-

Posts

15,039 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by StevenGuthmiller

-

I’d love that color on something from the 50s. So again, it’s not really the color as it is that color on that particular car. Steve

-

Tweezers!! And a good lighted magnifier. some other things I’d consider that I can’t do without: A pin vice with small bits. A small scissors. A small file set. A set of dental tools. Q-tips. (Including some of the small conical shaped swabs such as Tamiya carries) If you plan on doing any cutting, some sort of razor saw, and seriously think about a variable speed Dremel type tool with reamer bits. I don’t think I could do much of anything anymore without most of these items. Steve

-

Can this be cleaned up

StevenGuthmiller replied to junkyardjeff's topic in Model Building Questions and Answers

Personally, I wouldn’t waste my time. Get some .007 “lay film” and replace the glass. In nearly every case, kit glass is entirely too thick and looks completely out of scale and unrealistic anyway. I only re-use kit glass if it’s an odd shape, or has compound curves that are difficult to form with flat, clear sheet plastic. Thin plastic will give you a much more realistic looking windshield, and you won’t have to waste your time trying to save basket cases. These models have all had the glass replaced with lay film. Steve -

LA Awesome for chrome removal

StevenGuthmiller replied to gpal's topic in Model Building Questions and Answers

The shiny yellow coating you’re referring to is the lacquer base coat used in the vacuum metalizing process. It can occasionally be difficult to remove, but a good soaking in Super Clean will usually remove it. I’ve soaked styrene plastic parts in Super Clean for weeks with no damage to the plastic whatsoever, so you don’t need to worry about that. In any case, should the coating prove impenetrable, in most cases it’s not a big deal. You can paint or re-chrome without issue. At least I’ve never experienced any issue with it. Steve -

I agree with your assessment that most metallic paints, (even those designed to be used for scale models) often still have metallic particles that are too large for 1/25th scale, but often, this is only obvious in photographs, and almost completely imperceptible when viewing with the naked eye. If the paint you have used has flakes that are individually visible with the naked eye, you should certainly use different paint, but trying to find a perfectly in scale metallic paint is extremely difficult, if not nearly impossible, and even if you do find some that is very close to scale, in that scale, it’s almost impossible to tell that it’s even a metallic paint. The ‘58 Impala depicted below is about as close as I ever got to a correctly scaled metallic paint with MCW “Cay Coral” poly, but if you weren’t told that it was metallic paint, you’d be hard pressed to be able to see. I also agree about the toy like, overly shiny, “dipped in syrup”, or “hard candy” appearance that you often see with raw clear that hasn’t been toned down by polishing. This is a common effect that you often see with 2K clears, and I agree that more often than not, it appears, (to me at least) to be completely unrealistic. This is why I consider multiple coats of clear lacquer, followed by cutting and polishing a superior method, but of course, that’s just my opinion. 😉 Steve

-

This is part of the reason why I use as many coats of clear as I do. (Usually 5 coats) The depth of the clear helps to guard against burn through during the polishing process. Other than that, just going easy on body ridges and around panel lines, and starting with the finest grit possible. Just course enough to remove any orange peel or other imperfections. Contrary to popular belief, if the right materials are used, detail hide is virtually non-existent. I routinely use 5 or more coats of primer, 4 to 5 coats of color, (lacquer), as well as 5 coats of clear lacquer. Anyone who has ever built an AMT 1964 Pontiac Grand Prix kit can attest to the fact that the front quarter scripts don’t get much finer than these, yet I was able to foil these after 5 coats of primer and 4 coats of color, before spraying an additional color coat, cleaning the script, and then adding the clear coats. Even with that many coats, it’s obvious that there is virtually no detail hide whatsoever. Certainly less than you’re likely to get even with a couple of coats of enamel. Steve

-

Hardest job without doubt was 25+ years of drywall finishing. Mostly taping and texturing, but plenty of sheet rocking and painting too. Cold and miserable in the winter, and hot and miserable in the summer. I would have to say that the most fun was when I was a delivery driver for a large grocery store chain delivering groceries to people from all walks of life. Got to know some people so well that they cried on my shoulder when they learned that I was leaving. Tips were great too!! 😊 Probably most rewarding is my current part time job working as a guest services rep and valet at a cancer center. Nothing prepared me or surprised me more than how optimistic and cheerful the vast majority of people who are facing the most difficult fight of their lives can be. It’s very gratifying to interact with and support these folks when I can. Steve

-

What Did You Have for Dinner?

StevenGuthmiller replied to StevenGuthmiller's topic in The Off-Topic Lounge

My lovely wife talked me into making one of her all time favorites. Pretty simple recipe of Chicken Piccata with Garlic Spaghetti. Steve -

Got some free time this weekend. Doing some baking/cooking.

StevenGuthmiller replied to LDO's topic in The Off-Topic Lounge

I’m not much of a baker. I do my own pizza dough and make the occasional dessert, (flourless chocolate cake, lemon curd cake, flan, chocolate bread pudding, etc.) but my some day to be daughter-in-law bakes for a hobby. Today she sent pictures of her Sunday project. Sour dough bread and homemade English muffins. I just stuck to what I know best and made some Chicken Piccata and Garlic Spaghetti. 😊 Steve -

Oh, the horror!! 😊 Steve

-

Let’s face it. It’s not so much the colors. It’s the modern automobile that’s ugly!! Steve

-

That color is becoming quite popular. Toyota calls it “Moon Rock”. 😊 While I can’t say that it’s particularly pleasant for me either, I still think it beats 5 different shades of gray. I’m pretty sure that this shade of green was quite popular in the 40s and early 50s. Steve

-

Well, if you liked Pulp Fiction, you certainly have to like Django Unchained. Yeah, I know, Tarantino has a tendency to get a little political with his movies, but if you like shoot outs, they don’t get any wilder than the closing scene of Django Unchained…….Except for maybe the closing scenes in Inglorious Basterds, and Once Upon a Time in Hollywood. 😁 One of the funniest scenes that I’ve ever seen in a movie was the scene in Django when Don Johnson put together a posse to pursue Jamie Foxx and Christoph Waltz. It nearly had me rolling on the floor!!! Steve

-

The Good, the Bad, and the Ugly. Probably one of the most iconic scenes in film history. Certainly in Western film history. I remember watching a documentary about a group of The Good, the Bad, and the Ugly super fans in Spain getting together to try to restore the “Sad Hill” cemetery, which was created for the film in Santo Domingo de Silos in Spain. Very fun and interesting documentary which culminated in a showing of the movie at the cemetery site, and a taped statement from Clint Eastwood. Steve

-

Which vendors offer scale auto carpet?

StevenGuthmiller replied to Monty's topic in Model Building Questions and Answers

Personally, I like embossing powder. That said, I can see how flocking may better represent some newer vehicle carpets than embossing powder. Flocking will give you a more fibrous looking finish with it's long strands, which appears to me to be more conducive to more modern vehicles. Embossing powder is granular, which in my opinion better represents the short cut pile carpets seen in most older vehicles. I know that some people will use a sheet type material for carpets, such as felt or dryer sheets, but in all honesty, I don't think that they give you a better, or even as good of a look as embossing powder, and they are certainly more difficult to work with. It's kind of like the masking tape vinyl top solution that many use. I see it as less realistic and in scale than simply using a paint method, and it's certainly a more difficult procedure to accomplish correctly. Not to mention the questionable longevity factor. Anyway, Embossing powder also has the added benefit of being able to be mixed for desired color to some extent, and if not, it can be painted over. Here are a couple of interiors that used mixed embossing powders to achieve the desired color. Both were accomplished by mixing green and blue powders to create a turquoise or shade of green, which I didn't have. In other cases, such as with my '64 Bonneville, I used embossing powder and then painted over it to achieve the color that I was after. I was able to find a variety of colors through a company called "Hampton Art", which offers powders in solid and metallic colors. Each set contains 16 different colors. I often use the metallic colors because I feel it adds a little more depth and texture to the carpets, but that's a judgement call for the individual. The floor mats in the Bonneville used metallic powder, as did the '67 Ford and '65 Plymouth interiors shown above. The Hampton Arts sets offer a wide range of different colors, and in most cases, there will be a color that will compliment almost every interior that you do. Even some of the oddest colors are sometimes available, such as the "Sunfire Red" combination in my '64 Grand Prix. No mixing here. Straight from the bottle. (metallic powder) This is what you're looking for. In conclusion, I know that you were asking about other materials that come in the form of a sheet, but in all honesty, I can't see how using a material like that would be easy in a lot of circumstances. If you need to work around any obstacles, such as consoles, pedals, shift boots, etc, or proper fitting around sharp contours, etc, it seems to me that a lot of excessive measuring and cutting would be involved. With the powders or flocking, is just a matter of masking the items that you wish to remain free of carpet, applying the powder, and then unmasking.......Done! Steve -

It’s just “right of passage”. You can’t be one of the “pretty people” unless you have a flashy car that you never drive and know nothing about. Complete and absolute status symbols. Much like the morons who spend $10,000.00 or $15,000.00 on a Rolex watch that won’t do anything that a $30.00 Timex won’t do. Steve

-

-

Even if I was a billionaire, I wouldn’t piss away this kind of money on an oil change! Just ridiculous that these “supposedly” finely engineered cars can’t be engineered to make maintenance somewhat normal. Makes it quite evident to me that these companies view their clientele as cash cows to be milked for every cent possible at every opportunity, and apparently their clients are willing to shell out giant wads of cash just to compensate for their tiny…….. Oops, I better stop there. 😉 Steve

-

I have absolutely no desire to monetize my hobby. Now, that doesn’t mean that I won’t try to seek some form of return on all of my stuff someday when I decide to give it all up. My biggest issue with selling my finished models is that when I begin adding up the cost of the model kit, the materials, and all of the time and work that was put into it, there’s no way that anyone is going to be on the same page as far as value goes. Too often, people think anything from $50.00 to a couple hundred is fair when purchasing a built kit, but when I’m starting with an expensive vintage kit, and spending hours upon hours modifying it, well, how much is your time worth to you? If I spend a couple hundred on a rare kit, put $50.00 or $60.00 worth of materials into it, we’re already approaching $300.00 without figuring any time whatsoever. I can very easily put a hundred hours into a project, (often much more) so at even a meager $10.00 per hour, that’s $1,000.00, plus the kit and materials, means asking $1,300.00 for a model. I recently turned down an offer of $950.00 for a Johan ‘68 442. The bottom line being, if I’m going to put the time and effort into it, the prospective buyer better be willing to open his wallet really wide if he wants it. And I’m not going to change my building habits just to sell something, meaning I’m not going to start building OOB versus what I really love. I’ve had people make offers to me on occasion, and to be honest, the vast majority of those offers, I’ve considered insults more than anything. And I’m confident that the person making the offer thought I was crazy for turning down their $100.00 offers, but I’m not in the habit of giving things away, unless it’s to a close friend. Steve

-

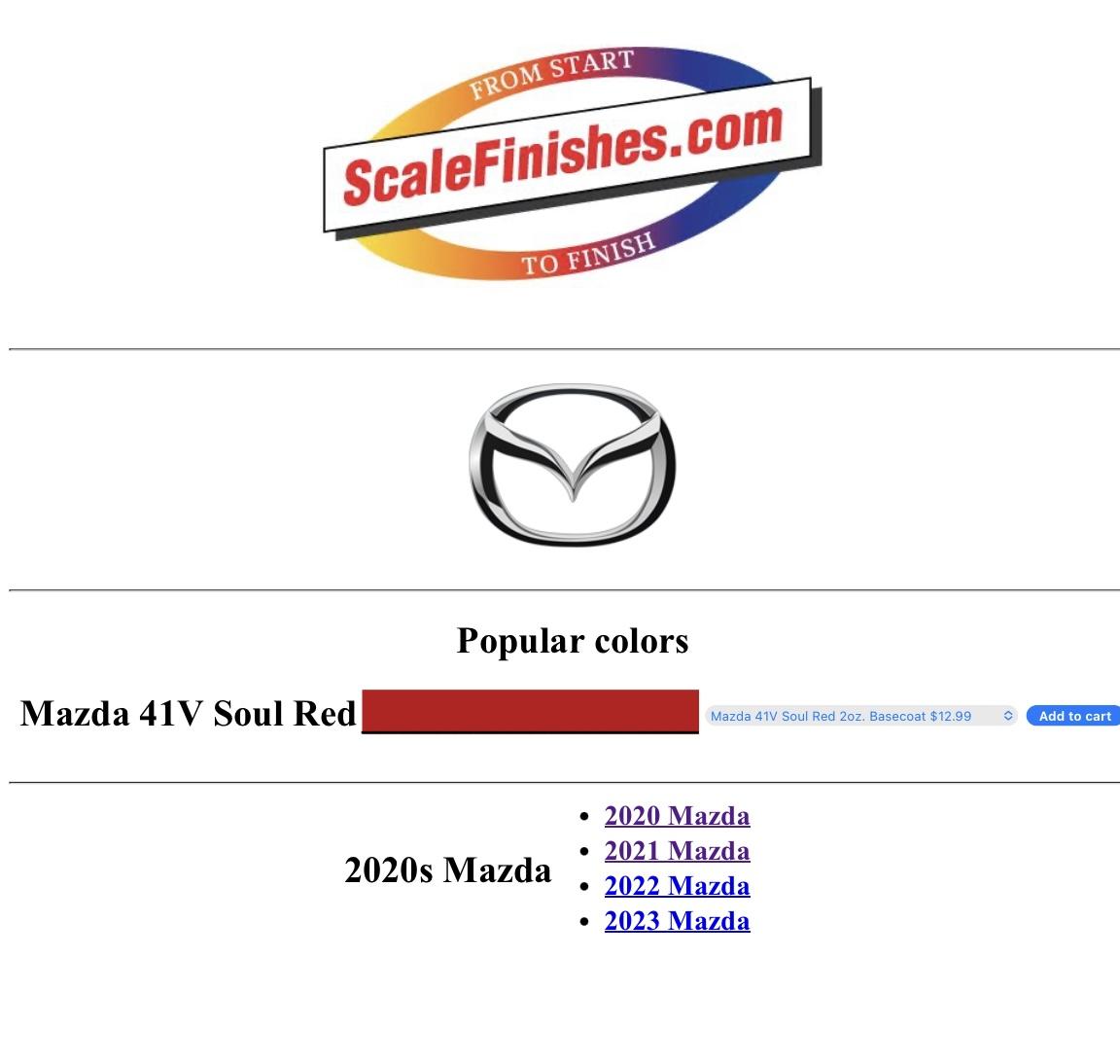

I struggled with obtaining show quality paint for many, many years and dreaded the painting process, until I resigned myself to the fact that it wasn’t necessary at all to try to get a perfect paint job straight from the can or airbrush. It was such a liberating experience when I discovered that a mediocre paint job can be transformed into a exemplary one just by spending a little time cutting and polishing. No more worrying about all of the usual issues that often accompany the painting process. Several coats of a good quality automotive primer, followed by a number of coats of lacquer color, and finally several more coats of a quality lacquer clear coat, and finished with cutting and polishing, and I’m all but guaranteed that I will end up with a perfect finish. I can’t remember the last time that I had to strip a paint job due to an application issue. I no longer have any use for experimentation or scrambling to find a color or a product that I have no experience with. Duplicolor sandable or “primer sealer”, MCW, Scale Finishes, or Duplicolor lacquer color, Duplicolor Perfect Match “Protective Clear Coat”, and cutting and polishing never fails me. Steve

-