-

Posts

8,901 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by peteski

-

-

AKA a Gundamn Marker .

The ones I use are Sakura Micron markers. https://sakuraofamerica.com/pen-archival# Not sure if those are used for Gundam stuff.

-

-

I think most people experiencing the cans oozing just throw them away. It might be a good idea for all the people who had this happen to them (in this thread) to open up a case with RPM (Rustoleum) to maybe open their eyes to the fact that there is a problem. With the advent of the internet, it is easy to notify the company about possible problem.

-

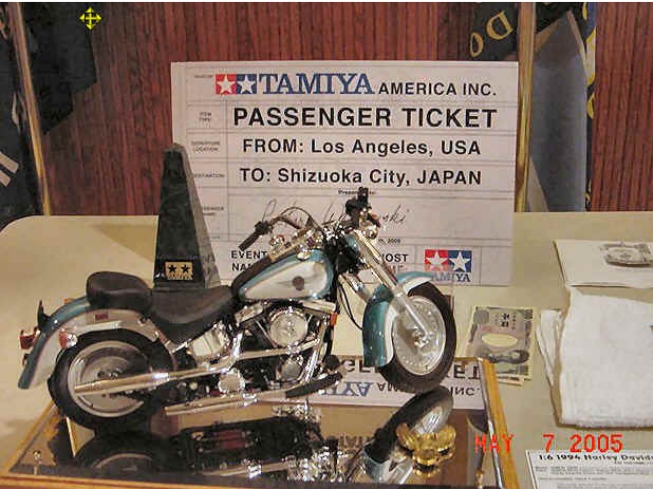

I think I have that same Fat Boy in same color. That fire engine is incredible though.

Thanks!

In the 1:6 Harley Fat Boy still unassembled?

-

So we were all partially correct.

Rapidograph is a type of a technical pen. Some are filled with India ink. I sometimes use very fine type of marker for accenting panel or door lines, or for some precision detail-painting.

-

Haven't seen any mention of 1/43rd scale.

My post stated "I have build models from 1:6 Tamiya Harley Fat Boy bike to 1:160 Photoetched brass vehicle kits from Micron-Art (and pretty much most of the scales in between)." That includes 1:43.

-

Looking at the overall body, the gas filler cap and the headlight bezels I know what make it is, but I'm too lazy to find the specifics. I guess I'll find out how close I was on Friday.

-

I for one, will be curious see what you find. I've lost my enthusiasm for Bondic over the last few months. I question how good of a bond am I really getting with the stuff? Once or twice I've had things come apart using Bondic.

That is because it is not a glue. Its website is https://notaglue.com .

-

The ingredients in ELO are related to what DOT 3 brake fluid contains.

If oven cleaner (the lye-based one) doesn't strip certain paint then Castrol Super Clean (or the generic versions) most likely wont either, since those are also lye-based.

-

Also, no way was this done with shiny metal wire. I'm thinking maybe a little gray-looking metalizer paint might help out.

Instead of paint you might want to chemically darken the brass wire. It will look good (weathered) and more durable than paint. I don't know where to find chemical blackener in your country but in USA we have several sources. Model Railroad shops sell A-West Blacken-it solution and also Micro-engineering rail weathering solution. Both will give aged look to brass. There are also various weathering/blackening solutions available from Jax Chemicals. That is what I use.

-

I have build models from 1:6 Tamiya Harley Fat Boy bike to 1:160 Photoetched brass vehicle kits from Micron-Art (and pretty much most of the scales in between).

-

I, too, have experienced this. I have several ancient Testor enamel cans that don't leak but have had about 5 of the newer lacquer cans leak. Something, perhaps, in the chemical composition of the contents? I'm interested to find out the answer.

I doubt it. It is most likely a mechanical problem. I suspect that the bottom of the an is not crimped very well and develops leaks under constant pressure.

-

Because its easier to remove Sharpie ink from clear plastic then is to remove paint from clear plastic without messing up the clear plastic

A damp rag of 91proof alcohol and the Sharpie Ink is gone and you can give it another go.

If you use a paint marker on a clear plastic and you mess up, you will notice you messed up right away (won't you?). If the paint is not fully hardened then alcohol will remove it almost as easily as if it was Sharpie ink.

I'm not a big fan of Sharpies. The ink can be rubbed off easily and it also runs/bleeds easily when exposed to solvent from many paints. it also has a glossy finish which is not really good for simulating rubber gaskets or trim (which is usually satin or flat).

-

I should also mention an alternative to the standard black Sharpies (which are really dark purple) and run when exposed to many paint solvents. There is also a "red label" Sharpie industrial marker. It seems to be more solvent resistant. The stated color is black but it is a really dark blue. You guys might want to give it a try. I just used it the other day to blacken some metal parts.

http://www.sharpie.com/markers/pro/industrial/SHIndustrial.html

-

"Radiography" is x-ray imaging.

I wonder if he means Rapidograph...

I took it as a marker used for annotating X-Ray photo films.

-

Peteski, that will all be under the interior tub, so I didn't bother with smoothing it, maybe I should've, and I still can!.

You have a point there.

But I hope that you smoothed out that seem on the bottom of the housing.

-

Calculator is nice, but we are talking elementary school math here. This is the time where we get to use those basic math skills we learned in school but always thought we would never need them in real life. We should be exercising our gray matter more.

-

Is it just me or does the black sharpie look a little on the blue side?

Sharpie ink is actually very, very dark purple. I usually don't use Sharpies for my models. But since people like the convenience of using a marker, why not use a black paint marker?

-

Thanks for that, never heard of it before so I was way off the mark. Basically what we call in England a felt pen, or marker pen, and when shaped a calligraphy pen. I use one that has a .2mm tip, for some reason I have never looked up it is sold as a radiography pen. Comes in handy for marking saw lines etc ?

We also have felt-tip pens or markers and calligraphy pens in USA. But those usually use water-soluble inks. Sharpie is a felt-tip pen (comes in several sizes) but the ink is permanent (waterproof). I wonder if the radiography pen uses waterproof ink?

-

Thanks Bill - it is good to hear from an actual user of the system. The other possible problem is the resolution. I make decals mostly for N-scale model trains (1:160 scale). Some of the lettering can be really small (where the letters are about 0.015" high). I'm not sure if that system is capable of such fine resolution. Plus it really is quite messy when compared to Alps. But as I said, if that is the only viable (and affordable) option, then go for it.

-

Actually, I misunderstood your post Bill. Not sure what I was thinking. I thought you were using the abrasive powder to scuff the shiny "chrome" finish to dull it down making it look like cast or brushed aluminum. But now I just re-read your post and you are scuffing the surface for the metalized paint to adhere better. That makes sense. I also agree that in some rare instances it might be possible that the masking tape might peel up the "chrome" finish.

-

The massacre in a Texas church this morning. What is this world coming too, where no one is SAFE anywhere?

Unfortunately no - no place is safe or sacred anymore. That is why many Americans yearn to go back to the good ol' days. But the Pandora's box has been open and we cannot put things back to the way they were. Going to my workshop and working on models (and listening to the music of my choice) makes me forget about the outside world for a while.

-

I'm puzzled by the way the color shows some fine texture pattern. It almost looks like hammered-metal paint. It is almost like the various paints don't want to be mixed together and they stay separate, creating areas of silver dots with blue halos. At least how I see it on the glossier spoon in the last photo.

-

And because I'm anal, I just want to mention that the "chrome" on plastic parts is actually vacuum-deposited aluminum. It is applied over glossy clear coat and it is only few atoms thick, so it looks like highly polished aluminum (which is a good substitute for chrome). But also because it is so thin (especially if it is not coated with a layer clear lacquer during manufacturing) it is very fragile, so by rubbing abrasive on it you are risking removing the thin layer of metal, exposing the plastic.

I have used Testors Dullcote for dulling the look of "chrome" and I have never experienced any bad effects. But there are also water-based satin or flat clears which should be very safe over the "chrome".

Esci/Revell Mercedes 500 SLC

in General Automotive Talk (Trucks and Cars)

Posted

I have both of those pictured kits. And the 190 too. I bought them because I like the unique subject matter. The hood is attached to the body by a thin layer of plastic - it is designed to be easily separated. The wheels are undersize (IIRC, they are more like 12 or 13" wheels). Then the tires make up for it, so they have tall sidewalls. I have been contemplating having new (correctly sized) wheels 3-D printed. I would also like to 3-D print the louvers in the side windows behind the B-pillar.