-

Posts

3,982 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Pete J.

-

The issues with scratch building

Pete J. replied to IbuildScaleModels's topic in Tips, Tricks, and Tutorials

Sherline https://www.sherline.com/product/45004530-lathe/ They start at about $655 but you can easily spend that again on special tools. Don't let that stop you though. You don't need to do that when you first buy the machine. They have three packages the top one, has a lot of stuff to get you going. I bought it and have parts I have never used, so my choice would be the middle one. Sherline has some of the best customer service on the planet. You can call them with a problem and they will be able to tell you how to do it. These guys are all master machinist and not sale people. They don't get anything extra for selling something. Not only that, they have actually designed and build special parts for me to overcome particular problems. Now I have to say, I have an advantage/disadvantage. I live less than 15 minutes from the factory and I say an advantage because I can buzz over there and get what I need. Disadvantage because I can buzz over there and get what I need.? -

Eight?? Most days I'm lucky to get four going at the same time. But sometimes I can get the turbo to kick in!?

-

The issues with scratch building

Pete J. replied to IbuildScaleModels's topic in Tips, Tricks, and Tutorials

Definitely not for everyone but the vast array of materials you can machine definitely makes these a good way to go. You can machine plastic, and a wide variety of other materials.For instance, german silver(a nickel and copper alloy) looks very much like chrome or other other silver surfaces, but it solders well to other metals such as brass. Unfortunately, this is not in everyones budget. -

Automotive (and other) toys from our childhood

Pete J. replied to Harry P.'s topic in The Off-Topic Lounge

OMG! I had one of those too! I may still have it around somewhere. GE had a number of these projects(you can see this one was #3) I learned about transistors from this. Of course that was before they had IC's . Thanks for the reminder! -

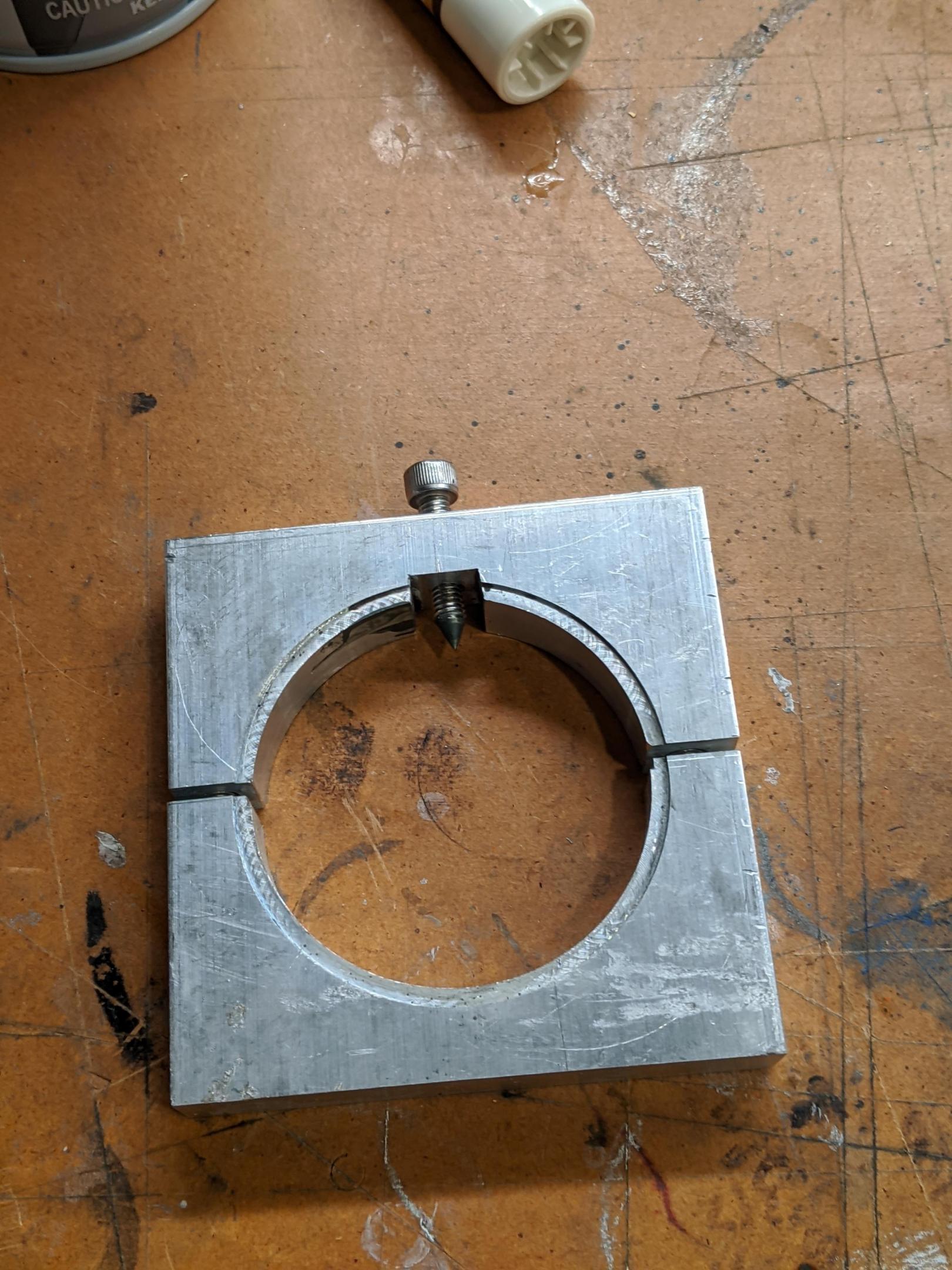

No, just an endmill. Here was my process. First I cut the hole on the mill with a rotary table and small mill end. Then I drilled the holes in the sides with the correct drill for the tap I was going to use to hold the two sides together. Then I used a slitting saw to cut the two parts in half. I tapped the bottom half and used a ream to make to top hole large enough to accommodate the screw without engaging the treads. You don't need a ream. A larger drill bit would do the same thing, I just happened to have a new set of reams. Then I drilled and tapped the hole for the puncture screw. Last I used a 1/4" mill end to cut the slot. (Since the jig is now in two halfs, you have access to the under side.) There is no reason that the groove needs to be flat. You could just releve it by cutting a semicircle with an mill end. I used a stainless steel screw that I pointed on the mill for the puncture screw. I found the sharper the angle but easier to control. Good luck and I can't wait to see your take on this project. Pete

-

Automotive (and other) toys from our childhood

Pete J. replied to Harry P.'s topic in The Off-Topic Lounge

I remember building one of these and playing with it. It had a system that steered the front wheels that used several cams to make it do ovals and several other driving paths. Very complex build for a kid! -

The one subtitle thing is flat part under the screw. That needs to be there for gases to escape you so you can see how deep the point is going.

-

What I use to do before I came up with this was use and ice pick. Being long and slender I could easily control the about of pressure coming out. Downside is I had to stand there and hold the ice pick and can until the pressure dropped to near zero.

-

Same idea as ken but I made this a long time ago. I like it because I can punch a hole close to the top and bottom seam. I use the top one to let the gas out. I generally let it sit overnight so most of the gas in the paint can come out of solution. Then I close the needle and shake the can up to get all the paint mixed. Once it is mixed I push the needle in as far as I can to enlarge the hole as large as possible. I then punch a hole in the bottom and use that hole to pour the paint out. When all the paint is out, I use a plastic pipette to put a lacquer thinner in the can and shake it around to get the last of the paint out. After I have done that, cut the can open to remove the glass beads in side the can. I throw those into the jar I am saving the paint in the aid in mixing it if it has to sit a while.

-

What Was the First Band You Saw in Concert?

Pete J. replied to Snake45's topic in The Off-Topic Lounge

Blood, Sweat and Tears. Moby Gym- Colorado State University- 1970. -

Been using Weld-on for years. Either 3 or 4. Compared to what you guys are talking about it is dirt cheap. $25 a quart! Not an ounce, a quart. You can buy sizes down a quarter of a pint(4oz) for $6 full retail. What I did was buy one of the small cans years ago and that is what I use on my bench. Then I refill it from a quart sized can. I do this because one time I left the lid off and it was gone overnight. The difference is that 4 is thinner and quicker drying that 3. I get it at my local pastices fabricating store but it is available in many places.

-

'30s Air Racers

Pete J. replied to Flynlo's topic in All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Not a racer per se but definitely a 30's aircraft. Air speed record -

wheels 1/24 vs 1/25

Pete J. replied to CharlieBravo's topic in General Automotive Talk (Trucks and Cars)

The question of scale is always a subjective one because model companies work with a more or less, "that looks about right" scale. They will be close but the differences in how they put things together means that they may not always interchangeable across brands, or for that matter model to model a single brand. They often try to get close, but they make sacrifices for the eyeball appeal and manufacturing expediance. For that reason, measuring is critical. Most resin companies will specify a particular kit or manufacture to assist with your choice. Some also give ID and OD. -

Mark, with your ventures into 3D printing, I am surprised you never converted you mill and lathe into computerised machines. Neither CAM or 3d is perfect for every job, but they each do things better the other. I always seem to get more satisfaction when the chips are flying and makin a mess. ?

-

Hey Tim, too bad all this work goes inside body work. As usual, your work is inspirational. Where in the heck did you get those zip ties?? Did a web search and can't find them. Thanks, Pete

-

Somewhat surprised by how many retired people are on this forum! Yes, both my wife and I are retired but have a lot to do. I have been in and out of hospitals and doctors offices and now teleconferences with doctors since February(cardiac and pacemaker issues), so I have had enough "getting out". I miss my club meetings and going to a restaurant when I want to though. Use to grocery shop a couple of times a week and now my kids insist(rightfully so) that we let them do that. Live in SoCal so going out to the backyard and enjoying the sunshine is a regular occurance. Lots of neighborhood walks. I find myself shutting down the TV and going out to my shop much more often, which is a good thing. I also find myself sorting through my stash and thinking, I don't need that! Will probably get real active on ebay soon, but then I need to go to the post office. Not sure how that is going to work. Definitely feel sorry for those who are out of work and now have to figure out how to make the bills and feed the family. Trying to figure out how to help without just throwing money at the charities and going out to expose myself to the virus. Right now, I really don't want to come down with it. Old folks with heart conditions are not fairing well! I would prefer not to be one of those statistics. Also learning that just about everything I need is available online. Shopping can be an adventure and so far have had no issues, but then I've been doing this for years, just not for things like groceries. Frankly, I have very little to be concerned about. My stock portfolio took a hit, but as a retired financial advisor, I know if I leave it alone, in a year or two, it will all come back. Just have to be patient. I worry about those who were paycheck to paycheck. A couple of thousand from the government isn't going to go very far, even with unemployment. In the words of Hill Street Blues,

-

Jewelers files would be a good choice. You can find them in just about any size and shape and price range you want. I have been dealing with Otto Frei for a long time and they have an amazing assortment of tools for the jewelry trade that work very well for our hobby. You can get them for as little as a couple of bucks up to sets that sell in hundreds of dollars. I bought a set of swiss made Grobet files a long time ago and they have served me well. The one similar to what you have is a round tapered file a.k.a. a rat tailed file. I also use the heck out of the triangular and mill files. The mill file is a nice one to have in that it doesn't have any teeth on the edge so it will file down perfectly flat without cutting into the sidewall. I am sure you can find these at Harbor Freight or other cheap source, but frankly, you get what you pay for. I have always paid good money for my tools and find that they work with me. Cheap tools seem to work against you. Take care of your tools and they will last a lifetime. https://www.ottofrei.com/jewelry-tools-equipment/bench-tools/files

-

Yes, a large part of the bit is the priceless reactions of three other actors trying to hold it together and shoot the scene as scripted and ultimately failing miserably. Also the total deadpan last line just tears it up. Actors could study this thing for years and not be able to recreate it.

-

Beside the total insanity of this segment, I think it shows just how potent timing is to any comedian. Tim had absolutely the best timing in this I have ever seen. Let them almost recover from their laugh and hit them with another one. Eventually they all wind up on the floor!

-

This spring is particularly sad for me! Totaled this back in October so there is no spring for me! '93 MR2 Turbo

-

Flying Boats

Pete J. replied to Flynlo's topic in WIP: All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Pretty was never the PBYs strong suit! The photos show the paint in theater, was pretty rough especially at the water line around the nose. Some came close to being striped in that area.