-

Posts

451 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by astroracer

-

My 1st car was a '73 Esprit. Florentine red metallic with a white interior and vinyl top. 350 2bbl and single exhaust. E70-14's on the Rallye II rims. I still have the car although it's been "enhanced" a bit. Right now it has most of a 14pt cage and no trunk floor or inner wheel wheels. i started Pro-Streeting it in '87 due to rusted out spring mounts and rear wheel wells. Never finished it. Mark

-

Jewelry suppliers have a huge selection of tools that can be used for modeling. I have a couple sets of the reamers and use them all the time. Check out this site and look through all of the sections. Tons of tools here. http://www.beadaholique.com/c-62077-cutters-and-files.aspx Go to Michael's or JoAnne's and look through their beading and jewelry departments. Mark

-

Welcome to the forum Brian. I am not to far from you. Byron. Mark

-

Can brass tube be annealed for bending?

astroracer replied to LDO's topic in Model Building Questions and Answers

LDO, if you are painting the chassis use 1/4" copper tubing for your difficult bends. It will solder to the brass just fine. Mark -

Woodward dream cruise

astroracer replied to tubbs's topic in General Automotive Talk (Trucks and Cars)

Just to make mention that, while Woodward is going on, so is Back To The Bricks in Flint. This show is an entire week long and has pretty much turned my head from the Dream Cruise. http://backtothebricks.org/ Also the Sloan Museum show is June 28-29. This is a huge show with nearly a thousand cars attending. Well worth a day trip if you want to see what Flint is all about. http://www.sloanautofair.com/ Mark -

Just an observation on my part. The Dobbertin/'Vette chassis is a bit too narrow for your Stealth body. Hopefully you will do some work to get the tires out to the fender openings. This is just a pet peeve of mine. I like the look of a wheel well STUFFED with tire. Besides, splitting the front chassis and widening it will give you tons of room for the V10 this car needs. Mark

-

Doesn't matter what you get or use. If they are too small cut the offending appendages off and drill a hole for your solder to glue into. Once they are glued wrap a piece of .010 sheet plastic around the solder to make the new slip joint. Mark

-

Yes Sir, Ken nailed it! As I have been saying in the MANY threads on this board about 3D printing, having a printer is useless unless you can create the 3D CAD models to print. The stuff Mike is doing is beautiful work. He is doing a lot of photo-realistic stuff that I have never done. Working for GM I have never had the programs to convert the files to a photo-realistic format. NX has some "canned" visibility options but nothing like what Mike is doing. I basically design the 3D models, make whatever drawings I need and then take those to the shop to build the parts. Having had a few parts printed I can also relate to the quality of an STL printed part. They not as perfect as most people think they are. There are a couple of other threads where this was discussed in depth so I won't get into here but a printed part really needs to be prepped and resin cast to be strong and usable part. Mark

-

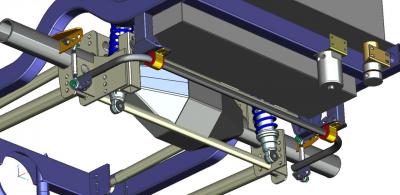

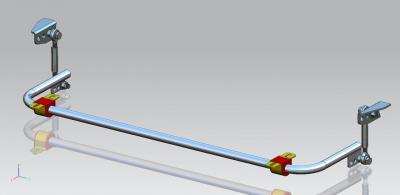

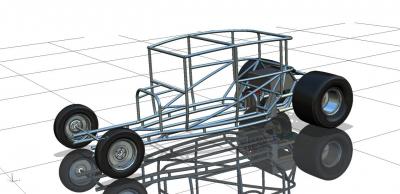

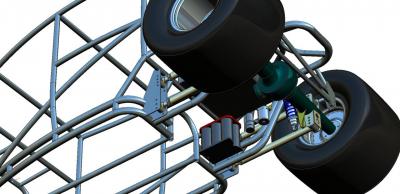

I use Unigraphics NX at work for stuff that pays the bills and at home for personal projects. Here are a few screen shots of an Astro van I am building and a '31 model A I am getting started on. These are 1:1 "models". The Astro is almost a roller with a full frame and the Model A is just a body with all of it's outside parts stored inside the body. I used my '31 to get overall dimensions and pulled some of the unimportant details from a 1/16th kit. The frame will be rolled from 2" DOM and I am planning a 331 Caddy for power. Mark

-

If you don't go the aluminum route use .010 or .015 thick sheet plastic. It will bend easily with your hand seamers and will not split for those small angle bends. I would go with the aluminum though, just as easy to work with and it will glue as well with the super gloo... For painting the aluminum use ScotchBrite to rough up the surface and then spray it with an epoxy primer. Keep it clean while painting and you should have no problems. Mark

-

Chroming the parts won't be an issue. Vacuum metalizing has no care as far as base material goes. The issue will be prepping the parts for the metalizing process. If Chrome-tech uses a sprayed on laquer basecoat that is where the problems will lie. Depending on how fine your photo-etched parts are you may see the paint filling in the open spaces between the bars. That will not look good after the chroming process. I would suggest talking to chrome-tech. I am sure they will want to see pics of some kind. Mark

-

Harbor freight has a couple of "hand seamers" that are perfect for bending small pieces of metal. I have a few different sizes I use in the shop all the time. 6 or 8 bucks apiece makes them very affordable. Also go to your local Home Depot or Lowes and ask for some aluminum flashing, it will be in the roofing section. This usually comes in 5" x 7" sheets and you can buy it by the sheet very cheaply. It is .010 thick and very easy to work. Mark

-

1970 mach 1 twister special with twister cobra

astroracer replied to freakshow12's topic in Model Cars

Nice job Fred. The door jamb and sill detail is impressive. It's one of those things no one "finishes" when they open the doors on a model car and is nice to see here. Mark -

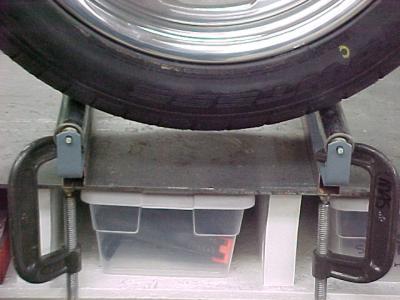

Bill has some good points Harry. You will have to step up through the grits to get the aluminum anywhere near ready for polishing. Just like I stated in one of my earlier posts, 2000 grit will be your minimum to get the shine back. And it will need to be feathered out to keep from making "waves". This is the rig I set up for polishing wheels. Much easier to stand upright to work on this stuff then bending over working on it on the floor. Couple of cheap rollers clamped to my fab table. The wheel spins in place and makes it easy to access all surfaces.

-

"Technically" for a model car, you can build your 732 starting with a 396 block. BBC's are essentially the same size, block wise, from the 396 up to the 672. There are some aftermarket blocks offered for the mega-motors but the only difference is in the deck height. The shape and physical size of the blocks are still the same. Mark

-

Plastic Injection Molding

astroracer replied to Ace-Garageguy's topic in General Automotive Talk (Trucks and Cars)

I used to do a lot of product/mold/injection mold and die design work. Some things you just can't do to make repeatable parts with a fast cycle time. Sink marks, ejector pin marks and porosity are all gremlins the mold makers fight against every day. Part quality changes minute to minute during a production run. As the mold heats up cycle times need to change to allow for additional shot time or cooling. Cycle time on a full kit sprue should be less then a minute from shot to die opening. Things have changed DRAMATICALLY since I was doing this work on manual layouts and calculating part shrinkage by hand... Sure does bring back some memories... Thanks! As you can see I will be interested in a report also. Mark -

looking to get a Mini Milling Machine

astroracer replied to dragzz's topic in Model Building Questions and Answers

I have a Smithy Lathe/Mill combo that I have been using for 22 yrs. I ran all of my product on this machine when I owned Machined Aluminum Specialties. I would recommend looking at one of these machines from Smithy, Jet, Grizzly, Enco, etc. Tooling is based on full size machines and is available from most machine tool suppliers. Multi-position tool blocks allow you to easily change tooling and the machines are much more stable then the smaller ones. This allows heavier cuts which saves alot time. The lathe side is much more versatile for machining wheels and You will get more use out of that then you will the mill. Mark -

Or just drill one big hole and carefully glue the wires in. Fill the hole with a little epoxy after the wires are set and paint. Who's to know you didn't drill 9 holes? Mark