-

Posts

451 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by astroracer

-

Not to muddy the waters but I have migrated away from most "automotive" type paints and moved into the nail polish realm... This Camaro was shot with a Chrome nail polish over Dupont sandable grey primer. You need to use Dupont or Rustoleum primers as most nail polishes are laquer based and are "hot" to the base plastic. Buying a couple bottles of nail polish at the dollar store is MUCH cheaper then a rattle can, even at Walmart. And the colors are endless. You will need a bit of laquer thinner for mixing and cleaning the airbrush but a quart of that is pretty cheap and lasts for a long time. Mark

-

POR-15 Marine Clean degreaser for resin bodies

astroracer replied to Matt T.'s topic in Model Building Questions and Answers

Soapy water is a lot different then these other concoctions the guys are using. Hot soapy water as your initial wash and scrub will remove 99% of the contaminants. A final washing and scrubbing with a TSP based degreaser simply gets the surface ready for paint. Handling the body with oily fingers after this prep is a no-no. It should be on a stand or handled with clean paper towels prior to spraying. Mark -

POR-15 Marine Clean degreaser for resin bodies

astroracer replied to Matt T.'s topic in Model Building Questions and Answers

I use the Grey pads. This is the FINE grade of pad. Mark -

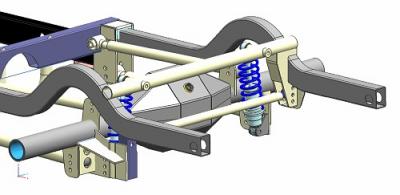

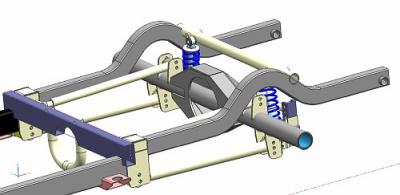

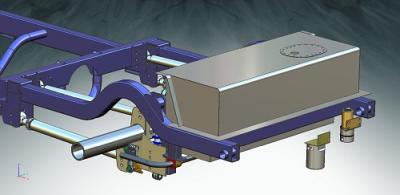

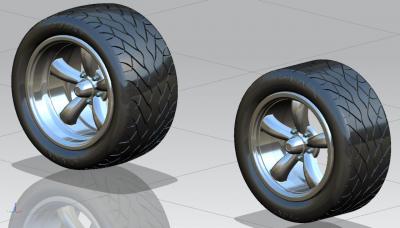

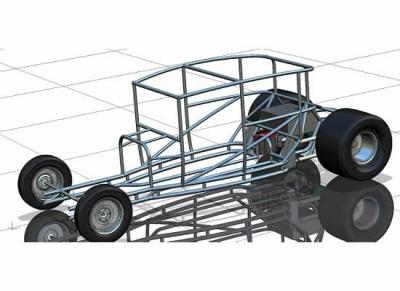

What do you need? These are pics of the 1:1 model Astro I am building. The chassis, suspensions, engine and most everything that required modification OR fabrication is modeled in 3D CAD on my home computer. As you can see I am well on the way to getting this done. The BIGGEST issue with producing parts like this is making them affordable. It is my first hand experience that no one wants to pay for the upfront cost of producing the 3D CAD and the printed masters. I have quite a few hours into the above tires and wheels and will bite the bullit on the design and printing costs just to see the products through to completion. I can't afford to do this with every single part I produce. Mark

-

POR-15 Marine Clean degreaser for resin bodies

astroracer replied to Matt T.'s topic in Model Building Questions and Answers

Hi Charlie, Right you are! NO MORE SOAKING!!! Soaking overnight has been an urban legend for as long as resin has been around. Don't know where/when it started but it is NOT necessary. Like Art and I have been saying, just a simple wash and a scrub will do the trick. Just like you never soak an injection molded body, why would it be necessary to soak a resin cast piece? Working with resin is not rocket science. Mark -

Got some quick rims turned this morning. I mocked the black tires up under a '69 Camaro convertible I am working on. Stance isn't perfect but the body and interior are just sitting on some spacers and, as you can see, there are no centers in the wheels. You guys tell me what you think. I am also looking for someone to resin cast these. if any one is interested PM me and we can talk. Mark Smakal MAS 3D In Scale

-

I got the test tires today! I had them printed in Black and in extreme detail frosted. The frosted is hard to photograph, they will need some paint to bring out the detail. The black ones actually look very nice. The tread shows up great and looks correct. The sidewall lettering is a little blobby but you can't really see it anyway unless you are looking thru opti-visors so I don't think it will matter. It's not like this style of tire has a raised white letter anyway. If I was using these I would put a thin coat of matte clear on them and build away. The Extreme Frosted are incredible! You can read the sidewall lettering. Even though I couldn't get a good photo of it, it is there. Let me know what you guys think but the black ones could be used as is with jus a little clear to seal them up. Mark Smakal MAS 3D In Scale

-

POR-15 Marine Clean degreaser for resin bodies

astroracer replied to Matt T.'s topic in Model Building Questions and Answers

THANK YOU ART! I hope the guys will listen when we say this. Soaking has been an old wives tale for so many years it's hard to dispell it. Soaking does nothing other then allow the soaking liquid to leach into the resin. This is not what you want. Washing and scrubbing will do the job and, after scrubbing with the ScotchBrite, the resin is in near perfect tooth for primer. Mark -

POR-15 Marine Clean degreaser for resin bodies

astroracer replied to Matt T.'s topic in Model Building Questions and Answers

I haven't bought TSP in years, I have a couple of boxes in my stash and it only takes a half teaspoon or so to do a couple model bodies. I also wash the kit styrene in it as their release agent is no different then the resin ones. The issue with the resin cast bodies is the molds are pure silicone and some of this does transfer to the resin as it cures because of the heat generated. I have found TSP removes the silicone better then anything else I have tried. If you can get the "diluted" version of TSP do it. I doubt the phosphate agent has any real benefit when degreasing. If you forgo the TSP, wash the model with Dawn and then Scrub it with ScotchBrite and a bit of laquer thinner. After that, wipe it down with any automotive wax and grease remover. You should be able to buy a pint or quart at your local auto painters supply. Mark -

POR-15 Marine Clean degreaser for resin bodies

astroracer replied to Matt T.'s topic in Model Building Questions and Answers

Matt, You don't have to do this. You do not have to soak the resin, you don't need any "special" cleaners other then some Dawn and a bit of TSP. I have been trying to dispell the soaking mythe for years! It is not necessary to soak the body in anything. Washing it with Dawn and hot water, inside and out, will get the mold release off. Scubbing the body with TSP (Trisodiumphosphate, it's a cheap degreasing agent used by house painters to clean before painting.) and a pad of ScotchBrite will have it nearly ready for paint. TSP is a couple of bucks for a box at your local hardware. Try it. I have never soaked a resin body prior to painting. I did quite a few display cars for Ray when R&R was still going and NEVER had an issue with adhesion or fisheyes... Mark -

Thanks Mike, I got an email from Shapeways yesterday the tires are on their way. Printed and shipped. Should see them tomorrow! By the way, I can print these out in any scale. I did the 1/24th first because that was the job, but if there is interest in 1/16th or even 1/12th that is doable. Here are some 1/16th scale cheater slicks I did a year or so ago. They are out being cast now. You can see how I did them in three pieces to make them easy to cast.

-

using aluminum foil

astroracer replied to jacoballardtattoo's topic in Model Building Questions and Answers

A pack of .010 thk x 4 x 12 Evergreen sheet styrene (4 sheets I think) is usually about 4 bucks, not that expensive. On that note, I built a 1/16th scale '56 post car out of a '55 hardtop and the side windows are "Please Do Not Smoke" placards from motel rooms. Most of the car was built on the road going to and from model shows... Mark -

Hmm. I doubt very much these will be available for 10 bucks. Resin Casters just can't compete with the quantity of injection molding. Pegasus is buying thousands of those injection molded tires and wheels at one time. A resin caster can't do that kind of production. I guess that will leave you out. Mark

-

Thanks for the input guys. I have NO idea what prices will be. That will be totally up to the resin caster. I am just modeling and proto-typing these right now. I do know I will have about 200 bucks of my own money into just the proto-types and that does not include my CAD time. Add another 2K to that for my time. I doubt any of you guys want to cough up 2200 dollars for a set of model car wheels and tires. I don't spend that much on the 1:1 stuff. If there are any specific sizes or wheel designs you are looking for that can be discussed later, IF this project gets off the ground. Mark

-

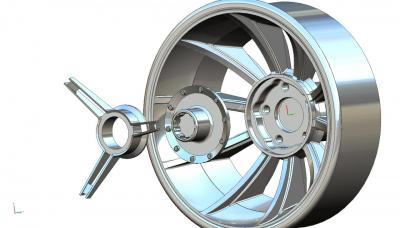

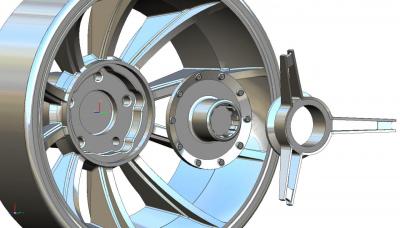

Thanks guys, I hope this comes to fruition also. Here are some jpegs of the 3D wheels with some paint. This is the wheel as I was asked to develope it. I did the intial work in good faith and the "customer" backed out after I had worked on these for a few hours. He said he would "happily" discuss the compensation in his Dear John Letter but then ignored my following posts with a total for services rendered. You can probably tell I am a bit miffed at this guy... There is a pic of the real wheel and the car they are mounted on also.

-

Hi guys, A lot of you know me from the days when I was operating Machined Aluminum Specialties. That has been 11 years ago when I handed the business over to Terry Kinnear. Anyway, I was doing these pieces for a customer when he stiffed me on payment so, I decided to finish them and offer them to you guys. These are highly detailed and, if the interest is there I can do other pieces and wheel styles. 1/24th scale 275/40-17's & 345/35-18's. These are pics of the 3D models. I have samples coming from Shapeways in extreme detail frosted and I will post pics when I get them. I am just gauging any interest in any of these pieces before i contact a resin caster to produce them. They will have to be resin cast to make them affordable. Mark Smakal MAS 3D in Scale

-

Favorite primer for airbrush?

astroracer replied to dawgvet's topic in Model Building Questions and Answers

Plasti-Kote or DupliColor Sandable Grey Primer. Decant from the rattle can and spray. Mark -

Ding, Ding, Ding! In order to print 3D you HAVE to have 3D models. No one can print anything of relevance until they have a 3D model of the subject. I have been doing 3D CAD design for 30 years. Modeling a body is tuff for me let alone anyone with no experience. This is one I have been working on for a while as a pet project. Using my 1:1 Model A body and a couple of 1/16th scale kits the 3D CAD is very close. I have quite a few hours into this and it is far from complete. This is the chassis design which is much easier to model. Just letting you guys know this stuff doesn't just fall off trees. It has to be made, to be made. Mark

-

Nice Buick! Reminds me of me back in 1990. Don't want to hijack your thread but I had to post this... Mark

-

Hi Jon, welcome from Byron. Mark

-

Need some help with a Pro Stock Car Idea I have.

astroracer replied to Zahadum's topic in WIP: Drag Racing Models

Just a pet peeve with me. Resin bodies do NOT need to be soaked in anything overnight. Just wash with warm water and any dishwashing soap. That will get them clean enough for paint. I will scrub the bodies in the warm water and soap solution with coarse ScotchBrite to rough them up for primer. That is all that needs to be done. Very simple. Treat the resin just like a molded kit body and you will be golden. Mark