-

Posts

3,982 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Pete J.

-

Thanks for the comments. I did like the base, but ran into a problem with it later. Because of all the white metal in the engine and oil and gas tanks, the landing gear started to sag under the pressure of all that weight. I had to straighten the gear and redesign the base with two more struts just inside of the gear mounts. The customer was still pleased with it.

-

Bill, what kind of lathe is it. Sometimes it can be converted back to manual. Using manual to start is a good way to learn how the machine works. Later you can get into the CNC stuff.

-

P.E. Callout!!! Bring out your Photoetched!!!

Pete J. replied to Plastic_Passion's topic in Model Cars

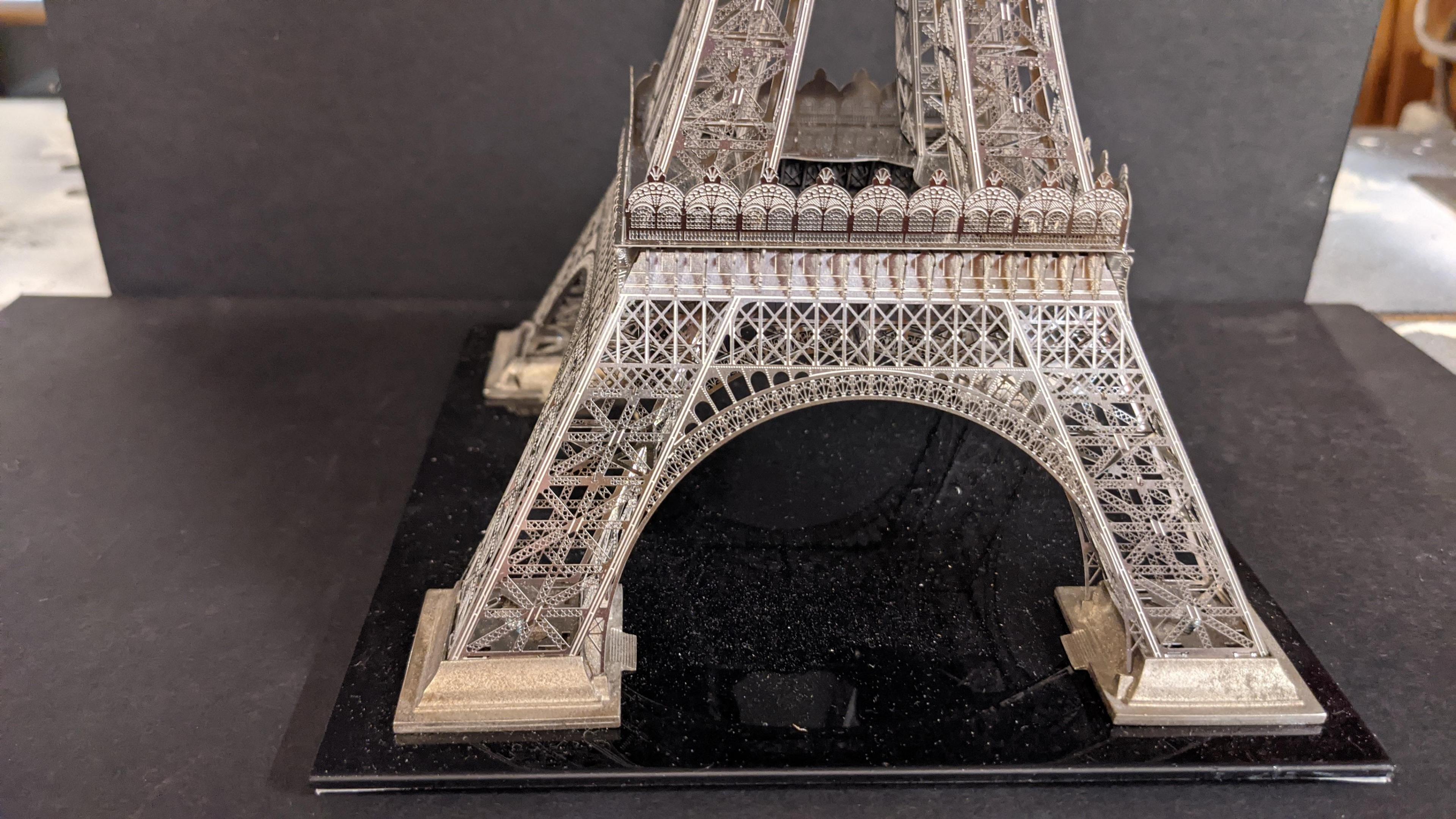

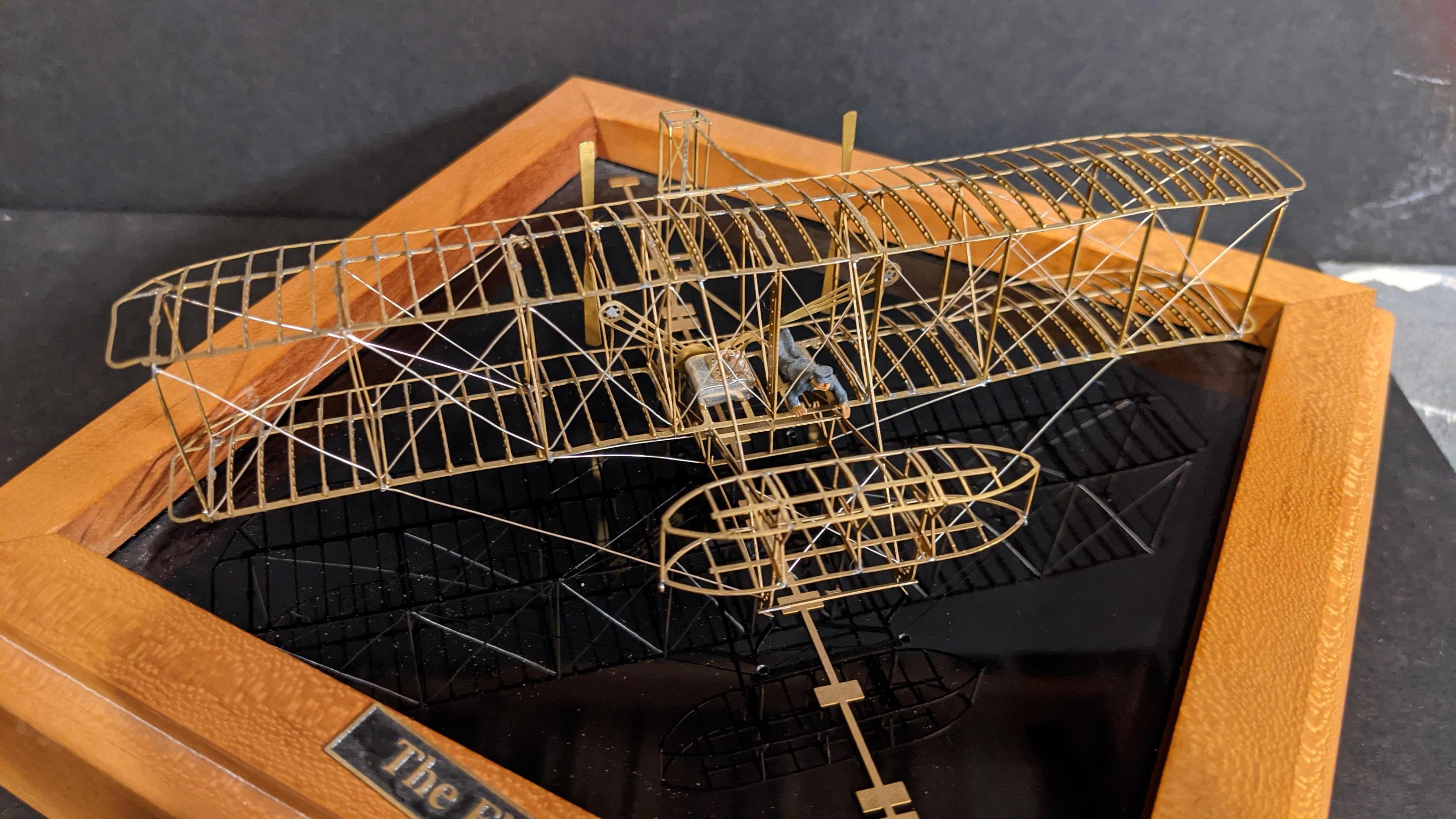

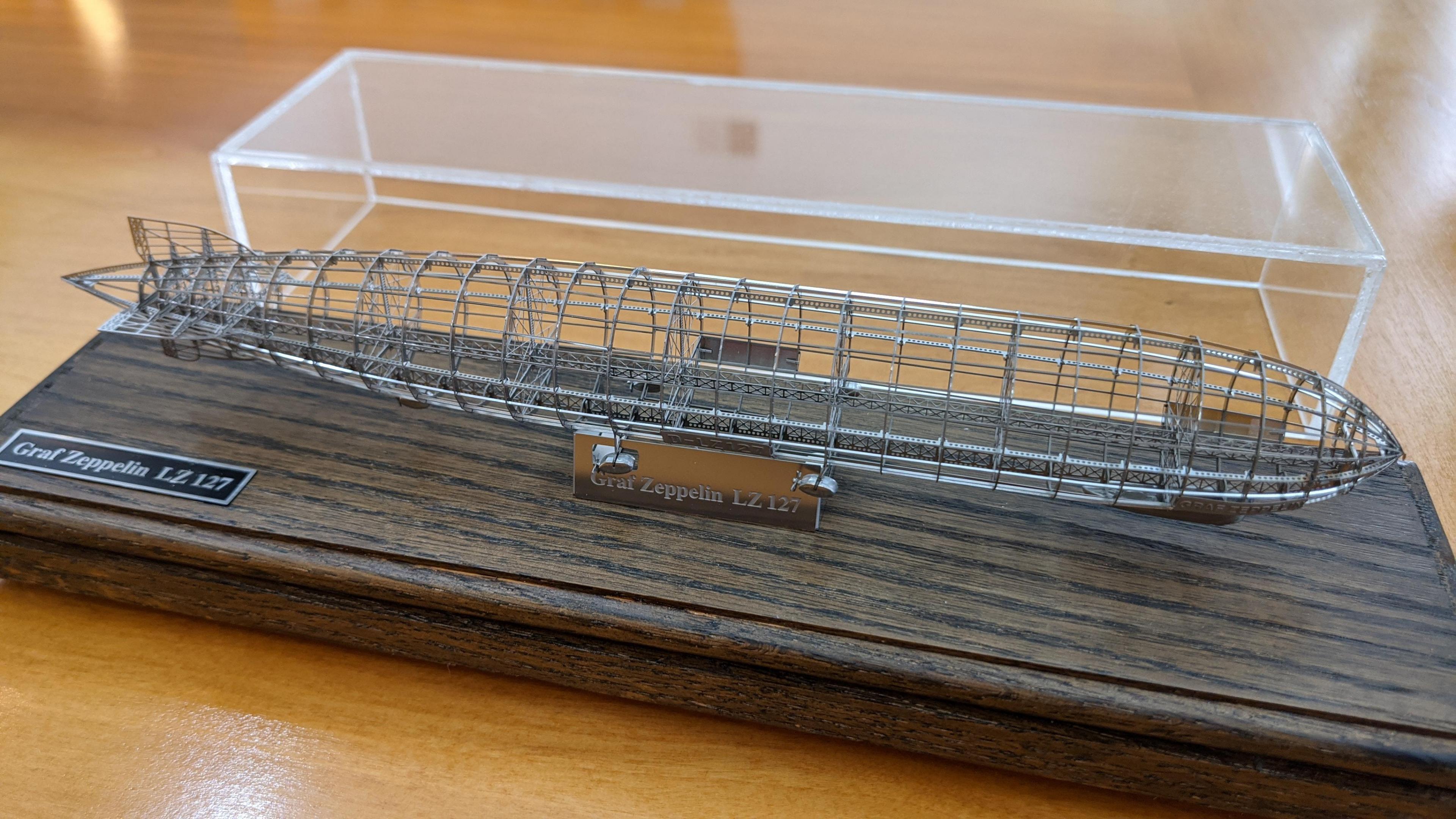

Three different photoetched kits. All by a Japanese company called Aerobase. I got them when I was in Japan 15 years ago but they are still available on Amazon of all places. A bit on the expensive side but then I am an old guy and remember when they were $50 and I thought that was expensive! -

Another piece of our childhood is going away.....

Pete J. replied to HomerS's topic in The Off-Topic Lounge

I just happy the Starrett tool factory in Athol, Mass. is still going. Best measuring tools in the world, bar none! -

For those who aren't paying attention to the news(and I don't fault anyone who is!) the west coast is on fire. Hot dry winds blowing and very dry vegetation. For the last 4 nights at 11:00 sharp, some idiots are shooting off fireworks! This is really the height of stupidity. I sincerely hope the police find them and throw them in the slammer for a while. Who is this stupid.

-

Welcome Joseph! Lived out in the valley from '77 to '88. Great town. Loved the skywalk system down town.

-

Yup, I would go back to one of my other hobbies. I took 6 years to build one model(Tamiya 935) twice and I can't count the number of times I lost interest and had to force myself to go back to the bench. It was a commission both times. That was not a lot of fun! Swore I would never do it again! Besides it is great fun to also build aircraft, ships, armor, motorcycles and caricatures. That is a little like saying you can only have hamburgers for the rest of your life. Great once in awhile for a treat, but that is about all.

-

For years Mitutoyo was the next choice after Starrett. They were what people bought if they wanted quality at a good price. The differences between Mitutoyo and Starrett were slight. The biggest difference still exists. You can send a broken Starrett tool back to the factory and they will refurbish and calibrate it to new standard for far less than the cost of a new tool. I've gotten to the point that if I need a tool, I scour the internet for a broken Starrett(there are many). Get it cheap and send it back to Athol. Two or three weeks later, I have a near new tool on the bench. There is cheap and then there is frugal. I prefer the latter.

-

Found them!!! Original manufacture and I would bet, based on the price they are pretty good quality. Next order, I am going to spring for a set. https://www.mscdirect.com/product/details/78579042

-

Anyone seen this engine kit?

Pete J. replied to randyc's topic in Model Building Questions and Answers

Reread the add. the base price is for a single cylinder. As shown in the photo about $300 for shipping. You have to click the "4 cylinder" box to get the price. -

P.E. Callout!!! Bring out your Photoetched!!!

Pete J. replied to Plastic_Passion's topic in Model Cars

-

I should mention, it works great for sectioning a body or chopping a roof which need parallel cuts.

-

This is the best one I have owned. It actually comes with a replacement blade. I use the heck out of it for chopping up models for various custom work. The blade is relatively thin, but very stiff. Cutting long straight lines is a piece of cake with this baby! https://www.tamiya.com/english/products/74024/index.htm

-

Interesting! I have seen that little box copied a hundred different ways. That is the first time I think I have seen the original. All the knockoffs can be very sketchy. I would bet the original "Made in the USA" stuff is really pretty good. I am also willing to bet that the Chinese knockoffs are junk! Strange as this sounds the best I have found is Kyocera Asia Pacific tools. I believe they have headquarters in Singapore. Good stuff but not cheap. I save them for drilling very delicate holes. It is fun the see a spiral chop the size of a hair come off of them.

-

Jim, Use and old T-shirt or well used cotton wash cloth. If it is only a small area a Q-tip will also do the job. Be sure to dilute the alcohol 50/50 with water. Pure alcohol will take dissolve Tamiya Lacquer. I use 91% to strip rattle can Tamiya, but in this case the dilution should not effect it. Last, if you do get a little dulling, you can buff that out with a little polish. Good luck!

-

Yes, sun and models on a hot day just don't get along. Retribution is probably the wrong word. Perhaps resurrection better describes what you are doing. Revisiting a model can be a pleasurable experience if you are in the right space for that. I can see me looking at the models and revisiting that moment when you saw them in ruin. Not sure I would have kept them. Probably would have thrown the whole batch in the trash and moved on. Good for you for searching out new kits and tackling the rebuild. I have a lot of respect for what you are doing.

-

Your dad gave you a gift with great love. I can see him in my mind working long hours in a machine shop to create a gift for his son. That is an amazing looking tool. I see many of the traits of some of the best built machines I am familiar with. I am especially taken by the drilling attachment. I may try and copy that for my machine. Your father was a true master craftsman.

-

You get what you pay for when you buy cheap from an unknown manufacturer. Here are some thoughts on what to look for. Motor: Watts is only one factor. For consistent machine speeds and torque you are best off with a variable speed DC motor. It also helps to be a belt drive with at least two different size pulleys. Some times you need high RPM. Other times you need torque. Also, an infinitely variable speed controller is necessary to control the rotation speed. On smaller parts you need more RPM and less on large diameter parts. Think of it this way. At a given rpm, the outside of a circle is travelling as a faster speed than the inside. A variable speed unit that you can control on the fly means you can turn across the face of a large piece. Start at the edge with a speed that gives you a good chip and increase the speed as the diameter gets smaller. This way you get a smooth face. All of this changes when you change type and grade of metal. If you are going to use aluminum only, it is very important. There are literally hundreds of aluminum alloys and all machine differently. Second is size. Having a bed that is longer than any part you can imagine making will give you room to work around all your pieces. Remember, if all you make are rims, you will need to be able to bore the center with a drill bit and finish it with a boring bar. This means you need to mount the piece in the chuck and the drill bit in the tailstock and have a bed long enough to handle all of that. As your skill grows, I can guarantee you will want to make more than just rims. While you are considering length of bed also consider the travel of the cross slide. Some tools work better on the back side and others on the front. Being able to mount a tool on the front and back at the same time, can save setup time. Example: when I cut off a series of discs, I have a parting tool that works on the back side. I keep it mounted because that saves me the hassle of changing tools after every cut. Next is the accessories. No lathe will ever come with every possible tool and attachment you need as your skill progresses. Having a manufacturer with a broad range of tool and jigs Is a plus in the long run. This also begs the question of how long the manufacture has been in business. Will they be there when you want other tools or parts that may ware out? By the way, over the last 10 years I have spend more on accessories than I did on the original lathe. So, I guess what I am saying is the machining rims sounds easy and simple. It isn't. It takes some skill. Those skills are easily learned but if you buy a cheap machine you are quite likely to give up in frustration and you will have wasted your money. Save your money and get a good machine. It will make the job easier and you can grow with it.

-

Assuming you used rattle cans a 50/50 mix of alcohol and water will do the job. Just wet a rag and rub lightly.

-

Reminds me a a story by Jeff Foxworthy. - Truck driver had a similar accident with a truck and an over pass. The truck driver is standing on the side of the road looking it over and sees the Highway patrol cop come walking up. Cop says " Got a little bit stuck there did ya?" Truck driver comes back with "No, I was just delivering this overpass and ran out of gas." HERES YOUR SIGN!?

-

These are often referred to as circuit board drills and the best but good ones can be quite expensive. https://www.mscdirect.com/browse/tn/Holemaking/Drilling-Drill-Bits/Circuit-Board-Drill-Bits/?rd=k&pcrid=396779935646&navid=12106101&gclid=Cj0KCQjwtZH7BRDzARIsAGjbK2Yv4a2rHh8Gt-qrVxBceOeqUDfPDFoSBhmYFWam4gq5K2ulcm_k2hEaAjtmEALw_wcB&mkwid=sSSWb1ooT|dc&cid=ppc-google-Returning+-+Holemaking+-+Product+-+PPC+-+Exact_sSSWb1ooT_circuit+board+drill+bits_e_396779935646_c_S#navid=12106101+4294955908 That is because they are very sharp and to be so means they are made from carbide steel. This also means that they are brittle. They will generally not tolerate the side deflection you can get with a pin vice. I have several sets that I use in my mill when I need very precise and very small holes. I only buy them as I need them. For more routine things I use a better grade of bit but not cobalt or carbide. https://www.mscdirect.com/browse/tn/Holemaking/Drilling-Drill-Bits/Circuit-Board-Drill-Bits/?rd=k&pcrid=396779935646&navid=12106101&gclid=Cj0KCQjwtZH7BRDzARIsAGjbK2Yv4a2rHh8Gt-qrVxBceOeqUDfPDFoSBhmYFWam4gq5K2ulcm_k2hEaAjtmEALw_wcB&mkwid=sSSWb1ooT|dc&cid=ppc-google-Returning+-+Holemaking+-+Product+-+PPC+-+Exact_sSSWb1ooT_circuit+board+drill+bits_e_396779935646_c_S#navid=12106101+4294955908 Regardless, I don't buy the cheap "hobby shop" drill bits. They are mass produced to be inexpensive, so the quality control standards are not high. If you want stuff that has a higher level of quality control, you have to pay for it. Also, I would suggest that if you want good bits you go to a good industrial supply house like MSC above. My other "go to" store is McMaster-Carr. https://www.mcmaster.com/drill-bits One caution about using either of these houses. Watch out for shipping. They ship everything over night express. That is great if you need it right now, but cost of shipping can easily exceed the cost of the item especially if you only need one or two items. Just make sure order enough.