-

Posts

15,071 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by StevenGuthmiller

-

Most Involved Part of Building?

StevenGuthmiller replied to JollySipper's topic in General Automotive Talk (Trucks and Cars)

I've begun take the same attitude when re-working interior door panels. As an example, my current '68 Coronet has had the majority of the door panels completely scratch built. I at first was concerned about getting them as close to exact as possible, but then your philosophy came into consideration. They don't have to be exact. There's no possible way to view both door panels at the same time once they're in the model. Steve -

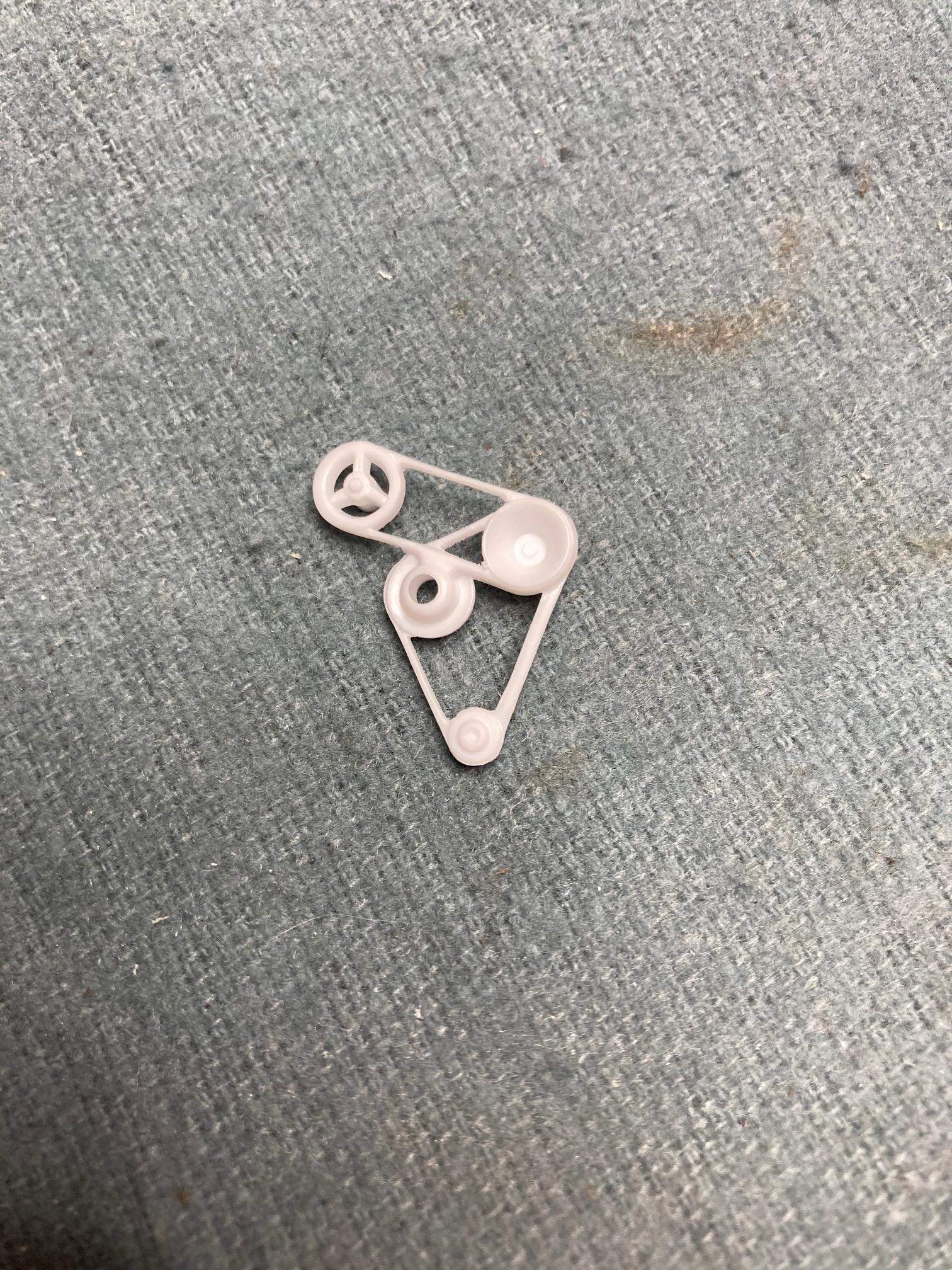

Thanks Mike! Here you can see the results of thinning the belts. All of the belts have been thinned except for the lower, (long) portion of the alternator belt for comparison. I don't think that I want to try to go much thinner for strength reasons. Steve

-

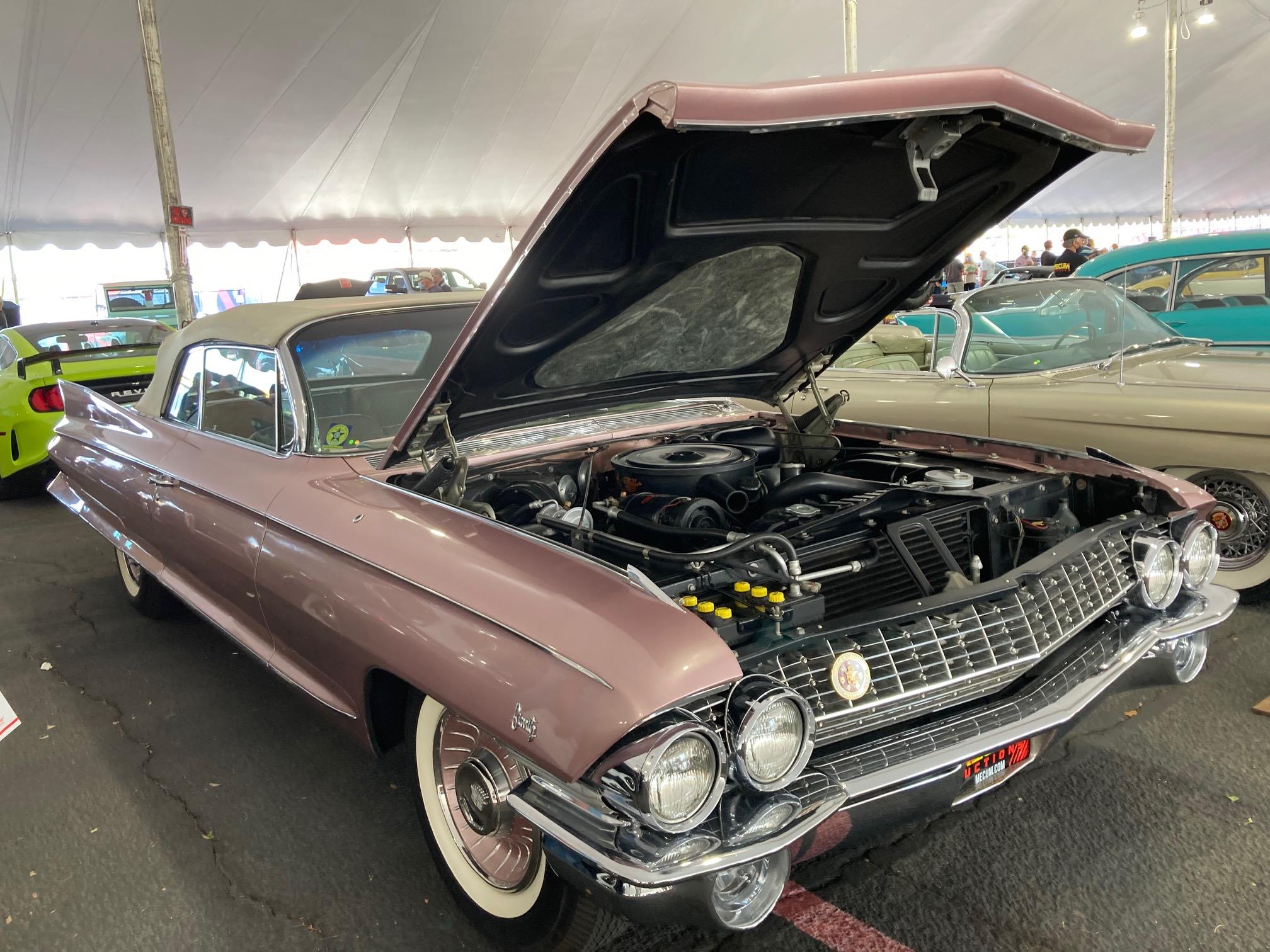

I haven't yet finished thinning the belts, but they're not too terrible on the Revell '68 Charger part as is, so they don't require too much thinning. I will be doing a little work with the alternator and power steering pump brackets as well. I didn't really thin the intake manifold flange. That would require quite a bit of work on the intake, and/or repositioning of the heads. What I meant by "trimming" was cutting back the edges and corners to fit the contours of the block and heads better. I don't know if you can see the difference or not in these photos. Steve

-

No problem Ed. No pressure from my end. Steve

-

No real updates of substance John. Just working on refining and making a few engine parts. Thinning belts, trimming the intake manifold around the edges, scratch building an oil filter........that sort of stuff. The interior is not holding things up at all. I have plenty to do without it. Steve

-

Most Involved Part of Building?

StevenGuthmiller replied to JollySipper's topic in General Automotive Talk (Trucks and Cars)

Isn't it funny how different operations are perceived by different people. I look forward to the foil work. It's one of the most relaxing and rewarding parts for me. Steve -

Most Involved Part of Building?

StevenGuthmiller replied to JollySipper's topic in General Automotive Talk (Trucks and Cars)

Most recently, the most involved portion of the build for me has been interior work. I've been spending a great deal of time rebuilding old annual interiors basically from the ground up. Overall though, I would say my "most involved" part of the build is the general engineering portion. With the kinds of models that I build, there is a considerable amount of engineering required to get chassis, engine bay and engine swaps to fit together properly with old kit bodies and revamped interiors. The vast majority of the work on my projects is done long before any paint flies. Steve -

What Did You Have for Dinner?

StevenGuthmiller replied to StevenGuthmiller's topic in The Off-Topic Lounge

Thursday night, it was more pulled pork sandwiches with baked beans with sausage and smoked pork. Steve -

What Did You Have for Dinner?

StevenGuthmiller replied to StevenGuthmiller's topic in The Off-Topic Lounge

On Thursday Morning, just looking for something to occupy some time, I decided to throw some jerky into the smoker. Steve -

What Did You Have for Dinner?

StevenGuthmiller replied to StevenGuthmiller's topic in The Off-Topic Lounge

I haven't posted here for a while, but I do have some photos from our recent vacation to show. On the night before we flew out, we stopped at Chevy's by the Mall of America in Bloomington Minnesota and ordered far more "Mixed Grille" fajitas than we could ever eat. Once in the Phoenix area, we made a trip to the small copper mining town of Jerome Arizona, where we had a nice lunch of pulled pork sandwiches and beans at "Bobby D's BBQ". On our last night in the Phoenix area, we were directed by a friend to a very nice restaurant called "St Francis". Very good service and terrific food. I had "Thai Style Mussels" and "Grits Stuffed Shrimp" from the appetizer menu for my meal, and my wife had "Seared Scallops with Risotto". Delicious! Steve -

Prep is extremely important due to the thinness of the chrome plating, but my experience has been that the biggest problem is the heavy application of the base coat under the chrome. The last time that I had Chrome Tech re-plate parts for me, the base was applied so heavily that it was to the point of obscuring detail. I chalk this up to the fact that most of the model kit plating outlets farmed out the actual plating operation to larger plating companies who may, or may not have been used to working with such small and finely detailed parts as a model car part. Any time you see detail hide, runs or sags, it's the fault of the base, not the chrome itself. Steve

-

I've had parts chromed by 3 different platers over the years, and I can't remember a time when all of my parts returned unscathed. In most cases, everything looked very nice, but in every situation, there were at least a few parts that exhibited some minor issues. Debris, minor runs, bubbles or dull spots were fairly common in every batch. Most of this is due to the lacquer base that is applied before plating, and some could be attributed to prep, but in the end, we have to remember that these providers are not large, "companies" of any description. They are mostly "one man shows" who in the past, were quite often only the middle man and were not performing the actual plating process themselves. Today, with the passing of most of these providers, the "ones" that remain, I have to believe, must be quite overwhelmed with the volume of work that they are tasked to complete. It seems almost impossible to me that there are not going to be circumstances arising such as this as the provider rushes to get through the heavy volume of work coming his way from a constituency which is often very impatient. I suspect that it will only be a matter of a short period of time before we won't have to worry about the quality of our re-plated parts anymore. The model kit plating industry is hanging on by a thread as we speak. I'm relatively confident that thread will snap in the not too distant future, and then it will just be a matter of whether or not some brave, and hopefully competent, individual will pick up the baton and wade into the quagmire. Steve

-

'59 Buick Questions

StevenGuthmiller replied to JollySipper's topic in Model Building Questions and Answers

Okay, I may have been mistaken with the nomenclature on the packaging. The “Craftsman” name may have made a later debut than I had assumed, but the premise remains the same. The “annual” kit would have been molded in white and included customizing parts. (ie skirts, louvers, etc) The “Junior” kits were usually produced some time later, included only stock parts, (+ antennas and mirrors), were molded in color and were for all intensive purposes a snap kit. The example that I posted above was one of these kits and was molded in a medium blue, as was a ‘59 Ford, a ‘59 Edsel and a ‘59 Merc that I have which was molded in yellow. Steve -

'59 Buick Questions

StevenGuthmiller replied to JollySipper's topic in Model Building Questions and Answers

You're probably thinking of an AMT 1959 Buick "Junior Craftsman" model. This kit differs from the Craftsman series which included custom parts and was molded in white. The Junior Craftsman kit only included stock parts, (basically an un-assembled promo) and was molded in color. There is little difference between the Craftsman and Junior Craftsman kit aside from those differences. They were both produced by AMT and were 1/25th scale. I built my '59 from a Junior Craftsman kit. Steve -

AMT '66 Buick wildcat

StevenGuthmiller replied to ranma's topic in Model Building Questions and Answers

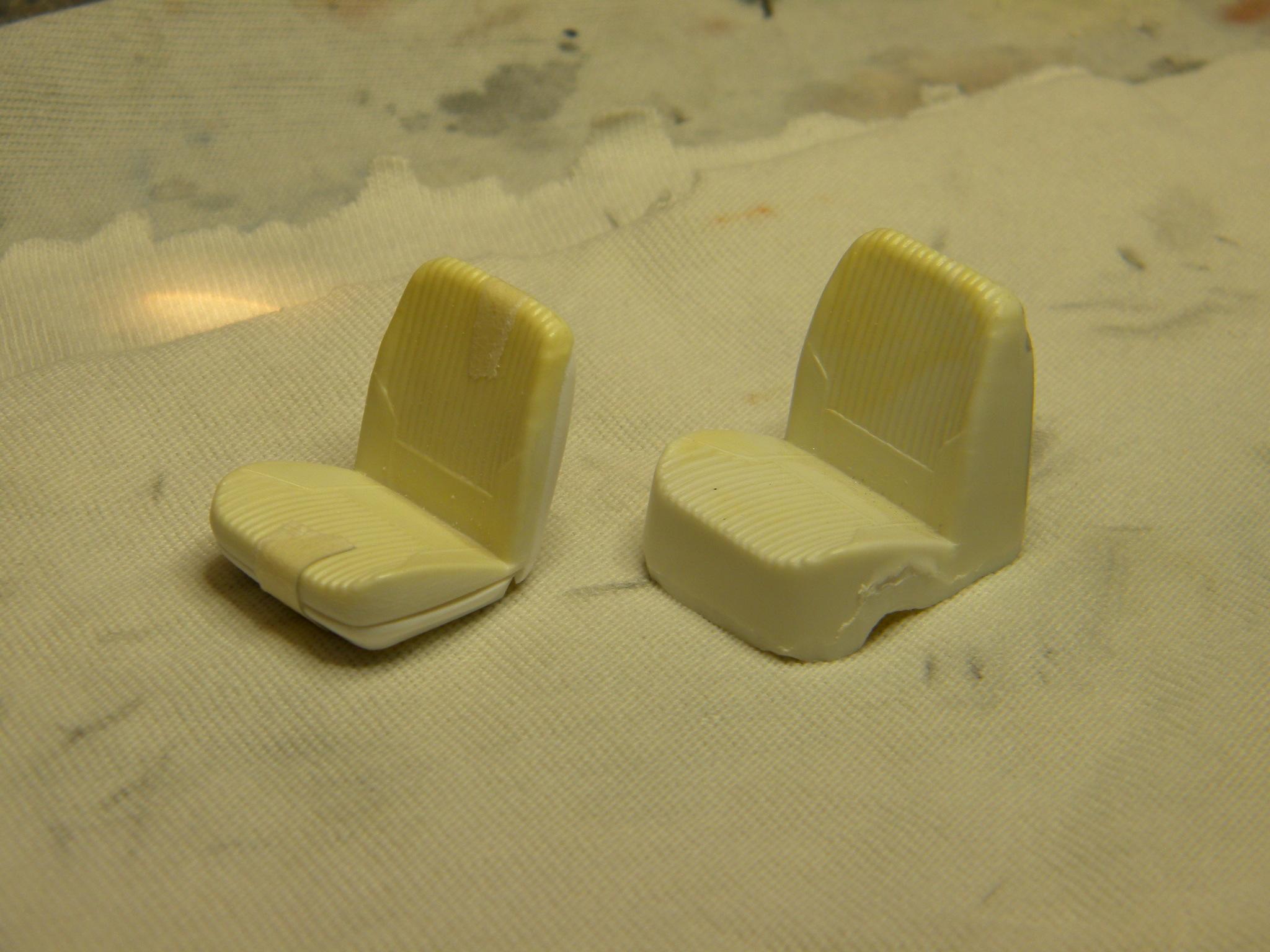

This is nothing new. I've begun cutting up and re-doing the seats in nearly every annual kit that I do. Some are worse than others, but they can all benefit from some work. Johan '68 Olds 442. Steve