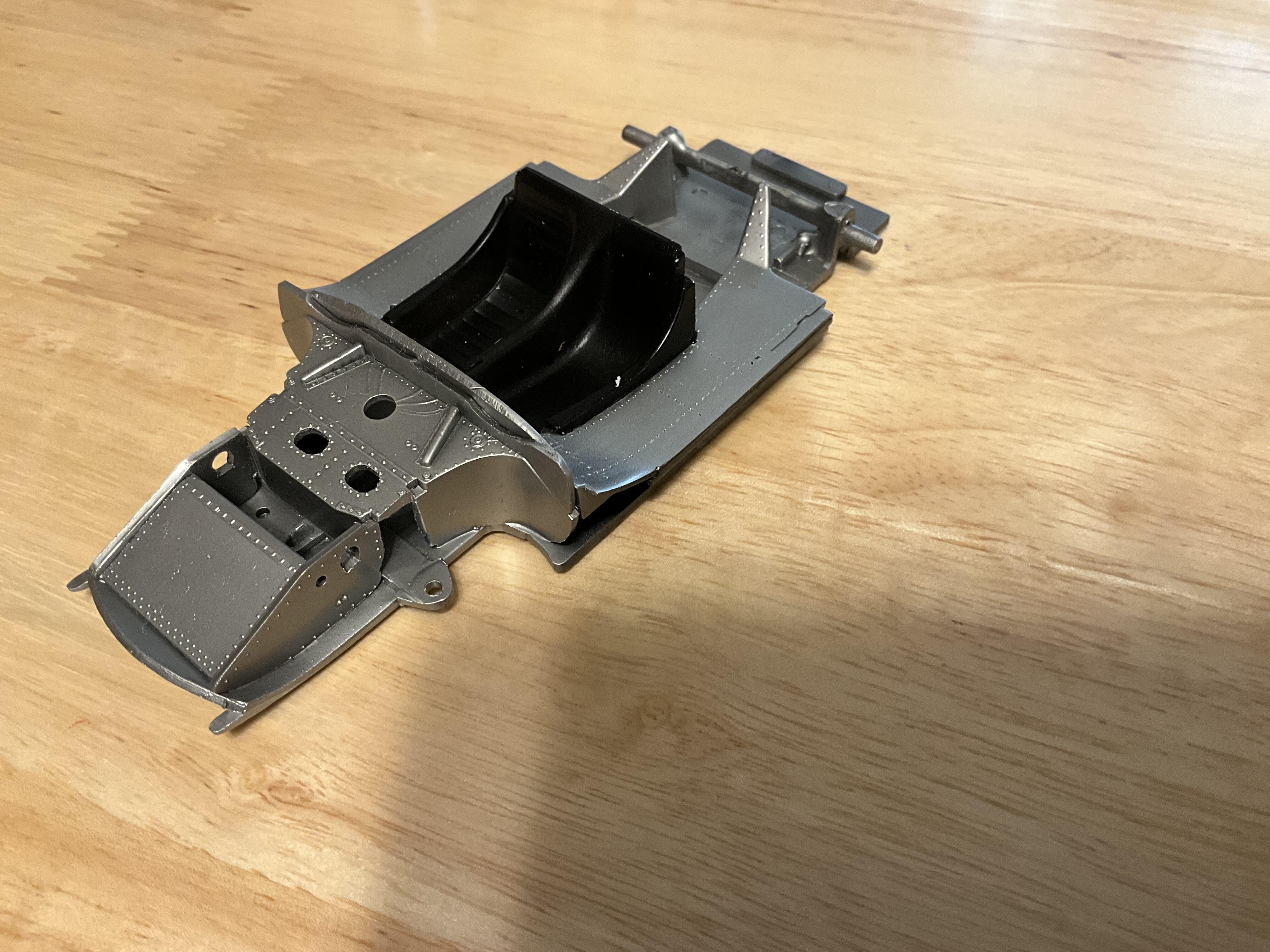

Interior update, got the gauges and console toggle switches in. Our “driver” is in for a test fit. Got his hand to set in the shifter, next step is the left arm on the wheel. Some sort of seat belts are needed. Front spindles are on, just need to make a tie rod. -

Following

-

Looks like a very interesting project.

-

Dan, just had the proverbial brain fart. While looking for the aluminum wire and being a retired electrician, I naturally thought wire for wiring motor armatures. I found it under craft wire. It’s used for making frameworks for various crafts, the framework is called an “armature”! I use hard aluminum for turning and this soft stuff I needed was right in front of me. Great tip for model builders!

-

Aluminum armature wire, eh? That might just be what I need! Also Greg, we might not make it perfect, but lathe work is just one cut at a time. Go for it and ask for help when needed.

-

1967 Ford F-100 Service bed

Mark W replied to nyguy's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

This came out really nice. Lots of cool details. -

cheetah reboot

Mark W replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Aahhhhh, no Dave your Cheetah is awesome. Now this build is on the next level. Really can’t compare it to our plastic kits. I’ll never attempt anything like this, but I’ll follow it every step of the way! -

cheetah reboot

Mark W replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

This is another level of modeling. Molding a body on a buck is a talent I can only wish I had. This will be most interesting. Are you making this a full build? -

cheetah reboot

Mark W replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

This will be one I will be following. -

ARII Chaparral 2C

Mark W replied to Mark W's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Maxx, take a close look at the chassis. It is indeed an early skinny tire, no fender flairs Grand Sport. -

ARII Chaparral 2C

Mark W replied to Mark W's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Good eye Maxx, but what makes this one a very limited production Corvette? -

ARII Chaparral 2C

Mark W replied to Mark W's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Aaaaagggghhhh!!!!! Yes, keep going! No, stop here! Don’t think I don’t lose sleep over this decision. But in the interest of moving on to other projects, I’m going to concentrate on what you would see on the 1:1 car if standing 5 feet away. And that does not include lying down! -

ARII Chaparral 2C

Mark W replied to Mark W's topic in WIP: Other Racing: Road Racing, Land Speed Racers

-

Looking very, very good so far Jim. The head and taillight mod is going to flow with the body lines perfectly. I agree about doing something with the roof, just don’t think you should do an “extreme” chop. More like 2” maybe? This type of custom is one of the best, glad you decided to resurrect it.

-

ARII Chaparral 2C

Mark W replied to Mark W's topic in WIP: Other Racing: Road Racing, Land Speed Racers

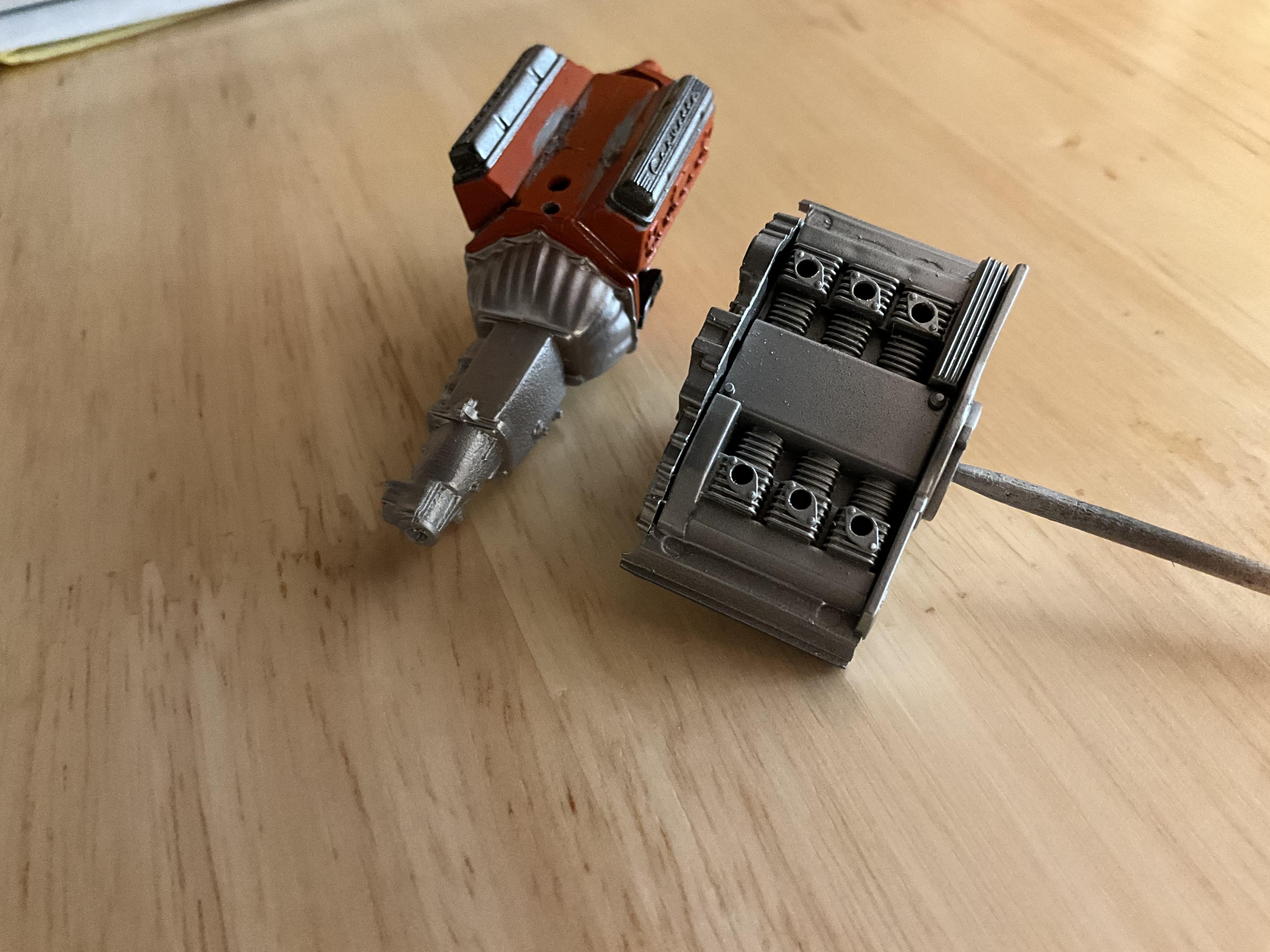

Progress today, and a bit of backstepping. But I learned a few things. Paint is on the body and I don’t see a clear coat going on. When I started spraying, seemed like the paint was going on a bit thick. But did I stop? No, just sprayed it on and hoped it would flow out. Which it did, but not totally. So when I sprayed the spoiler, I thinned it a bit and it flowed perfectly. Then I picked up the body and it really looked bad by comparison. Figuring I had little to lose since stripping it was in my mind, I put straight thinner in the gun and wet the body down. Sure enough (and to my surprise) it leveled a good bit. There will still be some sanding and polishing, but not near as much as I feared. Lesson learned, if it starts going bad ,stop! Fix the problem. Now the interior, after gloss black, on went Alclad aluminum. It turned out a bit grey. But a transmission that was sprayed at the same time was very bright. Later, figuring the metallics could have settled, I resprayed it and it was a bit better. Now the transmission was orange (overspray from the engine) and I just sprayed over it. I’m going to experiment with base colors and if it turns out well, I’ll share the results.