-

Posts

38,173 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Ace-Garageguy

-

Some time back, in a "kit review" thread that had a bad habit of running off the rails into "the kit manufacturers should do this and do that" (but with little grounding in the economic and technical realities of the model-kit-manufacturing industry as it exists), I posted several links to videos that illustrate pretty well what some of today's low-volume manufacturing options are, how they work, and a little about what they can do in the not-too-distant future. I don't think the majority here saw most of this info, so I'm going to post a 3-part series of links to what can be done TODAY in LOW-VOLUME DESKTOP MANUFACTURING. The technologies are game changers, can conceivably keep the scale-model hobby alive and well for decades to come, and take a capital-intensive industrial business model and put it within reach of a middle-class guy working on his own. ---------------------------------------------------------------------------------------------------------------------------------------------------------------- PART 3: One of the reasons so often cited for the high cost of producing injection-molded plastic model kits is the need to machine the dies necessary from solid blocks of metal. This cost can't readily be justified with runs of product that have limited appeal, and won't sell enough units to make the investment back and go on to generate a profit. True enough, but with the advent of "soft tooling" that can be printed directly, or made from high-performance composite materials and developed from high-quality 3D printed masters (as shown in the first video of this series), or even from masters produced using traditional methods, short-run injection-molded products become quite possible, while maintaining the ability to make a business-sustaining profit margin. Combine the ideas presented in these three videos, and you'll see what's entirely possible if a "yeah, we can do that" attitude replaces the "can't be done" that's so prevalent everywhere.

-

Some time back, in a "kit review" thread that had a bad habit of running off the rails into "the kit manufacturers should do this and do that" (but with little grounding in the economic and technical realities of the model-kit-manufacturing industry as it exists), I posted several links to videos that illustrate pretty well what some of today's low-volume manufacturing options are, how they work, and a little about what they can do in the not-too-distant future. I don't think the majority here saw most of this info, so I'm going to post a 3-part series of links to what can be done TODAY in LOW-VOLUME DESKTOP MANUFACTURING. The technologies are game changers, can conceivably keep the scale-model hobby alive and well for decades to come, and take a capital-intensive industrial business model and put it within reach of a middle-class guy working on his own. --------------------------------------------------------------------------------------------------------------------------------------------------------------------------- PART 2: We've been told repeatedly that the injection molding process takes hundreds of thousands of dollars invested in design and tooling, and because of that, it's impossible to develop and manufacture short-run subjects with limited appeal, while making enough money to sustain a business. The capability of the little injection-molding machine in the video below pretty much blows that "truth" out of the water. It's a small machine making small parts...but it makes them FAST. As it stands, it could revolutionize the "resin" parts aftermarket, allowing very high quality parts to be manufactured quickly without all the rigamarole associated with resin-casting. But the big idea to take away from this video is that this tech is scalable. All that means, in this context, is that it's not difficult to build larger machines capable of squirting out an entire 1/25 body, or an entire sprue of smaller parts.

-

Some time back, in a "kit review" thread that had a bad habit of running off the rails into "the kit manufacturers should do this and do that" (but with little grounding in the economic and technical realities of the model-kit-manufacturing industry as it exists), I posted several links to videos that illustrate pretty well what some of today's low-volume manufacturing options are, how they work, and a little about what they can do in the not-too-distant future. I don't think the majority here saw most of this info, so I'm going to post a 3-part series of links to what can be done TODAY in LOW-VOLUME DESKTOP MANUFACTURING. The technologies are game changers, can conceivably keep the scale-model hobby alive and well for decades to come, and take a capital-intensive industrial business model and put it within reach of a middle-class guy working on his own. -------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- PART 1: We'll start with 3D printing, since almost everyone here probably has at least some understanding of the idea. This is the quality that's available today, right now, for the home operator who has a little money. It's not up-to-the-minute state-of-the-art, and it's kindof a messy process, but the results speak for themselves.

-

Assembly Question Vintage 1950s Model

Ace-Garageguy replied to PB1983's topic in Model Building Questions and Answers

Pretty cool. Definitely one I've never seen. I assume outboard-engine powered. About how long is it? Any nominal scale? -

Assembly Question Vintage 1950s Model

Ace-Garageguy replied to PB1983's topic in Model Building Questions and Answers

Easiest thing to do is to try gluing two pieces of scrap or sprue together using conventional liquid "cement" made for plastic models. Let it dry thoroughly. Then try to break the joint. If it breaks with very little pressure applied, it's one of the solvent-resistant plastics, and you'll need CA or epoxy. It it's a pretty strong joint, you're golden. -

Fine job on a tough kit. Exceptionally clean and well-fitted. Fascinating car to see run, if you never did. On level pavement, it would do about 40 MPH with just the fans running, and other drivers hated the thing because it spit out everything it vacuumed off the track at the car following it.

-

A few 4bbl carburetor reviews

Ace-Garageguy replied to brodie_83's topic in Car Aftermarket / Resin / 3D Printed

1) Fireball's carbs are indeed the ones you want if quality means anything in your life. I bought a bunch from a dealer at a show here in November and was blown away by how good they really are. 2) While very similar, the resin carb on the right (below) is not a direct copy of the metal carb on the left. Some details, like the thickness of the rings around the throttle bores, simply would NOT change when a mold was made from the original. My guess would be that at least some work was done to the original to make it closer to a legitimate master and not a direct ripoff. -

Yeah. I know how that can be. Any time I see somebody carrying an AK, I get a little uneasy.

-

Don't really expect to get anything usable with "melted" styrene. The MEK is a solvent, and as it dissolves the plastic, which goes into suspension in the solvent, the mixture's volume increases over what the original volume of the plastic is. Obviously. So, when it "dries", the MEK solvent evaporates back out, the part shrinks by a rather large percentage, and will most likely also warp because of uneven evaporation for any number of reasons.

-

Assembly Question Vintage 1950s Model

Ace-Garageguy replied to PB1983's topic in Model Building Questions and Answers

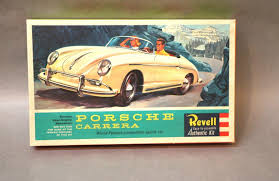

Not everything was AMT or Johan screwbottom. Early Monogram kits were all glue. So were early smaller scale Revell kits, and others. This is Monogram's very first kit. I have a couple, one in the original acetate, some in styrene. All glue. It's about 1/20 scale. Their second kit was also all glue, about 1/24 scale. Also glue: There are lots more. Early Revell 1/25 scale all glue: And there are still more. -

Aftermarket Racing Style Bucket Seats in Kits

Ace-Garageguy replied to Casey's topic in Model Building Questions and Answers

NOTE: The AMT '33 Willys kits have a pair of seats quite similar to #2 shown above, but with sharper side bolsters (as though the bolsters aren't upholstered). Each seat is on a pair of stanchions approx. 1/4" high. One has belt detail, one does not. (Pix when I have time)- 45 replies

-

- bucket seats

- aftermarket

-

(and 1 more)

Tagged with:

-

Fires destroy 2 resin casters

Ace-Garageguy replied to Gramps46's topic in Car Aftermarket / Resin / 3D Printed

Damm Brian. Glad you're OK. I hadn't looked at this thread since the day it went up, but seeing you asking for advice on (apparently) replacement tool purchases on another thread, I kinda got the feeling you might have been hit. This is unbelievably awful. Again, glad you're OK. You seem to have a good attitude about everything, and you (and everyone else who was in the path of a fire) have my sincere hope that things out there return to a semblance of normalcy ASAP. -

Aftermarket Racing Style Bucket Seats in Kits

Ace-Garageguy replied to Casey's topic in Model Building Questions and Answers

21 AMT '53 Studebaker- 45 replies

-

- bucket seats

- aftermarket

-

(and 1 more)

Tagged with:

-

Aftermarket Racing Style Bucket Seats in Kits

Ace-Garageguy replied to Casey's topic in Model Building Questions and Answers

13 AMT Wynns Jammer- 45 replies

-

- bucket seats

- aftermarket

-

(and 1 more)

Tagged with:

-

Absolutely pathetic. Just another perpetually knicker-knotted little be-offended-with-everything, no-sense-of-humor, ruin-everybody's-fun idiot. I swear the vast majority of these virtue-signalling fools don't really think they're making the world a better, kinder, safer place by antics like blacklisting an old Christmas standard. No rational mind could. At the core, it's all about getting attention directed towards themselves...and it's becoming a global phenomenon. There really IS something VERY wrong in the world today.

-

Thanks for your interest and comments. I've been following your BattleBird project. Love it, and the real car it's based on. Your pix of the uber-rare Y-block injection are most appreciated as well. Far as the tonneau goes, here's another way to do one...and feel free to ask away. Glad you found something worthwhile here, and thanks. Just trying to maybe finish something in this lifetime. And the furry helper found me. Just couldn't ignore the sound of a kitten crying outside in the middle of the night. I like almost all animals, but I have a special fondness for cats. Probably because they share something like 96% of their DNA with lions and tigers. Little scale model predator beasts. Very low maintenance too. I like low maintenance.

-

2020 Family Truckster !

Ace-Garageguy replied to 1972coronet's topic in General Automotive Talk (Trucks and Cars)

Agreed. But GM's long term plan seems to be to go totally electric. They have also made noises about getting out of "selling" vehicles at all, and teaming up with some concept like Uber to provide "on demand" transportation. It should be really interesting to see how that strategy plays out. The infrastructure still doesn't exist to be recharging the number of electric vehicles that might be coming online in the near future. And while the "transportation-on-demand" concept seems to make some sense in light of the fact that millennials are said to not give a rats rump about owning cars in general (and can't afford 'em anyway), the generation following seems to be returning to some more traditional ways of thinking. Not to worry though. There are millions of perfectly fine older vehicles needing good homes. The only trick is finding competent people to work on them, and high-quality parts. -

2020 Family Truckster !

Ace-Garageguy replied to 1972coronet's topic in General Automotive Talk (Trucks and Cars)

My thoughts exactly, and one of the reasons I harp on Mary Barra's 22 MILLION DOLLAR a YEAR compensation package. What makes a CEO worth that kind of jack when the company she runs seems to be unable to produce cars people want? I'm sure I could do every bit as uninspiring a job for $200,000 a year. ------------------------------------------------------------------------------------------------------ PS: Ever since I first saw a couple year old 2012 Kia Rio 5-door, I've really been thinking seriously about buying one for the daily do-almost-everything car. Only two things holding me back. 1) It's kinda hard to find a used manual-gearbox one in cherry shape (if you can find one at all), and 2) I'd like to know more about the long-term availability of the electronic components in it. -

Assembly Question Vintage 1950s Model

Ace-Garageguy replied to PB1983's topic in Model Building Questions and Answers

It depends on the specific "plastic" material the kit is made of. There are several possibilities. Some early Monogram kits, for instance, were made of "acetate". The liquid solvent-style adhesives most adult modelers prefer today don't have much effect on some grades of acetate. Likewise, some early Johan kits are made of a solvent-resistant styrene that's also difficult to join with typical solvent-style adhesives. In these two cases, CA (cyanoacrylate) "superglue" adhesives are my recommended choice. They come in an array of thicknesses (some will fill small gaps) and "fastness" (how much working time they give you). I've found a good all-round CA adhesive to be this Loctite product: If it's a less solvent-resistant grade of styrene, then the old standard MEK-based liquid solvent-style adhesives are best. For attaching clear parts, I highly recommend PVA-based "white" glues. They dry crystal clear and don't fog the clear parts like solvents and some CA adhesives do. The old style tube glue really has no place anymore in the adult modeling world. -

Fine looking buildup of a model we very rarely see. I bought several of these years back (when they were really cheap)...one to build straight as a historical reference, the rest to hack into other things. This is one of Georgetto Giugiaro's designs that demonstrates the man's extraordinary talent. Perfect proportions, subtle, elegant, yet brutally fast appearing without a lot of stuck on flippers and vents and whiffles that most of today's designers seem to find necessary. Hmmmm...looks like a ZF gearbox ala DeTomaso Pantera in there. Never noticed that before.

-

Aftermarket Racing Style Bucket Seats in Kits

Ace-Garageguy replied to Casey's topic in Model Building Questions and Answers

When all the slots are filled in, this will be quite a valuable little reference.- 45 replies

-

- bucket seats

- aftermarket

-

(and 1 more)

Tagged with:

-

2020 Family Truckster !

Ace-Garageguy replied to 1972coronet's topic in General Automotive Talk (Trucks and Cars)

I think they used your spoof design for inspiration. -

Aftermarket Racing Style Bucket Seats in Kits

Ace-Garageguy replied to Casey's topic in Model Building Questions and Answers

#5 appears to be from the old AMT T-bucket parts pack. I have one here that looks to be identical. No time for a photo right now though.- 45 replies

-

- bucket seats

- aftermarket

-

(and 1 more)

Tagged with:

-

Good looking, subtle hot rod. Perfect proportions from the just-right chop, stance is dead on, wheels and tires complete the look nicely. This is one of those models that reminds me why the '32 Ford is such an icon.

-

Aftermarket Racing Style Bucket Seats in Kits

Ace-Garageguy replied to Casey's topic in Model Building Questions and Answers

17 appears to be the 1963-issue Revell parts-pack seat, as I noted above.- 45 replies

-

- bucket seats

- aftermarket

-

(and 1 more)

Tagged with: