-

Posts

39,340 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

Epic Ad Fail, eBay...

Ace-Garageguy replied to Mike999's topic in General Automotive Talk (Trucks and Cars)

Yes, it has become systemic, bordering on existential. -

Current Hot Rod / Street Rod trends

Ace-Garageguy replied to OldNYJim's topic in General Automotive Talk (Trucks and Cars)

Look over the past few year's entries in the Grand National Roadster Show for a good idea of what's hot in rods, especially the contenders for America's Most Beautiful Roadster. Straight 'traditional' cars were on top for a while, but more modern flavoring has been creeping in. Here are the 2019 cars to get you started... https://www.classicarnews.com/2019/01/26/americas-most-beautiful-roadster-2/ ... -

Next Gen Air Racer

Ace-Garageguy replied to Flynlo's topic in All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Maybe a budding Patty Wagstaff... -

Long story short...in 1/25 scale, pretty much any Chevy smallblock engine can pass for any other Chevy smallblock (with the exception of the first 265s that had no boss cast on the block for an oil filter). If the block and heads are well rendered, swapping ancillaries like valve covers, intake and exhaust manifolds, and accessories like generators/alternators and AC units, you can period-date a smallblock Chevy engine anywhere you want. In fact, much the same is true in the real car world. For instance, a 1998 350 can easily pass for a 1962 327, and only the most knowledgeable Chevy engine aficionados will ever spot it. Find a photo of an engine of the era you want, and swap bits to get the right look to match. EDIT: the 3-carb, open header setup shown on the box was a popular setup as far back as the late 1950s, and still is today.

-

My '62 Bug came with a clapped out '58 36-horse engine. Every seal in the thing was hard and crispy, including the front main (flywheel) seal. Little car had lots of other problems as well, like a bent front torsion-bar housing, but I was too inexperienced to know any better. She'd drip a quart out on the pavement in about 5 minutes. I bought a junkyard 40-horse and went through it (my first major mechanical work on anything), stuck some headers and a 2-barrel on it, and thought I was hot stuff. Before I was out of school, I'd swapped in a mildly warmed-over Porsche 356 SC engine, started winning autocross events, and the rest is history.

-

For the most part, I've shied away from giving any opinions on this topic, as the potential to ignite a firestorm is very real. That said, the unkind truth is that, of the approximately 36 MILLION Americans unemployed by this mess, the great majority have no substantial savings, particularly the younger and lower-skilled members of the work force. Many shuttered businesses will never reopen, many jobs will never return, and making a blanket portrayal of those who want to get back to work as "reckless, selfish, and cowardly", as has been heard in several high-profile comments nationally is simply beyond comprehension. My current home state has been cautiously reopening for several weeks, and the fear-mongering predictions of catastrophe in Georgia's media-tagged "experiment in human sacrifice" have failed to materialize...though one comment from someone who should really know better stated that there was a 40% rise in new cases, an outright lie, easily discredited. We are NOT all in the same boat, as was noted here earlier, and those who have a comfortable cushion, safety net, or sufficient government help to survive through this unprecedented mess relatively easily would do well to consider the millions of American citizens who don't have it so good. EDIT: I include myself in the "those who have a comfortable cushion, safety net, or sufficient government help to survive through this unprecedented mess relatively easily", as I've been able to work full time and haven't been sick. I'm deeply concerned for those who aren't as fortunate. I will also stay away from voicing or endorsing any opinions regarding the handling of the pandemic or the lockdown, as it's obviously a very politicizing situation at this time.

-

Last time I actually got far enough with a model to paint it (using a clear) was back in 2012 or so, I think. I loved the Testors wet-look stuff, and it was such a good product I assumed it would be around forever. Too bad it's followed so many other good products down the same rabbit hole. I've used Duplicolor clears extensively since then on real parts, so I guess I'll have to look into trying them for models as well. Everything else they make works well at this time, once you understand the limitations of a specific material...like not being able to shoot a wet flow-coat on most styrene with their relatively hot primers.

-

What Did You Get Today? (Not Model Related)

Ace-Garageguy replied to LOBBS's topic in The Off-Topic Lounge

Got a two hour hike on the 'moderate' trails. -

Thanks for the heads-up. Lotsa products get reformulated but still carry the same SKU number. PlastiKote sandable primers were one. The stuff available now is garbage. I just bought some Model Master (Testors) Aluminum Plate Buffing Metalizer in the new Rustoleum-marked can. Objective review to follow soon.

-

It's nothing terrible, just the shape of the front wheel arches, the overall angle of the nose relative to the rest of the car, window shapes, upper door cut-lines, and a few other things. I've seen your work, you certainly have the skills to correct it, and even if you don't want to bother, it still makes a good looking model built up. It's just not quite right.

- 39,171 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

I bought a second 1/25 Monogram Porsche 904, because on close examination of the first one, I noticed several annoying Palmer-esque proportion and line issues. The 904 has a special place in my heart, along with several other older Porsches, and I really want a model of the damm thing that actually LOOKS like the damm thing. One for reference while I hack the second one to get it looking more like the real car. And before the "rivet counter" and "it's only plastic" and "I can't see anything wrong" onslaught starts...I can see what's wrong and it matters to me. I also acquired a few of the 1/24 Monogram curbside kits, based on the slot car. In all the photos I've seen, it looks to be a better representation of a 904, possibly the best one. We'll see. If it turns out to be the case, I'm not certain which way I'll jump, but at least I'll have the satisfaction of knowing for myself. Depending on how things shake out eventually, the 1/24 kits MAY get kitbashed using bits from the 1/25 kits as well as guts from Fujimi, especially their Porsche 4-cylinder cammer and 901 engines. Couldn't pass up a sweet deal on another one of these, too. It's arguably one of the best "parts kits" going if you're into early Ford hot-rods. Dog knows I didn't "need" another one, but it's kinda like having a junkyard out back full of virgin old tin.

- 39,171 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

-

Yup, very nice. An enviable collection of vintage plastic, even cooler because they're mostly rescues.

-

The issues with scratch building

Ace-Garageguy replied to IbuildScaleModels's topic in Tips, Tricks, and Tutorials

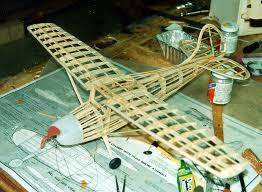

Regarding Renshape and similar tooling foams, I've used them extensively over the years prototyping real parts, and for building scale models. The cost for model work was never an issue, as I almost always had scraps left from the business. BEFORE I started using Renshape, I built this 1/10 scale model using bulkheads and stringers, much as we used to build model airplanes. It had to be built under-size, and laboriously fiberglassed, filled, and sanded to final shape. It could have been done in a fraction of the time using a tooling foam. -

The issues with scratch building

Ace-Garageguy replied to IbuildScaleModels's topic in Tips, Tricks, and Tutorials

Read the posts immediately above. Different materials excel for different applications. If you watch the video I posted, you should easily understand why you can do things with Renshape that would be very difficult with styrene. -

The issues with scratch building

Ace-Garageguy replied to IbuildScaleModels's topic in Tips, Tricks, and Tutorials

Exactly. In many ways it's much easier to use than any wood, too. Again, exactly. -

50,000 + kits from just one mold ?

Ace-Garageguy replied to Greg Myers's topic in General Automotive Talk (Trucks and Cars)

I understand what you're saying, but frankly, I think most novices would find building some of the older, simpler kits more enjoyable. Many novices aren't hard core car guys, and all those complicated mechanical bits some of us enjoy are just so much frustrating and incomprehensible drudgery. It wasn't hard to get decent looking results from a lot of those old kits, and with fewer detail parts to fret about, and an easy assembly sequence, a novice builder might be able to better concentrate on the basics...like generally clean workmanship, and acceptable paint. Just another way to look at it... -

1957 Reo Gold Comet

Ace-Garageguy replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That's pretty. I'm starting to get strong desire to build some old trucks. Seeing work like this is certainly inspirational.