-

Posts

4,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by gotnitro?

-

If I had a real Pete

gotnitro? replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Excellent work Jeff ! I can't get over the details on the Detroit engine, compared to kit offerings this is a huge improvement. I order from Paul quite a bit, very pleased w his selection -

I needed another project....T800

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks ! I kept changing my mind about color..yellow or white. Finally settled on this @BK9300 honestly unsure what equipment was used to cut the sides out. If I hear anything I'll let ya know for sure -

I needed another project....T800

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

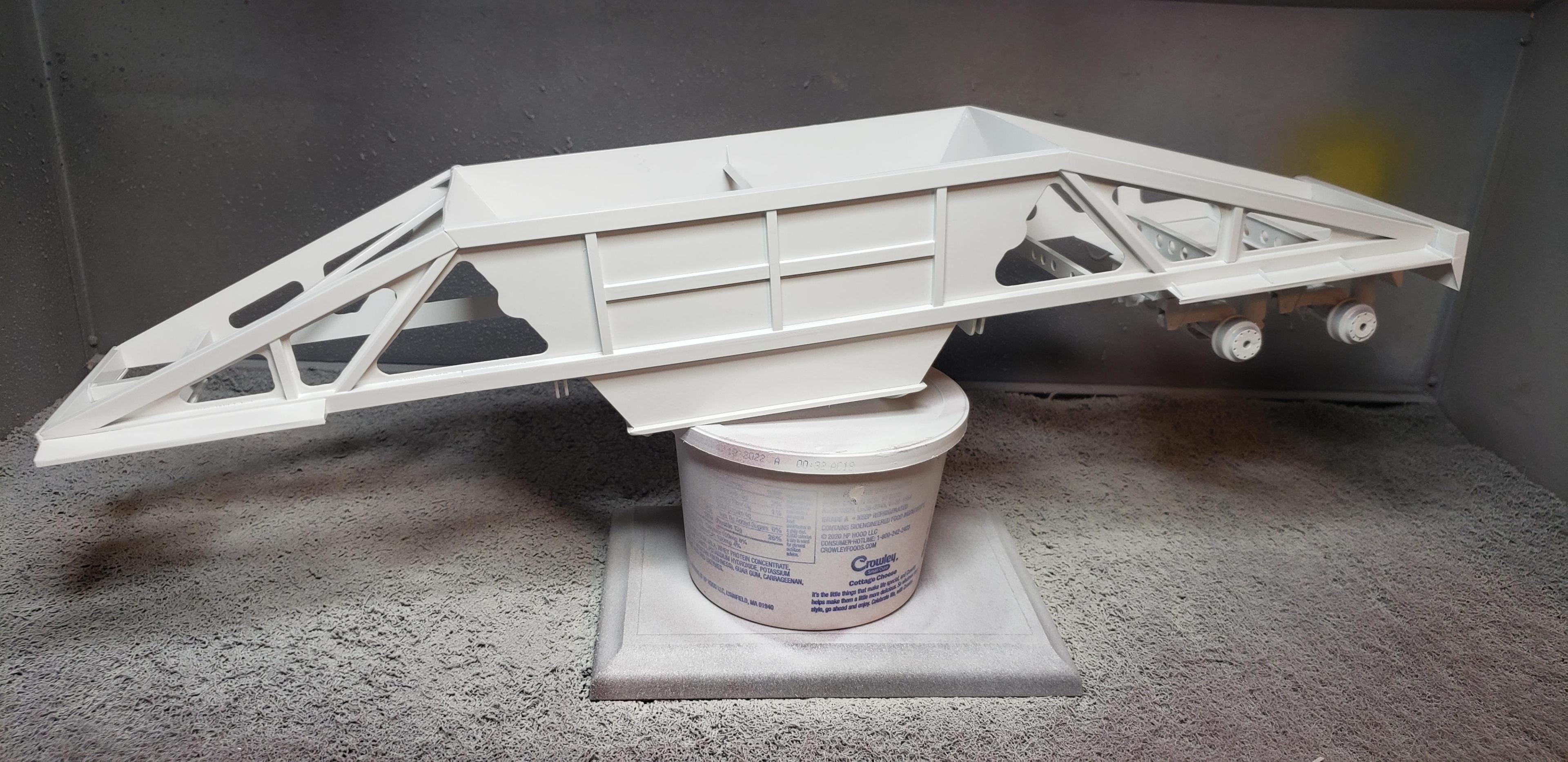

I sprayed the trailer this morning, Rustoleum white enamel that was sourced locally. I expect the paint to take several days to cure enough to handle, then start adding the plumbing and lights. -

Wow I'm blown away how nice this looks

-

KFS Michigan Loader

gotnitro? replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That would look really sharp pulled behind one of your Brockways! Sorry its that time of year again when the Huskies come back to Cortland lol everyone around here has sled dog fever this weekend -

Mack DM800 refurnish

gotnitro? replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice rebuild! Glad to see you remove all the ridiculous chrome this kit has -

Looking good! The stripes turned out nice and dull..unlike the kit offering lol Your engine bay details are popping too

-

KFS Michigan Loader

gotnitro? replied to Warren D's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Impressive beast ! -

Western Star 4900 FA plow truck

gotnitro? replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

ditto what everyone said about this build..love all the small hardware tying everything together sharing the actual parts really shows your attention to detail -

I needed another project....T800

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I pulled the T800 back down from the wip shelf planning to tackle those fender mods. After several hrs of muttering under my breath, I cut my losses and ordered a replacement hood. I'll just run the internal air cleaner, time to move along -

I needed another project....T800

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks for following along! Im almost ready for primer and paint on the trailer the laser cut frame rails were parts that a fellow model builder was working on before he passed away, and I was asked to finish the trailer -

I think we have the sluggish forum problems solved

gotnitro? replied to Dave Ambrose's topic in How To Use This Board

Thanks for all your hard work! -

I needed another project....T800

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks @Mopar - D I really enjoy the challenge of doing a build just from a couple random photos -

Western Star 4900 FA plow truck

gotnitro? replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Incredible scratchbuilding! The individual parts already show the potential for serious detailing as the build progress's -

M-20 Prime Mover is Finished

gotnitro? replied to Chariots of Fire's topic in Model Trucks: Big Rigs and Heavy Equipment

Beautiful work!!! That red Georgia clay looks great spread about the build, and the small details stowed in the boxes -

International 4300 tractor

gotnitro? replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Nice job on the railings! Your grandkids will definitely appreciate them Your bench is wayyyy to clean..time to clutter it up lol -

I needed another project....T800

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

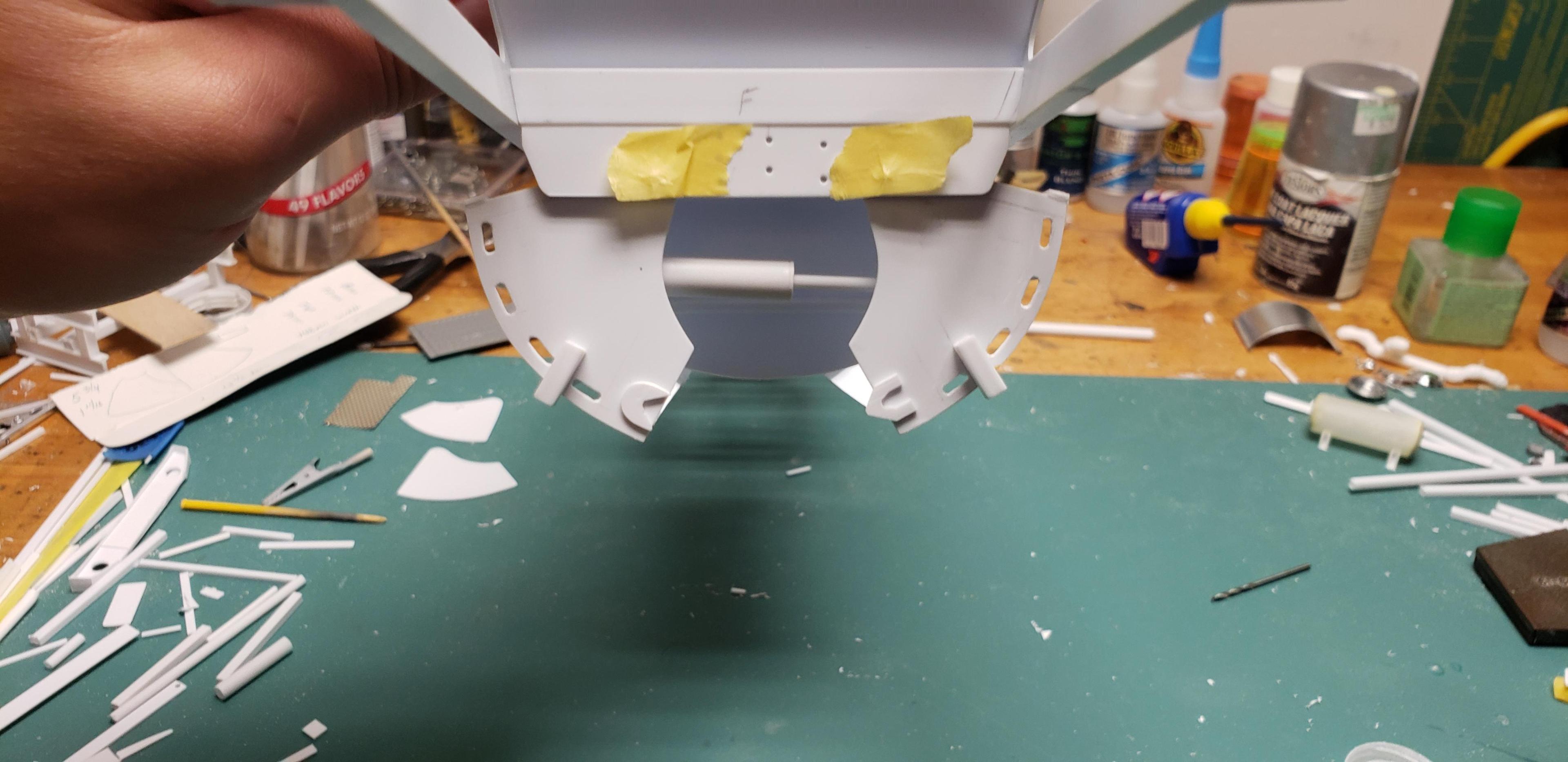

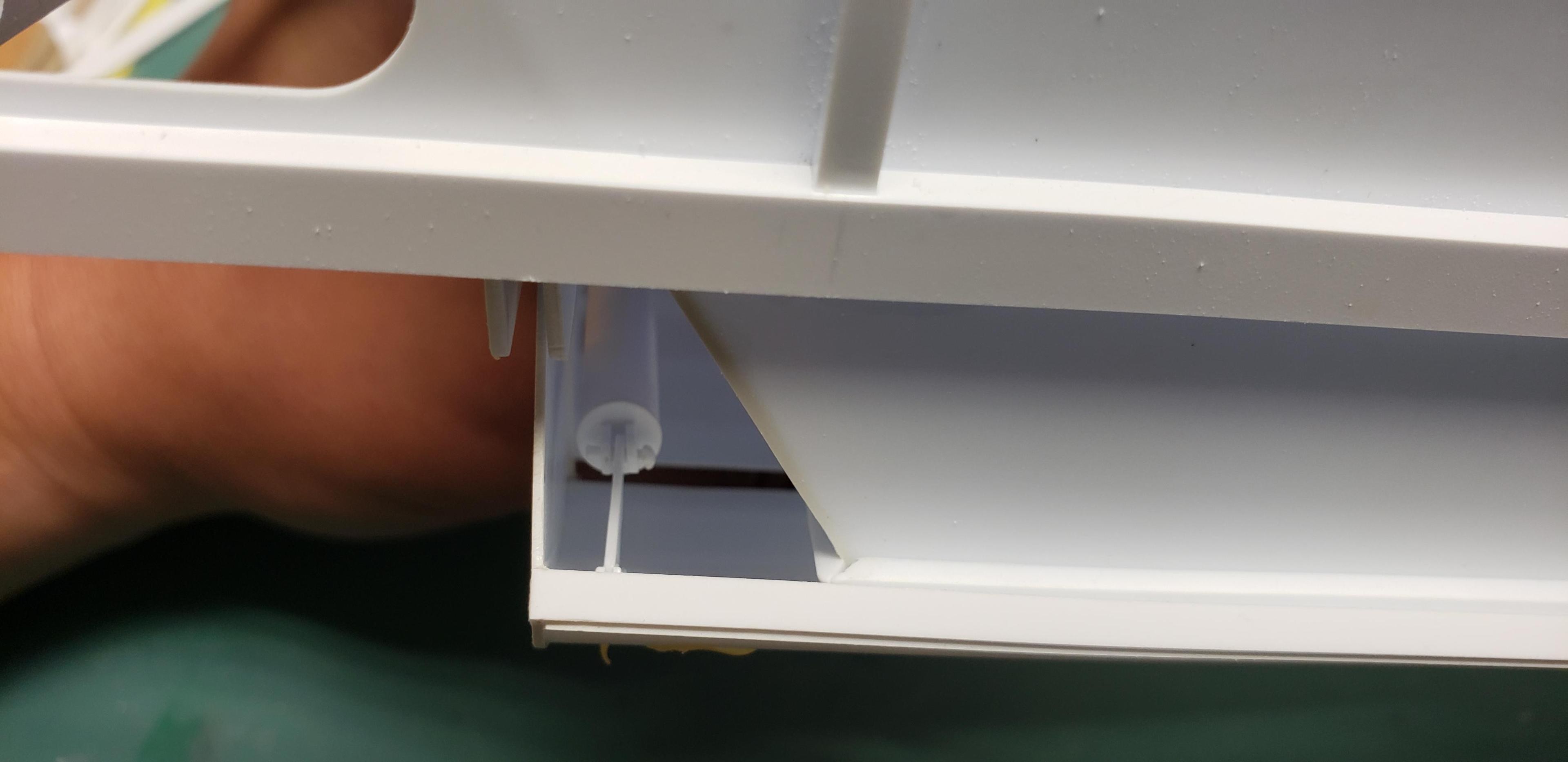

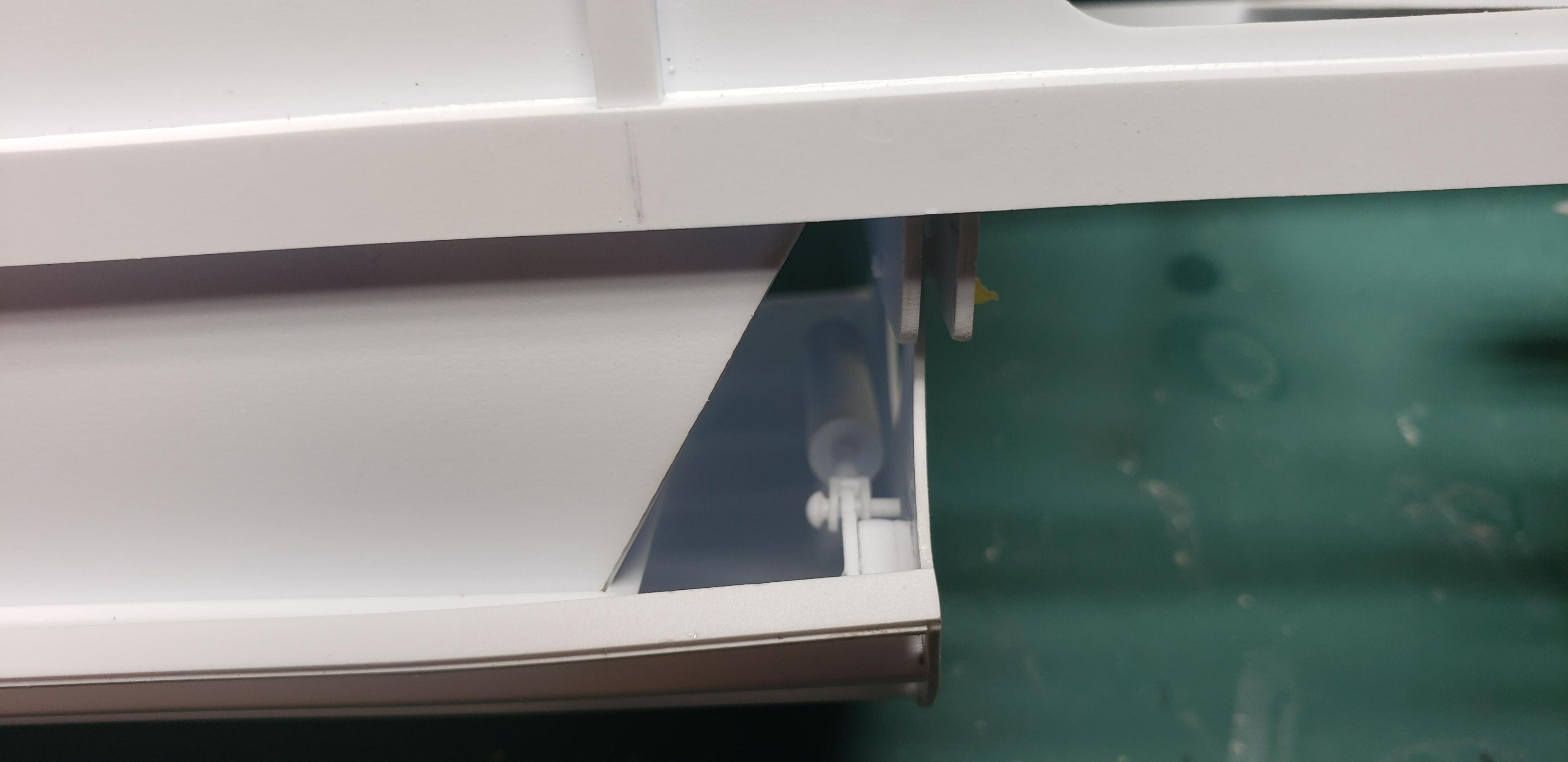

@Mopar - D thanks ! I used your photos to judge where the cylinders would fit best, keeping my pins held in the brackets made for some interesting language. I finally used a dot of poster putty to hold them..and attached the brackets I figure if it was easy..we'd have a kit of it by now lol -

Looking forward to your progress! Your definitely working out the bugs in this new release I had one in the stash that was slatted to be banana yellow, but a fellow builder talked me into selling it

-

M-20 Prime Mover

gotnitro? replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Incredible work! The little splashes of color on the glad hands and partially left down windows are a real eye catcher -

I needed another project....T800

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

This was way more difficult to align then I expected. I mounted the cylinders inside the doors, both sides had to fit precisely or they wouldn't open square..or be crooked. Oh well..its done and I'm chugging on Jeff -

2023 BRGB 70's Kenworth W 900

gotnitro? replied to lwwoodss's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Tough looking truck right there ! Nicely done -

I needed another project....T800

gotnitro? replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Haha ! I seem to struggle getting angles to match up on every build..this ones been no exception. It doesn't help that the frame isn't a standard angle my miter box has slots for.. I'm charging forward w the area I was putting off..those door actuators. Mopar-D sent a couple clear photos of them, which worked a treat. I found a parts reference for several trailers and nailed down a standard size. I need to finish making the brackets that attach the cylinders to the doors, then post pics ! -

Those under hood photos are off the charts, especially the decals on the heater hoses